HOME→Silica ore mill ore breaking process Silica ore mill ore breaking process Silica ore mill ore breaking process

Silica ore mill ore breaking process Silica ore mill ore breaking process Silica ore mill ore breaking process

FYEFEPS2HDZ49G5Z0[B.jpg)

PILOT PLANT PROCESSING OF SILICA ORE P2 InfoHouse

A pilot plant rod milling test was undertaken to adjust the grind so that deslimed ore could be rod milled to produce a product approximating the required size specifications (see FigureSilica mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read moreSilica Mining Processing Equipment Flow Chart Cases JXSC2020年9月9日 Mineral liberation and size reduction are the most critical steps before mineral separation Several investigations showed that mineral liberation degree could be affected by Breakage process of mineral processing comminution machines2023年11月29日 Using a laboratory model of a vertical centrifugal breaking machine, the milling efficiency of ore having different Mohs hardnesses is found The rational structural and Features of Ore Disintegration in DryMilling Centrifugal Breaking

Silica Processing Equipment, Process Flow, Cases JXSC Machine

2019年8月23日 Silica processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design2023年6月15日 In summary, we developed an SHGMS with coupling with acid leaching technology for recovery and preparation of highgrade silica from high‑silicon IOTs Firstly, iron Recovery and preparation of highgrade silica from iron ore 2023年12月1日 From a geometallurgical perspective, it is fundamental to understand how ore textures influence the generation of ore particles and their properties This contribution outlines All About Particles: Modelling Ore Behaviour in Mineral Processing2008年4月1日 This paper focuses on the effect of operational parameters such as feed rate, classifier rotational speed and grinding pressure on the breakage mechanism of silica in terms Effect of operational parameters on the breakage mechanism of

.jpg)

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals

2022年1月23日 All content in this area was uploaded by György Bánvölgyi on Jan 18, 年4月1日 Silica was extracted from nickel laterite ore by hydrothermal process with sodium hydroxide as reaction assistant The effects of reaction temperature, reaction time, and NaOHtoore mole ratio on The Extraction of Silica from Nickel Laterite Ore by Alkaline 2017年4月10日 Although perhaps not ore dressing in the strict sense of the term, the direct extraction of the metals (especially the precious metals) from the ores also is considered here as an oredressing or a “milling” process Preparation by ore dressing includes the concentration of the valuable minerals within a smaller bulk than that of the Ore Dressing Methods 911Metallurgist2022年4月21日 Silica was extracted from nickel laterite ore by hydrothermal process with sodium hydroxide as reaction assistant The effects of reaction temperature, reaction time, and NaOHtoore mole ratio on the extraction rate of silica were investigated by a singlefactor experiment The optimal reaction conditions for the preparation of silica were obtained as The Extraction of Silica from Nickel Laterite Ore by Alkaline

(PDF) Overview of Mineral Processing Methods ResearchGate

2015年8月3日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing 2022年1月1日 Ore that is less than 40 mm but greater than 8 mm is conveyed to the lump stockpile Ore that is finer than 8 mm, but greater than 1 mm is conveyed to the fines stockpile Any ore that is finer than 1 mm in size is conveyed to a desanding plant consisting of cyclones, upper current classifiers and two stages of spirals for further minution and classification technologies of iron oreCrushing, a form of comminution, one of the unit operations of mineral processing Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling Beneficiation is any process that improves (benefits) the Mineral processing WikipediaGrinding media is classified according to the type of ore they are designed to process The most common types are ball mills, impact mills, and belt mills Ball mills are the most versatile type of mill because they can be used to process a variety of oresFactors affecting ores grinding performance in ball mills

.jpg)

Iron Ore Processing, General SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of 2021年12月2日 A new process of extracting silica from laterite nickel ore by hydrothermal treatment with sodium hydroxide as reaction auxiliary agent was proposed The mineralogical transformation and silicon extraction kinetics of laterite nickel ore in alkaline hydrothermal treatment were studied The effects of reaction temperature (175 ~ 250℃), molar ratios of Alkaline Hydrothermal Treatment and Leaching Kinetics of Silicon 2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Effect of ball and feed particle size distribution on 2008年10月1日 In this research work, it was attempted to reduce the iron contents (Fe2O3) in silica from Shenin silica mine This silica sand contains 9375% SiO2, 044% Fe2O3, 278% Al2O3, and 008% TiO2 and Reduction of Iron Content from Silica Sand by Scrubbing Process

.jpg)

Production and characterization of precipitated

2019年3月1日 The element C was present in its carbonate form not only in the palm oil mill fly ash (POMFA) and the carbonate compound that resulted from the precipitation process of dissolving CO 2 in silica 2016年9月1日 In this work, the feasibility study of desulfurization process for iron ore used in the pelletizing plant was carried out in the fourth line of the GoleGohar Complex Two methods were examined REMOVING IMPURITIES FROM IRON ORES: METHODS AND 2017年2月1日 environment during the grinding process of the ball mill Furthermore, the density (2313kg/m3) and s pecific heat (853 J/kgK) of ore from P enolta mine were experimentally foundHeat generation model in the ballmilling process of a tantalum ore2020年5月21日 Iron ore pellets are largely characterized by inherent physical and chemical properties of the ore Alumina and silica play important roles in determining the productivity of a Blast Furnace On average, one percent increase in iron content improves productivity by 2% and reduces coke consumption by 1% Therefore higher iron ore feed content to blast furnace is A Study on HighGrade Iron ore Beneficiation to Reduce

.jpg)

Monitoring ore loss and dilution for minetomill integration in

Mill Milling is the process of crushing, grinding, and treating of raw material from the mine to extract a saleable product It also involves the processes of hoisting and transporting of broken ore to the mill via trucks or conveyor belts Minetomill integrationTable 2 — Beneficiation practices of lowgrade iron ore Country Company Ore type Feed Process techniques Product Fe (%) AI 2O 3 (%) Wt% Fe (%) AI 2O 3 (%) For highalumina iron ore fines 1 India BMM Mines Hematite, goethite 580 Crusher, scrubber, screen, spirals, hydrocyclones, LIMS, HGMS, primary and secondary ball mill, thickener, filterDevelopment of process for beneficiation of lowgrade iron ore The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling within the mill, similar to the action of a rotating drumUnderstanding the SAG Mill in Copper Ore Mining Process2016年3月10日 Flotation studies of naturally occurring iron ores further established the fact that it is easier to upgrade the iron values from a high silica ore compared to a high alumina ore It was possible to produce an overall iron concentrate containing 62% Fe with 86% recovery for a silica bearing ore, but the grade and recovery of an alumina bearing ore were found to be lowRole of silica and alumina content in the flotation of iron ores

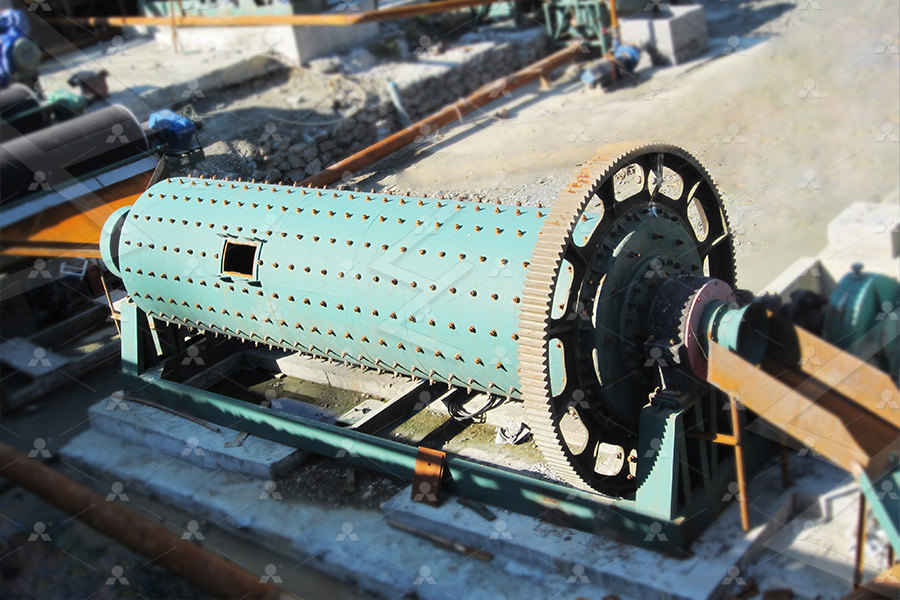

Buy Ore Ball Mill for Mineral Processing Iron Gold

The ore ball mill designed by our company, which is represented by gold ore ball mill and iron ore ball mill, is manufactured with highquality materials and advanced technology They have the characteristics of high efficiency, energy 2023年3月17日 The silica sand processing method varies from the silica sand source therefore, to process silica sand, while log washers are best for washing coarser sands and breaking down lumps Top 5 Methods to Silica Sand Processing: How to Separate Silica from Sand2018年2月1日 Agrowastes, especially ash containing silica, are promising sources of silica for synthetic amorphous silica production In this research, palm oil mill fly ash (POMFA) was used as a raw material Silica gel derived from palm oil mill fly ashDownload Citation On Jul 1, 2023, Yongkui Li and others published Innovative Technology for Preparation of HighPurity Silica from Vein Quartz Ore Through SHGMS Coupling Acid Leaching Process Innovative Technology for Preparation of HighPurity Silica from

.jpg)

The six main steps of iron ore processing Multotec

This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground Once the ore has been crushed, it is diverted to a stockpile The aim of this step is to ensure a smooth crushing process and minimise downtime in the event of a breakdown or to allow planned maintenance in the crushing system, without stopping the grinding and other further steps2017年8月24日 As commented previously, it is also essential to develop this process at the lowest suitable energy and grinding medium consumption The appropriate control of grinding process must manage the ore and water feed rate and the mill speed Other features that increment complexity to this control issue are ore size and the quantity of circulating loadMineral Processing SpringerLink13626 j mater res technol 2020;9(6):13625–13634 mic reduction using coke at 1250 C was studied by Kim et al [11] The product contained over 65% iron and the recovery of iron was more than 85%Ferrosilicomanganese production from manganese ore and 2012年7月30日 The startup of new concentrators to process lowgrade itabirite ores inthe state of Minas Gerais next year and tapping new ore bodies in Carajaswill allow quality to recover, Martins said Degrading ores from endoflifemines in the Iron Quadrangle had led silica levels to surge to 6% or more forsome cargoesBrazil's Vale says silica drag on iron ore price to fall with new

.jpg)

Comparative Study on Improving the Ball Mill Process Parameters

2021年2月19日 Taguchibased experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters influencing on the synthesis of ultrafine silica sand monolayer degradation To determine an optimal setting, Taguchi coupled optimization technique has been applied with a Silica sand ball mill is a professional ball mill equipment for grinding silica sand In some areas, it is also called silica sand grinding mill or silica sand grinding machineSilica sand is a chemically stable silicate mineral with particle size between 002 and 335mmBoth silica sand and quartz sand are mainly composed of SiO 2, but their hardness and shape are slightly different due to Wet Dry Silica Sand Ball Mill for Silica Sand Grinding2016年2月1日 Matthews [12] defined ore loss as a reduction of ore volumes in the mining process due to misclassification of ore as waste in the ore control process, exclusion of discontinuous mineralization Monitoring ore loss and dilution for minetomill 2020年1月3日 Iron ores obtained from different sources differ in their chemical and physical properties These variations make the process of grinding a difficult task The work carried out in this context focuses on three different samples of iron ore, viz, high silica high alumina, low silica high alumina, and low silica low alumina The grinding process for all the three iron ores is Estimation of Grinding Time for Desired Particle Size Distribution

Chemical Processing of Bauxite: Alumina and Silica

The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3The basis of the Bayer process is an understanding of the characteristics of the sodiumhydroxide—sodiumaluminate solution relationship, namely its ability to keep sodiumaluminate in a dissolved state Usually, in industrial applications, silica needs to go through a crushing process Usually, it is divided into several product categories according to the particle size of silica: raw silica ore, silica sand, and silica powder Among them, 120140 mesh silica powder has a large demand and great market potentialHow to choose a silica grinding mill for grinding 120 mesh silica?Energy Saving Factory Price Wet Ball Mill Gold Ore Grinder Silica Sand Grinding Ball Mill Ball Mill For Sale In Zimbabwe $4,90000 $5,50000 Min Order: 1 set 7 yrs CN Supplier 50 /5 8 reviews "good service" Contact Supplier Chat now wet and dry grinding mill mineral stone vibrating ball mill for silica sand $5,50000 $6,00000Simple Ore Extraction: Choose A Wholesale silica sand ball mill 2016年4月27日 Some ores, however, can only be treated by flotation to a greater extent in order to make an overall economic recovery Manganese Ore Concentration by Flotation The slime fraction of the ore overflowed by the hydraulic classifier and by the rodmill spiral classifier is thickened in a Spiral Rake Tray Thickener for treatment by flotationManganese Ore Processing 911Metallurgist

Extraction of Zirconium, Uranium, Hafnium and Silica Gel from

2020年4月12日 This SuperPro Designer example analyzes the extraction of Zirconium, Uranium, Hafnium and Silica Gel from Zircon Sand Ore The results include detailed material and energy balances, equipment 2023年7月3日 These pieces are then reduced to fine powder with the help of a ball mill or stamp mill This process is called pulverisation (2) Concentration of Ore or Ore Benefaction The ores are usually found mixed up with large amounts of nonmetallic impurities such as, sand, mica, limestone, felspar, earthy and rocky impuritiesCrushing, Grinding and Concentration of the Ore Class Notes2020年5月5日 This work describes a leaching process for the conversion of highmagnesium peridotite rock, which is a chromite ore overburden, into two valuable products: magnesium salts and micro silicaProcessing of Peridotite Rocks of Chromite Ore Overburden into WHIMS into RF process reduced silica to 202 mass%, and milling 200 μm using P13 disc mill (Fritsch Co, ore also contains silica and alumina of 3110 mass% and 765 mass% respectiveRemoval of Silica and Alumina as Impurities from LowGrade Iron Ore