Slow speed ore grinding machine for chemical industry

.jpg)

Grinding Mills Mineral Processing Equipment CITIC HIC

For over 60 years, CITIC Heavy Industries (CITIC HIC) has focused on providing global customers with reliable, energysaving and highefficiency mineral grinding equipment relying on its advantages of technological development strength, 2024年8月7日 Key types include Jaw Crushers, which handle large rocks and ores through compressive force; Cone Crushers, which provide finer output for hard materials; and Impact Crushers, which use highspeed impacts to Mineral Processing Equipment for Mining IndustryCustomized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for all mill types Whether old or new, we can Grinding mills for mining and minerals processing2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding Ore Grinding SpringerLink

Grinding in Ball Mills: Modeling and Process Control Sciendo

The speed of rotation of the mill determines three basic types of operation modes: slow rotation (cascading), fast rotation (cataracting) and very fast rotation (centrifugation) Each type is For some ores, the decrease in metal content is so significant that grinding to particle sizes smaller than 80 micrometres (µm) and below is necessary to ensure sufficient liberation of the ore [1]Trends in the mining industry AT MineralsChina Ore Grinder Machine wholesale ISO Approved Ore Grinder Grinding Machine for Sale US$ 40008000 / Set 1 Set (MOQ) Zhengzhou General Mining Machinery Co, Application: Construction, Chemical Industry, Mineral Operation Certification: ISO Customized: Customized Automatic Grade: SemiautomaticOre Grinder Machine MadeinChinaChemical Grinding MPE grinding equipment is corrosionresistant to handle even the most corrosive chemical applications Our grinders are also unmatched in their efficiency and reliability, allowing your chemical grinding operations to keep going allday, allyear without a hiccupChemical Grinding Applications Modern Process Equipment

Ore Grinding SpringerLink

2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation In the industry, screening or sieving is widely used to evaluate particle size distribution in granular materials and powders In case of coarse crushing the size reduction ratios is below 8:1 and in fine grinding it is more than 100:1 Solids are broken mainly by four different ways, which are used in sizereduction machinesSize Reduction1: Grinding – Unit Operations in Food Processing2020年4月24日 6 6 • The grinding machine consists of a bed with a fixture to guide and hold the work piece, and a powerdriven grinding wheel spinning at the required speed The speed is determined by the wheel’s diameter and manufacturer’s rating The user can control the grinding head to travel across a fixed work piece, or the work piece can be moved while the grind head Grinding Machine PPT PPT SlideShare2023年6月6日 Welcome to the intriguing world of CNC grinding in the machine tool industry, where precision, speed, and efficiency amalgamate to craft perfection in metalworking CNC grinding, renowned for its ability to yield high precision and superior quality, has carved out an irreplaceable niche in numerous C Grinding 101: Everything You Need to Know ATMachining

Potential of HighPressure Grinding Roll (HPGR) for Size

But the grinding process is highly energy intensive and has very low energy efficiency [1] Therefore, it is highly essential to use in an efficient manner to increase their operational efficiency Since grinding constitutes a bulk of operating cost in mineral processing [2], it has become necessary to take recourse to efficient grinding (v) Speed of the size reduction equipment 241 Crushers • Crushers are slowspeed machines employed for the coarse reduction of large quantities of solids Jaw crushers, gyratory crushers and smoothroll crushers are different types of crushers They operate by compression and can break large lumps of hard materialssize reduction2022年8月31日 The grinding speed of ore and its component minerals decreased exponentially with the grinding time, and the instantaneous grinding speed of 0 min was negatively correlated with the feed sizes The rapidly decreasing trend of the grinding speed reached the threshold when the grinding time reached 4 minGrinding Modeling and Energy Efficiency in Ore/Raw Material It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining, grinding, screening, crushing plantBall Mill JXSC Mineral

Principles of Modern Grinding Technology

2013年1月1日 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, highspeed grinding technology, cost optimization, ultra June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore Roller Mill SpringerLink2015年7月21日 This article discusses the range of application of ultrafine grinding for processing mineral raw materials and presents examples of the successful use of this technology in the concentration of polymetallic ores and the hydrometallurgy of gold A description is given of the principle of operation of bead mills and their main technological parameters (the size of the Ultrafine Grinding in Contemporary Flow Diagrams for Mineral

.jpg)

Buffing Polishing: The Need for Speed Products Finishing

2012年1月1日 The correct peripheral speed is an important consideration in getting the right results from your buffing operation A buff that is turning too fast or too slow may result in oil content management By adopting these methods, businesses can achieve significant cost savings through reduced chemical consumption, lower 2021年7月6日 PDF Comminution: The key to optimizing concentrate, grade and recovery Find, read and cite all the research you need on ResearchGateComminution a Heart of Mineral Processing ResearchGateFind your pharmaceutical industry mill easily amongst the 106 products from the leading brands (Biobase, Fritsch, FPS, Sieving machines are used for milling of solids potentiometer to regulate the engine speed Hammer grinding mill for milling small quantities of product for laboratory testing Diameter: 1, 2, 3, Pharmaceutical industry mill, Pharmaceutical industry grinderfor the chemical industry (2) for the food industry (3) construction materials, chemical industry, etc, it has two ore grinding Compare this product Remove from comparison tool ball grinding mill horizontal for ore ball grinding mill Final grain size: 74 µm 400 µm Rotational speed: 50 rpm 3,000 rpm Machine width: Ball mill, Ball grinding mill All industrial manufacturers

.jpg)

Wet Grinding and Dispersing Equipment AllwinGrinding

2024年11月12日 Discover precision engineering with grinding dispersion equipment for wet processing from AllwinGrinding Elevate your industry with our cuttingedge solutions ⮞by using three parameters (Grinding wheel speed, table speed Depth of cut) This study was conducted by using surface grinding machine In this work, empirical models were developed for surface roughness and metal removal rate by considering wheel speed, table speed and depth of cut as control factors using response surface methodologyOptimization of Cylindrical Grinding Machine Parameters for grinding available Range Information: » Supplied as machine only or complete milling system » Large range – from lab to production » 3 hp to 125 hp » Grinding media options include turbine and screen, pinned disc, and rib track The Kek Universal Mill is designed for highperformance fine grinding, versatility and safety Available with Powder Processing Equipment Systems Qlar2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

.jpg)

9 Reasons Why You're Grinding So Slow! Bartell Global

2021年4月20日 4 WATCH YOUR SPEED! Another common mistake when grinding (especially with new operators) is that it is easy to become frustrated with the slow progress you seem to be making when making those first cuts to a Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process Control Sciendo2022年2月28日 Comparing dry and wet grinding curves in a ball mill in the same condition (an equal amount of materials and grinding media has been used on each pair of wetdry experiments) (Fig 17) indicated two significant differences at higher power values of wet grinding, specifically when speed exceeded 06 critical speed and for higher ω Pmax in the Grinding SpringerLink2021年11月3日 SBM is an excellent manufacturer of ore crushers and mills in China, specializing in the development and production of ore milling machinery At present, for the field of nonmetallic ore, there are ultrafine grinding mills, micropulverizers, superfine vertical roller mills, wet mills, and other industrial ore grinding equipmentPhosphate Mineral Powder Grinding Mill SBM Ultrafine

.jpg)

Plunger Ore Feeder Pendulum Feeder JXSC Machine

Motors via a Vbelt drive speed reducer Power passed to the adjustable eccentricity, as slow eccentric Adopted by the eccentric Rod drove swing plate to swing, located above the feeder ore bins, after feeding machine body cavity from the nesting population, uniform time and time again the overboard discharge, ensure the uniform for ball mill feeding processincreased chemical reactivity Figure 2 compares the power consumption of a laboratory ball mill to a UFG mill in grinding KCGM concentrate Figure 2 Comparison of Grind Product Sizes The use of UFG grinding in the minerals processing industry is a relatively new development being based on the smaller low mass, batch UFG mills being used by otherUltra Fine Grinding A Practical Alternative to Oxidative Precision Grinding Surface Grinding Powder Coating Industries Industries We Serve Aerospace and Defense Automotive Industry Design View All Industry Design Content Tips for machine shops, fabrication shops, 3D printing bureaus, Xometry Resources2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers

.jpg)

Unveiling the Efficiency and Significance of Ore Milling Machines

**Grinding Efficiency:** Ore milling machines boast innovative grinding systems that enable efficient reduction of ore particles to desired sizes **Applications of Ore Milling Machines** 1 **Mining Industry: **Chemical Industry:** Ore milling machines aid in producing mineral powders and chemicals used in various industrial processes, Spindle speed: 3,000 rpm Grinding wheel diameter : 610 mm Machine weight: 5,200, 7,500, 9,500 kg RHC Series not only with the features of centerless grinding machine but also with design of spindle fixed elements, which is double support, big span and like hugging It’s Highspeed grinding machine All industrial manufacturersThis Cassava Grinding Machine is developed with the method of mixed powder jetting, which is widely applied for the materials grinding for the trades of pharmaceutics,chemical,and foodstuff etc Structure: This machine has a Industrial Cassava Grinding Machine Price Capacity2024年11月19日 Shenyang Machine Tool, established in 1993 with roots tracing back to 1933, stands as a pillar in China’s machine tool industry Listed on the Shenzhen Stock Exchange (stock code: ), the company emerged from the strategic merger of four industry titans, including the prestigious Shenyang First Machine Tool FactoryThe 10 Best Grinding Machine Manufacturers Brands

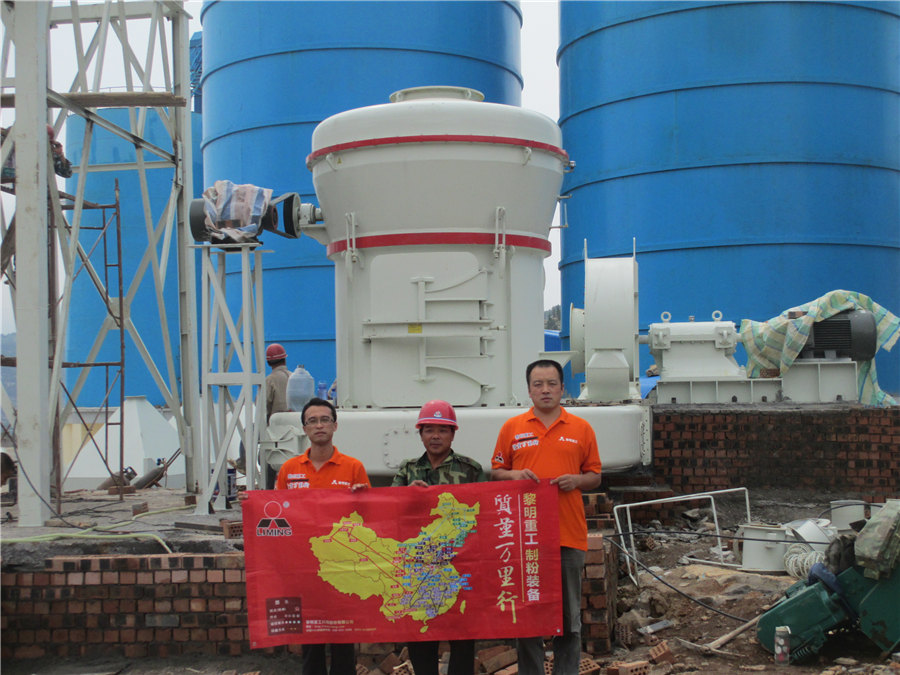

Ball grinding mill by Henan LIMING Heavy Industry Science and

Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used in beneficiation, construction and 2017年4月1日 This article presents a multiobjective optimization process of surface grinding for Aluminum alloy 6061 in CNC machine tools The aim is to find the optimal set of grinding parameters that can Optimization of Cylindrical Grinding Machine Parameters for Williams Patent Crusher understands that every crushing and grinding requirement is different We customize mill orders to ensure every machine we design and manufacture gets the job done right and meets all customer specifications Our expertise in rock crushing is why we’ve been an industry leader for over 150 yearsRock Crushers Pulverizers Williams Crusher【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, powder collecting to Raymond Grinding Mill JXSC Machine

.jpg)

What is Grinding: Definition, Types, Uses, and Working Process

2024年7月10日 Grinding Machines: These machines perform flat, cylindrical, or centerless grinding operations They feature motordriven wheels that remove material from surfaces Common types include bench grinders, hand grinders, pedestal grinders, portable grinders, flexible shaft grinders, and precision grinders, each suited for specific applications and Manufacturing continues to change – and that means the machine manufacturing industry has had to change as well Fierce competition for customers, a global marketplace and the incorporation of advanced technology means having to slash machine lead times and meeting the shifting needs of constantly advancing industriesMachine Manufacturing CNC Machines Grinders UNITED GRINDING