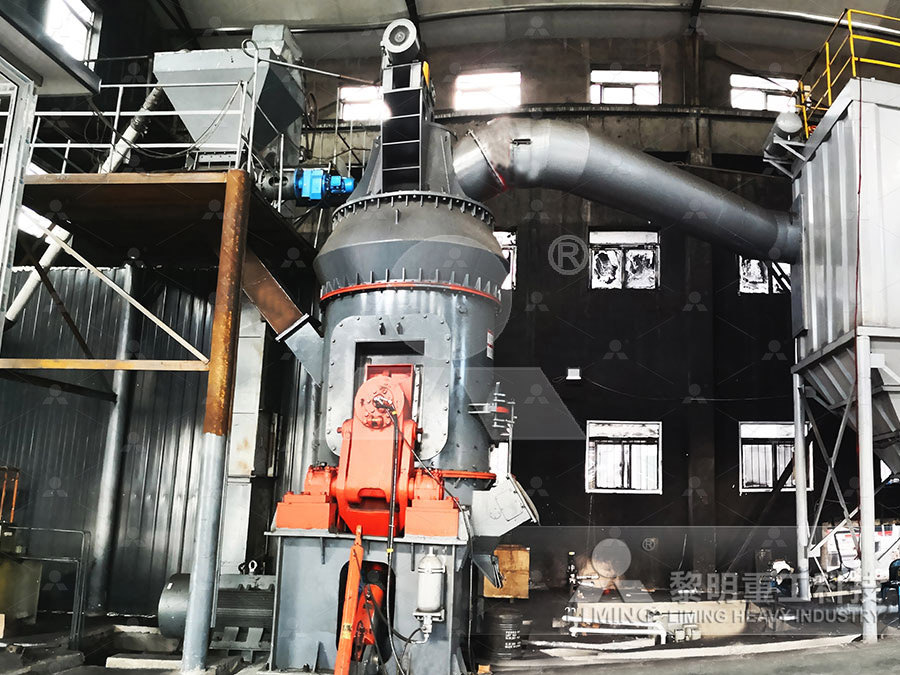

Carbon black grinding mill

.jpg)

Recovered Carbon Black Hosokawa Alpine

The carbon black granules are precrushed and prepared for the fine grinding stage using a magnet/metal separator For fine grinding, Hosokawa Alpine primarily uses the TDG fluidised bed opposed jet mill with integrated dynamic HGM carbon black grinding mill/grinder mill consists of bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure Carbon black grinding mill/grinder millAfter pyrolysis, an intermediate process step is required The carbon black granules are precrushed and prepared for the fine grinding stage using a magnet/metal separator For fine grinding, Hosokawa Alpine primarily uses the TDG fluidised bed opposed jet mill with integrated dynamic highperformance classifierRECOVERED CARBON BLACK Hosokawa AlpineCarbon black is a light, loose and fine black powder that contains carbon substances It can be used as a black dye to make ink, paint, rubber material, etc Carbon black ultrafine grinding mill is also called (threering fourring) medium Carbon Black Ultrafine Grinding Mill

Carbon Black Hosokawa Micron Powder Systems

The newly developed MikroeACM Carbon Black Air Classifier Mill greatly transcend the performance of conventional hammer mills It offer superior grit reduction capabilities, are more energy efficient and have lower costs of 2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill independently developed and produced by Tire pyrolysis carbon black deep processing grinding equipment2021年8月31日 When grinding carbon black with SBM ultrafine grinding mill machine, a powder modifier can also be added directly to mix and grind with the material The finished powder after grinding is the modified powder But the quality of powder modified by powder surface coating machines will be betterCarbon Black Ultrafine Powder MillCarbon black grinding mill/grinder mill Type : HGM carbon black grinding mill/carbon black grinder mill Capacity : 130 t/h Application field : Designed for carbon black super fine grinding, to solve the problem of cabon black light character ( * Please click on the more application fields"Free Consultation")Carbon black grinding mill/grinder mill

.jpg)

Efficient Carbon Black Milling Equipment Pulva

Our pulverizers are available in a range of sizes and power capabilities, so you can choose one that meets your business needs for a carbon black grinding mill The smallest model — the Pulvette PulvaSizer 3/41 1/2 HP — is perfect for pilot plants and smaller manufacturersThe internal parts and geometry of the grinding and classification sections have been modified to meet the particle characteristics and quality specification of carbon black The internal recirculation working principle of the air classifying mill has been replaced with our patented external coarse recycle systemCarbon Black Grit Reduction Mill Hosokawa Micron Powder 2015年5月1日 The Mikro® EACM is specially designed for the grit reduction of carbon black It is a hybrid product that possesses many of the same design features of the Carbon Black Grit Reduction Mill YouTubeNETZSCH offers machines which meet the specific requirements of recovered Carbon Black to achieve the highest performance with the finest cuts Grinding Dispersing Protein Shifting and Enrichment with the use of Dry Grinding and Classifying Event 10122024 – 12122024 Conference United States, CGS Fluidized Bed Jet MillRecovered Carbon Black NETZSCH Grinding Dispersing

.jpg)

Türkiye Pyrolysis Carbon Black Grinding Line Project

2023年12月14日 In 2018, a Turkish customer contacted SBMmill for the first time as a middleman and purchased equipment for the grinding link in the cracked carbon black production line and exported it to South Korea The 2022年11月9日 Home » Three Roll Mill For Carbon Black|High Grinding Dispersion Three Roll Mill For Carbon Black|High Grinding Dispersion Previous Next Three Roll Mill Three roll mill is the main equipment for grinding colored carbon black, as it is used extensively in rubber, plastics, paints, and inks, and some carbon black is addedThree Roll Mill For Carbon Black|High Grinding DispersionCarbon Black Powder Grinding Mill Finished Size: 1502500 mesh Processing Ability: 145 t/h Max Feeding Size: 1025 mm Application: Charcoal、Talc、Calcium Carbonate 、Limestone 、Kaolin、BentoniteCarbon Black Powder Grinding Mill in UzbekistanWorking principle of carbon black ultrafine powder grinding mill Carbon black ultrafine powder grinding mill mainly consists of main unit, classifier, powder collector, dust cleaner, blower, muffler, soundproof room, crusher, bucket elevator, storage hopper, and vibrating feeder After crusher by hammer crusher, the large materials become small ones and are sent to storage Carbon black ultrafine powder grinding mill

.jpg)

Green Oxidation of Carbon Black by Dry Ball Milling

2022年11月22日 A sustainable and green method is presented in this paper to produce highly oxidized carbon black using dry ball milling The mechanical energy by colliding milling balls is able to easily break and build chemical bonds providing new oxygenated functional groups The reaction is performed in the presence of air and in solventfree conditions achieving, for the The carbon black ball mill grinder machine is a device that destroys the raw materials to make the particles smaller after being mined or broken into small pieces As can be understood from its name, the carbon black ball mill is equipped with steel balls in a closed cylinder , Through the rotation of the cylinder, the steel ball falls from a high place and collides with the material to be Ball Mill Grinder Machine For Carbon Black PowderLecture Content:This webinar gives an overview of the state of the art of jet milling technology and tells about advantages of optimized systems with air andEfficient Fine Grinding of Recovered Carbon Black withGrinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low consumption, easy use +17Grinding MillIndustrial Grinding Mill, Ultrafine Grinding Mill

.jpg)

New life for old tiresCarbon black powder mill SBM Ultrafine

2023年7月17日 Carbon black powder mill Small model endows large production capacity, old tires are given new life, and SBM uses service to promote cooperation in Malaysia +17 [ protected] language The small model grinding mill creates a large production capacityOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial 2009年10月16日 The tests were made using a NETZSCH Labstar Laboratory grinding mill We premixed NegroMex carbon black, a pigment typically used for rubber applications This is a coarse carbon black that is difficult to grind to a fine particle size Fine Grinding of Carbon Black Ink WorldOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial

.jpg)

Optimisation and analysis of bead milling process for preparation

grinding of pigment Generally, high viscosity dispersions are not easy to grind using a labscale A method to effectively grind very high viscosity premixed dispersions of carbon black on a bead mill 2 A method to ascertain the effectiveness of a bead milling operation for preparation of high viscosity dispersionsPrecision Jet Milling with Proprietary “I” Mill Design; Mechanical Milling; 05 are among the hardest known materials, and are used as abrasives in cutting and grinding tools Carbon black is used as the black pigment in printing ink, automotive finishes, and laser printer toner Carbon black is also used as a filler in rubber products Carbon Micronization : Jet PulverizerHowever, carbon black’s production process has a tendency to leave behind a lot of grit in the carbon black Hosokawa Micron Power Systems has many applications capable of classifying and grinding down the grit, resulting in the production of carbon black These applications include: Mikro Pulverizer Hammer and Screen MillGrit Reduction of Carbon Black Hosokawa Micron Powder SystemsSpecially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black grinding, carbon black refining equipment, carbon black grinding mill, carbon black pellet making machine, carbon black briquetting machine, oil distillation machine, etccarbon black processing machine, tyre pyrolysis carbon black grinding

carbon black processing machine, tyre pyrolysis carbon black grinding

Waste Tyre Pyrolysis Plant for Carbon black Application field:Waste Tyre Pyrolysis Plant to make pyrolysis carbon black, oil, fuel, etc Type:Waste Tyre Pyrolysis Plant for Carbon black Capacity:120 tone per furnace Live Chat Carbon black grinding mill/grinder mill Application field:Designed for carbon black super fine grinding, to solve the problem of cabon black light characterCarbon Black Grinding Systems: We provide advanced grinding systems specifically designed micro pulveriser air classifying mills for carbon black These systems utilize specialized grinding mills and equipment to break down carbon black particles into finer sizes, enhancing surface area and improving dispersion in different applicationsBest Carbon Black Processing Plant Rieco Enquire Now2018年6月1日 Carbon blacks of the same particle morphology may vary considerably in their ease of dispersion Role of dispersants in kinetics and energetics of stirred ball mill grinding Int J Miner Process, 47 (1) (1996), pp 141152 (1996/06/01) View PDF View article View in Scopus Google Scholar [4]Optimisation and analysis of bead milling process for preparation cialty Carbon Black content in the mill base can also be increased Figure 1 Recommended Concentration of Specialty Carbon Black in solventborne Coatings in Relation to the Particle Size of the Specialty Carbon Blacks Viscosities were measured with Shear Rates of 800 s1 with a Cone and Plate 1 viscometer at 1 ° Contact Angle (at 23 °C)4Short Dispersion Guideline for Specialty Carbon Blacks in

What are The Differences Between Carbon Black and Graphite?

Introduction to Carbon Black and Graphite Carbon Black Carbon black is an amorphous form of carbon Light, loose and very fine black powder, with a very large surface area, ranging from 10 to 3000m2/ g, is the product of incomplete combustion or thermal decomposition of carboncontaining substances (coal, natural gas, heavy oil, fuel oil, etc) under the condition of 2024年7月16日 1about carbon black grinding mill 11 the importance of carbon black grinding mill Carbon black grinding mill plays a crucial role in industrial production, such as: it's usually be used in crushing carbon black particles, improving Carbon Black Grinding Mill for Fine Carbon Black Powder 2003年12月1日 The effects of bead mill size and dispersant chemistry on particle size reduction for difficulttodisperse carbon black pigments were investigatedFine Grinding of Carbon Black ResearchGatestep 2: pyrolysis carbon black grinding mill production linecarbon black grinding mill Shanghai Clirik Machinery has been in this field over 8 years, designed and produced HGM carbon black grinding mill, which are best for carbon black micro powder processing 1carbon black processing machine, tyre pyrolysis carbon black grinding

Short dispersion guideline for specialty carbon blacks in coatings

2024年2月21日 Total concentration of specialty carbon black in the mill base [%] 23 21 19 17 15 13 11 9 7 5 HCG, HCG (o) HCFa Mill base for an acrylate / melamine system; viscosity of the acrylate binder solution: 276 mPas Specialty carbon grinding carbon blacks OECTI 137503/ 2023 2 OECTI 137503/ 2023Carbon black, also known as carbon black, is an amorphous carbon Light, loose and very fine black powder with a very large surface area ranging from 10 to 3000 m2/g It is a carbonaceous material (coal, natural gas, heavy oil, fuel oil, etc) that undergoes incomplete combustion or thermal decomposition under conditions of insufficient aircarbon black grinding machine, carbon black grinding mill, carbon black Pin Type Grinding Bead Mill for Pigment, Ink, Carbon Black, Find Details and Price about Grinding Mill Bead Grinding Machine from Pin Type Grinding Bead Mill for Pigment, Ink, Carbon Black Shanghai ELE Mechanical Electrical Equipment Co, Ltd Home Tools Hardware Abrasive Grinding Grinder;Pin Type Grinding Bead Mill for Pigment, Ink, Carbon BlackCarbon Black Grinding Mill According to the aforementioned properties, a smaller particle size of conductive carbon black is beneficial for enhancing its conductivity However, it is also important to ensure that the particle size falls within an appropriate rangeWhat is The Role of Carbon Black in Lithium Batteries?