How to make money in fly ash processing plant, 3889215

.jpg)

Fly Ash Processing Plant Cement Equipment

The fly ash processing plant constructed by AGICO Cement is highly automated and mechanized, with low investment, high profit, simple structure and easy operation, which helps each region realize reasonable waste recycling and Safely converting the collected Fly Ash and disposing it through our Thermal Processing equipment is critical to mitigate the environmental impact By embracing sustainable practices and investing in advanced processing Fly Ash Production Process and Industry Trends Heyl 2023年8月16日 Fly ash is a fine powder that is a byproduct of burning pulverised coal in electric generation power plants It’s one of the most common kinds of waste produced by fossil fuel combustion Here’s how it’s formed and Fly ash processing: Tailored solutions for reclaimed fly 2021年9月1日 Fly ash can be modified or transformed into new materials for heavy metal ions adsorption The high content of Al 2 O 3 and SiO 2 in class F fly ash make it suitable for Fly ash properties, characterization, and applications: A review

Fly Ash Processing and Equipment to Collect Fly Ash

Because of coal fly ash’s composition, it’s become a valuable resource rather than a waste byproduct from coalbased energy production Yet, to harness its properties, fly ash must be properly processed, which involves proper drying Fly ash is a fine powdery substance that scatters or flies from coal combustion chambers, mostly in thermal power plants Emission control devices collect this flying ash, some of which include scrubbers, cartridge dust collectors, How the Fly Ash Industry is Growing Heyl PattersonJAYCEE offers ‘Total Ash Management’ solutions to coalfired thermal power plants to help them recycle and utilize all byproducts such as Fly Ash, Furnace Bottom Ash and Pond Ash With a partnership driven, valuesharing approach, Operations: Operated Own Processing and PackingWhat are Fly Ash Bricks? 1 Fly Ash 2 Sand 3 Sludge Lime 4 Gypsum 5 Grit 4 MM to 8 MM 6 Crusher Dust 0 MM 7 Cement 1 Mixing the Raw Materials 2 Moulding 3 Curing 4 Drying 5 Sorting and Stacking 1 Ecofriendly 2 How Are Bricks Made Fly Ash Bricks Manufacturing

.jpg)

Fly Ash Storage: Obstacles and Solutions to Handling Fly Ash

2020年5月13日 In this article, we will review the reasons why fly ash containment is important, the challenges that come with containing fly ash and solutions on how to better contain, store 2002年1月1日 Tomato plants (Solanum lycopersicum L) were developed in soils with different fly ash (FA) amendments (25, 50, 75, 100% FA) to measure the effects of FA on metal accumulation , chlorophyll Impacts of flyash on soil and plant responsesThere is good demand for fly ash bricks The awareness among the people is required and also at the same time the government has to give some special incentiHow to make fly ash Fly ash bricks manufacturing Cyclone furnaces: These produce the least amount of coal fly ash, composition of which is between 70 to 80 percent fly ash and 20 to 30 percent molten bottom ash Wetbottom boilers: Also known as a slagtap furnace, these produce Fly Ash Processing and Equipment to Collect Fly Ash

Comprehensive Extraction of Silica and Alumina from Coal Fly Ash

2023年11月30日 Coal fly ash (CFA) is an increasingly prevalent byproduct that necessitates more resourceful and ecofriendly processing methods Extracting aluminum from CFA is a crucial aspect of promoting sustainable development in the alumina industry In this paper, a technique for comprehensive extraction of silica and alumina from circulating fluidized bedbased CFA is 2011年6月25日 One of the major sources of Cr(VI) contamination is fly ash derived from coal combustion in thermal power plants (Gianoncelli et al, 2013; Mohanty and Patra, 2015; Verma et al, 2016)Fly ash from thermal power plants Waste management and overview2022年1月1日 Request PDF Fly Ash Cenosphere: Characterization, processing, and properties Fly Ash Cenospheres (FACs) are among the most valuable byproducts obtained from the burning of coal They are Fly Ash Cenosphere: Characterization, processing, and propertiesJAYCEE owns and operates South Asia’s biggest, independent Fly Ash processing plant with a capacity of 12 million tons per annum And is also the first player to obtain CE quality certification for Fly Ash in India case studies; news; sustainability How We Do ItOperations: Operated Own Processing and Packing JAYCEE

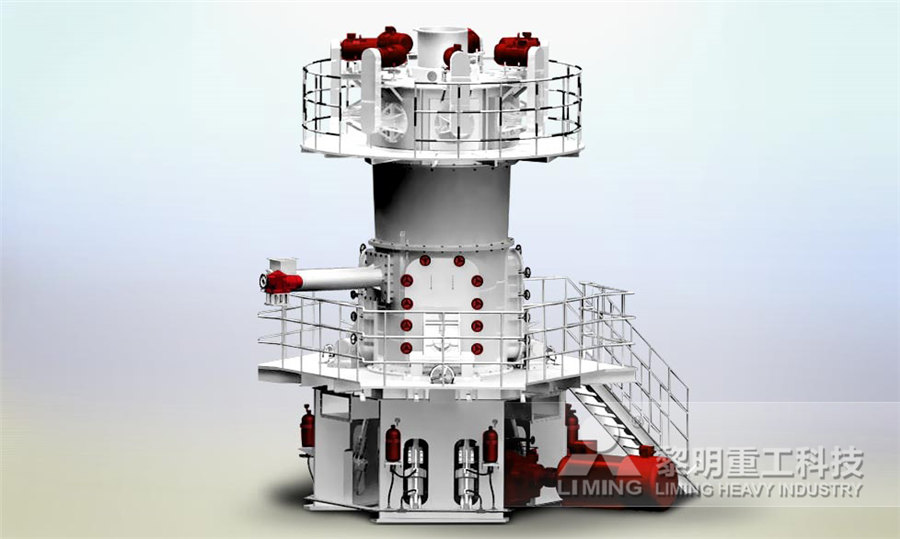

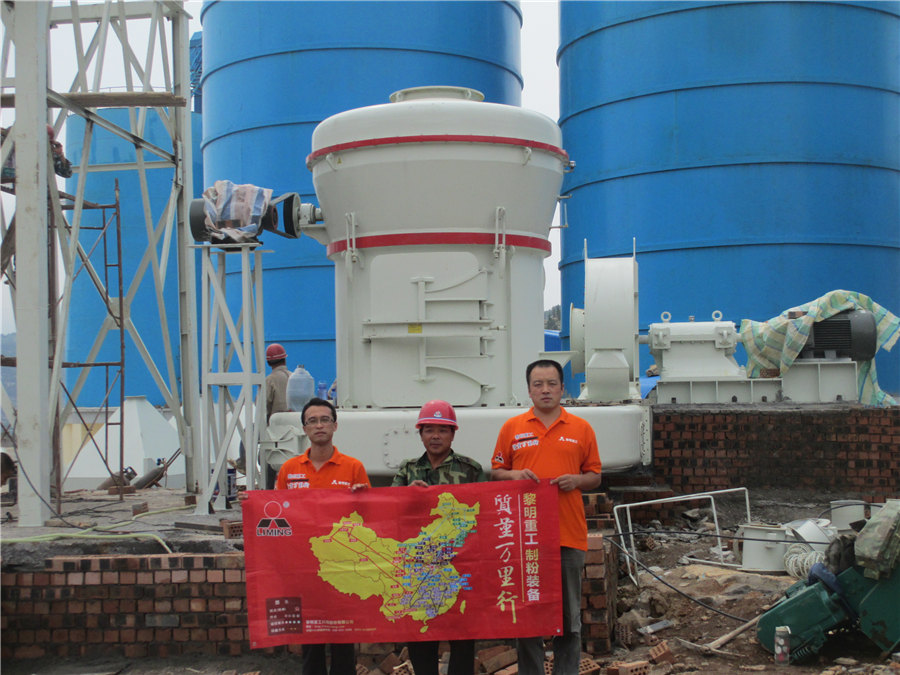

Fly Ash Processing Plant Superfine Final Product CNBMSINOMA

Fly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA prioritizes production efficiency and the quality of finished fineness and has developed the TRM series VRM for fly ash grinding and the TRMF series for Summary:The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc How to Process Fly Ash and What Is It Used for Fly ash is the fine ash collected from the flue gas after coal combustion Fly ash is the main solid waste discharged from coalfired power plantsHow to Process Fly Ash and What Is It Used for sbmchina2016年1月1日 Tests were performed on combined furnace bottom ash and fly ash from three massburn WTE plants, fly ash from an RDFfired WTE plant with acid gas scrubber, and combined ash from a multiplehearth wastewater treatment sludge incinerator The tests were performed in a sealed submergedarc electric furnace having a capacity of 1 t/hWastetoEnergy Ash Management in the United States2021年7月1日 Coal Bottom Ash, Coal Fly Ash and Cenosphere are three main wastes produced from power plant The aim of this study is to determine the characteristics of samples collected from different parts of Fly Ash properties, characterization, and applications: a review

.jpg)

How to Process Fly Ash and What Is It Used for

2023年1月9日 Raw material storage: the fly ash raw materials in the flue gas of the power plant are collected by the electrostatic dust collector or the pulse dust collector and transported to the powder tank for storage Grinding stage The fly ash in the powder tank is sent to the fly ash grinding mill through the electromagnetic vibration feeder for Fly ash has also been increasingly studied for its use as an adsorbent Adsorbents are widely used in applications to remove targeted components (often contaminants) from liquids and gases In combination with other factors, the porous structure of fly ash makes it a good candidate as a potential adsorbentValue in Waste: Fly Ash Reuse and Recovery OpportunitiesFirstly, fly ash is mixed and reacted with the hot acidic scrubber liquid; this leads to the neutralisation of the scrubber effluents and the formation of a salt brine including metals in solution Secondly, the fly ash particles with a size over 1 mm are removed; they represent less than 1 wt% of the fly ash and are returned to the WtE WastetoEnergy fly ash valorisation2023年8月16日 Harvested fly ash, an indispensable ingredient for contemporary cement manufacturing, is a fine, powdery byproduct of coal combustion originating from power plantsRich in silica, alumina, iron, and calcium, fly ash’s composition and properties are influenced by the type of coal used and the specificities of the combustion processFly ash processing: Tailored solutions for reclaimed fly ash Atritor

How to Start Fly Ash Bricks Business Fly Ash Bricks Startup

How to Start Fly Ash Bricks Business Fly Ash Bricks Startup Join this Training and get started: https://bitly/3tKkTF7 For More Details Call Now :2024年5月25日 Fly ash is the main component of fly ash bricks; Other ingredients include stone or sand dust as fine aggregate, lime as a source of calcium carbonate, which gives the bricks their label of “Selfcementing bricks,” gypsum to improve the fineness of the shape of the bricks (Nayak et al, 2022), and cement to strengthen the bond and bonding (Botchway et al, 2020)Converting Waste Fly Ash into Valuable Products: An Insight into Fly ash is a byproduct of coal combustion in power stations Aside from offering environmental advantages by reusing industry waste, adding fly ash also improves the overall performance and quality of concrete Fly ash affects the plastic properties of concrete by improving workability, reducing water demand, controlling bleeding, and lowering the heat of hydrationFly Ash Cement Australia2019年10月1日 Electric power in India mainly depends on coalfired power plants Commonly, Indian coal comprises ash in the range of 30–45% In order to sustain India’s economic growth, the country total Handling and Utilisation of Fly Ash from Thermal Power Plants

.jpg)

Fly Ash Characteristics A Challenge or Opportunity

2024年5月16日 Mechanochemical processing of FA can be considered ecofriendly, inexpensive and efficient, in particular for processing tons of readily available fly ash already stored in ponds or landfills2014年1月1日 Although all fly ash particles are generally the same, some mullite and iron crystals have different shapes (rounded to angular) By comparing to the SEM result from [5], as shown in figure 5, the (PDF) Study on Physical and Chemical Properties of 2012年2月1日 By Jayant Khambekar, PhD and Roger A Barnum, Jenike Johanson, Inc, USA Fly ash is a general name used for the residual products of combustion that rise with flue gases More than 100 million Fly Ash Handling: Challenges and Solutions Power 2010年1月14日 Flyash production depends on the quality of the coal, which contains a relatively high proportion of ash that leads to 1030% Flyash formation (Singh and Siddiqui, 2003)In India 75% of electricity is generated by coal based thermal power plants, according to the data revealed in Table 1, provided by Government of India 112 million tones of this kind of waste is Use of Flyash in Agriculture: A Way to Improve Soil Fertility and its

.jpg)

(PDF) Incineration Fly Ash and Its Treatment to Possible

2020年12月17日 Incineration has gained popularity over landfill as a key solution for the reduction of massively increasing volumes of municipal solid waste (MSW) generation worldwide and in particular ChinaEmbark on a profitable journey! Learn the 8 key steps to start your fly ash brick plant in India Expert guidance for successStarting a Profitable Fly Ash Brick Plant in India: 8 Steps Guide2022年2月27日 Fly ash is one of the largest types of industrial wastes produced during the combustion of coal for energy generation Finding efficient and sustainable solutions for its reuse has been the subject of substantial research worldwide Here, we review the recent research data related to (i) the use of fly ash as a lowcost adsorbent for pollutants in wastewater and soils Applications of fly ash for pollutant adsorption in water SpringerSouth Africa has large coal reserves It mainly burns coal to produce electricity at 13 existing coalburning power plants, situated mainly in Mpumalanga, a province in the country’s east In South Africa, coal power generation results in at least 36 million tonnes of solid waste residue called fly ash being produced annuallyThat’s the equivalent of six dumps each the size of the Pyramid How to tackle 'fly ash' generated from coal power plants

.jpg)

Incineration Fly Ash and Its Treatment to Possible Utilization

2020年12月17日 Incineration has gained popularity over landfill as a key solution for the reduction of massively increasing volumes of municipal solid waste (MSW) generation worldwide and in particular China However, it is not the end solution The disposal of the incineration residues, which are enriched with a wide range of heavy metals and soluble salts, has become Processing Fly Ash The processing of fly ash involves several steps to ensure that it is suitable for its intended use The following are the common steps involved in processing fly ash Collection The first step in processing fly ash is its collection from power plants Fly ash can be collected using two methods: electrostatic precipitators How do You Process Fly Ash?2020年6月18日 Background Fly ashes from municipal solid waste incineration contain significant amounts of (technology critical) elements Processes to recover Cu or Zn are already in practice, but it still remains difficult to evaluate Municipal waste incineration fly ashes: from a multi 2022年5月12日 Bottom ash generated from Waste to Energy (WtE) processes is complex to manage and dispose of with minimal environmental impacts Most European (EU) nations and many Asian countries have tested THE CHALLENGES OF UTILISING BOTTOM ASH FROM WASTE TO ENERGY PLANT

.jpg)

Fly ash management and use in the United States

1 Landfills; 2 Reports 21 2011 report on hexavalent chromium; 3 Accidents and contamination 31 Virginia residents file $1 billion suit against Dominion over fly ash site; 32 4,000 gallons of sludge spill in Maryland; 33 Coal ash pile in Orange County, FL may be leaking radioactivity; 34 Coal waste spill at TVA's Widows Creek plant in Alabama; 35 Retention pond wall collapses 2023年8月18日 Lime manufacturing plant cost When lime kiln plant manufacturers create equipment quotations, they consider a variety of factors based on the user’s requirements for raw material particle size, fuel selection, daily production demands, equipment models, manufacturer investments, desired profits, and moreHow To Start A Lime Manufacturing Plant?2024年3月26日 To start Fly Ash Bricks Business, you will need : Fly Ash: The waste produced from thermal power plants is known as fly ash Fly ash is the primary component alternative for sand clay in bricks manufacturing In India, more than 6 Lakh Tonnes fly ash is produced per year which is equal to India's yearly cement consumptionHow to start FLy ash bricks manufacturing business in 年1月1日 In 1995 Vliegasunie put the Maasvlakte Fly Ash Processing Plant in Rotterdam, The Netherlands, in operation With a capacity of 250000 tonnes per annum, this installation has an important role in maintaining a record of 100% use of Dutch fly ash by continuing to meet the customer's need for fly ash of constant quality and quantityMaasvlakte Fly Ash Processing Plant ScienceDirect

.jpg)

Bricks from Fly Ash Money Making Opportunities

In India itself, the annual production of fly ash is projected to be about 200 million tons by the end of the 12th fiveyear plan and about 500 million tons by 2032 Related Projects: Fly ash based value added products, Coal Ash utilization, Fly Ash as Raw Material, Products from Waste Project Reports Benefits of Using Fly Ash There are Our process experts are wellversed in fly ash processing and regularly conduct feasibility studies in the Innovation Center to test and evaluate the best pelletization solution for each unique sample MATERIAL PROCESSING Agglomeration We offer disc pelletizers, pug mills, Fly Ash Processing Equipment FEECO International Inc2017年11月11日 Thermal coal power plant is the huge industry which contributes majorly in energy production sector However, this also produces the fly ash as a byproduct during the combustion process(PDF) Heavy Metals in Fly Ash; Its Impact on HumanHoang Son’s fly ash processing plant officially operated since 2023 solved the above problems We are proud to be a pioneer and expert in quality control of fly ashHoang Son Fly Ash Cement JSC LinkedIn