What is the density of drilling slag

Densities of some typical slags from iron and

Slag density is a significant factor in determining the process efficiency of the electroslag remelting (ESR) process, where calcium fluoride (CaF2)based slag is formed synthetically to refineMolten slag containing gas bubbles is projected through a water spray so as to form pellets These are rounded in shape and have a smooth coated surface However, crushing (which Blast Furnace Slag an overview ScienceDirect TopicsThe software calculates the following properties of crystalline, glassy, and liquid slags (where appropriate) as a function of temperature: heat capacity, enthalpy, density, viscosity, thermal conductivity, electrical conductivity, and surface Estimating the physical properties of slags SciELO2017年1月15日 There are several methods to determine the density of slags, such as weighing a fixed volume, using a manometer or analyzing sessile drops There are also several Slag density and surface tension measurements by the constrained

7TOCS.jpg)

Characteristics and environmental aspects of slag: A review

2015年6月1日 The hard and dense nature of the aircooled slag makes it suitable as a construction aggregate The strong cementitious properties of granulated slag help increase its 2020年10月13日 The bulk density of slag is 1267 kg/m 3 When classified in accordance with the PNEN 13055 standard, the material studied has the properties of lightweight aggregate Physical and chemical characteristics of slag produced during Pb 2013年1月15日 In terms of mechanical (especially plasticity), service properties, density and cleanness, the ESR steels significantly shift the similar materials produced by methods of traditional metallurgy(PDF) Understanding the Properties of Slagselting or refining of an ore in a blast furnace ‘Slags’ are formed during the smelting or refining of many ore types, and consequently there are (for example) copper slags, lead slags and, of Ground Slag Properties, Characterisation and Uses

.jpg)

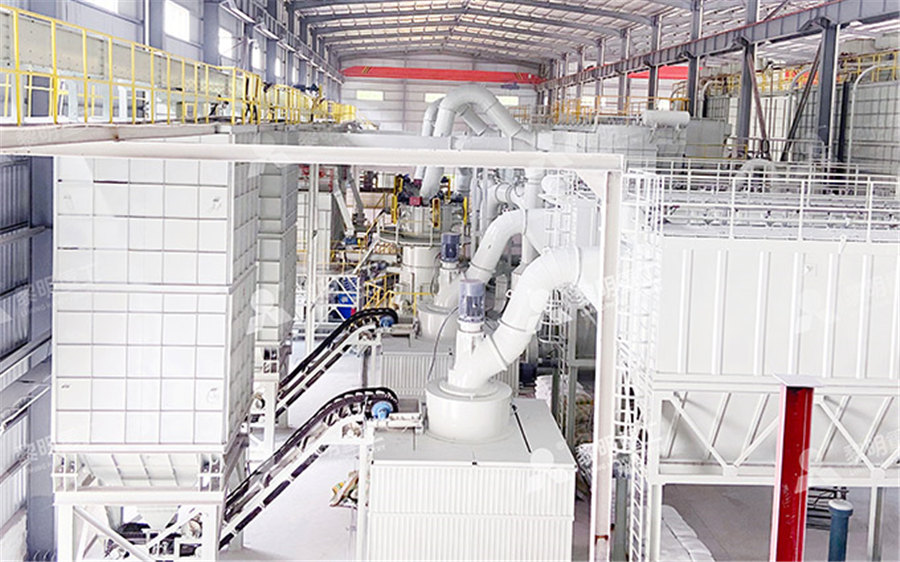

Characteristic Tests for Waste Mud and Drilling Sludge

2023年4月17日 The density of the drilling slag was measured using the wax sealing method, and it was found to be 209 g/cm 3 The density of the mixture of mud and drilling slag was also measured, ranging from 14–17 g/cm 3 at a SLAG DENSITIES IN SIfELTIKCf series it will be found that an increase of 753 per cent in the ferrous oxide, while the silica remains nearly the same, causes a considerable increase in Volume 8 Pittsburgh Parper On the Use of Determining Slag 2017年1月15日 With sessile drops, the accuracy of surface tension measurements is greater when the contact angle (θ in Fig 1a) is large and the drop volume is large [9]Unfortunately, the contact angle of slag on most materials able to contain slag at high temperatures (eg, molybdenum, platinum and alumina) is relatively low [10]Slag density and surface tension measurements by the 2015年4月23日 The lower density of the slag caused it to fill up the space in the hearth above the metal, Drilling by drilling machine which can be electrically, pneumatically or hydraulically operated The tap hole is drilled open using a Blast Furnace Tap Hole and Tapping of the Furnace

.jpg)

(PDF) Understanding the Properties of Slags

2013年1月15日 Electroslag remelting is the leading processes of special melting for highquality steels and alloys production In terms of mechanical (especially plasticity), service properties, density and 2015年6月1日 Slag is a waste product from the pyrometallurgical processing of various ores Based on over 150 published studies, this paper provides an overview of mineralogical and geochemical characteristics of different types of slag and their environmental consequences, particularly from the release of potentially toxic elements to waterCharacteristics and environmental aspects of slag: A reviewdrilling operations (see “Underground Blowout”) Blowout Preventer (“BOP” or “BOPE”) A large valve at the top of a well that may be closed if the drilling crew loses control of formation fluids By closing this valve (usually operated remotely by hydraulic actuators), the drilling crew usually regains control of the reservoir, andDrilling Terms and Abbreviations2021年1月11日 Cement Density The density of cement can vary from less than 833 ppg for foamed cement to as much as 20 ppg for densified slurries Cement density properties in oil gas wells must be varied to prevent lost circulation or to control abnormal formation pressures Normal densities for API cement are shown in Table 3Gas Oil Well Cement Properties Drilling Manual

Density of Slag, solid in 285 units of density AquaCalc

Slag, solid weighs 2114 gram per cubic centimeter or 2 114 kilogram per cubic meter, ie density of slag, solid is equal to 2 114 kg/m³ In Imperial or US customary measurement system, the density is equal to 1319727 pound per cubic foot [lb/ft³], or 1222 ounce per cubic inch [oz/inch³] ; Bookmarks: [ weight to volume volume to weight price density ]Slag In welding, the term "slag The flux material is chosen so that the density of the molten flux/slag is lower than the density of the metal to be welded, Inclusions can have a negative effect on weld quality and may need to be removed by What is slag in welding? A full guide to welding slagDrilling Fluid Monitoring Abstract Continuous, accurate and reliable measurement of drilling fluid volumes and density is contributing to improved efficiency / safety of drilling operations, reductions in Non Productive Time (NPT) and increased well production Micro Motion Coriolis flow and density sensors areUnderstanding and Selecting Coriolis Technology for Drilling Fluid 2016年7月28日 In lowdensity formations, more of these scattered gamma rays are able to reach the detector than in formations of higher density Because hydrogen is a major constituent of both water and hydrocarbons and because water and hydrocarbons concentrate in rock pores, the concentration of hydrogen atoms can be used to determine the fluidfilled porosity of a The Defining Series: Basic Well Log Interpretation SLB

Drilling Fluids Calculations For Drilling Mud

2021年1月5日 WT = Density of combined fluids or final weight (lbm/gal) Note Drilling / Mud Engineer shall know that this drilling fluid calculations formula assumes fluids are totally miscible, no precipitation reactions occur, and fluids Drilling muds Johannes Fink, in Petroleum Engineer's Guide to Oil Field Chemicals and Fluids (Third Edition), 2021 145 Prediction of drilling fluid density A universal model for the prediction of a drilling fluid density at high pressure and high temperature seems not to be available [147]This would be valuable for the performance of drilling fluid loss controlDrilling Fluid Density an overview ScienceDirect TopicsBarite Weighting material with a specific gravity of 437 used to increase the apparent density of a liquid drilling fluid system Barite [BaSO4] is the most common weighting agent used today It is a mined material ground to an API GLOSSARY OF OILFIELD TERMS Drilling Operationsof drilling, triangularshaped drill pipe has stronger slag discharge ability and efficiency than smooth round drill pipe and spiral drill pipe, which can quickly form holes in soft outburst coal seam Hou Hong et al [89] think that the triangularshaped drill pipe has larger slag discharge space than the smooth drill pipe, and the arc edge Numerical Simulation Analysis Based on the Study of the Slag

Slag density and surface tension measurements by the

2017年1月15日 With sessile drops, the accuracy of surface tension measurements is greater when the contact angle (θ in Fig 1 a) is large and the drop volume is large [9]Unfortunately, the contact angle of slag on most materials able to contain slag at high temperatures (eg, molybdenum, platinum and alumina) is relatively low [10]Some researchers have achieved a 2023年11月6日 During the drilling process, cuttings settle under the action of gravity, which easily results in the formation of a cuttings bed, which then results in wellbore cleaning problems The settling law of cuttings in drilling fluid is essentially a problem of solid–liquid twophase settling This study analyzes and summarizes the effects of the wall effect, the rheology of the A Review of the Settling Law of Drill Cuttings in Drilling Fluids2023年9月1日 Drill cuttings are characterized by a mixture of rock fragments generated during well construction It is generated by the action of the drill bit and brought to the surface by drilling fluids (Seyedmohammadi, 2017; Agha and Irrechukwu, 2002; Melton et al, 2000)The physicalchemical properties of these materials are inherently variable (Kujawska and Pawłowska, Physical and chemical characterization of drill cuttings: A reviewWhat is a Drilling? Drilling is a cutting process where a drill bit is spun to cut a hole in a circular crosssection in solid materials The drill bit is usually a rotary cutting tool, often multipointThe bit is pressed against the workpiece and rotated at rates What is Drilling? Definition, Process, and Tips Mechdaily

Slag Mineral Products Association

Slag processing GGBS; How Is Slag Used? The main uses of Slag are in construction, water treatment, agriculture, cementitious applications Full details of the specific properties and applications for each of the types of slag can be found on the below covering: Aircooled Blast Furnace Slag (ABS) Aircooled Basic Oxygen Steel Slag (BOS)2007年8月1日 Drilling muds have four basic properties that determine the behavior of the mud as a drilling fluid – viscosity, density, gel strength and filtration Several other properties, although of lesser importance, need to be checked, especially if problems are anticipated or encountered These properties include sand content, pH (alkalinity or acidity) and calcium content (hard water)Properties of Waterbased Muds The Driller2018年11月14日 As slag is a coarse glass, it maintains high permeability (0045 centimetres per second) regardless of how much water has passed through it The permeability of the slag is reduced when it is compacted or grounded into Properties and Uses of Steelmaking Slag – IspatGuru2016年1月31日 Drilling fluid density/type is an important factor in drilling and production operations Most of encountered problems during rotary drilling are related to drilling mud types and weightsInvestigation of mud density and weighting

Chemical, Mineralogical, and Morphological Properties

2011年10月26日 The slag generated from a steelmaking cycle is later processed, and the final product after processing is referred to as basicoxygenfurnace slag (BOF slag) The chemical reactions occurring during the removal 2020年9月17日 This is because specific technological advances made over the past 30 years have truly revolutionized the industry By combining better drilling techniques with ultrasophisticated frac designs, today’s proppant solutions help improve the production capacity of wells, delivering more oil and natural gas, day in and day outWhat is Proppant and How Is It Used in Fracing? Black 2024年11月11日 The paper outlines the principles of the directional drilling method with the use of hydraulic fracturing, demonstrating the impact of drilling cuttings and coal combustion waste on the environment It presents the results of physical and chemical analysis of drilling cuttings from the VostochnoChumakovskoye oil field and boiler slag from the OGK2Novocherkassk SDPP Influence of the Addition of Boiler Slag from the Novocherkassk 2016年1月17日 It is one of the most important drilling fluid properties because it controls formation pressure and it also helps wellbore stability What will happen if there is insufficient drilling fluid density? Well control The well will be in an underbalanced condition so any formation of fluids – gas, oil, Mud Weight and Its Importance in Drilling

Copper Slag Sand Blasting: Pros And Cons ShunTool

2024年6月28日 Copper slag abrasive has a higher density than coal slag, resulting in faster blasting and reduced product consumption Copper slag is a byproduct of copper extraction by smelting It is a popular choice for abrasive blasting due to 2024年8月20日 Through core drilling, teams can learn the density, chemical composition, strength, and other properties of specific materials The reason it’s important to use a hollow drill is that the purpose of core drilling is to extract a sample from the surfaceWhat is Core Drilling How Does It Work? SafetyCulture2019年8月30日 Density of Slag, solid in a few select units of density measurement: Density of Slag, solid g cm3 = 2114 g/cm³ Density of Slag, solid g ml = 2114 g/ml Density of Slag, solid g mm3 = 0 g/mm³ Density of Slag, solid kg m3 = 2 114 kg/m³ How is liquid slag used in steel making? Liquid slag from the steelmaking or other ferrous and What is the density of slag? – TeachersCollegesj2019年3月13日 The user will be able to interpret the lithology by using several logs, there are gamma ray, spontaneous potential, resistivity, and density logBasically, a formation with high gamma ray reading indicates that it is a shaly or shale, when the low gamma ray reading indicates a clean formation (sand, carbonate, evaporite, etc), lithology interpretation is very important in Well log analysis for reservoir characterization AAPG Wiki

.jpg)

Calculation for density of molten slags using optical basicity

2013年11月11日 As one of the important properties of metallurgical molten slag, the density of the slag has many effects on metallurgical processes, eg metal–slag separation, foaming, etc Accurate density valu2018年11月21日 shale shaker with spud mud When drilling through the reservoir, the key is to minimize damaging reactions between the mud and the reservoir that lower the production possible from the well If a well loses only 10% of its potential production rate due to avoidable damage from the mud, the cost to the operator in lost profit over the full life of the well will be Designing the Drilling FluidCirculation in a drilling well can be lost into highly permeable sandstones, natural or induced formation fractures, and cavernous zones; such a loss is generally induced by excessive drillingfluid pressures Drilling mud flowing into the formation implies a lack of mud returning to the surface after being pumped down a wellDrilling Fluid Additives1999年9月1日 This work discusses the effect of incorporating blast furnace slag (BFS) as an additive in waterbased drilling fluids The intent of this treatment is rapid development of a thin, impervious, and Investigation of Drilling Fluids Containing Blast Furnace Slag

Calculations of drilling fluid

pm1 to ρm2 , equ2 become with bentonite density = 208Ib/gal But when reduce the density of mud by added water or oil, equ1 becomes when using water, density =833Ib/gal Note: for lab Calculations can convert field units to lab units Example1: The volume and density of drilling fluid (water+ bentonite) is2003年6月1日 The density of drilling mud changes continuously along with increase in pressure and reduces with high temperature for HPHT wells [6, 11] Continuous measurements can provide such information; Determination of Drilling Mud Density Change with Pressure 2022年1月31日 Drill cutting and mud waste management is the principal concern in gas and oil drilling operations As oil has a lower density than water, contamination stays rest on the water surface and form an oily layer mixed with water In lineup procedures, the top oily part of the water source is pumped into a reservoir; Drilling Waste Management Based on New Methods of 2016年1月17日 Any increase in solid content in drilling mud such as barite, drill solid, lost circulation material, etc, will result in higher plastic viscosity In order to lower the plastic viscosity, solid content must be removed and it can be achieved by using solid control equipment and/or diluting drilling mud with base fluidViscosity of Drilling Mud

.jpg)

Calculation of Equivalent Circulating Density and Solids

2016年4月11日 We propose a method for calculating the cuttings (solids) concentration in the annular space and the equivalent circulating density (ECD) in deepwater drilling, both in the pilot hole drilling step and in the reaming step We have found that drilling a pilot hole followed by reaming has certain advantages over drilling with no pilot hole When using technology 2023年4月17日 The density of the mixture of mud and drilling slag was also measured, ranging from 14–17 g/cm 3 at a mud to drilling slag ratio of 4:6 or 5:5 The fine aggregates, such as sand, were replaced with drilling slag to prepare the concrete blocks for an unconfined compressive strength measurementCharacteristic Tests for Waste Mud and Drilling Sludge and Reuse