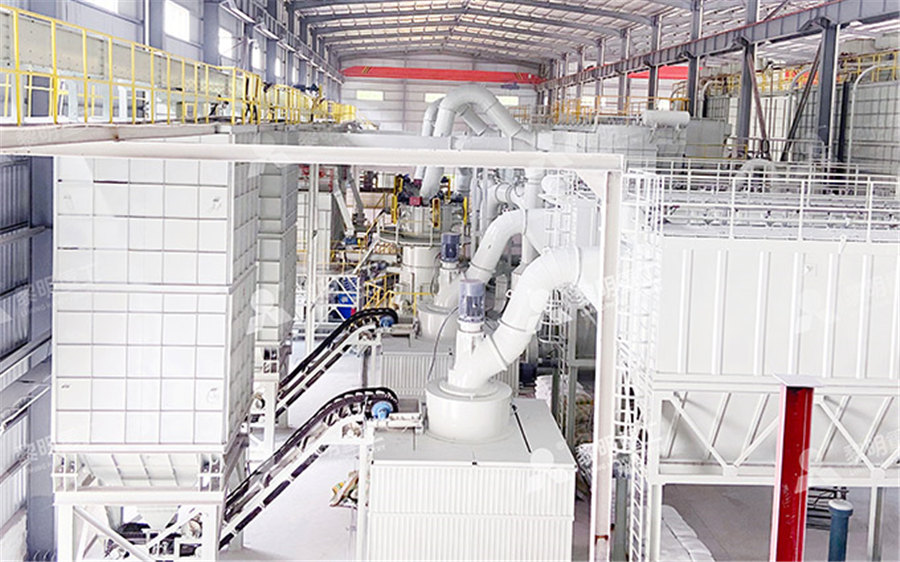

PF1210 vertical grinding ore mill fluorite mine

Impact crusher PF1210 Shanghai Joyal Machinery Co, Ltd

The limestone Impact Crusher is used for primary, secondary, fine crushing mining and rocks (for example, the granite, marble, and limestone) materials with compressive strength less than Find detailed product information for Unique PF1210 Impact Crusher for Stone Production Line and other products from Zhengzhou Unique Industrial Equipment Co, Ltd PF1210 impact Impact Crusher Pf1210 Crusher Mills, Cone Crusher, Jaw CrushersCLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17CLUM Ultrafine Vertical Grinding MillThe Tower Mill is another type of grinding mill used in the mining industry This vertical mill consists of a cylindrical chamber filled with grinding media, which are stirred by a shaft that moves vertically up and down Tower Mills were Understanding the SAG Mill in Copper Ore Mining

}@~3SRDG`IA1KP_ICWAA.jpg)

Ball Mill Is The Key To Grinding Lithium Ore JXSC

5 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process 3 Double PositionLimiting Technology Makes Operation More Stable In the CLUM series ultrafine vertical roller mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical limiting protection technology, which can avoid the destructive impact (eg the grinding roller directly smashing the millstone) caused by machine CLUM Series Ultrafine Vertical Roller Mill2022年4月28日 Kalium ore powder grinding mill machine 28/04/2022 admin Kalium mine crushing equipment Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 WhatsApp: +86 Click to chat (Web) Click to chat (App)Kalium ore powder grinding mill machine2021年6月24日 QuartzFluorite Ore Flotation Flowsheet CarbonateFluorite Ore Flotation Flowsheet Conclusion Let's get started! Processing of fluorite ores is the process of separating fluorite concentrate from fluorite ore Fluorite, also known as fluorspar, has a chemical composition of CaF2, which is usually symbiotic with quartz, calcite, barite, and Fluorite Processing Methods and Flowsheet Miningpedia

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, TürkeyMineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig, only jig can deal with the coarse fluorite ore Fluorite (Fluorspar) flotation equipment is similar to other mineral flotation equipment including crusher, ball mill, flotation machine, etc 【Application】Fluorite Mining Processing Equipment Flow Chart Cases JXSC2014年1月1日 Vertical stirred mill is expected to upgrade the iron concentrate by further size reduced efficiently The tests for fine grinding of iron ores from Baiyun Boyu iron ore, Baogang Goup, iron Application of vertical stirred mill in iron ore fine grindingVertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this millLM Vertical Roller Mill, Vertical Mill Manufacturer

.jpg)

Micro Powder Grinding Mill

The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, Talc Powder Ultrafine Vertical Roller Mill Shanghai Raymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the Raymond Roller Grinding Mill Vertical Roller Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

.jpg)

fluorite grinding mill in Thailand Stone Pulverizer

Malaysia Silica Sand Grinding Mill For Talcum,Fluorite,Iron Ore , Find Sand Grinding Mill Price,Silica Sand Grinding Mill For Sale from Mine Mill Supplier or has the chance to visit working machines or complete plant in the site vertical mill etc the client from Mexico needs t1 o purchase one set of grinding mill to expand their Check now2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill integration in The particle size of the finished fine powder is arbitrarily adjusted between 3253000 mesh, and the output can reach 0445 tons per hour >>Equipment composition The HGM grinding mill production line usually consists of hammer crusher, bucket elevator, storage bin, vibrating feeder, micro pulverizer host, frequency conversion classifier, double cyclone powder collector, pulse HGM Ultrafine Grinding Mill Vertical Roller Grinding Mill

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, This mill accepts grinding set weights of up to 30 kg, The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bedFigure 3: Relationship between feed size (F80) and Bond efficiency factor (Huang et al, 2019) VERTICAL POWER MILL (VPM) – PRINCIPLE OF OPERATION Declining ore grades and more complex ore bodies, as well as waste management and global net zero initiatives, lead to a clear trend for high tonnage yet energy efficient grindingRECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2013年4月16日 ABSTRACT In this study, ultrafine grinding of a refractory silver ore tailings was studied A laboratory scale pintype vertical stirred mill and ceramic beads were employed for the grinding testsInvestigation of some parameters affecting the Ultrafine grinding

Ball Mill Is Indispensable For Lithium Ore Processing

2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common 2024年11月21日 Fluorspar mineral processing is a complex field that requires a variety of methods to extract and refine this valuable mineral One common type is gravity separation, which involves separating fluorspar from other minerals based on differences in densityThis method is costeffective and environmentally friendly, making it a popular choice in fluorspar processingFour Common Types Of Fluorspar Mineral Processing Methods2019年8月23日 Need more fluorite processing solutions? Contact us now to get more fluorite processing flowsheet PDF and get a free customize processing flow by our mining experts and engineers 【Advantages】 1 Fully crushing and grinding steps reduce the consumption of flotation reagents 2Fluorite Processing Equipment, Process Flow, Cases JXSC Coal Vertical Roller Mill (VRM) is an air swept, mediumspeed, vertical pulverizer with integral classifier It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grinding roller onto a rotating bed of coal Grinding pressure can be adjusted to account for variations in coal grindability and desired product finenessCoal Vertical Roller Mill (VRM) for Grinding Stone

.jpg)

UNDErsTaNDINg MINE TO MILL 911 Metallurgist

Understanding Mine to Mill is presented in five parts Part A – Setting the Scene provides some definitions of Mine to Mill (M2M) and the historical background A chronology of Mine to Mill developments is followed by brief descriptions of the very wide range of Mine to Mill applications which have been implemented over the last 15 years2021年9月9日 Diatomite ultrafine grinding mill is an efficient ore stone powder making machine It can grind 100+ kinds of ores into a fine powder (1503000mesh)Diatomite Ultrafine Grinding Mill SBM Ultrafine Powder 2014年10月20日 Rio Paracatu regrind circuit Santos Júnior et al (2011) presented some data on the Paracatu Vertical Mill circuit process, as well as its comparison to the plant's conventional ball millRegrind of metallic ores with vertical mills: An overview of the Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), such as gypsum, calcium carbonate, limestone, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcLimestone Ultrafine Vertical Mill

Processing Materials SBM Ultrafine Powder Technology

SBM has been focusing on the field of mining ore crushing and grinding machinery for many years Our grinding equipment can grind 100+ kinds of nonmetallic +年11月1日 The application of vertical mills in regrind circuits is consolidated This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when compared to Vertical mill simulation applied to iron ores2021年4月19日 PDF Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher Find, read and cite all the research you (PDF) Feasibility and necessity of mine to millIn the calcium carbonate superfine powder vertical mill, the contact point between the grinding roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive effects caused by machine vibration (such as the direct crushing of the grinding roller and the grinding disc) ( Such as the grinding roller Calcium Carbonate Ultrafine Powder Vertical Mill

.jpg)

Research of iron ore grinding in a verticalrollermill

2015年3月15日 The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemBetween the working surfaces of track and rollers, particle bed comminution takes place A dynamic air separator (3) is located above the grinding chamber, The Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantVertical Roller Mills used for the comminution of mineral oresThe Hotsale Models and Capacity 3r2115, 4r3016, 5r4128 are the popular models we recommend to our customers The output size of the final product can be 075mm (80mesh) to 0045mm (325mesh)Talc/Barite/Fluorite/Quartz/Silica/Limestone Vertical Powder Grinding 2020年8月12日 Altun et al [15] explored the influence of the parameter settings of a vertical roller mill on grinding performance and demonstrated the influence of grinding pressure values on the size and mass An investigation of performance characteristics and energetic

Tower Mill Operating Work Index 911Metallurgist

2016年6月3日 IsaMills, Tower Mill and Verti Mill Ultrafine Grinding in a Tower Mill The Tower Mill is a vertical “stirred” ball/pebble mill recently introduced in the Western Hemisphere This device offers a significant power savings on wet fine grinding applications when compared to conventional tumbling mills2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a professional manufacturer of milling equipment for the ore industryBarite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder