Main process parameters of roller mill mill

.jpg)

Optimization of working parameters of highpressure roller mill

2024年11月15日 In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is sought, GM1601402017年4月1日 The main parameter related with the product rate and product particle size is the classifier rotor speed The cut size of classification can be controlled by adjusting the speed of Operational parameters affecting the vertical roller mill With the introduction of the high compression machines such as High Pressure Grinding Rolls (HPGR), Vertical Roller Mills (VRM) and Horomills, efficiency of the grinding circuits was (PDF) Operational parameters affecting the vertical roller mill 2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, Review on vertical roller mill in cement industry its performance

Operational parameters affecting the vertical roller mill

2016年9月1日 Furthermore, VRM separator speed (rpm) is one of the key operational parameters that determines product particle size Increasing the classi er rotor speed from 60 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method Analysis and Optimization of Grinding Performance of 2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) Analysis of vertical roller mill performance with changes in material 2019年2月21日 In addition, the shape, relative motion, and form of rollers on outer rings and solid plate provide good conditions for moving the load in the preparation, grinding, and A study of operating parameters of a roller mill with a new design

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Optimize the Rolling Process Parameters for Material AA1100

In this paper, Taguchi optimization technique is used to predict the best results for the given inputs such as roller diameter, friction value, velocity of the rollers and percentage reduction to 2014年11月1日 Various rolling models and optimization methods are applied in each step The procedure starts from the customer product mix and the annual production A pass schedule program is applied toOn the Optimization Procedure of Rolling Mill DesignCement production is highly energy consuming process with energy utilization of around 110150 kWh/t (Villa, 2005) Design parameters of the vertical roller mill arePerformance Evaluation of Vertical Roller Mill in Cement Grinding: Making “digital twins” for rolling processes and mill equipment should begin with the development of mathematical models of the deformation zone The deformation zone of twohigh flat mill rolling have been studied in detail, Calculating Power Parameters of Rolling Mill Based

A study of operating parameters of a roller mill with a new design

2019年2月21日 The paper analyzes the interrelation of: motion, particle size of ground rice grains, displacement, and grinding in a roller–plate mill The purpose of the stud Skip to Main Content Close A study of operating parameters of a roller mill with a new design Józef B Innovation and wheat corn mill process control By the nature of the change, they correspond to the results of experimental studies However, the degree of impact of the process parameters on the rolling pressure, the mill torque and the metal flow are different The closest coincidence of the calculated and experimental data is provided by the mathematical modelCalculating Power Parameters of Rolling Mill ProQuest2019年10月24日 The quality characteristics of the mill roller in sand casting has been affected by casting defects caused by in proper process parameter usage and intern affects its proper function that lead to large number of shop floor trials, high rate of rejection, and low casting yield The objective of this research is to design and analyze sand casting process of mill roller In Design and analysis of sand casting process of mill roller2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance modelOperational parameters affecting the vertical roller mill

.jpg)

Session 11 Optimisation of Roller Press System PDF Mill

Pregrinding increases ball mill throughput by 1525% while hybrid sees a 65% increase Specifications include pressures of 50400 MPa, roller speeds of 0518 m/s, and ability to process feed up to 60mm Operating parameters that affect performance include accumulator settings, gap size, vibrationDuring the first 5 to 15 minutes of operation the mill has to be stabilized The operator has to watch the process parameters carefully and take the right steps Indicators for the stability of the process are: # vibration velocity at the gearbox # differential pressure of mill #power consumption of mill main drive #air flow through millPROCESS TRAINING for operators of Vertical RAW MillsWhere does a Hot Strip Mill fit in the flatroll production process? Making, Shaping and Treating of Steel: 101 3 4 11/2/2020 3 Making, Shaping and Treating of SURFACE: Rolled in scale is a bad thing Controlling Finishing Mill parameters can determine whether or not it is present 37 38 11/2/2020 20 Making, Shaping and Treating of Steel Principles of Hot Rolling AISTthe main material for construction, which is cement and which has been key to the process of human civilization [3] For the cement grinding process, two machines can be used, which are: a ball mill or a VRM vertical roller mill The ball mill makes use of grinding bodies and they have been the main tool for more than 100 years,Parameters for the Grinding Process in Vertical Mills Using

The influence of rolling mill process parameters on roll thermal

2019年1月23日 This study analyzes the impact of operational parameters of hot rolling mill in the degradation process of a roll surface by thermal fatigue A methodology was developed to determine a coefficient that could identify when operational parameters become crucial to initiate this degradation process This new coefficient, named the surface damage coefficient (κ), is 2021年1月6日 VRM construction, its process and parameters which affects the performance and productivity of vertical roller mill are discussed Also the consequences of variations in parameter explainedReview on vertical roller mill in cement industry its 2021年1月29日 Unground material would stay over the classifier, and they have to be kept inside the mill to meet the desired size One of the critical factors through the process is controlling the mill body Increase productivity of vertical roller mill using seven As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperatureTechnical specifications of vertical roller coal mill

.jpg)

Chapter 7 Roller Milling of Wheat ScienceDirect

2007年1月1日 This chapter describes how the flour milling process interacts with the wheat kernel structure to separate it into its functional components It traces briefly the historical development of flour milling technology leading to the introduction of roller mills a century ago, introducing the themes of wheat hardness, bread quality and the international grain trade that 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure which is the product Moisture containing materials are dried in the process of contacting with hot airflow By working rollers (a fixed roller and a movable roller), the driving system (main motor, reducer, belt pulley, and gear shaft), the Roller Mill SpringerLinkThe main performance parameters of the highpressure Roller Mill are production rate, power consumption and percentage of discharge size, which can be predicted based on material characteristics Optimization of working parameters of highpressure roller mill The mill process is cement freestanding roller grinding raw coupling between the most comple QianHong Wang et al / Physics Procedia 33 ( 2012 ) 437 – 443 441 x systemDesign and Realization Of Roller Mill Control System

.jpg)

Using the eightroller mill on the front passages of the reduction

2008年3月1日 DOI: 101016/JJFOODENG200707007 Corpus ID: ; Using the eightroller mill on the front passages of the reduction system @article{Fite2008UsingTE, title={Using the eightroller mill on the front passages of the reduction system}, author={Aleksandar Fi{\vs}te{\vs} and Gavrilo Tanovic and Jasna S Mastilovi{\'c}}, 2016年11月9日 Rolling mill vibration is a worldwide problem, although it has been found that the mill structure defects are the main cause of vibration, but the inhibition measures are difficult to implement So we discussed the rolling force parameters influence on rolling mill vibration and suppression measures from rolling technology in this article The results show that the rolling Rolling process and its influence analysis on hot continuous The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement Vertical Roller Mill Operation in Cement Plant2020年1月3日 The main process parameters are disclosed View The rolling mill produces sections with diameters from 90 mm to 200 mm Traditional technology does not provide opportunity for rolling the 2020 Technology and Operation of a Hot Rolling

An investigation of performance characteristics and

2020年8月12日 Altun et al [15] explored the influence of the parameter settings of a vertical roller mill on grinding performance and demonstrated the influence of grinding pressure values on the size and mass 2017年9月11日 This explains the significant increase in the share of roller mills in the cement mill market The grinding process in such mills occurs due to abrasion, respectively, in the process of work wear (PDF) Performance Evaluation of Vertical Roller Mill in2023年7月19日 Through theoretical analysis, the main influencing parameters were screened, mainly used for grinding nonmetallic minerals such as calcite, marble, and chalk Compared with vertical roller mill (VRM) or ball mill, due to its simple structure, easy maintenance, low price, stable performance, simple process, and convenient Research of grinding efficiency and main duct wear of pendulum mill 2020年9月1日 Basic force parameters such as roller torque, radial load of the roller and axial load of the chuck are measured during the rolling process This rolling mill can be used to produce parts that are from 25 to 55 mm in diameter and up to 1000 mm in lengthProblems of forming stepped axles and shafts in a 3roller skew

.jpg)

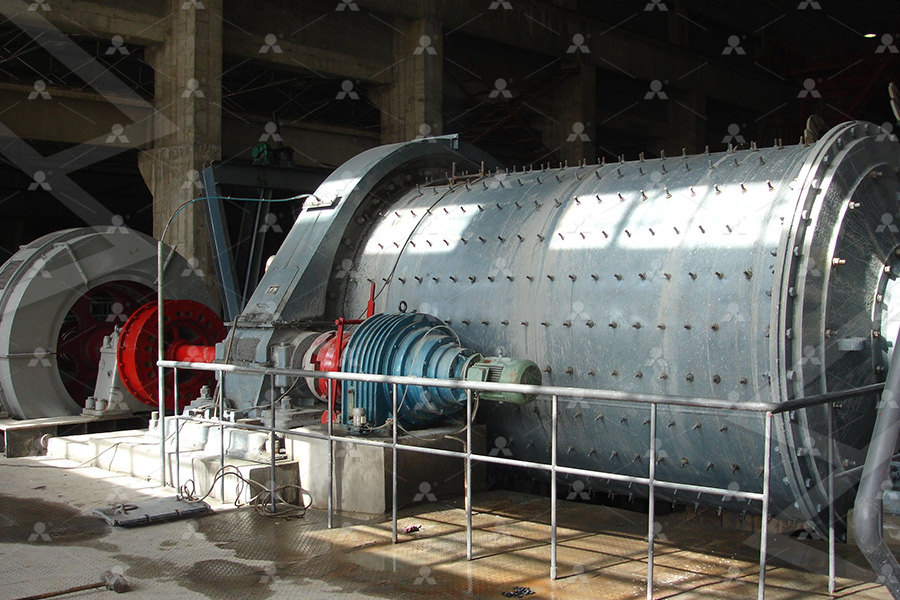

Optimization of processing parameters of a ball mill refiner for

2007年12月1日 As an alternative to the conventional process consisting of roller refiners and conches [6], In ballmill technique, the main process parameter variables are temperature (5070 C), Download scientific diagram Process parameters of plate mill from publication: Torque Model in Plate Rolling Process with Biting Impact Considered In this paper, the research work of the Process parameters of plate mill Download Scientific Diagramstate of the rolling mill and the rolling process parameters is established One of the main methods to solve this problem is the datadriven intelligent optimization approach for the operational state of the rolling mill In terms of optimizing rolling process parameters: Wang [12] simulated the coldVirtual commissioning and process parameter optimization of 2019年2月21日 The paper analyzes the interrelation of: motion, particle size of ground rice grains, displacement, and grinding in a roller–plate mill The purpose of the study was to analyze and evaluate A study of operating parameters of a roller mill with a new

A datadriven decisionmaking framework for online control of

2020年5月1日 A datadriven decisionmaking framework for online control of vertical roller mill Author links open overlay panel Mingrui Zhu, Yangjian Ji, Zhen Due to the inappropriate setting of process parameters or the great difference in Feedback Value of Main Roller Pressure: L0028: Dust Collector Outlet Temperature: L0048: Feedback A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, Energysaving and Efficient Vertical Roller Mill Fote ½ 2in / 1050mm, the roller mill can produce particles ranging from coarse, granular products of approximately 10% R2000 micron 90% minus 10 mesh (10%R2000 microns) to as fine as 999% minus 325 mesh (0001%R44 Raymond Roller Mill airswept vertical ringrollNORMAL MILL PRACTICES Not to monitor lift of top roller It is assumed that top roller lifts only that value considered during mill setting calculations Normally actual lift of top roller during operation is higher than considered in mill setting calculation Higher thickness of cane/bagasse blanket passes through mills due to excessive lift of top rollerMILL DESIGN MILL OPERATION

Process optimization in poultry feed mill Scientific Reports

2023年6月19日 The improvement approach is conducted by observing the main operating parameters of productivity; Process optimization in poultry feed mill Pellet mill die and roller design2012年12月31日 PDF a Distributed Control System(DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT The Find, read and cite all the research Design and Realization Of Roller Mill Control Systemroller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Roller mills: Precisely reducing particle size with greater efficiencyOperational parameters affecting the vertical roller mill performance × In this context, gold ore was ground under different process conditions The main parameter related with the product rate and product particle size is the classifier rotor speed(PDF) Operational parameters affecting the vertical roller mill

.jpg)

[PDF] Optimization of processing parameters of a ball mill

DOI: 101016/JJFOODENG200704014 Corpus ID: ; Optimization of processing parameters of a ball mill refiner for chocolate @article{Alamprese2007OptimizationOP, title={Optimization of processing parameters of a ball mill refiner for chocolate}, author={Cristina Alamprese and L Datei and Quirico Semeraro}, journal={Journal of Food Engineering}, 2021年1月19日 In order to start the optimization process of hammer mill working process, 12 parameters were defined Bond ball mill, knife mill, and ringroller The main parameters for the hammer mill (PDF) Optimization Issues of a Hammer Mill Working Process