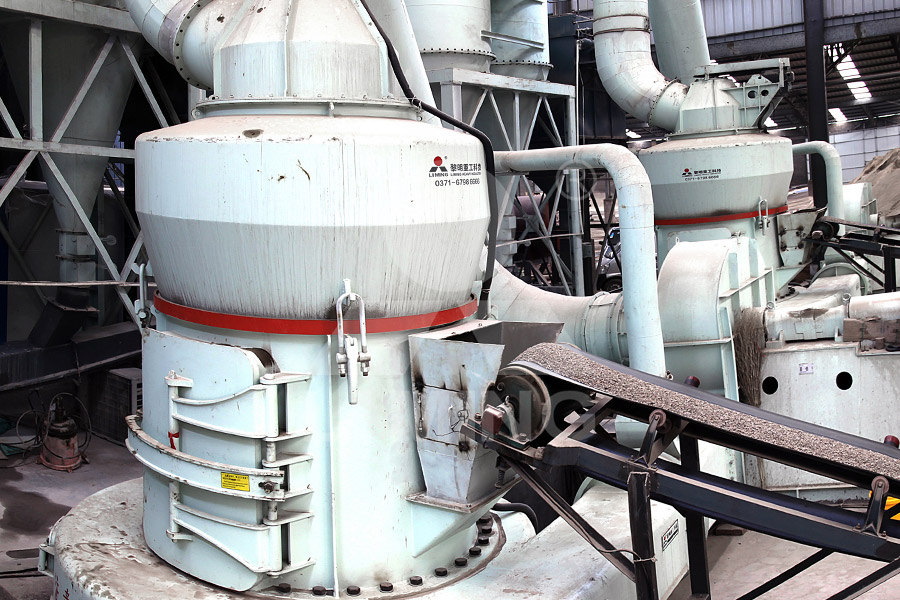

Blast furnace slag powder making process

.jpg)

Ground Granulated Blast Furnace Slag ScienceDirect

Ground granulated blastfurnace slag (GGBFS) is a byproduct of making iron and steel, ie, a fine powder grounded from the glassy, granular material that forms when molten iron blast furnace 2023年7月21日 Overview of blast furnace slag treatment process in China Currently, the water quenching granulation process and the dry granulation process are widely used in China The Comprehensive utilisation of blast furnace slag Taylor Francis Blast furnace slag is a byproduct acquired in the production of pig iron in the blast furnace and is involving essentially of silicates and aluminosilicates of calcium and of other bases, which is Blast Furnace Slag an overview ScienceDirect Topics2019年1月1日 In this regard, this review study aims to provide an overview of and a collective approach to various uses of blast furnace and steelmaking slag in diverse applications and An Overview of Utilization of Blast Furnace and Steelmaking Slag

.jpg)

Blast furnace ironmaking process with super high TiO2 in the slag

Aiming at the process of smelting ultrahigh (>80%) or even full vanadium titanomagnetite in blast furnace, we are conducting a series of works on physics character of high TiO2 bearing blast 2011年1月1日 Ground granulated blast furnace slag (GGBS) is a byproduct from the blastfurnaces used to make iron Blastfurnaces are fed with controlled mixture of ironore, coke Ground Granulated Blast Furnace Slag SpringerLink3 天之前 The blast furnace slag of Shasteel Group Co, LTD, located in Jiangsu province, China, serves as the primary raw material for this experiment Additionally, industrial aluminum Full article: Synthesis of βSiAlON materials from blast furnace slag 2022年7月18日 In some studies, it has been demonstrated that using a composite mineral admixture known as groundgranulated blastfurnace slagsteel slag composite binder can increase the fluidity of fresh concrete, A Comprehensive Review on the Ground Granulated

.jpg)

Mechanical Strengths of AlkaliActivated Blast Furnace

2023年3月22日 In this paper, the influence of water glass types, the modulus of water glass, the alkali content, the water consumption, and plant fibers on the mechanical strengths of alkaliactivated blast furnace slag powder (BFS) is Blast Furnace Slag In the blast furnace, the slag floating over molten pig iron (hot metal) is flushed out in slag pot and then sent to slag granulating plant or to cooling pits Depending upon the cooling process, three types of slags are generated, namely, aircooled slag, granulated slag and expanded slag Aircooled slag is produced by SLAG IRON AND STEEL IBM2019年1月1日 The schematic diagram of pig iron and blast furnace slag production process is given in Fig 1 Fig 1 Schematic illustration of pig iron and slag production process in a blast furnace 518 Dervis Ozkan et al / Materials Today: Proceedings 11 (2019) 516–525 3An Overview of Utilization of Blast Furnace and Steelmaking Slag PDF On Dec 27, 2019, Mr Bhavesh R Rana published ironsteel making From start to finish Find, read and cite all the research you need on ResearchGate(PDF) ironsteel making From start to finish

LECTURE NOTES ON IRON MAKING SUBJECT CODE: PCMT 4307

1 Introduction to Iron Making 2 Blast Furnace Plant 3 Raw materials and their properties: Iron ores an flux 4 Raw materials and their properties 19 Blast furnace slag: composition and its control, Metalslag reactions 20 Process Control: Factors affecting fuel consumption and productivity 21 Recent developments in Blast furnace operations The blast furnace gas (BFG) generated in the BF is cleaned through a series of steps before transporting it to the BFG Holder vi) Slag Granulation Plant (SGP) / Slag Dumping Yard: During the process of iron making, the impurities are fluxed and removed as slag The hot liquid slag is made into slag granules by means of highIn the Blast Furnaces (BF) liquid iron (popularly termed as ‘Hot 2022年2月1日 1 Introduction The steel industry as one of the most energy and carbon intensive industries, has attracted much attention in achieving the goals of carbon peak and carbon neutrality [1, 2]The treatment of liquid blast furnace (BF) slag, a byproduct of the ironmaking process, is one of the breakthrough points, since it contains a large amount of highgrade Cooling and phase evolution of a molten blast furnace slag 2020年7月15日 Currently, approximately 95% of hot metal is produced by the blast furnace ironmaking process, which is also predicted to be the largest single ironmaking process until 2050 because of its advantages in production cost and efficiency Therefore, replacing fossilbased fuels with H 2 as the reductant is expected to relieve environmental concerns and, Blast Furnace Ironmaking an overview ScienceDirect Topics

.jpg)

Modeling on Dry Centrifugal Granulation Process of Molten Blast Furnace

2015年7月30日 Lots of iron molten slag from blast furnace can be produced during iron making process It is generally cooled by water quenching method which causes many problems, such as water consumption 2017年3月22日 Today, roughly twothirds of the world’s steel is produced via the integrated blast furnacebasic oxygen furnace (BFBOF) route In this process, iron ore is reduced mainly by coke in the blast furnace (BF) This coke also produces the required heat by reacting with the available oxygen (from the hot blast and the FeO)Sulphur removal in ironmaking and oxygen steelmakingSlag processing George C Wang, in The Utilization of Slag in Civil Infrastructure Construction, 2016 53 Blast furnace slag processing Iron blast furnace slag results from the fusion of iron ore, fluxing materials, and coke; the reduction reactions; and the separation of iron from the ore As indicated in Chapter 2, the term blast furnace slag is used often to refer to iron blast furnace Blast Furnace Slag an overview ScienceDirect Topics2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of What is Blast Furnace Slag and How to Process It?

The steel production transformation process in Europe:

The main challenge of the steel industry for the next decade is the steel production transformation process, starting in Europe The CO 2 intensive blast furnace/basic oxygen furnace (BOF) route will be substituted by a combination 2018年6月21日 These hot gases rise up in the blast furnace and cool down From a maximum of 2000 °C at the level of the hotblast nozzles (tuyere), the temperature decreases to around 200 °C up to the throat At this temperature, Blast furnace process tecscience2024年10月8日 To utilize blast furnace slag in an environment friendly, economically efficient and high valueadded manner, this study successfully prepared glass–ceramics by directly using highbasicity blast furnace slag (R = 126) as raw material through lowpressure sintering method (80 kPa) This study examined the influences of particle size, heat treatment temperature and Preparation of Glass–Ceramics Using LowPressure Sintering Blast furnace slag (BFS) is a secondary material generated during the process of producing iron in blast furnaces, Removal of phosphate from aqueous solution using layered double hydroxide prepared from waste ironmaking slag Bull Chem Soc Jpn, 89 (4) (2016), pp 472480 Crossref View in Scopus Google ScholarUnlocking the potential: A comprehensive review on blast furnace slag

-2.jpg)

Crystallization Behaviors of Blast Furnace (BF) Slag in a Phase

2016年3月7日 Blast furnace (BF) slag is the principal byproduct formed during the ironmaking process, which generates a considerable amount of thermal energy However, to simultaneously recover the maximum amount of residual heat and obtain vitreous slag using a low conduction coefficient of air is a primary challenge of the dry granulation technique, which has not been Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses coke, iron ore and limestone to produce pig iron Coal traditionally has been a key part of the cokemaking process The coal is crushed and ground into a powder and then charged into an Steel Production American Iron and Steel Institute2011年1月1日 Ground granulated blast furnace slag (GGBS) The process of granulating the slag involves cooling of molten slag through highpressure water jets H, ElKair, HA: Mechanical properties and durability of Portland cement concrete incorporating ground steel making slag AEJ Alex Eng J 36, 1–14 Ground Granulated Blast Furnace Slag SpringerLink2020年6月10日 Blast furnace iron making is the most popular process for extraction of iron from its ores Other wellknown processes are EAF and Direct Reduction Iron (DRI) processes However, blast furnace will continue to be the most efficient route to produce pig iron for its high productivity and cost optimization, for many years to come [1, 2]Iron and SteelMaking Process SpringerLink

.jpg)

Chemistry of the Ironmaking by Blast Furnace Process

2013年11月22日 The slag formed in the upper part of the slag formation zone is called the ‘bosh’ or ‘primary’ slag, and the slag leaving the zone at the bottom is the ‘hearth’ slag The Primary slag is normally assumed to be made up of all burden slag components including the iron oxides not reduced in the granular zone, but does not include the ash from the coke or injected coalisation of blast furnace slag and improve the economic benefits of the steel industry, this paper will introduce the current status quo of comprehensive utilisation of blast furnace slag from the current blast furnace slag sensible heat recovery of molten steel 1 Overview of blast furnace slag treatment process in ChinaComprehensive utilisation of blast furnace slag Taylor Francis 2019年9月8日 The blast furnace iron making process (BFIMP) is the key of the integrated steel enterprise for energy saving due to its largest energy consumption proportion In this paper, an allfactors analysis approach on An AllFactors Analysis Approach on Energy 2021年2月22日 Slag, as shown in Fig 1, is the 16th ingredient of highperformance concrete production [22], called supplementary cementitious materials (SCM) [23], that can enhance the strength and durability of concrete [2]The highly fine slag powder, with a surface area of 400–600 m 2 /kg and a bulk density of 1200 kg/m 3, can be mixed with free lime to replace 40% to 65% Slag uses in making an ecofriendly and sustainable concrete: A

.jpg)

Ironmaking 101 – From Ore to Iron with Blast Furnaces

2017年10月10日 Many technologies are leveraged in a blast furnace to enhance iron making yield, throughput and hot metal quality such as modern tuyere and oxygen injection designs, refractories with improved iron and slag resistance, improved burden feeders, gas and energy recovery and advanced process control systemsSteel slag is a solid waste generated in the process of steel making and is mainly composed of oxides Steel slag may also be referred to as steel furnace slag, steel making slag, steel Chen et al (2019a) found that using a 25% granulated blast furnace slag as a replacement of OPC reduced the compressive, split tensile and Steel Slag an overview ScienceDirect TopicsLots of iron molten slag from blast furnace can be produced during iron making process It is generally cooled by water quenching method which causes many problems, such as water consumption, serious pollution, energy wasting etc To solve these problems, much more attention has been paid to various dry granulation methodsModeling on Dry Centrifugal Granulation Process of Molten Blast Furnace 2023年9月8日 A stable and efficient operation of the ironmaking blast furnace is prerequisite to reduce the greenhouse gas emission JSW Steel, Salem have been proposed many projects to reduce greenhouse gas Blast Furnace process optimization for sustainable Iron making

Iron processing Smelting, Refining, Alloying Britannica

Iron processing Smelting, Refining, Alloying: The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention here Alternative methods known as direct reduction are used in over a score of countries, but less than 5 percent of iron is made this way2020年3月3日 The only critical operating parameter is the temperature of the hot metal and slag which must be greater than 1425 °C for these products to be tapped from the furnace in the molten state Metal composition is not a critical feature of the blast furnace process because virtually all blast furnace hot metal is subsequently refined to steelBlast Furnace Process SpringerLinkCement additives Johannes Fink, in Petroleum Engineer's Guide to Oil Field Chemicals and Fluids (Third Edition), 2021 Furnace slag A furnace slag cement slurry can have a density of 15001600 kg m −3A combination of silica flour and furnace slag may be used to achieve service temperatures exceeding 200 °C [100]A gas may be suitable as a foaming agent [101]Furnace Slag an overview ScienceDirect Topics2020年3月29日 Blast furnace slag is a byproduct of the ironmaking process while producing pig iron The present research provides an understanding of the two different types of slags of water quenched granulated slag and aircooled slag that are generated from iron making process through the blast furnace routeUtilisation perspective on water quenched and aircooled blast furnace

Synergistic preparation of highperformance composite blast furnace

2024年1月12日 Blast furnace slag (BFS) is a byproduct generated during the ironmaking process in a blast furnace It mainly consists of silicates and aluminosilicates, with a high content of amorphous structure BFS is commonly used in the cement and construction industries [1], [2]2023年10月6日 The smelting process of blast furnace is carried out in the shaft furnace of a closed countercurrent reactor and heat exchanger The complex physical changes and chemical reactions are completed in the process of the countercurrent movement of the charge and gas in which the raw materials containing iron oxide (sinter, pellets, etc), coke, slag flux (limestone) Blast Furnace Ironmaking SpringerLink2022年11月28日 Applications of Blast Furnace Slag Cement There are numerous applications and uses for the slag cement such as: Produces concretes with higher strength; Produces concrete with lower permeability which make it suitable for locations vulnerable to chloride and sulfate attacks; for example, piles and marine structures; Makes concrete with lower heat of Blast Furnace Slag Cement: Production, Properties and ApplicationsMilled Slag (NMS) S GGBFS is manufactured by the grinding of dried granulated iron blast furnace slag (a by product of the iron making process) The resultant powder produced from the milling process is light coloured in appearance and has 33 bulk and relative density properties similar to Portland cement SUPPLYGround Granulated Blast Furnace Slag PDS CCL Cockburn

Blast Furnace Slag: Production, Types, Composition, Applications

2022年11月28日 Blast furnace slag powder Classification of blast furnace slag According to the American Concrete Institute (ACI), slag is classified based on its slag activity index (SAI) Slag manufacturers have little control over the chemical composition of the slag, since this is dictated by the ironmaking process 2023年12月7日 This study investigates the alterations in the ratios of components such as class C fly ash (FA), blast furnace slag (BFS), and waste stone powder (WSP) types of limestone powder (LP) used in the production of geopolymer concrete These components are meticulously examined concerning the physical and mechanical attributes of geopolymer concrete Using The Effects of Fly Ash, Blast Furnace Slag, and Limestone Powder 2024年9月23日 This critical review systematically explores the innovative utilization of ground granulated blastfurnace slag (GGBS), steel slag (SS), and other steel waste in concrete, addressing a crucial research gap in predicting concrete properties with these materials By analyzing 97 publications, this review offers a comprehensive understanding of how these Enhancing concrete properties with steel waste: a comprehensive 2019年10月31日 Compressive strength for water cured S3000 and S4000 concrete at 28 days Properties of BlastFurnace Slag Cement Concrete Subjected to

Blast furnace Wikipedia

Former AHM blast furnace in Port of Sagunt, Valencia, Spain A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper Blast refers to the combustion air being supplied above atmospheric pressure [1]In a blast furnace, fuel (), ores, and flux are continuously supplied