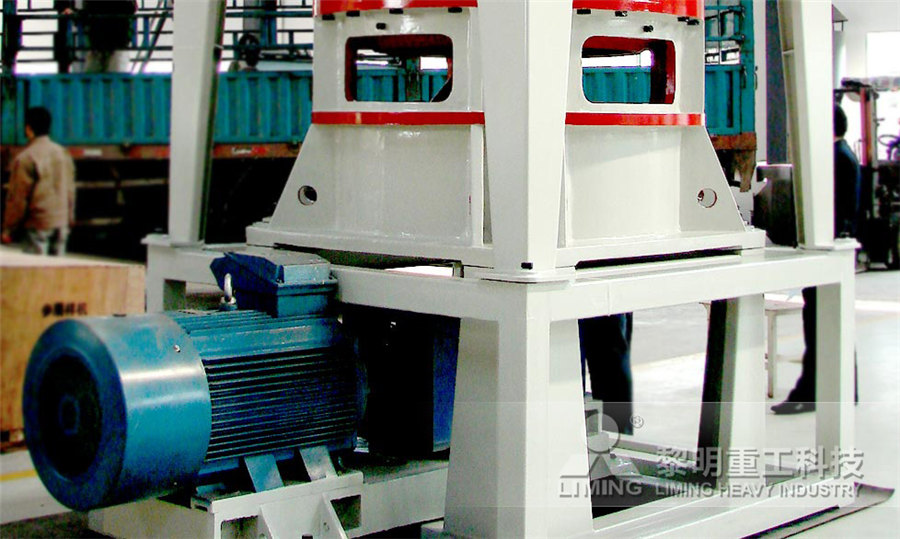

SCBF700 coal gangue fine sand powder equipment

A review of intelligent coal gangue separation

2023年11月6日 Conventional coal gangue separation equipment, such as spiral separation equipment, heavy medium shallow trough separation equipment, and TBS interference bed separation equipment have the advantages of mature 2023年7月3日 The application of coal gangue (CG) powder as cementitious material is significant for the sustainable management of CG However, concrete containing a small Utilization of coal gangue powder to improve the sustainability of 2024年1月18日 Coal gangue refers to the waste or byproduct produced when coal is extracted from coal mines These wastes usually include coal gangue (without valuable crushed coal and gangue), rocks, soil, and other mineralsCoal Gangue: Composition, Processing, Use And 2024年2月23日 Gangue fine aggregate concrete is used in concretefilled steel tube and reinforced concrete stubs The increase in rGS increases the ductility of the coal GSCFST Utilization of coal gangue sand in structural concrete as fine

Review Highcapacity utilization of coal gangue as supplementary

2024年7月12日 Utilization of coal gangue in engineering is an ecological and sustainable way The pretreatment intensity varies across different utilization methods Progressed coal gangue 2024年9月7日 Given the coal gangue properties and global land degradation severity, the resourceful utilization of coal gangue as soil conditioners is believed to be a universally Opportunities, challenges and modification methods of coal 2022年9月30日 Using coal gangue (CG) as a building material does not only reduce the disposal of industrial waste and promote the resource utilization of solid waste, but also solves the Preparation of coal gangue ceramsite highstrength concrete and 2024年2月28日 Currently the main method of mine solid waste disposal and utilization is to apply gangue to underground filling For the grading characteristics of coal gangue in the Study on the macro–micro evolution of compaction characteristics

Influence of Coal Gangue Powder on the Macroscopic

2023年10月3日 Integrating recycled aggregates (RAs) and coal gangue powder (CGP) into concrete is an effective approach for waste management However, CGP can affect the performance of traditional recycled concrete This study 2022年4月6日 Among coal miningrelated wastes, coal gangue (CG) is the heterogeneous waste generated during the mineral processing or coal washing phase of coal mining A The Sustainable Utilization of Coal Gangue in Geotechnical and 2022年9月13日 Coal gangue powder is widely used in the construction field +17 [ used equipment includes vibrating feeder, vibrating screen, belt conveyor, jaw crusher, impact crusher, ultrafine powder mill and Coal gangue ultrafine powder mill2019年12月1日 The accumulation of considerable coal gangue not only occupies a great deal of land resource, but also results in serious environmental problems, eg, soil pollution, air pollution, and geologic hazards (Stracher and Taylor, 2004)The heat continues to accumulate during the accumulation process, which leads to spontaneous combustion with the oxidization of coal Comprehensive utilization and environmental risks of coal gangue: A

Synergistic performance of microwaveactivated coal gangue with

2024年11月1日 Sand: The sand used is standard sand produced by Xiamen Aceo Standard Sand Utilizing microwave activation for the production of 1 kg of activated coal gangue powder can reduce CO 2 emissions by approximately 132 Activity of calcined coal gangue fine aggregate and its effect on the mechanical behavior of cement mortar 2021年8月1日 Request PDF Performance of microwaveactivated coal gangue powder as auxiliary cementitious material Coal gangue is presently the largest stock of industrial solid waste that poses Performance of microwaveactivated coal gangue powder as 2023年11月6日 Recognition and separation of Coal/Gangue are important phases in the coal industries for many aspects This paper addressed the topic of Coal/Gangue recognition and built a new model called (CGR A review of intelligent coal gangue separation technology and equipment 2024年9月28日 Coal gangue (CG) can be a potential aggregate for concrete production considering its huge production However, its porous structure and high water absorption significantly impact the workability of concrete, restricting its comprehensive utilization This paper proposed a straightforward presoaking technique for CG, where the presoaked CG (PCG) is Internal Curing for Tunnel SelfCompacting Concrete Using Pre

.jpg)

How To Effectively Use Coal Gangue?

2021年10月13日 Coal Gangue Pulverizer Raymond Mill Finished product fineness: 80325 mesh Production capacity: 15100t/h It is suitable for the processing of more than 300 kinds of highfine powder materials in nonflammable and explosive mineral, chemical, construction and other industries with Mohs hardness not greater than 7 and humidity below 6%2023年8月9日 Coal gangue is a kind of solid waste A highductility cementcalcined coalganguepowdercompositebased rapid repair material (HDRRM) was prepared by partially replacing cement with calcined coal gangue powder (CCGP) for achieving high ductility and rapid hardening and conforming to the strength requirements of pavement layers First, the physical Preparation of HighDuctility CementCalcined CoalGanguePowder 2010年10月1日 This paper presents an experimental investigation on the effect of two kinds of activated coal gangue powder on compressive strength, porosity and pore size distribution of hardened cement mortarsEffect of two kinds of activated coal gangue powder on 2023年1月31日 Degradation Mechanism of Coal Gangue Concrete Suffering from Sulfate Attack in the Mine EnvironmentDegradation Mechanism of Coal Gangue Concrete Suffering from

.jpg)

Experimental research on bearing characteristics of coal gangue

2024年4月6日 To make a comprehensive use of coal gangue, it is proposed to use this solid waste instead of fine aggregate to prepare gangue concrete pile for pilenet composite foundation The influences from substitution ratio of fine coal gangue aggregate upon the mechanical parameters of concrete were analyzed through laboratory test, and the labscale model test 2022年12月2日 The clay brick and powder recycled from construction and industrial waste may be utilized as recycled construction materials To alleviate the negative environmental impact of the cement industry’s CO 2 emission, waste clay brick was used as fine aggregate, clay brick powder (CBP), and coal gangue powder (CGP) were utilized as supplementary materials to Ecological Mortar from Recycled Composite Powder with Waste 2022年8月22日 The characteristics of raw materials used in the test, such as cement, CGP and coal gangue, are shown in Table 1In this experiment, the coal gangue produced by Zhang Jiamao coal mine in Shenmu City, Shaanxi Province is selected, and the XRD7000L Xray diffractometer was used to obtain the mineral composition analysis of coal gangue, activated Study on the influence mechanism of activated coal gangue powder 2024年10月25日 Fly ash, coal gangue powder, cement kiln dust, recycled concrete powder are the most popular used byproduct materials, which can serve as a substitute for cement Adding fly ash can slow down heat growth at a initial stage, and there's evidence that it may reduce chloride infiltration, increasing the durability of reinforced concrete structuresDurability of high strength selfcompacting concrete with fly ash, coal

Degradation Mechanism of Coal Gangue Concrete Suffering from

Materials 2023, 16, 1234 4 of 20 as CGC30 was also considered S0, S5, S10 and S15 refer to 0, 5%, 10% and 15% sulfate corrosive solutions in mass fraction, respectively2022年6月1日 PO425 grade cement was selected as the binding material, mechanized granular coal gangue and fine sand were used as the filling aggregate, and then the specimens were curing at room temperature Experimental study of microorganisminduced calcium carbonate Appl Sci 2020, 10, 3229 2 of 19 and fine aggregate of concrete mixtures, the environmental impact caused by both coal gangue and overexploitation of sand and gravel can be reducedFrost Resistance of Coal Gangue Aggregate Concrete Modified by Steel 2024年5月1日 The coal gangue was collected from Fuxin, northeast of China The large particles of coal gangue were crushed and sieved into gangue fine aggregate, according to GB/T 146842022 [48]The cumulative screening percentage and physical properties of natural and gangue fine aggregate are listed in Table 1 and Table 2 respectively The macroscopic and Mechanical and environmental performance of structural concrete

(PDF) Utilization of Coal Gangue Aggregate for Railway Roadbed

2020年6月4日 Coal gangue aggregate was employed as highgrade railway subgrade filler andprepared concrete for roadbed drainage (named coal gangue roadbed protecting concrete—CGRPC)2022年2月25日 coal gangue slag concrete and mixed coal gangue and slag as binder with sand to prepare geopolymer concrete with compressive strength of 621 MPa at 28 days [ 17(PDF) Compressive and Flexural Properties of UltraFine Coal Gangue 2024年3月14日 However, compared with natural river sand (NRS), the reclaimed coal gangue sand (RCGS) fine aggregate is coarse and has more edges and corners, and its packing density is large, its mud content is small, its water absorption is strong, and its stone powder can make up for the defect of less fine grain content in natural sand, and the stone powder contained in it Sulfate Corrosion Resistance of Reclaimed Coal Gangue Sand 2015年12月15日 DOI: 101016/JCONBUILDMAT201509050 Corpus ID: ; Activity of calcined coal gangue fine aggregate and its effect on the mechanical behavior of cement mortar @article{Dong2015ActivityOC, title={Activity of calcined coal gangue fine aggregate and its effect on the mechanical behavior of cement mortar}, author={Zuochao Dong and Junwu Xia Activity of calcined coal gangue fine aggregate and its effect on

.jpg)

Study on the modification effect and mechanism of tailings powder

2023年1月30日 Based on the problems of high carbon emission and high cost of traditional mining methods and filling materials, the tailings powder modified Coal Ganguebased Cementitious Backfill Material (CGCBM) was used for paste filling mining In this study, the samples were prepared with different tailings powder content and different curing ages The 2020年5月6日 Airvoid characteristics test for coal gangue aggregate concrete (CGAC), (a) Rapid air concrete airvoid analyzer; (b) Treated surface of CGAC before air structural testingFrost Resistance of Coal Gangue Aggregate Concrete Modified by Steel 2024年2月23日 Coal gangue is the main tailings of coal mine, accounting for about 10% ∼ 20% of coal production At present, China is the largest coal production country reaching 5 billion tons, rising at an annual rate of 150 million ∼ 200 million tons [1], [2]In recent years, the average annual consumption of concrete in China has exceeded 436 million tons, and the average Utilization of coal gangue sand in structural concrete as fine 2023年11月3日 To improve the mechanical properties of coal gangue concrete, this paper designs fourlevel and fourfactor orthogonal tests with coal gangue ceramide substitution rate, coal gangue ceramide sand Study on mechanical properties and microstructure of steel

Effects of Coal Gangue on Cement Grouting Material Properties

2018年5月1日 Coal gangue powder (600 ~ 700 ℃ calci ned and fine grinded), cement, aggregate, expansive agent and additives were b lended together after weighing to get the dry mixtures The wat er reducer,2019年10月1日 Broken gangue from the collapsing roof of a longwall coal panel can be used as the backfilling material for goaf backfilling The particle size gradation has important influence on the compressive Effects of particle sizes on compressive deformation and particle 2023年6月5日 Study on Sound Propagation Performance of Mechanized Coal GangueFine Sand Filling Body June 2023; Shock and Vibration 2023(1):110; DOI:101155 breakage of gangue used for coal mine goaf Study on Sound Propagation Performance of Mechanized Coal GangueFine Download Citation On Feb 1, 2024, Tong Zhang and others published Utilization of coal gangue sand in structural concrete as fine aggregate towards sustainable production Find, read and cite Utilization of coal gangue sand in structural concrete as fine

.jpg)

Technology and engineering test of filling goaf with coal gangue

2023年11月23日 Process of filling goaf with coal gangue slurry The process of filling goaf with coal gangue slurry is shown in Fig 2Specifically: the coal gangue is crushed by a multistage crusher and enters 2024年11月1日 For example, calcined coal gangue powder as supplementary cementitious materials [14]; coal gangue fine aggregate replaces natural river sand [15]; coal gangue coarse aggregate replaces natural crushed stone [16] Using thermally activated coal gangue as precursor and aggregate is one of its highvalue utilization pathways [17]Hybrid fiber reinforced ultrahigh performance coal gangue 2023年4月5日 Based on this, this paper uses coal gangue powder as admixture and coal gangue as coarse and fine aggregate to prepare coalganguebased green cemented filling body (CGGCFB) with different mass (PDF) Influence of Mass Concentration on 2022年1月26日 Thus, the use of coal gangue (CG) and coal gasification slag (CGS) as SCMs in concrete attracted more researcher’s attention This paper investigated the mechanical strength, porosity, and Durability of Concrete With Coal Gasification Slag and Coal Gangue Powder

.jpg)

Comparative study on mechanical and environmental properties of coal

Download Citation On Oct 1, 2023, Tong Zhang and others published Comparative study on mechanical and environmental properties of coal gangue sand concrete Find, read and cite all the research Coal gangue, a byproduct produced during the process of coal mining and washing, has a serious impact on the environment Using coal gangue as a concrete aggregate has been proven helpful in potentially improving its value and reducing its environmental impact to a certain extent However, the high water absorption and low strength of coal gangue aggregate cause a poor Frost Resistance of Coal Gangue Aggregate Concrete Modified by Steel 2023年11月20日 Coal gangue (CG) is an environmental waste that faces an urgent demand for disposal in China The utilization of CG in construction materials has broad application prospects and gained increasing interest However, the poor compatibility of polycarboxylate superplasticizer (PCE) with CG powder hinders its efficiency in a wide range of applications Here, this paper An alternative approach to improve the compatibility of PCE in Moreover, coal gangue was a byproduct of the coal mining and washing processes, accounting for approximately 10 %–25 % of the total raw coal production [[9], [10], [11]]Its carbon content was relatively low and its hardness was higher than that of coal [12]According to the data of China Resources Comprehensive Utilization, the production amount of coal gangue in 2021 Synergistic action and effect mechanism of coal gangue powder

Study on Mechanical Properties of PET FiberReinforced Coal Gangue Fine

strength [4]; coal gangue is calcined at a temperature of 750 ° C for 10 minutes, and the 28d compressive strength of coal gangue aggregate concrete is about 39% higher than that2024年9月1日 As a byproduct of coal production, coal gangue, if not handled properly, will pose an important hidden danger to the environment and safety Using underground intelligent coal gangue sorting technology can increase efficiency, protect the environment, and enhance safety, which is essential for achieving efficient and ecofriendly coal productionResearch and prospect of underground intelligent coal gangue