Micro powder grinding operation tutorial book

.jpg)

Machining Processes and Machines: Fundamentals, Analysis, and

2020年12月15日 The text provides a holistic understanding of machining processes and machines in manufacturing; it enables critical thinking through mathematical modeling and 2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent decades Removal rates and quality Principles of Modern Grinding Technology ResearchGatePowder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituentsPowder metallurgy – basics applications IIT GuwahatiBasic grinding operations are defined and elements that form parts of grinding systems The main aim and content of the book chapters is described so as to reveal the book structure Principles of Modern Grinding Technology ScienceDirect

.jpg)

Powder Technology Handling and Operations, Process

2006年11月28日 Drawing from the third edition of the bestselling Powder Technology Handbook, this book concentrates on handling methods and unit operations for powder and Grinding fluids reduce grinding temperatures in two different ways The first is by directly cooling the process within the grinding contact area In creepfeed grinding, direct cooling is a Principles of Modern Grinding Technology ScienceDirectTopics written by invited, internationally recognized authors review the advances and present results of research over a range of wellknown grinding processes A significant introductory Modern Grinding Technology and Systems MDPI Books2019年10月31日 The handbook offers a wellrounded perspective on powder technologies in gas and liquid phases that extends from particles and powders to powder beds and from basic Powder Technology Handbook, Fourth Edition Taylor Francis

A comprehensive review of microgrinding: emphasis on toolings

2019年5月18日 This paper describes the microgrinding process mechanism considering toolworkpiece interaction Thereafter, a comprehensive review on microgrinding tool The handbook offers a wellrounded perspective on powder technologies in gas and liquid phases that extends from particles and powders to powder beds and from basic problems to actual Powder Technology Handbook, Fourth Edition 4th EditionBrief introduction Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, Micro Powder Roller Mill for Getting Ultrafine Powder Indepth, practical, comprehensive grinding education for hardcore grinders working in production grinding Overview: The Book of Grinding is the most indepth, comprehensive, practical resource in existence for engineers, machine The Book of Grinding

.jpg)

Powder Processing Equipment Systems Qlar

fine grinding, versatility and safety Available with various interchangeable grinding media, this mill offers unsurpassed high energy, onepass size reduction It ensures a controlled size reduction with a high degree of fineness, typically grinding with a milled particle size range D50 of 100μ to 20μ A full range of models are available to China Micro Grinder wholesale UltraFine Rubber Powder Grinding Plant for Fine/Micro Rubber Powder Grinder US$ 5000 / Set 1 Set (MOQ) Xuchang Huarui Machinery Co, Ltd It's essential to consult with a reputable supplier to determine the best option for your operation Q What advantages does Micro Grinder MadeinChinaModels of Ultrafine Mill: HGM80, HGM90, HGM100, HGM125and HGM1680L finished production fineness: 3003000mesh(574 micron) the capacity (ton/hour) ranges: 05 to 45 ton per hour Ultrafine Mill is a device that breaks solid materials into powder by grinding, Such comminution is an important unit operation in many processesHGM Series Grinding Mill,Stone Powder making machine MW Series Micro Powder Mill is equipment designed for customers who need to make ultrafine powder This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise,The fineness can reach to 0pared with jet mill, It is economiccost, highcapacity, and the spare parts just need to exchange once a year, The bag filter is added MW Series Micro Powder Mill SMMVIK Machinery

.jpg)

Investigation of Micro Grinding via Kinematic Simulations

2023年7月11日 Micro grinding is an abrasive process which is suitable to machine brittle materials such as hardened steel, silicon [], or glass []Micro structuring such materials can be used to create special surface properties and structures which are necessary for the application in optical or electronic industryCharacterized by outstanding feature, stable quality, easy operation and simple maintenance, micro powder grinding mill is widely applied for customers in differe Email: service@tdaxy Call us: +86Micro Powder Grinding Mill – Zonelion Taeda Rotary Dryer 2024年1月1日 Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials to give a usable form or to separate their components In developing countries, it is the common method for food powder processing In general, grinding is part of a larger set of operations involved in the process of size reductionGrinding for food powder production ScienceDirect2020年3月10日 Nano zerovalent iron (NZVI) was prepared using sonochemical leaching of the obtained powder from mechanochemical treatment of natural pyrite with metal powder of aluminumNovel Method of Nanoparticle Synthesis using Surface Grinding

.jpg)

6 different milling technologies for powders

Particle size reduction can be achieved through different types of fragmentation: Cutting: reduction of very large blocks of material from quarries or mines into pieces with dimensions greater than 100 mm; Crushing: reduction to sizes 2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent decadesPrinciples of Modern Grinding TechnologyAverage surface roughness is typically >10 μm, while it can be improved down to 1 μm R a when using micropins for grinding operation [41,42] Minimum hole diameters obtained by ultrasonic machining are typically around 150 μm with MicroHole Drilling on Glass Substrates—A Review2022年8月20日 In this article, a method of grinding small ceramic elements using hyperboloid and conical grinding wheels was presented The method allowed for machining with a lower material removal speed and extending the grinding zone without reducing the efficiency of the process In order to assess the process output parameters, numerical simulations were carried Modeling and Analysis of MicroGrinding Processes with the Use

Grinding for food powder production ScienceDirect

2013年1月1日 Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials to give a usable form or to separate their components In developing countries, it is the common method for food powder processing In general, grinding is part of a larger set of operations involved in the process of size reduction2006年11月28日 Drawing from the third edition of the bestselling Powder Technology Handbook, this book concentrates on handling methods and unit operations for powder and particle processing techniquesItexamines the purpose and factors involved in each processincluding planning, equipment, measurements, and other necessary considerationsPowder Technology Handling and Operations, Process More please visit:breakday/2013en/grinding/hgmmicropowdermillhtml HGM series Threering Mediumspeed micropowder mill is designed basiHGM Micro Powder Grinding Mill YouTube2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed Grinding in Ball Mills: Modeling and Process Control

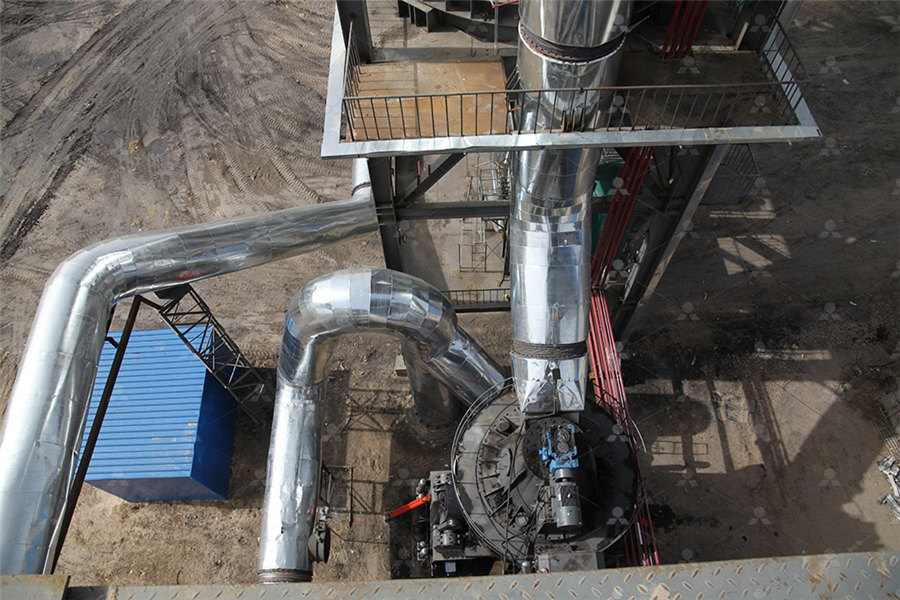

SBM Ultrafine Powder Technology Industrial Grinding Mill,

Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Focus on the field of micro powder grinding 10+ Production experience 20+Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤9Dolomite Micro Powder Grinding MillHigh Crushing ratio High Energy Utilization Primary processing D97 ≤ 10 μ M fine powder, and 3 µ m fine powder accounts for about 40%, with a large specific surface area; It not only has the advantages of high efficiency and low consumption of highspeed impact crusher, but also has the fineness close to that of air millHCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra we have established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, Europe a version coarse grinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on CLIRIK ultrafine grinding millindustrial grinding mill,

Micro Grinding Applications ResearchGate

2013年8月9日 Download Citation Micro Grinding Applications This chapter presents an overview of the micro grinding technologies developed for hard and brittle materials It summarizes the principle and This was only a highlevel overview of one of the most complex machining operations Grinding is a true craft with many variables and can take years to master I just purchased a older BrownSharp 8x18 micro master Never operated a surface grinder in my life, dont know really why i purchased anyway! LolHow to Master Your Surface Grinding Machining Operation2022年1月13日 The grinding process is one of the most important and widely used machining processes to achieve the desired surface quality and dimensional accuracy Due to the stochastic nature of the grinding process and process conditions, the instantaneous micromechanisms between each grain and the workpiece are momentarily changing and are different from the Analytical simulation of grinding forces based on the micro 2018年4月28日 Grinding is a staple sizereduction process to produce food powders in which the powdered form is chemically and microbiologically stable and convenient to use as end products or intermediate products The moisture content of food materials before grinding is a particularly important factor, since it determines the materials’ physical properties and the Effect of Moisture Content on the Grinding Process and Powder

.jpg)

Powder Technology Handling and Operations, Process

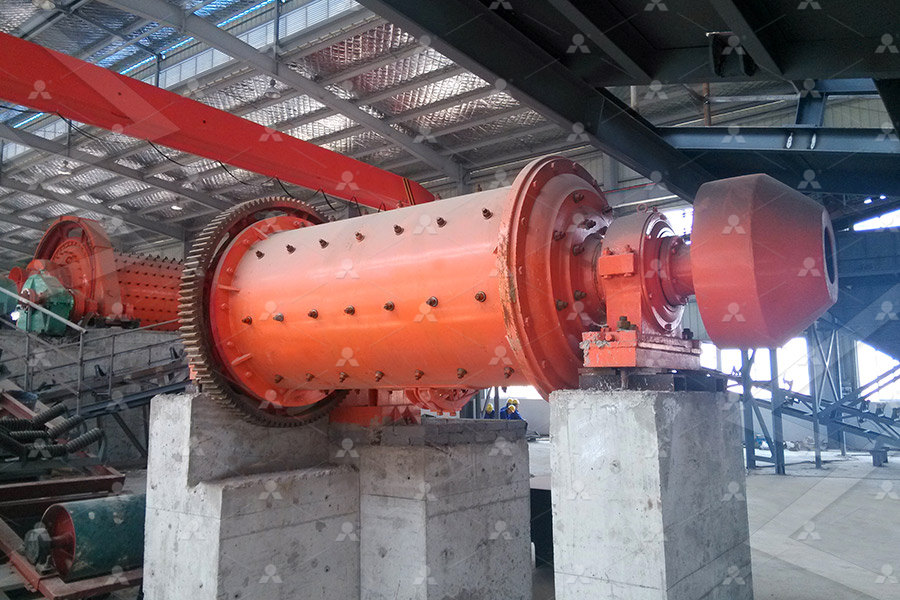

Drawing from the third edition of the bestselling Powder Technology Handbook, this book concentrates on handling methods and unit operations for powder and particle processing techniques Itexamines the purpose and factors involved in each process—including planning, equipment, measurements, and other necessary considerations This book carefully Overview Micro Powder Grinding Mill is widely used in making fine powder or micro powder, and the raw materials should be noninflammable and nonexplosive under the Moh’s hardness less than 6 grade such as limestone, calcite, dolomite, kaolin, bentonite, talc, illite, pyrophillite, barite, meerschaum, fluorite, potash ore, etc The lifetimeMicro Powder Grinding Mill CM Mining MachineryDrawing from the third edition of the bestselling Powder Technology Handbook, this book concentrates on handling methods and unit operations for powder and particle processing techniques Itexamines the purpose and factors involved in each process—including planning, equipment, measurements, and other necessary considerations This book carefully Powder Technology : Handling and Operations, Process Google BooksBall Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner management are Ball Mill Grinding Process Handbook

Micro Powder Grinding Mill

Advantages of Micro Powder Grinding Mill 1The yield is 40% higher than other mills 2High utilization rate of Wear material: 25years 3Adjustable particle size: 3253000mesh 4High safety and reliability The design of the mill is rigorous, so no screw loosening to damage the machine 5Closed system, so it is the green and ideal equipment for environment protectionMicro electrical discharge machining (microEDM) is a thermoelectric and contactless process most suited for micromanufacturing and highprecision machining, especially when difficulttocut materials, such as super alloys, MicroElectro Discharge Machining: Principles, Recent 2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag 2023年5月4日 In book: Fabrication of Micro/Nano Structures via Precision Machining (pp287299)Introduction to Precision Grinding and Injection Molding Micro

An experimental and numerical study of microgrinding force and

2020年9月1日 The grinding surface of sapphire machined by conventional micro abrasive tool is displayed in Fig 16, the experimental results disclosed that there is no obvious high residual on the workpiece surface due to the increase of the number of abrasive particles involved in the actual cutting, when the number of grinding times is r, and the surface roughness is June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: This specialist edition features key innovations in the science and engineering of new grinding processes, abrasives, tools, machines, and systems for a range of important industrial applications Topics written by invited, internationally recognized authors review the advances and present results of research over a range of wellknown grinding processesModern Grinding Technology and Systems MDPI BooksMicro powder grinding mill is designed by our RD department on the basis of multiple innovation and testing It has been proved by easy operation and maintenance It is the ideal equipment for the in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Micro Powder Grinding Mill,Ultrafine Mill,Ultrafine grinding mill

Introduction to Precision Grinding and Injection Molding Micro

2023年5月4日 However, microstructure machining of hard and brittle materials is the technical bottleneck of microfine and precision machining At present, the main problem to be solved is how to improve the 3D microstructured form accuracy and surface quality of the mold at micron scale, and the quality of the microstructure polymer microinjection molding, so as to realize the introduction to micromachining , vkjain (editor) published by narosa publishers, n ew delhi (2009) (second edition) micromanufacturing processes by v k jain (editor), crc press advanced machining processes by vk jain , allied publishers, new delhi nonconventional material removal processes by vkjain, block4, indira gandhi national open university (ignou), newMICRO MACHINING PROCESSES IIT Kanpur