Huayang large vertical mill vertical Roller mill belt

.jpg)

Operational parameters affecting the vertical roller mill

2016年9月1日 This paper investigates the milling behavior of two industrial wood pellet qualities (designated I1 and I2 as per ISO 172252:2014) in largescale coal roller mills, each equipped 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Operational parameters affecting the vertical roller mill TRM Series Cement Vertical Roller Mill System is a one fan finish grinding system The mixed material is fed to vertical roller mill via belt conveyor and air lock valve Material in mill internal TRM SERIES CEMENT VERTICAL ROLLER MILL TRM SERIES HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill

.jpg)

Vertical roller mill, Vertical roller grinding mill All

Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchases large (1) Submit exhibit TRM SERIES CEMENT VERTICAL ROLLER MILL TRM SERIES The mixed material is fed to vertical roller mill via belt conveyor and air lock valve Material in mill internal was moved from center to grinding table edge when grinding table rotates In the meanwhile, it is stressed andTRM SERIES CEMENT VERTICAL ROLLER MILL TRM SERIES CEMENT VERTICAL 2020年11月5日 We compare 3 cement milling and cement mill processes, including cement ball mill, vertical roller mill, and rod mill Find your answer here! Skip to content +86 Cement Belt Conveyor; Air Slide Conveyor; Cement Screw Conveyor; Pulverized Coal Burner; The feeding size of vertical roller mill is large, generally, 3 Necessary Cement Milling Comparison Ball Mill, Vertical Roller Mill2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC tools

Roller Mill Belt

Avoid downtime with durable and dependable Flour Power roller mill belts Automated milling machines are widely used in foodprocessing Plants run 24 hours a day, seven days a week in adverse conditions Flour Power belts offer a durable and efficient belt for reliable power transmission Roller mill drive belts are typically dual sidedPDF On Jan 1, 2017, J Harder published Drives for large vertical roller mills Find, Schmitz, T: Quadropol QMCRD World's First Vertical Roller Mill with Driven Rollers(PDF) Drives for large vertical roller mills ResearchGate2023年10月3日 Founded in 1958 Zhejiang Tongli Heavy Machinery Co, Ltd is an equipment manufacturer very famous in China domestic market for making ball mill, vertical roller mill, rotary kiln and all sorts of cement fertilizer production equipment, even though not as famous as FL Smidth, but Tongli is constantly improving to provide toptier product and service to global What is a vertical roller mill (VRM)? A Comprehensive Guide to Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary

Operational parameters affecting the vertical roller mill

Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateVertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball millsof 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg certain length of the belt and then weighed to calculate (PDF) Performance Evaluation of Vertical Roller Mill

(PDF) EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)

1999年4月18日 belt conveyor campuran ini kemudian diumpankan ke Vertical Cement Mill Material yang masuk kedalam Vertical Cement Mill akan digiling menggunakan 4 buah rollerVertical roller mills (VRM) have become increasingly popular in recent years, as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localized rises in cement demand The demand for cement has grown rapidly in recent years, creating a need for a more efficient way to grind clinker and other raw materials used in How does Vertical Roller Mill Work? ball mills supplierVertical roller mill Vertical cement mill is a large cement grinding equipment Tongli has successfully developed various models such as ZJTL vertical ultrafine powder roller mill in the field of cement and slag grinding with technological innovation over the years In 2016, Tongli developed the largest limestone raw material vertical mill and cement clinker vertical mill with a Vertical roller mill CEMENTLCHAENG can manufacture highquality rocker arms The rocker arm is one of the main components of the vertical roller mill Each set of rocker arm includes an upper rocker, a lower rocker, a center shaft, a bearing seat, and a bearing, mainly to transfer hydraulic pressure to the grinding roller, and turn it into the grinding force to the material bedVertical mill rocker arm CHAENG

Roller Mill Springer

The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinderrollermill,highpressurerollermill,Raymond mill, and column mill Vertical Roller Mill2024年1月1日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column millRoller Mill SpringerLinkVertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec; Sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizesVertical Roller Mills LNV TECHNOLOGY2023年12月4日 Numerical Investigation of Vertical Roller Mill Operation Using Discrete Element Method Conference paper; First Online: 04 December 2023 pp 323–334; Cite this conference paperNumerical Investigation of Vertical Roller Mill Operation Using

.jpg)

How to Improve Grinding Efficiency of Vertical Roller

The stability of the material layer is a prerequisite for safe operation of the verticle roller mill The amount of feed in the mill can be tested by 3 methods: Grinding roller limit device clearance; The power of the mill (ie the main motor current); Vertical Roller Mill Free download as PDF File (pdf), Text File (txt) or view presentation slides online Vertical Roller MillVertical Roller Mill PDF Mill (Grinding) Industries2020年8月12日 Altun et al [15] explored the influence of the parameter settings of a vertical roller mill on grinding performance and demonstrated the influence of grinding pressure values on the size and mass An investigation of performance characteristics and energetic 2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column millRoller Mill SpringerLink

.jpg)

Dolomite Ultrafine Vertical Roller Mill

The vertical roller mill integrates crushing, drying, grinding, and conveying Dolomite ultrafine vertical roller mill is mainly used for the production of dolomite powder +17Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related matters Vertical roller mill for raw Application p rocess materialsof 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population 2020年3月27日 34 Ensure the leakproofness of the grinding roller The leakproofness of the grinding roller has a great influence on the bearing Be sure to use a specific rotating oil for sealing, this can Vertical Roller Mill Wear Mechanisms and Preventive Measures

.jpg)

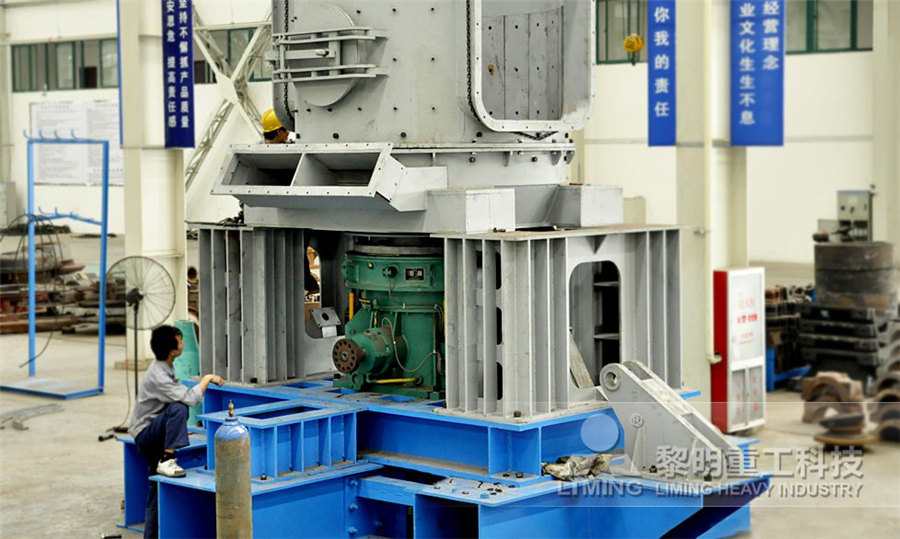

CLUM Ultrafine Vertical Grinding Mill

Vertical Roller Mill Working Principle Low energy consumption and large output The production of finished products of different specifications can realize rapid switching The products are highly professional, and the initial investment is relatively large belt scales, buffer bins, starshaped feeding valves, screw conveyors, Vertical Roller Mill is a new kind of large scale power mill which is designed specially to solve the problems of low capacity and high consumption of industry mills With a decade of years research of mills, Vertical Roller Mill is designed Zenith Large Capacity Lm Series Vertical Roller MillVertical Roller Mill Free download as PDF File (pdf), Text File (txt) or read online for free Vertical roller mills are energy efficient grinding machines used to grind materials into extremely fine powder The mill contains multiple rollers Vertical Roller Mill PDF Mill (Grinding)2019年3月3日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Modeling and simulation of vertical roller mill using

Vertical Roller Mills

Projects More than 100 customer cases of vertical mill production lines CHAENG vertical roller mill is applied in many large production lines, playing an important rolls in slag, cement and other material production lines, such as: Shanghai Baosteel 1,500,000 tons /year composite powder (slag, steel slag) production line, Henan Meng Electric Group 1,000,000 tons/year GGBFS The ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and energy savingTable Roller Mill Vertical MillThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Vertical Roller Mill Operation in Cement PlantThe largest vertical roller cement mill is the FLSmidth OK816™ vertical mill, with a grinding table diameter of 808 m (26 ft 6 in) and roller The cement mill contains 6 rollers and one large grinding table Records change on a daily basis and are not immediately published online For a full list of record titles, please use our Largest vertical roller cement mill Guinness World Records

Analysis of vertical roller mill performance with changes in

2022年5月31日 Analysis of vertical roller mill performance with changes in material properties and operating conditions using DEM Author links open overlay panel The maximum throughput is 015 kg/s, for a feeding rate of 0395 kg/s The difference is caused by a large number of nondischarged metaparticles and fraction particles remain on 2019年10月14日 62 Vertical Roller Mill Market Size Forecast By Application 621 Manufacturing Industry 622 Mining 623 Foundries 624 Cements 625 Power Generation 626 Chemical Processing 627 Ceramics 628 Agricultural 629 Others 63 Market Attractiveness Analysis By Application Chapter 7 Global Vertical Roller Mill Market Analysis and Forecast Vertical Roller Mill Market Report DatainteloBrief description of vertical roller mill operation: The most basic reason why vertical roller mill is widely used is that it has low power consumption, and several units are operated in one machine, and it exhibits excellent operational flexibility and can produce various kinds of The different highquality products are now briefly described as follows:Vertical roller mill Hengtu Machinery