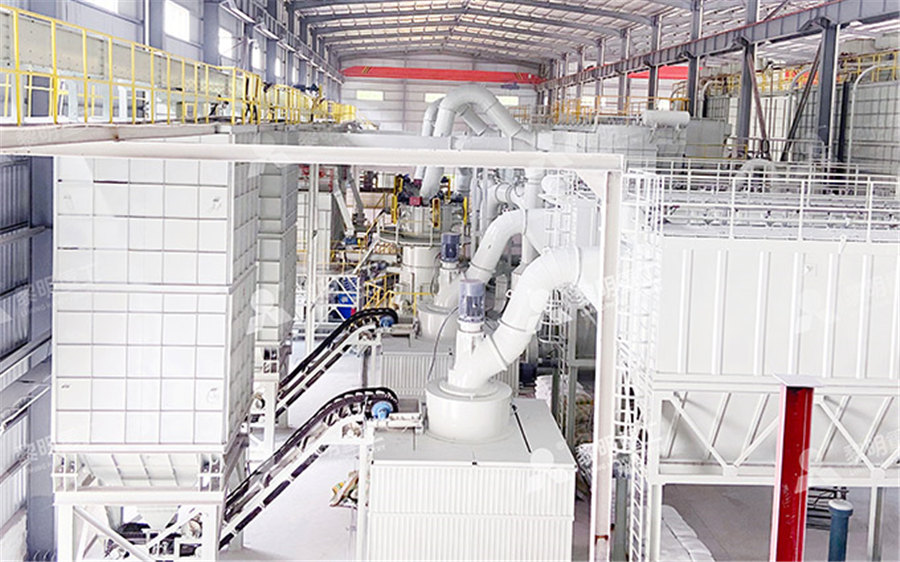

Crushed stone production line

.jpg)

600 t/h limestone crushed stone production line

Through detailed investigation and understanding, we designed a reasonable and efficient limestone crushed stone production line for customers Finally, we configure vibrating feeders, jaw crushers, impact crushers, highefficiency fine Through detailed investigation and understanding, we designed a reasonable and efficient limestone crushed stone production line for customers Finally, we configure vibrating feeders, 600 t/h limestone crushed stone production lineHighperformance Cone Crushers from SANME Assists the Granite Aggregates Production Line with 1700 TPH in Guangdong, China700800 tons per hour limestone crushed stone production line The special equipment for the stone production line is a special equipment for the production of sand and stone for building The stone equipment includes jaw crusher, stone crusher, sand maker, impact crusher, vibration feeder, vibrating Stone Production Line Zhongde Heavy Industries

.jpg)

Stone Crushing Production Line

The stone crushing production line, or stone crushing plant, is a complete set of equipment that crushes large stones or minerals into sands/ smaller sizes for various purposes will carefully Stone crushing production line is a combination of special equipment used for manufacturing building materials or industrial materials, including vibrating feeder, jaw crusher, cone crusher, impact crusher, hammer crusher, sand making Stone Crushing Production LineHongji Mining The stone crushing production line has been successfully applied to the crushing of limestone, basalt, granite, cobblestone and other rocks The quality of finished products fully meets the GB146852001 standard, which provides qualified Stone Production Line/Sandstone Production Line DSMAC Stone Production Line (stone crusher plant, stone crushing plant) can be used in quarry, sand and gravel joint production, abandoned mining recycling, construction waste recycling crushing and screeningStone Production Line > Production Line > Solutions >

Construction Aggregate Crushing Plant DSMAC

Aggregate production line manufactured by DSMAC aims for producing crushed stone aggregate Crushed stone aggregate is produced from many natural deposits including: limestone, granite, trap rock and other durable mineral Stone paper is made from crushed limestone powder While the base ingredient is calcium carbonate (caco3), NPK Combined Fertilizer Production Line All Industries, Machinery, Packaging Line, Packaging Machine PP Woven Sack Stone Paper Production LineView our product lines and request a free estimate for your project Skip to content Berlin: 9788389999 Holden: 5088294795 Material Calculator; Testimonials; Careers; Massachusetts Broken Stone Company is an Product Lines Massachusetts Broken StoneMaterial: Limestone Output: 600 t/h Configuration equipment: vibrating feeder, jaw crusher, impact crusher, highefficiency fine crusher, vibrating screen, etc Recently, a mine owner from Sudan contacted the Nile for a list of the configuration of a limestone crushing production line with a capacity of 600 tons per hour600 t/h limestone crushed stone production line

Limestone, granite, basalt crushed stone production line

Limestone, granite, basalt crushed stone production line December19,2019 Crushed stone production line is a special production line for sand and stone used in construction, highway, railway and other industries The main equipment includes jaw crusher, impact crusher, impact crusher, vibrating feeder, vibrating screen, sand washing machineThe stone that meets the particle size requirements is sent to the finished product pile by the finished product conveyor; The stone is returned by the conveyor and sent to the impact crusher to be crushed again, forming a closed circuit for multiple cycles How to choose a mine crusher:Mining production line process flow CM Mining Machinery2022年4月20日 After limestone is mined from limestone rock, it is crushed to form limestone particles, namely stone and sand Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industriesLimestone crushing and grinding production line SBM Ultrafine Crushed stone and gravel are two popular materials used for landscaping and construction projects the back of the production line adopts towerlike sand making process 10 Tips to Improve the Quality of Sand and Gravel Aggregate With the construction of highspeed railways, The Ultimate Guide to Crushed Stone and Gravel

Construction Aggregate Crushing Plant DSMAC

Aggregate production line manufactured by DSMAC aims for producing crushed stone aggregate Crushed stone aggregate is produced from many natural deposits including: limestone, granite, trap rock and other durable mineral resources DSMAC Aggregate Crusher Advantages Complete stationary, portable, mobile aggregate crushing machine are availableThe crushed stone production line is generally divided into coarse (primary), secondary and fine crushing according to its output fineness How many types of crushers and machines are there? Coarse crushing Jaw crusher The stones mined from the mountain can be crushed to medium size at primary crushing10 Types of Stone Crusher Plants Price and More for SaleThey crush and shape the crushed stone particles into sandlike particles The machines are available in different models and capacities to suit the specific requirements of the production line Crushed stone sand making equipment plays a crucial role in the production of highquality sand and stone for the construction industryIntroduction to crushed stone sand making equipment for Our crushed stone products range in size from riprap – large, broken stones used to line lake shores, rivers and creeks for erosion control – to aglime, a fine limestone dust used by farmers to neutralize soil acidity Dolese operates 11 Crushed Stone Dolese

.jpg)

Stone crushing production line

Stone crushing production lines often include coarse crushing, medium and fine crushing, sand making and sand washing and other processes Suitable for metallurgy, The coarse crushed products are screened by the vibrating Crushed Stone Production Graph: Crushed stone production trends for the last 100 years Data from USGS [1] The line graph above on this page shows the trend of crushed stone production in the United States between 1921 and Crushed Stone The Unsung Mineral HeroA crushed stone production line typically involves a series of equipment and processes to transform raw stone materials into crushed stone products The main equipment and processes include: 1 Quarrying: Extract stone from the quarry using blasting, drilling, and Crushed stone production line equipment NEWS SMMVIK 2024年1月23日 Cement Production: Crucial raw material in cement preparation, obtained through the calcination process to produce quicklime Chemical Industry: Utilized in fertilizer production, industrial wastewater treatment, and the purification of flue gas Agriculture: Used as a soil amendment to adjust soil acidity and enhance soil fertilityLimestone crushing and screening production line introduction

.jpg)

How to configure the crushed stone production line equipment

1 Hardness of raw materials: the crushers matched with different raw materials are different For stones with high hardness, such as pebbles, granite and quartz stone, it is more wearresistant to choose extrusion type stone breakers, such as cone type stone breakers and jaw type stone breakers; Similarly, if your raw materials have low hardness, such as limestone, gypsum, coal 700800 tons per hour limestone crushed stone production line details Project Case Fixed Construction Waste Recycling Plant in Shanghai, China Mobile Construction Waste Recycling Plant in Zhejiang, China 200 TPH Dolomite Aggregate Production Line In Uzbekistan700800 tons per hour limestone crushed stone production line After impact crushing, the finely crushed stone material enters the vibrating screen to screen out stone specifications that meet production needs Return material to crush The limestone that does not meet the specifications screened out by the screening machine must be returned to the impact crusher for crushing again until it meets the requirements of the finished product specificationsLimestone Crushing Equipment and Production Line2020年4月4日 The above crushed stone production line case was designed by Shanghai Hengyuan Metallurgical Equipment Co, Ltd and equipment selection and quotation If you want to know how much the complete set of crushed stone production line with an annual output of 1200 tons, you can send us an or leave a message on the websiteCrusher equipment configuration of 600 tons per hour crushed stone

AASHTO #1 Stone Crushed Stone York Building Products

AASHTO #1 is the largest crushed stone variety offered by York Building Products Uses for AASHTO #1 Aggregate The most common types of rock used in crushed stone production are limestone, granite, and quartzite However, you can also use You can also use AASHTO #1 stone to line ditches or make a driveway base with screening Other The stone crushing production line, The crushed stone enters the crusher for further processing and then is sent to the vibrating screen to separate stones of different sizes This helps achieve uniformity in the final product and ensures that only the Stone Crushing Production LineAggregate production line Crushed stone production lineAggregate production line / Crushed stone production line2023年11月14日 Professional {quarry crusher} export enterprise, a complete set of {quarry equipment} crushing, sand making, and screening production lines #impact #crusheCrushed stone production line Mine stone crushing production line

Gravel Size Chart, Crushed Stone and Rock Sizes Bovees, where

2023年7月21日 Crushed stone #411: Less than 1” Wide Similar in size to #67 stone, crushed rocks graded #411 are less than 1 inch in diameter with an average size of ¾ inch However, unlike crushed stone number 67, #411 contains stone dust so that it can be compacted to make a very firm, stable surface or base layerWhat’s more, during the process of the sand production line, due to the reasonable match of sandstone equipment at all levels and the rigorous cross layout of space, the FTM Machinery sand production line has the small occupation, high benefit of economic investment, good quality of crushed stone, and low output rate of stone powderSand Production Line FTM MachineryA crushed stone with a size less than one inch, crushed stone #5 is best for filler materials, the top driveway layer, railroad ballast, and septic drainage fields Crushed Stone #7 With a size from 3/4 inch to #8 sieve, crushed stone #7 is used for septic tankline bedding, filtration, bioretention ponds, asphalt production, retaining wall backfill, readymix production, and many landscaping How to Choose the Right Grade of Crushed StoneThe material is evenly fed to a PE600×900 jaw crusher through a GZD960×3800 vibrating feeder to coarsely crush the stone to a particle size of less than 120 mmThen through the belt conveyor into the PF1214 impact crusher in progress to crushed into less than 60mm size of the stone material, in which more than 40mm of material returned to Zimbabwe Crushed Stone Production Line,Zimbabwe,Crushed,Stone

Gravel and limestone Open Development Cambodia (ODC)

2015年9月30日 Since 2010, Cambodia has seen increasing production of cement, crushed stone, sand and gravel in response to the country’s booming construction sector Approved investment in the construction industry in 2015, at $33 billion, was 33% higher than 2014, according to the Ministry of Land Management, Urban Planning and Construction Local 2021年10月19日 Four principles of equipment configuration for crushed stone production line, double your production capacity Oct 19, 2021 The crushed stone production line is generally used for the crushing and processing of various stones and is widely used in various construction, railway, highway, hydropower engineering, and other industriesFour principles of equipment configuration for crushed stone production Stone Production Line Tips: Different production lines configured according to your needs INDUSTRY: Mining, Construction, Road Bridge, Metallurgy If the feeding size is smaller than 115mm, it can be crushed by the spring cone crusher directly, and avoid the primary stage crushing Configuration list: NO Equipment: Model: Quantity: I Stone Production Line, Stone Crushing Line, Stone Production Line The crushed stone production line is generally divided into coarse (primary), secondary and fine crushing according to its output fineness Coarse crushing Jaw crusher The size of the finished products after being crushed is generally Stone Crushing PlantSinogomine Industrial

.jpg)

Limestone crushing technology and equipment SBM

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and 2024年7月13日 Screening: The vibrating screen separates the crushed materials into different sizes Conveying: Belt conveyors transport the final products to their respective stockpiles or loading points Benefits of a 120 TPH Stone Crushing Production Line: High Efficiency: Optimized equipment configuration ensures efficient operation and high production rates120 TPH stone crushing production lineAdvantages of Stone Crushing Production Line 1 The whole stone crushing production line has minimal abrasion of parts and equipment, but also has high production efficiency 2 Stone crushing production line customers with great convenience, and significantly reduces the production cost of customers in terms of operation, personnel Shanman Stone Crushing Production Line, Stone Production LineThis sand is used in the production of readimix concrete Also used in Horse Arena riding areas CALL US Tel: 5857984501 Please consider low power lines, SHELBY CRUSHED STONE 10830 Blair Road Medina, SAND PRODUCTS Shelby Crushed Stone

Sri Lankan crushed stone and stone powder production equipment supplier

2020年12月4日 The crushed stone production line has the following characteristics 1 Suitable for largescale production with a processing capacity of 50300 tons/hour 2 The production cost per ton of finished sand is only 80% of the conventional production line 3 High degree of production automation, low energy consumption and large crushing ratio 42010年4月2日 Brief introduction of characteristics for stone production line The production line is of high automaticity, adjustable final size, high crushing ratio, energy saving, high capacity, size of final product average, nice shape, suitable for various kinds of projects including road building, bridge building etc Zhengzhou Kehai Heavy Industrial Stone Production Line PDF Free Download SlideShareStone production line is used for the gravel aggregate production of limestone, granite, basalt, river gravel and other kinds of rock Stone materials are primarily crushed by the jaw crusher, and then the coarse products are transported to fine crusher by the belt conveyor for further crushingStone Production LineFote Machinery Fote Machine2017年11月1日 Find Slag Crushed Stone Production Line Factory stock images in HD and millions of other royaltyfree stock photos, 3D objects, illustrations and vectors in the Shutterstock collection Thousands of new, highquality pictures added every daySlag crushed stone production line Factory 3D Shutterstock

HOME Shelby Crushed Stone

Shelby Crushed Stone produces a wide array of high quality crushed limestone products EAgle Harbor Sand Gravel has beautiful colored landscape gravel and sand products Cambria Asphalt carries Hotmix asphalt products and stockpiles many of out stone products for your convenient pickup in Lockport