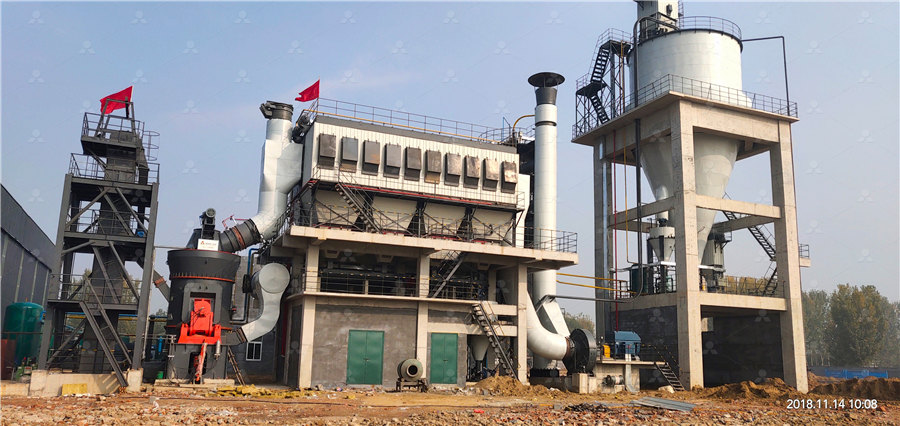

Cement stone mill

.jpg)

Cement Production Process Cement Manufacturing

2020年8月25日 In general, a full cement production process includes the stone crushing, raw mill process, clinker process, and cement grinding process, cement packing process, and related process2024年11月23日 Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are Cement Extraction, Processing, ManufacturingThis page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in Cement manufacturing: components of a cement plant 9 Cement milling The clinker is ground by differentsize steel balls while it works its way through the mill’s two chambers, with gypsum being added to extend cement setting timesCement Production: How Cement Is Manufactured CEMEX UK

How Cement is Made (Video) Cemex USA CEMEX

6 Raw material mill This takes places in vertical steel mill, which grinds the material through the pressure exerted by three conical rollers Which roll over a turning milling table Horizontal 2023年12月20日 How cement manufacturers can help ensure cement quality From the limestone mine, to crushing, blending, the raw mill, kiln and beyond, elemental analysis is a critical component to driving process control, The Cement Manufacturing Process Thermo Fisher The raw materials of Cement Mill Process are lime and silica Alumina and ferric oxide are used as fluxing agents Collection of raw materials such as lime stone This is transported to the mill site and crushed there if the quarry is far off If Cement Mill Process Requirement of Mill Motors Kiln The final step before installing the stone is to apply approximately a half inch of scratch coat to the wall CEMENT BOARD (INTERIOR ONLY) For interior walls or fireplaces, cement board is the easiest and most efficient application The cement board is attached to the studs and then the natural stone veneer is applied directly to the cement boardInstallation Natural Thin Stone Veneer Quarry Mill

.jpg)

The Stone Mill, Inc Thin Veneer Stone from Michigan

The Stone Mill is a Michiganbased producer of roughcut and thin veneer natural stone We believe every dream deserves real stone Skip to content About Us; Products; Contact; real dreams deserve real stone Our Products Our story Find your stone mill easily amongst the 60 products from the leading brands (LONGI, Eriez, Liming, ) on DirectIndustry, the industry specialist for your professional purchases horizontal for cement stone Contact ball mill Final Stone mill, Stone grinding mill All industrial AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw MillStage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process

.jpg)

How Cement is Made (Video) Cemex USA CEMEX

6 Raw material mill This takes places in vertical steel mill, which grinds the material through the pressure exerted by three conical rollers Which roll over a turning milling table Horizontal mills, inside which the material is pulverized by means of steel balls, are also used in this phaseThe Cement Mill Process has different Stages in Cement Production and they are : The raw materials of cement are lime and silica Alumina Grinding of this crushed lime stone after the addition with bauxite, iron ore, etc By passing air through bottom the lime powder is Cement Mill Process Requirement of Mill Motors Kiln DrivesCoal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal preparation system is one Cement Mill Cement Grinding Machine AGICO Cement Grinding Millthe Mill’s operation Boteler and Reynolds built a small experimental kiln followed quickly by a larger kiln, to burn or “calcine” the stone The mill then ground the calcined stone to cement to ship to construction sites By late 1828, construction had begun on the CO Canal on the Maryland side of the Potomac, whichThe Cement Mill: Ruins of Historic Site Tell a Story of Industry and

Cement Kilns: About Roman Cement

Parker situated his production plant at Northfleet because of the availability of a tidal mill and windmill for grinding Packing was done quickly because of the extreme moisturesensitivity of the powder, contact with damp air causing a considerable reduction in strength One ton of cement stone was said to yield about 21 bushels of cementThe Potomac Mills was a mill complex located along the Potomac River roughly 5 miles (080 km) downriver of ShepherdstownBuilt in 1826, the complex was originally used as a gristmillIn 1829, the mill began producing cement for the Chesapeake and Ohio Canal's construction The factory continued to produce cement after the canal opened, and it shipped its product along the Potomac Mills (Shepherdstown, West Virginia) WikipediaAs a kind of cement equipment, cement separator is mainly used in the coal mill grinding system, raw mill grinding system, and cement mill grinding system of the cement production line To improve the efficiency of these systems and Cement Separator – Cement Mill Separator Cyclone Ball Mill Cement Ball Mill Raymond Mill Jaw Crusher Cone Crusher Vertical Sahft Impact Crusher Impact Crusher for example,rotary kiln, ball mill, stone crusher, jaw crusher, hammer crusher, impact crusher To provide comprehensive and Rotary Kiln, Rotary Dryer, Ball Mill, Stone Crusher

.jpg)

Mill (grinding) Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of cement crushers required for cement raw material crushing: cone crusher, impact crusher, hammer crusher, jaw crusher, and fourroll crusherCement Crusher – Crusher In Cement Plant AGICO CementThe stacker and reclaimer is the prehomogenization system in the cement plantAs a necessary part of the cement production line, it can concurrently or respectively complete the stacking and reclaiming The stacker and reclaimer play a vital role in the limestone prehomogenization, stabilize the condition of cement kiln, ensure the clinker qualityStacker And Reclaimer Cement Plant PartsA cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

quadropol® thyssenkrupp Polysius Grinding Technologies

Cementos Cibao SA, cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types Compact plant arrangement with service tower, quadropol® vertical roller mill and main filter are part of Stone was born in Chicago, Illinois, on May 4, 1902His father died in 1905 leaving his family in debt In 1908 he hawked newspapers on the South Side of Chicago while his mother worked as a dressmaker By 1915 he owned his own newsstandIn 1918 he moved to Detroit to sell casualty insurance for his mother [1]Stone dropped out of high school to sell insurance fulltimeW Clement Stone WikipediaChina Cement ball mill catalog of Fly Ash Ball Mill Grinding Powder Used for Cement Plant, Hot Sale Output Adjustable Size 80425 Mesh Cement Ball Mill/Cement Grind Mill Plant/Cement Mill Clinker Equipment provided by China manufacturer Cement ball mill Baichy Heavy Industrial Machinery Co, LtdBall mill liners are essential components in the operation of a ball mill They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan Ball Mill Liner: What is it and How it Works? AGICO

.jpg)

Maweni Limestone World Cement Association

Maweni Limestone is one of East Africa’s leading manufacturers of cement operating in Tanzania In 2020, it was acquired and reconstructed by China Huaxin Cement, becoming one of the largest cement manufacturer in the 2014年6月10日 Cement manufacturing process – Sand (SiO2) – Shale, Clay (SiO2, Al2O3, Fe2O3) – Iron Ore/Mill Scale (Fe2O3) 10 Portland Cement (cont’d) Calcareous Component • Called “Portland” because concrete made with Cement manufacturing process PPT Free DownloadCement Ball Mill AGICO Adopt Efficient Cement Separator The function of cement separator is to reduce the unnecessary grinding amount of cement ball mill and improve its grinding efficiency by screening out the particles with certain fineness in time The key technologies of cement separators are dispersion, classification, and collectionBall Mill For Cement Grinding – Cement Ball Mill Ball Mill You can gather stone by hitting rocks with your bare hands or using a pickaxe It is primarily used in crafting and in building structures in the base Personal Mill: Mill: 50 × Wood 40 × Stone Monitoring Stand: Monitoring Stand: 30 × Wood 10 1 × Cement Stone Pickaxe: Stone Pickaxe: 5 × Stone 5 × Wood Stone Pit: Stone Pit: 50 × Stone The Palworld Wiki

Limestone Grinding Mill That You Need To Know Mortar Plant

2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Ball Bill, a laboratorygrade ball mill designed to obtain small particle size samples for testing standards This powerful device is capable of grinding a wide range of materials, including hard and medium hard bauxite, samot, ore, stone, sand, quartz, limestone, marble, slag, coal, uranium ore, ferro alloys, mud, silicate, cement clinker, and similar fastdrying inorganic materialsBall mill Vector Scientific Testing Devices horizontal / for cement Take a look at our interactive animation of the cement production process to learn how cement is made by us at CEMEX The quarry stone is delivered through chutes to the crushers, Raw material millCement Production: How Cement Is Manufactured CEMEX UK2024年10月14日 Other critical heavyduty machines for the effective operation of a stone mill include the belt conveyors, vibration feeder, vibrating screens, and a central control system for all these machines Understanding the variety and importance of each machine is essential for anyone involved in operating a successful stone crushing plantWhat Machines Do Stone Crushing Plants Need? Fote Machinery

Raymond Mills Raymond Roller Mill Grinding Mill AGICO Cement

What Is Raymond Mill Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc Under normal conditions, these materials’ 2023年12月20日 The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement The powdered cement is then mixed with water and aggregates to form concrete that is used in construction Clinker The Cement Manufacturing Process Thermo Fisher AGICO provides the cement ball mill, rod mill, cement vertical mill, Raymond mill, air swept coal mill, etc Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment CALL US +86 Grinding Mill Grinding Equipment Cement MillApplication: coal, cement, stone, sand, clay, ore, etc In general, cement bucket elevator work with cement crusher, raw mill, cement mill, and other cement equipment Bucket elevator is suitable for lifting from low place to high place Cement Bucket Elevator TGD And Chain Type Bucket

.jpg)

Rod Mill Ball Mill Cement Milll AGICO Cement Equipment

Rod mill is a kind of cement ball mill used in cement plants MBS series rod mills are used for further grinding after the raw material is broken It is an essential machine widely used in the cement manufacturing plantThe length of the crushing stone is also an important factor as it has significant effect on the capacity and screen analysis of the crushed “Experience with the OK roller mill,” Asian Cement and Construction Materials Magazine, September 1998, pages 4044 Brugan, J Mark, “Upgrading raw mills,” International Cement Review, August Everything you need to know about cement Materials Preparation What Is Air Swept Coal Mill The airswept coal mill is also called a coal grinder It is the main equipment of the cement plant, used for drying and pulverizing coal powderIt mainly consists of the feeding device, main bearing, rotary part, transmission device, discharging device, highpressure starting device, and lubrication systemAir Swept Coal Mill Coal Mill In Cement Plant AGICO GROUP2023年5月27日 Then feed the mixture into a cement mill for fine grinding Portlandlimestone cement (PLC) Type IL is governed by ASTM C595 or AASHTO M 240 Standard Specification for Blended Hydraulic Cements It is a blended cement manufactured with a limestone content between 5% and 15% Necessary matters about limestone grinding Conclusion2 Major Roles of Limestone in Cement Manufacturing

Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same specification, which will lead to poor comprehensive performance of finished cement, low system output and unsatisfactory enterprise benefitsInclusion Engagement Powered by our legacy of safety, health and doing the right thing, Martin Marietta is anchored in the truth of a diverse team who is always good for our word; and fortified by a heart of genuine, hardworking people who respect and take care of each other to create an inclusive environment for allHome Martin Marietta MaterialsWe have a few firsts in the Cement industry in the North East some of which may be highlighted as under Provision of Reverse jet bag filters for transfer points, Bag house for Kiln and Raw mill, ESP (Electro Static Precipitators) for 116 Km Stone (NH 44), SubDivKhliehriat, DistJaintia Hills Meghalaya, PinTAJ DHALAI+ :: Home