Spherical activated carbon production process

.jpg)

Progress on fabrication and application of activated carbon sphere

2023年4月25日 Activated carbon sphere (ACS) is a special type of activated carbon that has a high compressive strength and low ash content Coal, asphalt, resins, polymers, lignin, 2024年6月16日 Herein, for the first time, a superhydrophobic spherical activated carbon (SSAC@PhSO 3 H) is engineered as a catalyst via a novel synthetic approach and tailored in Jatropha curcas oil (JCO) biodiesel synthesisA Spherical Superhydrophobic Activated Carbon 2024年1月2日 Spherical activated carbons prepared from DOWEX 50WX2 microporous gel (GCB) and DOWEX MSC macroporous resin (MSC) were designated GCBmt and MSCmt, Numerical analysis of the porous structure of spherical activated In the chemical activation process, nonincinerated carbonaceous material is initially mixed with dehydrating or oxidizing chemicals and heated to between 400 and 800° C The activation Activated Carbon and its Applications

.jpg)

Spherical carbons: Synthesis, characterization and activation

Controllable synthesis of spherical carbon particles transition from dense to hollow structure derived from Kraft lignin Waste biomass valorization through production of xylosebased 2023年4月25日 The carbon sphere activated at 1000 °C is a highperformance adsorbent with good reusability Thus, the present study provides a synthesis process to produce the Progress on fabrication and application of activated carbon sphere 2024年2月28日 as a low softening point, a long stabilization time is required to produce spheric e pitchbased activated carbon manufacturing pro s have the advantage of easy control of Manufacturing of spherical activated carbons using anion 2021年10月2日 The present research identifies two different methodologies of preparation of spherical activated carbons using polymeric ion exchange resin (waste) as a starting Developing spherical activated carbons from polymeric resins for

Porous carbon spheres: Recent developments and applications

Activated carbon spheres produced using these processes has been successfully utilized as adsorbent materials for removal of heavy metals, organic dye, carbon dioxide, volatile organic Due to its high bulk density, BAC is able to achieve high fill density compared to coalbased activated carbon or coconut shellbased activated carbon of the same volume capacity High flowability Due to the high flowability ensured by its BAC Kureha2024年6月16日 A Spherical Superhydrophobic Activated Carbon Catalyst for Biodiesel Production ‐Exploring Process Efficiency, Kinetics, Thermodynamics and Life Cycle Cost AnalysisA Spherical Superhydrophobic Activated Carbon Kureha’s Beadshaped Activated Carbon BAC is a highly spherical activated carbon with high purity and less metal, which comes from the raw material, petroleum pitch Because of its low levels of impurity, BAC offers various BAC Bead Activated Carbon Kureha Carbon Products

A Spherical Superhydrophobic Activated Carbon Catalyst for

2024年6月16日 A Spherical Superhydrophobic Activated Carbon Catalyst for Biodiesel Production Exploring Process Efficiency, Kinetics, Thermodynamics and Life produced in situ or as a byproduct Herein, for the first time, a superhydrophobic spherical activated carbon (SSAC@PhSO 3 H) is engineered as a catalyst via a novel synthetic 2021年10月15日 Activated carbon (AC) is produced by a physical or chemical activation process Physical activation methods are commonly adopted in industry because of their low production costs, but the insufficiency of activating agent diffusibility into core parts of the particles and microdomains of carbon materials causes a lower activation yield and degree of pore Pressurized physical activation: A simple production method for 2014年3月1日 Spherical activated carbons are receiving considerable attention for their various potential advantages over granular or powdered activated carbons such as high wear resistance, high mechanical strength, good adsorption performance, high purity, low ash content, smooth surface, good fluidity, good packaging, low pressure drop, high bulk density, high micropore Spherical carbons: Synthesis, characterization and activation 2023年4月25日 In recent years, only Tripathi’s group has summarized and described the development and application of ACS in 2018 Compared with their work, this review provides a more detailed description of raw materials used to prepare ACS, fabrication process of nanosized CS (NCS) and hollow CS (HCS), as well as applications of ACS in energy storage, adsorption Progress on fabrication and application of activated carbon

.jpg)

Methods for preparation and activation of activated carbon: a

2020年3月1日 Activated carbon refers to a wide range of carbonised materials of high degree of porosity and high surface area Activated carbon has many applications in the environment and industry for the 2020年1月4日 Activated carbon refers to a wide range of carbonised materials of high degree of porosity and high surface area Activated carbon has many applications in the environment and industry for the removal, retrieval, separation and modification of various compounds in liquid and gas phases Selection of the chemical activator agent is a major step controlling the Methods for preparation and activation of activated carbon: a The raw materials for activated carbon are derived from plant biomass, petrochemicals or coal To start, the materials are converted to a raw activated carbon by the use of dehydrogenation agents or dry distillation This is then fully activated by partial oxidation using a special activation reagent at 700 to 1000 °CActivated Charcoal – Development and Production IBUtec2021年9月1日 21 The general production process of the activated carbon The activated carbon production is a typical twostep process, which is composed of carbonization and steam activation stages [31, 32]Both carbonization and activation reactions occur in rotary furnaces as shown in Fig 1The raw biomass (wood chips) is fed into the carbonization reactor and is converted into Theoretical study of activated carbon production via a twostep

A Spherical Superhydrophobic Activated Carbon Catalyst for

Engineering the wettability of functional materials holds significant interest, focusing on the need for superhydrophobic catalysts, crucial for their ability to prevent the poisoning of active sites by water, produced in situ or as a byproduct Herein, for the first time, a superhydrophobic spherical activated carbon (SSAC@PhSO3H) is engineered as a catalyst via a novel synthetic approach Typically used in gas phase reactions, EACs are a heavyduty activated carbon as a result of the extrusion process Additional Types Additional varieties of activated carbon include: Bead Activated Carbon (BAC) Bead shaped activated carbon (BAC) is a highly spherical activated carbon with petroleum pitch as its raw materialLecture11 activated carbon National Institute of Technology, 2023年9月9日 In this work, the chemical preparation of activated carbon (AC) using walnut shell (WS) and plastic wastes (primarily consisting of polyethylene, polypropylene, and polystyrene) as feedstocks and chemical activators (KOH and NaOH) was investigated in a fixedbed reactor Thermogravimetric analysis (TG) (TGA) was used to carbonize WS together with plastic The chemical process of producing activated carbon using The main raw materials of spherical activated carbon are various wood chips coconut shells or pitches materials are relatively wide, spherical in shape, roughly grayblack in color, odorless, and of course nontoxic The production process is generally carried out by crushing, mixing, spherical, drying, carbonization, and activationSpherical activated carbonCoal activated carbon,activated carbon

Spherical carbons: Synthesis, characterization and activation processes

2013年1月1日 In the process of preparing asphaltbased spherical activated carbon, the molten asphalt must be formed into qualified spherical particles through the granulation process2020年12月1日 @article{Sekar2020BiomassAC, title={Biomass activated carbondecorated spherical $\beta$Ni(OH)2 nanoparticles for enhanced hydrogen production from sulphide wastewater}, author={Sankar Sekar and Sejoon Lee and Deuk Young Kim and V Preethi and K Kalirajan and S Sutha and Somasundaram Saravanan and Anirudh Therli and Mahuya Roy Biomass activated carbondecorated spherical βNi(OH)2 Activated carbon is used in methane and hydrogen storage, [1] [2] air purification, [9] capacitive deionization, supercapacitive swing adsorption, solvent recovery, decaffeination, gold purification, metal extraction, water purification, medicine, sewage treatment, air filters in respirators, filters in compressed air, teeth whitening, production of hydrogen chloride, edible electronics, [10 Activated carbon Wikipedia2024年2月28日 process compared to the pitchbased activated carbon manufacturing process because production of spherical particles [6, 15] Ion exchange resins are one of the polymers, andManufacturing of spherical activated carbons using anion

.jpg)

Study on Pelletizing Process of Spherical Activated Carbon

2023年3月25日 21 Materials The production process of asphaltbased spherical activated carbon has three parts: the first part is asphalt balling [], the second part is nonmelting treatment, and the third part is carbonization and activationHighsofteningpoint asphalt, with a softening point higher than 250 °C, is generally used as the raw material for asphalt spheroidization, and 2024年11月11日 This study presents a sustainable approach to synthesizing carbon nanoparticles (CNPs) from orange peel waste through a process involving thermal treatment, chemical activation, and ultrasonication, producing spherical CNPs of approximately 70 nm in size The surface of the CNPs was modified with chitosan, resulting in a chitosan@CNPs Synthesis of spherical carbon nanoparticles from orange peel and In this study, we used coal based activated carbons as starting material and phenolic resin (PR) as a bonding agent to prepare spherical shaped activated carbons The textural properties of SAC were characterized by BET surface area, XRD, SEM, iodine adsorption, strength intensity and pressure drop According to the results, the spherical activated carbon prepared with activated [PDF] Preparation of Spherical Activated Carbon and Their 2020年10月8日 Request PDF Biomass activated carbondecorated spherical βNi(OH)2 nanoparticles for enhanced hydrogen production from sulphide wastewater Aiming at demonstrating the highlyefficient Biomass activated carbondecorated spherical βNi(OH)2

.jpg)

(PDF) Polymerbased spherical activated carbon ResearchGate

2020年7月1日 Polymerbased spherical activated carbon ultrafiltration (UFPBSAC) for the adsorption of steroid hormones from water: Material characteristics and process configuration July 2020 Water Research Activation process of spherical and fibrous carbon precursors for Gas phase adsorption of volatile organic compounds leading to a spherical activated carbon with surface area up to 1600 m2/g and mechanical strength similar to those of commercial activated carbons The production of carbon materials by hydrothermal carbonization of Spherical carbons: Synthesis, characterization and activation 2023年5月10日 Activated carbon has long been used for filtering contaminants, Figure 13 Illustration of the physical activation process of carbon parameter in the production and reactivation of AC Activated Carbon: Fundamentals, Classification, and Properties2011年1月1日 Moreover, solid olive residue as high carbon materials can be considered as a potential raw material to produce activated carbon materials The production process of activated carbon follows two Activated carbons: Classifications, properties and applications

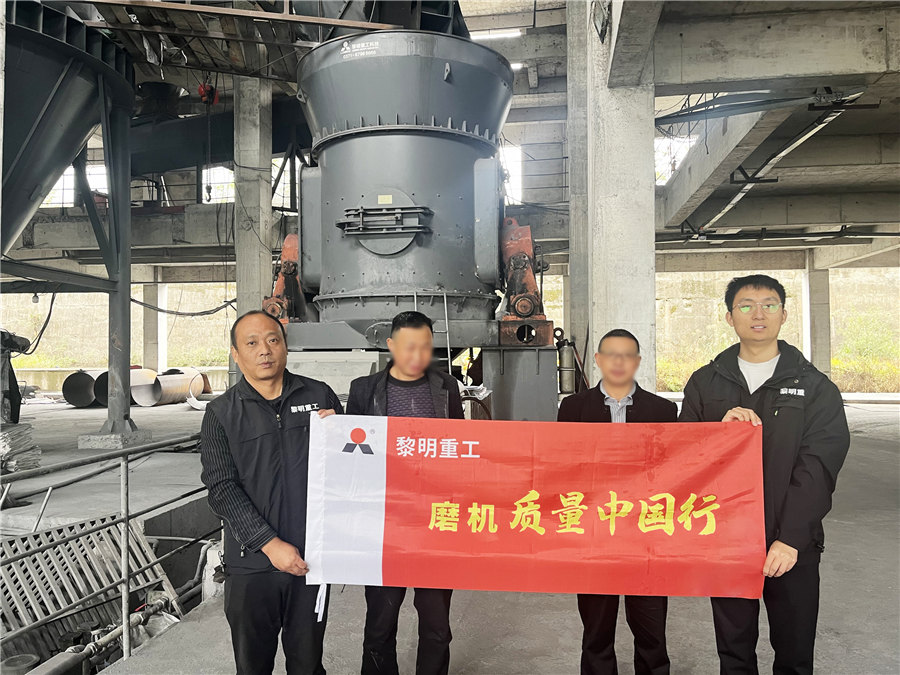

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Production, Characterization, and Applications of Activated Carbon

production process Activated carbon is defined as a carbonaceous material with a large internal surface area and highly developed porous structure resulting from the processing of raw materials under high temperature reactions It is composed of 87% to 97% carbon but2024年9月24日 A simple suspension polymerization coupling with oxidative stabilization, carbonization, and H2O steam activation are applied to synthesize a series of hierarchical porous millimetersized pitchbased spherical activated carbons (PSAC) The asobtained PSAC possess a tunable specific surface area from 975 m2 g− 1 to 1761 m2 g− 1, a pore volume of 044 ~ Pitchbased spherical activated carbons with small mesopores for 1 Introduction Activated carbon (AC), with its exceptionally large specific surface area, high pore volume, welldeveloped internal porous structure, and abundant surface functional groups (polar characters), has been widely applied in various industrial processesActivated carbon derived from spherical hydrochar This activated carbon is produced from selected high polymers through the process of curing, This activated carbon is produced from selected high polymers through the process of curing, carbonization, activation and refinement and steam as HighIodine Spherical Activated Carbon Share: Applications Gas Purification Waste Gas TreatmentHighIodine Spherical Activated Carbon XMACC

.jpg)

Polymerbased spherical activated carbon ResearchGate

1 Polymerbased spherical activated carbon – ultrafiltration (UF PBSAC) for the adsorption of steroid hormones from water: material characteristics and process configurationThe production process of activated carbon typically involves four steps: carbonization, activation, washing and drying, and sizing and packaging In the carbonization step, the raw material is heated in the absence of oxygen to drive off volatile components and leave behind a carbonrich char The activation step is crucial for creating the porous structure of activated carbonActivated Carbon • production process activation2020年12月1日 Aiming at demonstrating the highlyefficient wastewater treatment via photocatalytic hydrogen production, the nickel hydroxideanchored biomass activated carbon (NHAC) nanocomposites were synthesized through the facile solgel method followed by the ultrasonication processThe NHAC nanocomposites exhibited an aggregated nanostructure Biomass activated carbondecorated spherical βNi(OH)2 2015年4月18日 As an example, production of activated carbon using a vertical retort is described below reheats the firebricks on the downside of the retort, enabling the process to be selfsupporting I want to buy Spherical Activated Carbon;Activated Carbon Manufacture: Steam Activation

.jpg)

(PDF) Process of Activated Carbon form Coconut Shells

2020年4月29日 Process of Activated Carbon form Coconut Shells Through Chemical Activation Lignocellulosic wastes are potential lowcost feedstock for the production of high surface area activated carbonActivated Carbon is a porous material that removes organic compounds from liquids and gases by a process known as “adsorption” In adsorption, organic molecules contained in a liquid or gas are attracted and bound to the surface of the pores of the activated carbon as the liquid or gas is passed throughActivated Carbon Calgon Carbon Corporation2021年7月6日 The production of activated carbon from eucalyptus wood chips by steam activation in a 2000 kg batch intermittent rotary kiln with continuous carbonization–steam activation process conducted at Activated carbon preparation from eucalyptus wood chips using 2021年10月2日 In method 2, the metal modification was carried out after the production of spherical activated carbon using the process as described above—by carbonizing the polymeric resin in an inert atmosphere of nitrogen in a temperatureprogrammed horizontally aligned electrical tube furnace (Nabertherm, Germany) at 600 °C for 3 hDeveloping spherical activated carbons from polymeric resins for

Factors governing the adsorption of ethanol on spherical activated carbons

activated carbons in form of pellets [29], granular activated carbons [30], powdered activated carbons [31,32], nanotubes [33], nanofibres [34], carbon monoliths [35] and, furthermore, spherical activated carbons (SACs) [36] can be used for organic compounds adsorption