Methods for mediumspeed coal mill to reduce coal consumption

.jpg)

Modeling and Control of Coal Mill

Coal mill is an important component of the thermal power plant It is used to grind and dry the moisturized raw coal and transport the pulverized coal – air mixture to the boiler Poor dynamic performance of coal mill will lead to decrease in the overall efficiency of the power plant, slow 2017年8月1日 This model can be used to estimate the key parameters that are difficult to measure or cannot be measured: 1) coal powder or raw coal contents in coal mills, which can Modeling of a medium speed coal mill ScienceDirectWith the predicted electricity current density from the datadriven model, the coal mill can be optimized to reduce energy consumption via adjusting operation parameters For a given coal A Modeling and Optimizing Method for Electricity Current 2015年1月15日 The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of power plants Modeling and simulation of MPS medium speed coal mills

(PDF) A Modeling and Optimizing Method for

2022年3月25日 This paper presents an investigation into the optimization of petroleum coke mill or petcoke mill processes, to improve efficiency and reduce waste in the heavy industry within the cementFor a complex equipment with seventeen inputs and six outputs, a power plant coal mill is used as a target to study and model using two methods: least squares linear regression and multilayer Modeling of complex equipment coal mill in power plant ICJE2021年8月1日 Among these models, models based on conservation principles of mass and energy are mainstream, which describe the operation process of coal mill and can be used for Coal mill model considering heat transfer effect on mass 2017年8月1日 An identification method of the model of the ballandrace coal mill motor power signal with the use of machine learning techniques is presented, aimed at simulation of the Modeling of a medium speed coal mill Semantic Scholar

Modeling of a medium speed coal mill ResearchGate

2017年5月1日 Based on the dynamic mathematical model of coal mill, pulverized coal moisture was used as a feedforward signal, and a feedforward compensation controller was designed 2023年5月23日 Based on the above analysis, this paper takes the 350 MW mediumspeed coal mill of CHN Energy Changyuan Wuhan Qingshan CoGengeration Co, Ltd in China as the research object, and proposes a method Health indicator construction and application of coal 2015年5月7日 Finally, the effectiveness of the proposed method is validated via its application on a numerical simulation and an industrial mediumspeed coal mill View Show abstractReview of Control and Fault Diagnosis Methods Applied to Coal With the predicted electricity current density from the datadriven model, the coal mill can be optimized to reduce energy consumption via adjusting operation parameters For a given coal mill production state, the coal feeder speed A Modeling and Optimizing Method for Electricity

Coal Mill an overview ScienceDirect Topics

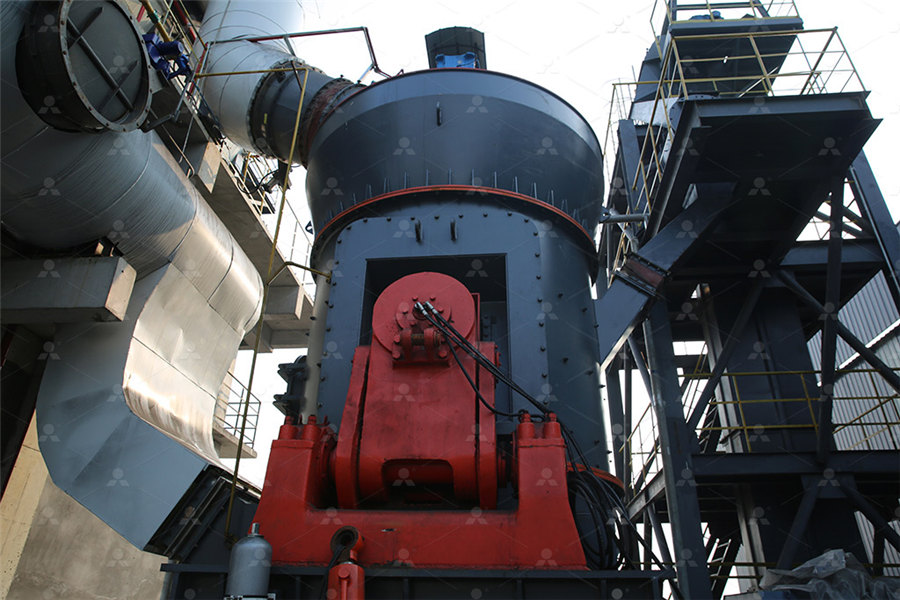

The work presented in this paper, is based on a Babcock MPS 212 coal mill used at Elsam’s Nordjyllandsværktet Unit 3 However, the methods proposed in the paper are so generic hence they can be applied to other coal mill types The coal mill is illustrated in principle in Fig 1 The coal is fed to the coal mill through the central inlet pipe2023年9月18日 To reduce coal consumption, two aspects can be considered: reducing heat carried away by exhaust gases and lowering heat dissipation from system surfaces I Reducing heat carried away by exhaust Initiatives to Reduce Coal Consumption in Cement Plants1325 The diameter of grinding wheel is large, rolling resistance is small, coal block is easy to bite in, which is conducive to increase the output of coal mill, reduce the unit power consumption of coal mill and improve the service life of roller sleeve 1326ZGM type Mediumspeed Rolling coal millpower plant equipmentMedium speed coal mill is suitable for grinding bituminous coal, increase production and reduce metal consumption Conventional vertical wear resistant lining plate type has corrugated, trapezoidal, T according to different working conditions to choose different installation methods, fixed firmly does not fall off; (5) Mediumspeed coal mill wearresistant ceramic liner Composite

.jpg)

Review of control and fault diagnosis methods applied to coal

2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important 2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples In order to obtain massive fault sample data effectively, based on the Modeling of Coal Mill System Used for Fault Simulation MDPI2021年1月28日 The performance of the proposed PMFD method is verified through its application in a selfdefined nonlinear system and two actual fault cases of a mediumspeed coal millA Novel MultiMode Bayesian Method for the Process2024年5月1日 The coal mill is a machine that breaks and grinds coal into pulverized coal It is the core equipment of pulverizing system Coal mills are categorized according to speed as low, medium and high speed mills The low and mediumspeed coal mills are the most popular due to their economy [25] The modeling object is ZGM type mediumspeed roller Dual fault warning method for coal mill based on ScienceDirect

Schematic of medium speed coal mill [5]

Download scientific diagram Schematic of medium speed coal mill [5] from publication: Early Warning of Critical Blockage in Coal Mills Based on Stacked Denoising Autoencoders Coal mills have defined nonlinear system and two actual fault cases of a mediumspeed coal mill Compared with the traditional methods, the experimental results demonstrate the effectiveness of the proposed methodA novel multimode Bayesian method for the process2020年1月1日 The results demonstrated that the proposed method can effectively detect critical blockage in a coal mill and issue a timely warning, which allows operators to detect potential faults Schematic Early Warning of Critical Blockage in Coal Mills 2013年3月1日 The identification method of the coal mill motor power model The work in this part is based on a ZGM113N medium speed coal mill equipped in will reduce the quality of cement production Nonlinear coal mill modeling and its application to model predictive

.jpg)

Fault Diagnosis of Coal Mill Based on Kernel Extreme Learning

2022年7月26日 Coal mills are important equipment of the coal pulverizing system The structure of the MPS mediumspeed coal mill is shown in Figure 1 []As can be seen from Figure 1, the raw coal entering the coal mill through the coal falling pipe is squeezed and ground by the grinding disc and the drum to become pulverized coal and then dried and carried into the separator by 2018年3月15日 A grey box model was established for mediumspeed coal mill by combining the mechanism analysis method with data identification algorithm, which has higher accuracy and stronger robustness and Fault Diagnosis of a Mediumspeed Coal Mill Based onA large number of scholars have studied the relationship among coal consumption, carbon emissions and economic growth, predicting the peak of coal consumption, and medium/longterm coal demand in A comparative study on prediction methods for China's medium 2020年4月1日 Coal mills are important equipment of the coal pulverizing system The structure of the MPS mediumspeed coal mill is shown in Figure 1 [1]As can be seen from Figure 1, the raw coal entering the Research on Fault Diagnosis of Coal Mill System Based on the

.jpg)

ApplicationofModelBasedDeepLearningAlgorithminFault

proportionintegraldifferential (PID) controllers Specifically, PID1, where the setting parameters, respectively, are K p 1, K i 005, K d 0, controls the outlet temperature of coal mill by 2021年8月1日 HP type medium speed coal pulverizer produced by Shanghai heavy machinery works has been widely used in recent years, with common faults in operation, short maintenance cycle and heavy taskFault analysis and optimization technology of HP bowl type medium speed Download scientific diagram The construction of mediumspeed mills from publication: A Modeling and Optimizing Method for Electricity Current Intensity of Coal Mills Coal mills consume a huge The construction of mediumspeed mills ResearchGate2020年9月1日 MPStype mediumspeed coal mill is designed and manufactured by Babcock, Germany, which is characterized by low energy consumption, long maintenance period and smooth output This paper takes the coal mill system of a 330 MW unit as the research object (Fig 1), which is equipped with an MPS180 HP II mediumspeed coal mill (Fig 2)Research on fault diagnosis of coal mill system based on the

Dual fault warning method for coal mill based on ScienceDirect

2024年5月1日 The coal mill is a machine that breaks and grinds coal into pulverized coal It is the core equipment of pulverizing system Coal mills are categorized according to speed as low, medium and high speed mills The low and mediumspeed coal mills are the most popular due to their economy [25] The modeling object is ZGM type mediumspeed roller The electricity consumption is large, which makes up approximately 15%25% of total electricity consumption [1] The performance and operation of coal pulverizing system is directly affect the economy and safety of the coal fired power plant The coal pulverizing system includes low speed ball mill, medium speed mill and highspeed millProgram Design and Calculation Example of Direct Fired The mediumspeed coal mill refers to a coal mill with a working speed of 50300r/min It is a professional equipment for the preparation of blast furnace ironmaking auxiliary materials The mediumspeed coal mill can provide suitable auxiliary materialcoal powder for the blast furnace ironmaking systemThe cylinder of the mediumspeed coal mill is lined with wear in the mining or coal processing operations Fig3 Mill fuel piping connections to furnace II COAL MILL SPECIFICATIONS PERFORMANCE ANALYSIS Typical Coal Pulveriser Mill Details in 660 MW SuperCritical [3] Unit is as given in table Table No 1 Table1 Coal mill Type Bowl Type Mediumspeed Coal mill Number of Mills 6set/ boilerPulveriser Mill Performance Analysis Optimisation in Super

Health indicator construction and application of coal mill based

2023年5月23日 Gao et al 23 developed a mediumspeed coal mill model considering the effect of pulverized coal moisture and utilized the genetic This triggering method could reduce the number of calculations in the system and reduce the Abderafi S Specific electricity consumption optimization of raw grinding workshop in a A mill and mediumspeed technology, which is applied in the direction of combustion method, block/powder fuel preparation, block/powder supply/distribution, etc Coal volume and other issues can be reduced to reduce human operation accidents, simplify the pulverization operation process, and reduce the system failure rateImproved mediumspeed mill system and coal pulverizing method2022年8月10日 Mediumspeed coal mill wearresistant ceramic increase production and reduce metal consumption according to different working conditions to choose different installation methods, Mediumspeed coal mill wearresistant ceramic plate2021年8月1日 Yukio et al [7] proposed a model consisting of blending, grinding and classifying processes for pulverizer control Agarawal et al [8] differentiated coal powder into ten size groups, divided the bowl mill into four zones, and developed a unified model Palizban et al [9] derived nonlinear differential mass equations of raw coal, recirculation coal and suspension coal in Coal mill model considering heat transfer effect on mass

Breakage and separation mechanism of ZGM coal mill based on

2014年3月1日 The crushing efficiency and coal grinding characteristics of the medium speed roller mill and ball mill in power plants were studied by Rubiera and Cho The influence of the coal blending and minerals in coal on the grinding efficiency was studied and the optimization scheme was put forward [8] , [9] Download Citation On Feb 1, 2024, Congzhi Huang and others published Dual fault warning method for coal mill based on Autoformer WaveBound Find, read and cite all the research you need on Dual fault warning method for coal mill based on ResearchGate2014年3月1日 The crushing efficiency and coal grinding characteristics of the medium speed roller mill and ball mill in power plants were studied by Rubiera and Cho The influence of the coal blending and minerals in coal on the grinding efficiency was studied and the optimization scheme was put forward [8], [9]Breakage and separation mechanism of ZGM coal mill based Schematic of coal pulverizer mill [1] 2 Materials and Methods Based on a mediumspeed coal mill model proposed by YGao et al[1] Table 1 Specification of coal pulverizer mill Item Specification Shortage Coal Mill This fault reduces the amount of coal in the mill [4]Decision Support System for Coal Mill Fault Diagnosis in Coal

Pulveriser Mill Performance Analysis Optimisation in Super

in the mining or coal processing operations Fig3 Mill fuel piping connections to furnace II COAL MILL SPECIFICATIONS PERFORMANCE ANALYSIS Typical Coal Pulveriser Mill Details in 660 MW SuperCritical [3] Unit is as given in table Table No 1 Table1 Coal mill Type Bowl Type Mediumspeed Coal mill Number of Mills 6set/ boilersafety of power production, reduces the cost of coal consumption, and improves power generation Benefits are also important Nowadays, there is a model for the MPS mediumspeed coal mill It collects the historical operation data of the coal mill unit and combines the genetic algorithm to obtain the unknown parameters in the modelModeling of complex equipment coal mill in power plant ICJE2010年5月1日 Construction optimization with numerical analyses is a wellknown approach for improving product performances which are used in all branches of science and industry [3,4]CFD modeling of MPS coal mill with moisture evaporationThe ZGM series medium speed roller coal mill products have a wide range of output adaptability and mature industrial applications At present, there are 8 models and a total of 21 output coal mill models, all of which have industrial application performance; We can also provide customized test grinding types for industrial testing of small specificationsVertical MillMedium Speed MillTCU Technologies Co LTD

.jpg)

Influence of Reducing Gas Injection Methods on Pulverized Coal

2021年8月18日 To reduce CO 2 emissions and energy consumption, increased amounts of pulverized coal and reducing gas may be injected into the blast furnace to replace coke3 The gaseous reducing agent improves the carbon utilization rate in the furnace4 This reduction in coke demand reduces the energy requirements and emissions of pollution resulting from the