What type of carbon powder is used for 1025 machine

.jpg)

SAE – AISI 1025 Carbon Steel – Properties, Uses and Composition

SAE carbon steel 1025 is composed of 022028% carbon, 030060% manganese, 004% (max) phosphorus and 005% (max) sulfur It also 展开Steel 1025 is a Low Carbon Steel material with 03% carbon content Most Carbon steels have between 008% to 1% carbon content The machinability is very sensitive to the amount of Steel 1025 : Machinig Data Sheet (Machining Doctor)• Used for special purposes like (nonindustrialpurpose) knives, axles or punches • Most steels with more than 25% carbon content are made using powder metallurgyA519 Grade 1025 CARBON STEELAISI 1025 Steel is used for forged motor shafts, hydraulic shafts and pump shafts, as well as for machinery parts AISI 1025 Steel is forged from around 2250ºF down to a temperature in the ASTM SAE AISI 1025 Carbon Steel Forging Materials CHINA

SAE 1025 Alloy Digest ASM Digital Library

SAE 1025 is a plain carbon steel for generalpurpose construction and engineering It is used in the hotworked, coldworked, normalized or waterquenchedandtempered condition It also is SAE/AISI 1025 steel is known for its good machinability, weldability, and formability It has medium strength and toughness, making it suitable for a variety of applications such as shafts, SAE/AISI 1025 Carbon Steel Composition and PropertiesThis page is mainly introduced the 1025 chemical information,mechanical properties, physical properties, mechanical properties, heat treatment, and Micro structure, etc It also contains the SAE 1025 chemical composition, properties, heat treatment, steel 2022年4月1日 1025, 1026, C25, C25E, and C25R are wrought lowcarbon nonalloy steels that are used in the normalized, cold worked, or quenched and tempered conditionSAE 1025, SAE 1026, CEN C25, ISO C25 STEEL DATA SURVEY

.jpg)

Hot Rolled 1025 Carbon Steel MakeItFrom

2020年5月30日 Hot rolled SAEAISI 1025 is SAEAISI 1025 steel in the hot worked condition The graph bars on the material properties cards below compare hot rolled SAEAISI 1025 to: Choosing the right type of coffee powder is essential for achieving the desired flavor and aroma in your brewed coffee Common options include ground coffee, whole bean coffee, and instant coffee, each offering unique characteristics What kind of coffee powder for coffee machine1 天前 Carbon steel and mild steel are widely used materials across various industries due to their strength and versatility Carbon Steel Carbon steel is an alloy made primarily of iron and carbon The carbon content in carbon steel ranges from Carbon Steel vs Mild Steel Corrosion: What’s the Difference?2016年10月25日 When I built the Remember the Maine cannons, I used 1010 hot rolled solid round and drilled the bore The Highest carbon content steel I use [which needs special precautions for proper welding] is 1026 DOM This is the black powder cannon industry standard for full scale cannon liners sleeves [rifled or smooth bore] and reproduction steel tubesSuitability of Steels for Blackpowder Cannons

.jpg)

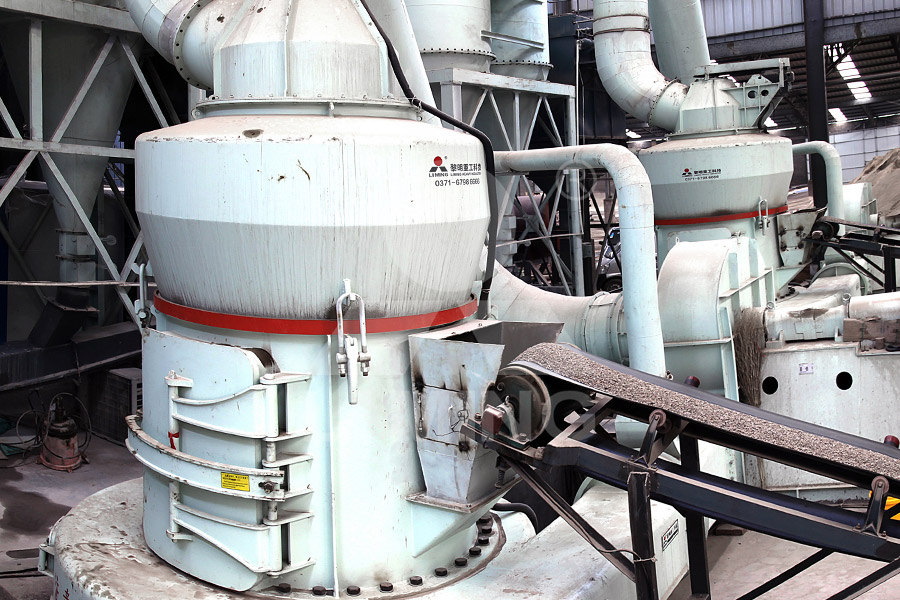

Powder Metallurgy: What Is It? Processes, Parts, Metals Used

2024年2月2日 Chapter Five Equipment Used for Powder Metallurgy Each step of the powder metallurgy process requires special equipment that varies according to the process being used Powder metallurgy is a method for producing structural parts and bearings using a variety of techniques and equipment2013年6月16日 Continuous Casting Mould Powders satyendra; June 16, 2013; 245 Comments ; continuous casting, Fly ash based powder, mould, mould powder, Prefused powder, Synthetic powder, viscosity,; Continuous Casting Mould Powders Continuous casting mould powders are used primarily to facilitate the passage of liquid steel through the mould of the continuous Continuous Casting Mould Powders – IspatGuru2023年6月22日 This makes it ideal for applications that require intricate machinings, such as gear teeth or small engine parts The higher carbon content of 1025 carbon steel makes it more challenging to machine, but this can be offset using appropriate tooling and operating conditions Conclusion Both 1025 carbon steel and 1020 steel have their pros and cons1025 Carbon Steel vs 1020 Steel – What’s the Difference2020年12月22日 AC is used in atomic hydrogen welding and carbon arc processes where 2 carbon electrodes are used It allows a uniform rate of welding and electrode consumption In a carbon arc when one electrode is recommended then direct current straight polarity is the choice and here electrode consumption at a slower paceWelding Electrodes – Learn About Its Types and Uses

Carbon Black Processing: Turning Soot into Industrial Gold

2024年6月14日 Historically, carbon black was commonly used as a pigment for murals Today, it is classified into various grades based on combustion conditions, materials, and temperatures It finds application in rubber, plastics, coatings, inks, cosmetics, beauty, energy storage, and automotive industries, with Ntype carbon black being the most prevalent type2024年4月19日 Maintenance and Care for Grinder Machine Carbon Grinder machines are used for a variety of tasks, from grinding coffee beans to shaping metal One common element in many grinder machines is carbon Carbon is used as a component in the construction of the grinder machine to provide stability and durabilityUnderstanding The Role Of Carbon In Grinder Machines: APDF On Mar 25, 2021, Zahid Hasan and others published Design and Development of Automatic Sieving Machine for Granular/Powder Materials Find, read and cite all the research you need on Design and Development of Automatic Sieving Machine for Granular/Powder It is well recorded that barrels of many calibers to pistols and rifles have been made from plain steel, including rebar, even proven to be accurate so to suit for bench rest shooting, so we are not exclusively talking about garage guns of spray and pray type here Plain high carbon steel can be used in a similar manner, but mostly on non What steel alloys are generally used for making gun parts?

Welding of Carbon Steel: Explained MachineMFG

2024年8月9日 Itype butt joint with beveling: Use H08A electrode Medium thickness plate with beveled joint Use H08MnA or H10Mn2 electrode Thick plate with deep bevel joint Use H0Mn2 electrode HJ431: H08Mn2Si: HJ350: Q390: Carbon black is a fine black powder, essentially composed of elemental carbon, and is vital in making many products we The ultimate degree of dispersion is also a function of the mixing procedures and equipment used Powdered What is Carbon Black? Carbon Black 101 Birla The carbon brush is the integral part on the transfer of current in the rotating machine and although they differ in size, shape and technical composition carbon brushes and collectors all fulfil the same basic function This is to transfer current from a moving device to a stationary point or vice versa within an electric circuitCarbon Brush Holder Technical Handbook Morgan 2019年7月30日 Consisting of iron with more than 2% carbon, cast iron is a versatile metal that’s used in a wide range of consumer and commercial applications It’s been around since the 5th century BC, during which cast iron was used to make weapons as well as agriculture products Since then, it’s become an increasingly common type of metalThe 4 Types of Cast Iron OneMonroe

Mould Fluxes in the Steel Continuous Casting Process

2012年9月26日 1 Introduction During the last decades, the continuous casting process has made enormous advances and more than 90% of the world steel production is now continuously cast []In this process, the liquid steel is poured into a watercooled copper mould through a submerged entry nozzle (SEN), see Figure 1 []At this stage the solidification process begins2021年2月11日 Carbon steel has a higher concentration of carbon than other types of steel (up to 25% carbon), which adds to carbon steel’s strength Carbon steel is commonly used to make construction materials, tools, automotive components, and more Types of carbon steel Carbon steel is organized into three main categories:TYPES OF STEEL STEEL GRADES CHART Service Steel WarehouseAISI 1025 carbon steel finds applications in various industries and sectors due to its favorable combination of properties Here are some common applications of AISI 1025 carbon steel: Automotive Components: AISI 1025 steel is used for manufacturing various automotive components such as shafts, gears, axles, and crankshafts due to its good SAE/AISI 1025 Carbon Steel Composition and PropertiesA519 GRADE 1025 CARBON STEEL Datasheet for A519 Grade 1025 Carbon Steel Specification Seamless Carbon and Alloy Mechanical Tubing Type Seamless Size 159mm to 3238mm Thickness 35mm to 127mm Length 6000mm, • Most steels with more than 25% carbon content are made using powder metallurgy 4 Application of Carbon SteelA519 Grade 1025 CARBON STEEL

Powder Bed Fusion types SLS, DMLS, EBM MJF Pros Cons

2024年6月8日 What is Powder Bed Fusion? Powder bed fusion is one of seven Additive Manufacturing techniques, in which either laser, heat or electron beam is used to melt and fuse the material together to form a threedimensional object Figure 1 Powder bed fusion ( source:GE) Types of Powder bed fusion Both metal and plastic parts can be made using this 2023年6月21日 Difference Between 1025 and 1045 Steel Chemical Composition The primary difference between 1025 and 1045 steel lies in their chemical composition These steels have carbon as their main alloying 1025 vs 1045 Steel What's the DifferenceFreeCutting Steels (SAE 11xx, 12xx, 12Lxx) FreeCutting (FreeMachining) Steel is a nickname for carbon steel with an increased amount of alloying elements for the sole purpose of improving its machinability11xx series: the amount of Machinability of Steel Machining DoctorFINGERPRINT POWDER Color Selection Black is by far the most commonly used latent print powder color Black powder is manufactured from a variety of carbonbased powders with a binder added for stability This carbonbased powder readily adheres to the oily residues generated by contact from fingers and other body parts Black powders are easy Choosing the Best Fingerprint Powder for Your Scene Loci

Cutting Tool Materials – Types, Composition, Properties , Application

Applications of high Carbon Steel : 1 It can be used as material for hand tools and tools working at low motion 2 This type of carbon steel can be forged after heat treatment Therefore it is used for lathe tools, handoperated screwing dies and tape, reamers, and broaches Now desired properties of highcarbon steel can be obtained by in which heat is used to alter the properties of a metal or alloy Because time at temperature is also important, heat treatment can be further defined as a series of timetemperature treatments Heat treatments are used for a variety of purposes, the most important being to control the mechanical properties,SUBJECT GUIDE Heat Treating ASM International2024年3月18日 Powder Activated Carbon Manufacture and Composition Similar to granular activated carbon, powder activated carbon is crafted from premiumgrade carbonaceous materials such as bituminous coal, coconut shells, or select wood typesThese raw materials undergo a meticulous activation process, wherein they are subjected to high temperatures in a carefully What Is Powder Activated Carbon? CPL/Puragen Activated Single station powder compacting presses are available in several basic types such as cam, toggle/knuckle, and eccentric/rank presses with varying capabilities This type of compactor is commonly used in the pharmaceutical industry to make tablets since they are high speed machines that can create thousands of tablets in a small periodPowder Compacting Equipment Selection Guide: Types, Features

.jpg)

Material 155PH : Machinig Data Sheet (Machining Doctor)

Machining Material 155PH 155PH is a martensitic chromiumnickel stainless steel containing precipitationhardening elements such as copper, niobium, and tantalum Its cracks resistance, corrosion resistance, and strength are better than the regular martensitic chromiumtype stainless steel (400 series) It is used in applications requiring high strength and a modest level of 2024年8月1日 For this reason, it is used to make mill linings, shotblasting nozzles, railroad brake shoes, slurry pump housings, rolling mill rolls, and crushers NiHard Iron is specifically used for mixer paddles, augers and dies, liner plates for ball mills, coal chutes, and wire guides for drawing wires Red cast iron machine parts lined up for inspectionIntroduction to Cast Iron Casting Blog Reliance Foundry Co Ltd2023年6月22日 1025 and 1026 steel have a carbon content between 022% and 029%, but their differences lie in their chemical composition Both steel sheets are lowcarbon and mild, but 1026 has a slightly higher carbon content than 1025 Additionally, 1026 steel contains higher amounts of manganese, phosphorus, and sulfur than 10251025 vs 1026 Steel What's the Difference ThePipingMart BlogCobalt steel is a type of highspeed alloy steel used primarily for cutting tools Introduced to manufacturers in 1900, highspeed steel, containing a mixture of tungsten, chromium, and trace amounts of carbon, enabled manufacturers to Cobalt Steel M42 Steel Griggs Steel

.jpg)

All About Tool Steel Xometry

2022年10月24日 Materials that are used to make tools should understandably be particularly hardy, and tool steel fits the bill “Tool steel” as a term refers to carbon and alloy steels that are strong enough to be made into tools that can Chapter One What is Powder Metallurgy? Powder metallurgy is a manufacturing process that produces precision and highly accurate parts by pressing powdered metals and alloys into a rigid die under extreme pressure With the Powder Metallurgy: What Is It? Processes, Parts, 2023年9月5日 2 Preparation Methods of Metal Powder: 21 Physicochemical Methods 211 Reduction Method The reduction of metal oxides and salts is a widely used method for powder preparation Solid carbon can be used to reduce iron and tungsten powder, while hydrogen or decomposed ammonia is used to produce tungsten, molybdenum, iron, copper, cobalt Metal Powder Preparation Methods and Principles: A 2023年9月5日 4 How to understand “Powder metallurgy technology is both ancient and young”? Powder metallurgy is an emerging field, yet it also has ancient roots Archaeological evidence suggests that as far back as 3000 BC, Egyptians used a type of bellows to reduce iron oxide to sponge iron with carbonPowder Metallurgy: A Comprehensive Guide for Beginners

From Powders to Parts: CARBON Graphite MANUFACTURING

Carbon graphite manufacturers are able to take advantage of this network of porosity by impregnating it with various substances The type of impregnation used is highly applicationdependent, which is a topic we will address in Part II of this blog series Plain carbon graphite bearings are widely used in many types of industrial applications 2023年7月16日 In the pharmaceutical industry, punches and dies used in tablet compression machines are typically made from highquality tool steels The material of construction (MOC) for punches and dies can vary depending on factors such as the type of tablet formulation, desired tablet characteristics, and the manufacturing processMaterial of construction (MOC) of punches and dies Pharma 2023年8月21日 Sintering machines precisely control heat just below the melting point of the powdered metal, adding mechanical strength, density, and translucency to the workpiece Laser Sintering (Selective Laser Sintering) Fig 10: Laser Sintering Laser sintering is an innovative addition to powder metallurgy, a part of additive manufacturing technologyPowder Metallurgy: Definition, Process, Advantages, Applications2023年11月16日 In the realm of precision grinding, the choice of grit size in diamond and CBN (Cubic Boron Nitride) grinding wheels is critical for achieving the desired surface finish on a workpiece Whether working with hard materials like carbide and tungsten carbide or honing highspeed steel (HSS), the right grit size can make a significant difference in both the efficiency of A Guide to Choosing the Right Grit Size for Precision Grinding

Method of manufacturing carbon brushes for electrical machines

A binder consisting of an aromatic polymeric material in which aryl groups are connected together by singlebond linkages over one or more atoms of carbon, sulfur, oxygen, nitrogen, phosphorus or silicon, preferably polyphenylenesulfide, is mixed with carbon particles, with or without the addition of copper powder and the mixture is then pressed in a mold, removed from the mold,