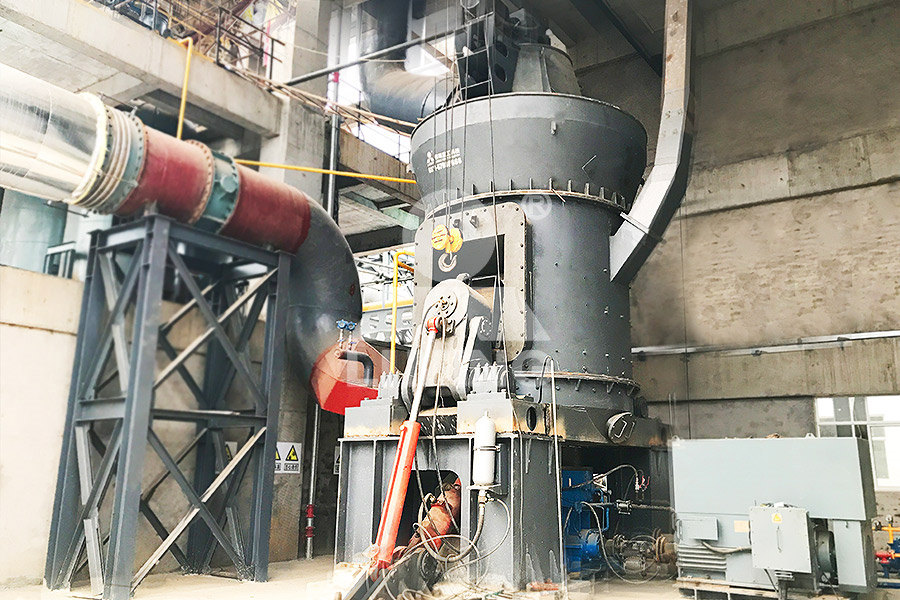

LM220k vertical mill repair and maintenance

LM Series Vertical Mill Liming Heavy Industry

LMseries vertical mill is one advanced mill, adopting top technology domesic and abroad, and based on many years’ mill experiences It can crush, dry, grind, and classify the materials LM This document provides a technical agenda for optimizing the performance of vertical raw mills It aims to help plant teams manage mill performance through structured approaches, Molinos Verticales PDF Mill (Grinding) Valve Scribda vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSWe dismantle and maintain the main parts of mill after longterm usage and restore them to fresh condition Furthermore, we can provide the suitable maintenance proposal according to the UBE Vertical Mill|SERVICES|UBE Machinery Corporation, Ltd

VF/VM Maintenance Haas Service Manual Haas Automation Inc

Clean the locating pins and bushings Inspect the pallet wipers Inspect the door for proper operation Grease the door side guide rails Clean the chips from the tool changer Inspect the Why is Preventive Maintenance Beneficial for you? 1 Reduces downtime 2 Saves you money 3 Reduces complete breakdowns 4 Extends the lifespan of your machine and cutting tools 5 Haas Preventive Maintenance Haas Automation Inc2023年3月15日 From aspects of grinding efficiency, powder drying, abrasion of vulnerable parts and maintenance replacement of spare parts, SBM’s LM Vertical Grinding Mill achieves LM Vertical Grinding Mill SBM Mill Crushermethods of operation and maintenance of the LMV mill To ensure the maximum performance and precision operation, it is imperative that operators, maintenance and repair personnel read the LMV Sharp Industries

Services Loesche

We carry out regular maintenance and repair works Furthermore, we can offer regular monitoring and inspection of your grinding plant within the terms of a service contract Should a This grinding mill integrates crushing, drying, grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling LM Vertical Grinding MillSBM Industrial Technology GroupLM vertical mill adopts new milling devic and automatic electric control system, integrating drying, grinding, saving 40% 50% power consumption compared to ball mill 3Easy maintenance and low operating cost Grinding roller bearings are lubricated with forced thin oil, longer bearing life Model Capacity (t/h) Output finenessLM Vertical Roller MillGrinding mill machine, mineral mill, Pulp Paper Mill Repair IWM has become our regions expert in paper mill repairs paper factory maintenance Providing Paper Producers with many custom parts and repairs, such as: Paper Mill Roll Repair Over the many decades, we have worked on nearly every type of paper mill roll on both the repair and fabrication sides of the processPaper Mill Repair, Roller Repair Factory Maintenance IWM

UBE Vertical Mill|SERVICES|UBE Machinery

Utilizing our knowhow as vertical mill manufacturer and the largescale processing equipment at our own workshop, we respond to every request, from product production to maintenance of various parts, technical support, and on 2024年3月18日 However, like any other industrial equipment, it requires proper maintenance and operation to ensure peak performance and longevity This guide provides a comprehensive overview of the essential maintenance tasks and operational strategies for the Raymond Mill Routine Maintenance For Raymond Mill Daily Maintenance 1Guide to Raymond Mill Maintenance: Schedule and Best PracticesGain the knowledge and understanding to properly maintain your vertical mill necessary to develop improved maintenance plans for your specific equipment and learn how to perform the necessary maintenance and repair work to prevent breakdowns and improve reliability Vertical Mill Maintenance Seminar CourseNr: US24009 SEE OPEN COURSESVertical Mill Maintenance Seminar FLSmidth Cement2023年1月10日 Advantages of Slag Vertical Roller Mill 1 Costeffective, less comprehensive investment Large functions are integrated in one, occupying an area of about 50% of the ball mill system, and can be arranged in the open air, greatly reducing investment costs; the system design is simple and reasonable, saving the total investment in equipment Slag Vertical Roller Mill

LM Vertical Grinding MillSBM Industrial Technology Group

LM Vertical Grinding Mill Based on the absorption of advanced technologies of famous international corporations and 30 years' experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, powder selection, drying and material conveyingINSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES TP5260 Revised DO NOT ALLOW the operation or repair of equipment by untrained threads, and slots The vertical mill, or “column and knee” mill, is the most common milling machine found in machine shops today The general construction of this Bridgeport Vertical Mill Manual DocsLibThe Vertical Mill, Easy Maintenance: The Vertical Mill is designed for easy maintenance and replacement of parts, reducing downtime and ensuring continuous operation LM220K: LM280K: Diameter of turntable (mm) 1300: 1500: 1700: 1900: 2200: 2800: Output (t/h) 1028: 1338: 1848: 2368: 36105:Vertical Roller Mill, Vertical Raw Mill, Vertical Cement MillSimple and reliable operation: Limit device for preventing the direct contact between grinding roller and grinding table, to avoid the severe vibration of the mill caused by the collision between roller and tables; With hydraulic roller turningout device, the grinding roller can be turned out of the machine completely to ensure enough maintenance space,which replace and repair easy LM Vertical Roller Mill, slag vertical mill, coal vertical mill

.jpg)

Manual Mill and Lathe Repair Houston Machine

Manual Mill and Lathe Repair Houston Machine Tool Services has qualified technicians with the expertise to help you with any issues you may have with your Manual Mills and Lathes Manual mills and lathes are still a big part of the LMseries vertical mill is one advanced mill, adopting top technology domesic and abroad, and based on many years’ mill experiences It can crush, dry, grind, and classify the materials LM series vertical milling machine can be widely used in LM Series Vertical Mill Liming Heavy IndustryVertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity With the experience gained from repairs worldwide, Castolin Vertical Roller Mill Repair: Enduring PerformanceMaintenance and Repair Services 8(a), AS9100D ISO 9001:2015 CERTIFIED Vertical Boring Mill; Vertical Turret Lathe; Community Involvement Every product we make and service supports Workshops for Warriors, a 501(c)(3) nonprofit dedicated to training, certifying, Maintenance and Repair Services VetPowered

Steel Mill Maintenance and Repair Services GMB Heavy Industries

Our steel mill maintenance and repair services consist of: Surveys/Inspection, Maintenance/Repair, Services for scheduled annual shutdowns Skip to content Address: 5165 Timberlea Blvd Mississauga, Ontario, L4W 2S3 Tel: +1 9052829395, +1 8772829724 REQUEST A QUOTE Home; About Us Mission Vision;Introduction The LM Vertical Grinding Mill , launched by SMMVIK Machinery, integrates five functions of crushing, grinding, powder selection, drying and material conveyingIt is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionLM Vertical Grinding Mill SMMVIK Machinery2016年10月20日 General Ball Mill Maintenance After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we recommend the use of a check list This is particularly recommended for multiple mill installations where it is difficult to control the different phases of installation for each and every millBall Mill Maintenance Installation Procedure 911Metallurgistmaster model pellet mill photograph 2 general information 3 start up instructions 6 terminating pellet mill operation 9 trouble shooting 10 lubrication 11 recommended lubricants 13 description and maintenance: feeder mixer feed chute deflectors cutting knives mainshaft bearing shear pin assembly die 14 14 15 1 5 15 15OPERATING, MAINTENANCE and

Cement Raw Vertical Mill Area Maintenance

Cement Raw Vertical Mill Area Maintenance Dam Ring There is high wear and deformation in the dam ring segments new dam ring segments worn out and deformed dam rings segments 2 The repair kit for the piston head of roller no2is defected and there is oil leakagePreventive Maintenance Productivity’s machine tool preventive maintenance pays for itself How? Productivity provides CNC preventive maintenance for most makes and models of machine tools as well as FANUC robots We offer flexible service CNC Machine Tool Preventative Maintenance Productivity IncThe ball mill maintenance guide mentions that the lubrication of the machine needs to be checked regularly The first time you use the ball Regularly Inspect and Repair All Parts of the Ball Mill Each part is also a key point of ball mill maintenance 1 The Ball Mill Maintenance Procedure GuideOur team of skilled mechanics specializing in lathe machines and mill machines possesses the ability to repair virtually any type of conventional lathe or mill At Machine Techs, our dedicated service technicians work on a wide range of Conventional Lathe + Mill Repair machinetechs

.jpg)

Basic Maintenance Methods of Milling Machine

Vertical Lathe Single Column Vertical Lathe; 2Axis CNC Single Column Vertical Lathe; Double Column Vertical Lathe; 2Axis CNC Double Column Vertical Lathe; Horizontal Lathe Flat Bed CNC Lathe; Slant Bed CNC Lathe; FT200/FT300 CNC SLANT BED LATHE; Conventional Lathe; CNC Boring Mill CNC Horizontal Boring Mill; Floor Type Boring Mill; Table 2015年1月26日 Page 2 and 3: Vertical Roller Mill repair Our lon; Page 4 and 5: Vertical Roller Mill repair Specifi; Page 6 and 7: Vertical Roller Mill repair CastoLa; Page 8 and 9: Vertical Roller Mill repair Wear an; Page 10 and 11: Vertical Roller Mill repair Some Su; Page 12: Vertical Roller Mill repair StrongeVertical Roller Mill repair Castolin Eutectic YumpuDiscover the ultimate solution for highefficiency grinding with the Vertical Bead Sand Mill by Longly no leakage, stable and reliable performance, low energy consumption and low heat generation Installation, repair and maintenance are more convenient Technical Parameters of Dual Power Vertical Nano Bead Mill: LSK Applications of Dual Vertical Bead Sand Mill Longly Dongguan Longly Machinery – It has high energy efficiency during the milling process due to its vertical milling zone – Easy maintenance and repair – It is easy to replace a pin with the highest rate of wear – It has adopted a separator with grid rings to fundamentally prevent the outflow of beads – Milling parts : Pin type – Bead size: Ø03~03mmVERTICAL BEADS MILL – 나노인텍

Mill Maintenance Methods Miller Magazine

2018年5月8日 1UNSECHEDULED MAINTENANCE (CORRECTIVE MAINTENANCE) It is also called emergency maintenance, breakdown maintenance or repair maintenance Maintenance and repair are performed when machine or equipment fails As a result, loss of production during repair is high Defects also can harm other machines or toolsMaintenance and repair are performed when machine or equipment fails As a result, loss of production during repair is high Defects also can harm other machines or tools When performing corrective maintenance; the mill or its equipment is returned to base or original conditions and productivity by replacing parts or materials only after Cement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENTSimple and reliable operation:Limit device for preventing the direct contact between grinding roller and grinding table, to avoid the severe vibration of the mill caused by the collision between roller and tables; With hydraulic roller turningout device, the grinding roller can be turned out of the machine completely to ensure enough maintenance space,which replace and repair easywear LUM series superfine vertical roller grinding mill2020年7月15日 PDF Vertical Mill is one of the main equipment in the Indarung IV factory PT With the maintenance and repairs are well scheduled, then we can avoid the causes of a damage from the beginning(PDF) Optimalisasi Sistem Perawatan dan Perbaikan Mesin Vertical Mill

.jpg)

Vertical roller grinding mill LM series Shibang

Comprehensive Optimization, Lower Operating Costs From aspects of grinding efficiency, powder drying, abrasion of vulnerable parts and maintenance replacement of spare parts, SBM’s LM Vertical Grinding Mill achieves lower Automation Accessories Shop Support Mill Toolholding Mill Cutting Tools Boring Systems Mill Workholding Lathe Toolholding Lathe Cutting Tools Lathe Workholding Package Kits ER Collets Chucks Holemaking Threading VF/VM Maintenance Haas Service Manual Haas LM Vertical Grinding Mill LM series vertical roller mills are a excellent grinding equipment, which have the capacity of 24hours constant running Because of this automatic operation, this VRMs are popular in the condition, which needs easy monitor, large capaity, constant running, stable product quality, like large mineral powder plant, cement plant, GGBS powder plant, coal LM Vertical Grinding Mill Vertical Roller MillLM Series Vertical Roller Mill is large size Powder Grinding Machine that designed and manufactured by our company Its technology is origin from Japan of advanced process and reliable structure design by combing drying, grinding, separating and conveying together for diverse materials and different size grinding systemsLm Series Cement Vertical Roller Mill (LM 130K/LM150K)

The World of Steel Mills: Engineering, Maintenance, and More

2023年9月16日 The Human Touch Behind the towering structures and sophisticated machinery, it’s the skilled workforce that drives steel mill operations Engineers and technicians use upgraded equipment to create a harmonious environment where innovation and precision intersect As GMB Heavy Industries is part and parcel of the steel mill industry, our experts provide top tier The maintenance of the pulverizer mill affects the availability and reliability of the operating unit The efficiency of the mill in providing the desired coal and air mixture to the furnace has increased cost consequences with the addition of NOx controls 1142 Vertical Shaft Pulverizer Maintenance Guide, Volume 1 Raymond Bowl MillsLM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical indus : English French(français) Russian(русский) Spanish(español) HOME 3Simple, maintenance convenient and reliable operation 4High drying ability 5The stability of product qualityLM Series Vertical Mill LIMING(Shanghai)requirement for maintenance and repair, energyoptimized operation, overall active redundancy for grinding rollers, mill drives and mill motors, fi rstclass quality of all components and their worldwide availability plus our renowned Pfeiffer service throughout the lifetime of your mill Cement grinding plant on EPC basisPFEIFFER VERTICAL MILL WITH MULTIDRIVE MORE POWER

.jpg)

Key Industry Program Castolin Eutectic

Crack repair of Ball Mill Crusher with PTA wear facing Onsite repair of Roller Press Our applications Based upon hundreds of successful applications approved by our clients across the globe, Castolin Eutectic can provide optimized solutions with a wide range of products and technologies to combat wear in VRM (Vertical Roller Mill) and many moreWe are currently offering general training sessions on vertical roller mills as well as ‚customtailored‘ training units on: Grinding technology; Mechanic design of a vertical roller mill; Maintenance procedures for vertical roller mills; Operation, process parameters, and control loops; Quality control; Hydraulic systems; Customised trainingServices Loesche