How much investment is needed to process quartz sand and limestone

Limestone Quarrying and Processing: A LifeCycle Inventory

Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Figure 22019年4月12日 CDE Global estimates that the cost of constructing the modular two million tonne per annum processing plant will be about $182 million According to VRX, estimates costs for the plant feeder, water supply and Cost estimates revealed for sand processing plantSandstone is a sedimentary rock comprised of lithified sands Most is primarily quartz sand or a mix of quartz and feldspar sands in conjunction with interstitial cementing materials including A LifeCycle Inventory of Sandstone Quarrying and Processing2023年7月1日 Based on the report from the OneStop Integrated Service Investment Office (2019), in general, investment study in the exploitation of quartz sand in situ deposits to supply Turning waste into profit: Circular economic optimization of quartz

Quality Requirements of Quartz Sand in the Building Industry

Quartz sand is a valuable raw material for the building and construction industry Individual branches demand very different sand qualities The requirements of the following products are 2023年7月1日 This paper analyzes whether the mining industry can apply circular economy principles in its investment, using two business scenarios of the circular economy Scenario A Turning waste into profit: Circular economic optimization of quartz 2024年5月30日 In IOTA8 quartz sand, the total metallic impurity content has been decreased to below 10 mg/kg, while the SiO 2 content reaches as high as 999995% This highpurity quartz sand, used in the production of premium Advanced Processing Techniques and Impurity 2020年6月22日 This paper provides an insightful review on the processing of highpurity quartz, covering the analytical techniques, separation methods, and the critical procedures used to A Critical Review on the Mineralogy and Processing for High

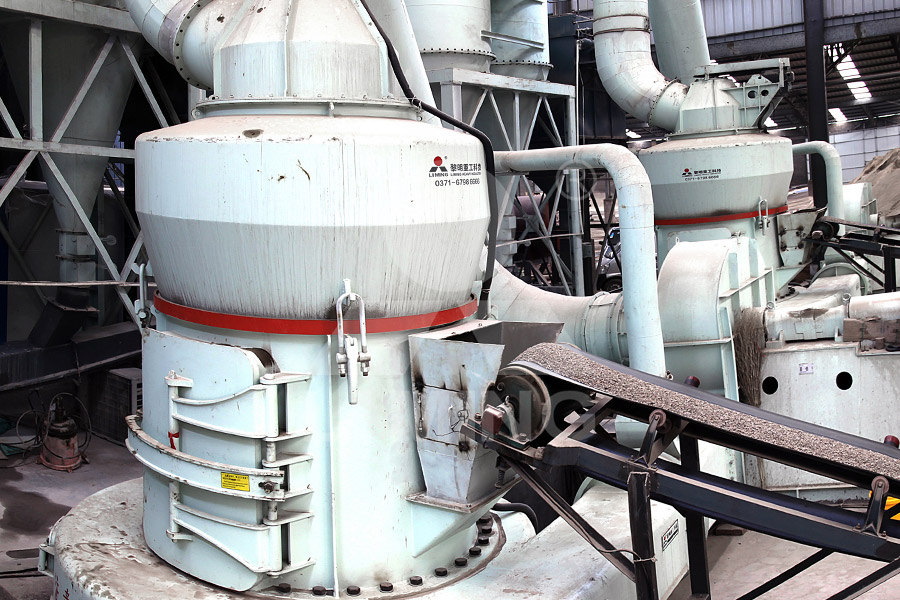

How to Deploy a Quartz Sand Production Line by Ch

Deploying a quartz sand production line is a strategic investment that can yield significant returns By carefully planning and executing each stage of the production process, businessesBefore making investment, it is necessary to master some quartz sand production principles, which will be of great benefit to future investments Below, we have listed detailed steps to help you understand how to make quartz sand How Is Quartz Sand Applications and How to Make Quartz Sand2022年6月10日 To keep sharp edges you need to work each face of the crystal separately Always wet sand your quartz It’s not worth trying to do it dry and spreading the dangerous dust even more Make sure your mask is on properly How To Cut and Polish Quartz Crystals (StepByStep Sand Casting Process Metalworkers widely use sand casting technology because it is suitable for casting steel, iron, brass, and most nonferrous alloys—as well as for final products that weigh anywhere from less than a pound to thousands of pounds The sand casting process begins with creating a sand moldInvestment Casting vs Sand Casting — What’s the Difference?

.jpg)

High Purity Quartz Sand: What Is It Used for and How

2023年4月11日 Quartz sand concentrate: The SiO 2 content in the concentrate is 9962%, and the Fe 2 O 3 content is 00062% Picture 2 Quartz sand purification process of a company in Fengyang, Anhui 3 Roasting, water 2023年6月27日 With the continuous development of various industries, the demand for quartz sand continues to increase, so building a quartz sand beneficiation plant is a very promising investment Before we have talked about the 7 steps to build a quartz sand processing Plant How Much does It Cost to Build A Quartz Sand Beneficiation Plant?Limestone is a very common sedimentary rock consisting of calcium carbonate (more than 50%) It is the most common nonsiliciclastic (sandstone and shale are common siliciclastic rocks) sedimentary rockLimestones are rocks that are composed of mostly calcium carbonate (minerals calcite or aragonite) Carbonate rocks where the dominant carbonate is dolomite (calcium Limestone Sedimentary rocks Sandatlas4 天之前 Quality frac sand is key for the hydraulic fracturing process, but how is frac sand used during drilling? Read on to learn more (314) 5000595; Contact Us; and the steps of the process Here’s everything you need to know: Understanding Frac Sand Frac sand is quartz sand material with high purity and durability, typically Frac Sand in the Hydraulic Fracturing Process Pontotoc

.jpg)

How much does the quartz sand plant need to invest?

This quartz sand production line is composed of vibrating feeder, jaw crusher, TCL straight through centrifugal crusher (sand making machine), vibrating screen and belt conveyor and other equipmentAccording to different process requirements, various types of equipment are combined to meet the different process requirements of customersLimestone 160 lb/ft The shape, size and type of stone all factor into working out how much you need to successfully complete the project If you’re not sure how to calculate volume or cost then scroll down for more information Otherwise, STONE CALCULATOR [How Much Stone do I Need]2023年8月22日 In the realm of manufacturing, casting is a cornerstone process that enables the creation of intricate and complex metal parts Investment casting and sand casting are two prominent methods within this realm, each offering distinct advantages and drawbacks This comprehensive article endeavors to explore and dissect these differences, shedding light on Investment Casting vs Sand Casting: Progress, Material, Surface 2023年10月21日 Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO3) in the form of mineral calcite or aragoniteIt is one of the most common and widely distributed rocks on Earth, with a wide range of uses in various industries and natural settings Limestone forms through the accumulation and compaction of marine organisms, primarily the Limestone Types, Properties, Composition, Formation, Uses

How Limestone is Formed, Where Does it Form? –

Time and Stability: Limestone formation is a slow process requiring millions of years of accumulation and preservation Stable geological conditions are crucial for this process to occur efficiently By understanding these factors and 2024年6月18日 Quartz sand is one of the common raw materials in the sand and gravel industry How to make quartz sand into qualified sand and gravel products is a concern of many customers Today we will take a look at the Quartz sand production process LZZG2024年1月31日 Investment castings can be held to much tighter tolerances than sand castings or forgings: close dimensional tolerances down to + – 015mm/25mm can be achieved through investment casting Exceptional surface finish Investment casting gives a very smooth finish thanks to the ceramic mould, typically offering 16 Ra to 32 Ra surface finish as An Overview of Investment Casting and its Key BenefitsLimestone, or calcium carbonate, is the common rock found throughout the world Oldest and perhaps slightly overlooked, limestone is very much part of our everyday life It may be hidden with your walls, in the water you drink, the food you consume, or in the cosmeticsLimestone Formation, Composition, Types and Uses Earth Eclipse

Sandblasting 101: Everything You Need to Know MachineMFG

2023年8月15日 Sandblasting (referring to rust removal or plating on metal surfaces) uses quartz sand, ordinary quartz sand, and refined quartz sand: with high hardness and good rust removal effects, the physical and chemical indicators are as follows: SiO2≥98—998%, Fe2O3≤006—0005%, refractoriness of 17501800℃, uniform particle appearance, Investment casting is renowned for its combination of precision and fine detail while avoiding the major upfront costs of die casting The Investment Casting Process Castings can be made from an original wax model (the direct method) or from wax replicas of an original pattern that need not be made from wax (the indirect method)Investment Casting: Definition, Process, Pros and Cons2019年8月26日 Quartz sand purification is a difficult separation process to remove impurities from quartz sand and obtain refined quartz sand or high We have no interest in cooperation and investment! 82476 ABOUT US About Us Our Partners; This means that every time you visit this website you will need to enable or disable cookies again Quartz Processing Equipment, Process Flow, Cases JXSC Machine2021年11月15日 Were it not for the thin sheath of water and carbonbased life covering it, our home planet would perhaps be best known as the “Silicon World” More than a quarter of the mass of the EaMining And Refining: Pure Silicon And The Incredible Effort

Limestone Calculator

Limestone has a lot of uses in various industries We cut limestones into bricks, pavers, or tiles in the construction industry or pulverize them for cement productionCheck out our cement calculator to learn more about cement We can also crush limestones and use them as aggregates to mix with cement and sand for different concrete and mortar mixes2023年12月28日 Overview of Each Casting Process Sand Casting Sand casting is a process as old as metalworking itself, with roots stretching back thousands of years It involves the creation of a sandbased mould into which Choosing the Right Casting Process: Sand casting vs2022年9月14日 To make glass, quartz sand, also known as silica sand, is heated above 3,090 degrees Fahrenheit until it melts into a clear liquid The glass industry requires fossil sands, river sand, lake sand, and wind sands due to How To Make Glass From Sand Learn Glass Blowingprocess flow diagram for limestone processing operations 3 list of tables 6 6 table 1 gross energy to produce one ton of limestone products table 2 water consumption for limestone quarrying and processing table 3 lci inputs for limestone quarrying and processing table 4 lci outputs for limestone quarrying and processing table 5Limestone Quarrying and Processing: A LifeCycle Inventory

.jpg)

Limestone Geology is the Way

Recognition of limestone Limestone can be recognized easily thanks to its effervescent reaction with hydrochloric acid (HCl) Calcite and aragonite, indeed, react with HCl diluted in water at 10% producing CO 2, according to the reaction: CaCO 3 +2HCl⇌ CO 2 + H 2 O+CaCl 2 Dolomite also reacts with HCl but at such low dilution (10%), the reaction is very slow and does not 2019年5月11日 Nigeria is often described as a country endowed with abundant mineral resources, including the occurrence of over 40 different solid minerals at approximately 450 locations(PDF) Solid Mineral Deposits and Mining in Nigeria: A Sector in 2019年4月18日 But silicon does not occur naturally in the pure form needed for electronic applications, for which it must contain less than one in a billion nonsilicon atoms The starting material really is sand Not just any sand, but silica sand, specially quarried for this purpose and having concentrations of quartz (silicon dioxide) as high as 95%From Sand To Wafers Semiconductor EngineeringSilica Sand Mining introduces Foundry silica sand is the quartz as the main mineral composition, particle size of 0020 mm to 3350 mm refractory particles, according to the mining and processing methods of different can be divided into artificial silica sand and sand washing, sand washing, selection of natural silica sand such as sand (flotation)Silica Mining Processing Equipment Flow Chart Cases JXSC

.jpg)

Limestone Characteristics, Formation, Texture, Uses, Facts

2024年10月30日 Limestone, sedimentary rock composed mainly of calcium carbonate, usually in the form of calcite or aragonite It may contain considerable amounts of magnesium carbonate (dolomite) as well; minor constituents also commonly present include clay, iron carbonate, feldspar, pyrite, and quartz2021年12月30日 The compressive strength of the concrete was 2680 MPa when quartz residue was used and 292 MPa when limestone was used The quartz residue generated by the venture can be reused as aggregate for (PDF) Quartz Mining Waste for Concrete Production: Environment 2021年10月25日 The water/binder ratio was 05, and the replacement ratio of quartz/limestone was 20% The experimental results showed that adding 20% quartz/limestone to BRC effectively accelerated the carbonation curing process, and the acceleration effect of quartz was more obvious than that of limestoneEffects of cement types and addition of quartz and limestone on 2019年7月9日 In sand casting, the mold has to be split apart to release the castings, so the parting line is more obvious And because the sand is rough, the surface is also relatively rough and requires additional time and cost to Comparison between investment casting and sand

Silicon processing: from quartz to crystalline silicon solar cells

FROM QUARTZ TO METALLURGICALGRADE SILICON Silicon is the second most abundant element in the earth’s crust, second only to oxygen It is naturally found as fairly pure silicon dioxide and as silicates The silicon dioxide is found as huge deposits of quartzite or quartz sand Moreover, many rocks contain quartz crystals2019年9月16日 In this paper, a sustainability framework for global and scalable payment systems is introduced It is based on energy and resource consumption and pollutant classes and is inspired by ISO14040 Why do we burn coal and trees to make solar 2016年4月21日 With investment casting, technicians may need to modify or replace the solid metal pattern, or make new molds for turning out wax versions, which can be a more complicated processWhat’s the Difference Between Investment Casting and Sand 2022年6月18日 Usually, common mineral impurities in quartz sand, such as feldspar, mica and other silicate minerals, are mostly removed by flotation process Quartz sand flotation can not only remove mica and feldspar minerals, but also flotation of phosphorus, iron and other minerals, and can also remove secondary iron mixed in crushing and grindingUltimate Guide of Silica Sand Processing Miningpedia

.jpg)

VALUE ADDITION TO THE NATURAL RESOURCES AND MINERALS

2023年3月24日 All content in this area was uploaded by National Science And Technology Commission Nastec Sri Lanka on Apr 04, 2023However, a different set of data and a deeper understanding are needed to make more efficient use of limestone as a cement raw material Further, there are certain other naturally occurring raw materials like limestone that are also used in cement manufacture, although in smaller quantities and only when required, and they include clay, bauxite, iron ore, sandstone, and so onBasics of mineral resources for cement productionLimestone is therefore an essential part of the batch However, limestone comes in two basic types: high calcium and dolomitic The difference between the two relates to the relative magnesium (Mg) content Highcalcium limestone is almost entirely CaCO Limestone in Glassmaking: What You Need to Know Carmeuse2012年4月28日 Quartz sand processing equipment must be high quality to ensure the purity of the sand, which is needed for different applications There are two main types of quartz sand production lines dry and wet The dry line uses jaw crushers, impact crushers, sand makers, and screens to process the quartz into sandQuartz sand production line and machinery PDF SlideShare

.jpg)

Investment Casting Vs Sand Casting: Differences and Advantages

Investment casting and sand casting are reliable, costeffective, quality manufacturing processes that allow for flexibility in budgets, timelines, and design When manufacturers choose casting to mass produce complex parts, they have the option of choosing investment casting, which is also called the lost wax process, or sand casting The following is a breakdown of the two distinct