HOME→1000 cubic meters per hour steel mill steel slag mill vertical mill Raymond mill which manufacturer has a good reputation

1000 cubic meters per hour steel mill steel slag mill vertical mill Raymond mill which manufacturer has a good reputation

Loesche Mills for Metal Recovery and Filler Production from Steel

steel slag combines all the advantages of conventional processes: • Efficient and costeffective metal recovery in the coarse range • Virtually 100% metal recovery down to the finest fractionsGuilin Hongcheng understands the market demand, maintains a development vision of advancing with the times, and provides a new generation of vertical mill equipment that has been How efficient is the steel mill equipped with steel slag vertical mill2007年3月1日 The main purpose of LD process is to convert the molten pig iron and steel scraps into high quality steel In India, the generation of steel melting slag is over 2 MT per An overview of utilization of slag and sludge from steel industries2012年2月8日 This article presents a review of the slag energy potential on a global scale, and a proposal for a recovery plant in the factories of ArcelorMittal in Asturias (Spain), based on a Steel mill slags energy potential: the case of the steel factory of

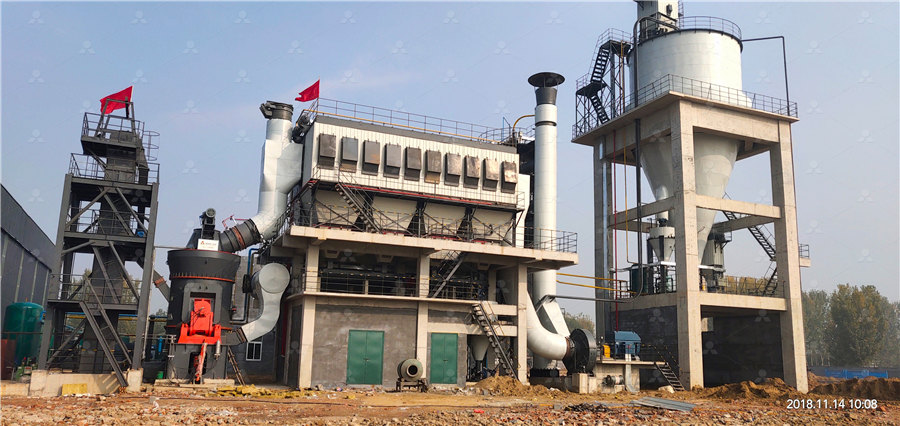

Steel Slag Vertical Mill CHAENG

The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder Capacity: 200,0001,500,000t/a What is the difference between Raymond mill and vertical mill? Vertical mills and Raymond mills are similar to "standing work", and they are quite different from horizontal ball millsvertical roller mill clirikultrafine vertical mill, Raymond vertical Steel slag vertical mill is a kind of grinding machine for grinding materials Steel slag is used as high performance cement and concrete admixture to improve the performance of concreteIntroduction of steel slag vertical mill production line and slag The slag vertical mill is equipped with a conical grinding roller device that offers low running resistance for the grinding roller, resulting in low energy consumption The optimized grinding Slag Grinding Vertical Milling Machine Vertical Mill Manufacturer

Steel Slag Utilization — Overview in Indian

2016年8月31日 Current total productions of steel slag in India, are around 12 million tonnes per annum (Indian Minerals Yearbook, May 2016), which is far behind the developed countriesThe coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure Chaeng(Great wall machinery) Vertical Roller Mill has simple Vertical Coal Mill Great WallBuy slag mill for steel slag grinding 1000: MB3654: 3600: 5400: 100330: ≤25: 085: 145: 94: 192: 1120: As a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical Steel Slag Ball Mill Quality Ball Bill Supplier Provide 2018年8月1日 Steel slag has a short history of being utilized as an industrial byproduct in China Reporting on the recovery of steel slag in China only began in the 1970s (Shan, 2000) The utilization of steel slag in China has undergone three stages, which are illustrated in Fig 3Steel slag in China: Treatment, recycling, and management

.jpg)

Comprehensive Utilization Technology of Steel Slag

2019年5月23日 The yield of the mill ground steel slag that is 100% not treated via magnetic separation is 1998% lower than that which is 100% treated via magnetic separation From this, it can be seen that the iron content in steel slag is crucial to the efficiency of the grinding of steel slag in a vertical mill (3)Materials: Raymond mill grinds minerals like gypsum and limestone, while ball mill processes metal ores and cement clinker b Output: Raymond mill produces less than ball mill but uses less power c Dust pollution: Raymond mill has cleaner dust control, whereas ball mill is larger, harder to manage, and causes more dust pollution dHighefficient Raymond Mill Fote MachineryFind here online price details of companies selling Steel Slag Get info of suppliers, manufacturers Sell Help Messages IndiaMART > Steel Stainless Steel Products > Industrial Steel > Steel Slag Steel Slag (1000+ products available) View by: List Grid Location Steel Slag Mill Scale, For Manufacturning ₹ 8,000/ Tonne Steel Slag at Best Price in India India Business DirectorySteel Slag Vertical Mill Ball Mill Raw material mill Coal Mill Slag Mill Cement Mill Rod Mill Ball Mill 10005000kw: Fineness: 33004000cm²/g: Download Product Brochure The vertical roller mill has been widely used and promoted in the electric power, Vertical Roller Mill Great Wall

.jpg)

Chemical, Mineralogical, and Morphological Properties of Steel Slag

2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes up to 300 tons of steel can be manufactured per cycle (a cycle takes one to three hours to supplied representative samples of BOF slag consisting of particles smaller than 15 mm The Whitesville Steel Mill at Nucor Steel, which is located in 2021年5月27日 Blast Oxygen Furnace (BOF) slag represents one of the largest waste fractions from steelmaking Therefore, slag valorisation technologies are of high importance regarding the use of slag as a secondary resource, both in the steel sector and in other sectors, such as the construction or cement industries The main issue regarding the use of BOF slag is its Comprehensive Analysis of Steel Slag as Aggregate for Road2019年1月1日 In an integrated steel plant, wastes (including solid, liquid and gas) are generated for every ton of steel produced In India, almost 100 million tonnes of steel is produced every year, and along Recent trends in slag management utilization in whereas 15 to 200 kg per tonne of slag is generated per tonne of liquid steel Lower grade ores yield much higher slag fractions, sometimes as high as one tonne of slag per tonne of pig iron produced Table – 1 : Plantwise Capacity of Ir on and Steel Slag in the Countr y Steel Plant Capacity for granulation ('000 tpy)Slag Iron Steel 2015 IBM

.jpg)

Slag Vertical Roller Mill

2023年1月10日 Slag Vertical Roller Mill Author: SBM Recently, the installation and commissioning of the production line with an annual output of 80,000 tons of slag powder built by SBM has been completed!2002年7月1日 The iron in steelmaking slag has the advantage of either being partially reduced to iron oxides such as magnetite (Fe 3 O 4) or wustite (FeO) or being completely reduced to metallic iron The steelmaking slag is currently sold as aggregate, stockpiled, inventoried, or in the worst case, it is landfilled at costs of US$5–100 per tonPelletizing steel mill desulfurization slag ScienceDirectRaymond mill is a common type of cement mill used in cement plant and lime calcination plant, and generally apply for the production of mineral powder or coal powder, such as the fine powder processing of raw ore, gypsum, coal and other materials Why choose Raymond mill from AGICO? AGICO Cement is one of leading raymond mill suppliers in China, we can offer any Raymond Mill, Raymond Mill For Sale For Cement and Lime PlantButler Mill Service @ Steel Dynamics 4506 North County Road 59 Butler, IN 46721 Materials and Usage Guide Commercial Steel Slag Aggregates **Note Duraberm cannot be used in confined spaces, such as under concrete For More Information, Please Contact: Sales: 2609995161 Plant (Office): 2608685123 Plant (Fax): 2608685885Materials and Usage Guide Commercial Steel Slag Aggregates

Loesche Mills for Metal Recovery and Filler Production from Steel Slag

and dry processing of steel slag Loesche Mill type LM 15200 under construction Loesche Mill type LM 15200, Wolica, Poland, 2009 3 1 10 11 2 12 3 13 4 14 5 15 6 16 7 17 8 18 9 19 of slag with the Loesche vertical mill 1 Wheel loader 2 Conveyor belt 3 Jaw crusher 4 Impact crusher or cone crusher 5 Conveyor beltIntroduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materialsVertical Raw MillEXCEPTIONAL CASTING CAPABILITIES BROUGHT TO LIGHT We are a leading manufacturer of high performance steel millrelated castings, including the world’s finest slag pots, mining casting components, coiler drums for steckel mill applications, mechanical mill parts and metalworking press castingsSlag Pots Large Castings WHEMCO2023年8月25日 steel slag discharged from the steel mill is stored in the slag disposal yards and r elies on rain and moisture in the air to consume fCaO and fMgO Natural aging does consume(PDF) Application of Steel Slag as an Aggregate in ResearchGate

Steel Slag Vertical Roller Mill

CHAENG steel slag vertical mill has complete models and strengthens the iron dressing process, with the feeding size of ≤ 5mm 【Product capacity】: 200,0001,500,000t/a 【Specific surface area】: 450~500 m²/kg 【System power consumption】: ≤50 kWh/t Order Online Chat Now E Steel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500㎡/kg, which is widely used in cement and concrete admixture, realizing the highvalue resource utilization of steel slagSteel Slag Grinding Plant CHAENG5Axis CNC Vertical Mill with 30" x 20" x 20" travels 5axis machining is an effective means to reduce setups and increase accuracy for multisided and complex parts The Haas UMC Series universal machining centers are cost UMC750 5Axis Mill 40Taper Vertical Mills – whereas 15 to 200 kg per tonne of slag is generated per tonne of liquid steel Lower grade ores yield much higher slag fractions, sometimes as high as one tonne of slag per tonne of pig iron produced Steel slag output is approximately 20% by mass of the crude steel output Ferro Scrap Nigam Ltd (FSNL), a wholly ownedSlag Iron Steel 2015 IBM

.jpg)

Steel Mill

2 The vertical roller mill’s noise control meets the Industrial enterprises noise discharging standards (GB123482008) During working, the vertical roller mill do not have the noise of steel ball crashing in ball mill, so it is noise is low Lower 20 Slag ball mill is a kind of equipment used to grind the slag into powder particles The technical that uses the tube mill on the production of slag has been very mature The slag produced can be used as concrete admixture, reducing the project costs significantly and enhanced the compressive strength, tensile strength, shear strength and bending strength of the concrete Per machine Slag Mill Great Wall2018年1月20日 mesh powder by a Raymond mill Though steel slag has been used for various applications, Firing at 1000°C yielded a dense anorthite ceramic when the finest calcite powder was used(PDF) Preparation and Characteristics of Steel Slag Ceramics It covers an area of 700, 000 square meters and has a total asset value of RMB 500 million We have strong engineering design ability and perfect High Capacity Vertical Mill Manufacturer for Slag Plant FOB Price: US $1 / Piece Min Order: 1 Large Scale Steel Slag Production Line FOB Price: US $1 / Piece Min Order: 1 Vertical Roller Mill Manufacturer, Ball Mill, Rotary Kiln Supplier

Steel Slag; Chemistry, Mineralogy and Morphology ResearchGate

2015年3月17日 Steel slag is a byproduct of the steel industry Understanding of the chemical, mineralogical, and morphological properties of steel slag are necessary for its use in sustainable practices2007年3月1日 Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel During the production of steel, 2–4 t of wastes are being generated per tonne of steel producedThe various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, An overview of utilization of slag and sludge from steel industriesIf you want to further understand the characteristics and structural principles of steel slag vertical mill, please contact mkt@hcmilling or call at +86773, HCM will tailor for you the most suitable steel slag grinding mill program based on your needs, more details please check hcmillingNews Can steel slag Raymond mill be used to processed steel slag 2012年6月1日 is lined with mill liners protecting the steel body of the mill and which is measured in tons of producti on per hour 10001005 49 Wills, B A, T J NapierMunn M i n e r a l P r o c Grinding in Ball Mills: Modeling and Process Control

Environmental benefit assessment of steel slag utilization and

2022年2月1日 Steel slag (SS), accounting for about 15–20% of the total steel amount, has been produced in huge quantities worldwide (Han et al, 2015; Shi, 2004) Initially, SS was treated as a waste material and disposed of as landfill, which not only took up land resources but also severely impacted the natural environment and human health due to the highly alkaline leachates ( Vertical Roller Mill for Cement, Clinker, Slag, etc See details Release time 20/10/2017 What is the difference between Raymond mill and vertical Jaw Crusher gold separator Nitrile Gloves Production Line CG Safety China Freight Elevator Cuplock Scaffolding Steel Rail Manufacturer Cnc Machining custom aluminum parts Factory vertical roller mill clirikultrafine vertical mill, Raymond vertical 2023年11月17日 The growth of electric arc furnace (EAF) steelmaking in North America has occurred mainly in the past 40 years due to low electricity prices, an abundance of steel scrap (especially near large population centers), and the development of mini and macro steel mills based on metal recycling Scrap availability and price has made steel produced by remelting in Electric Arc Furnace Steelmaking and Slag Formation, 2019年4月5日 In general, two routes are currently used worldwide to produce crude steel These are the blast furnace (BF) / basic oxygen furnace (BOF) route and the electric arc furnace (EAF) route []Regarding the situation in the EU28, 162 million tons crude steel were produced in 2016, whereas 605% were based on the BF/BOF route, and the residual 395% originated from the RecoDust—An Efficient Way of Processing Steel Mill Dusts

.jpg)

Vertical Cement Mill Great Wall

Steel Slag Vertical Mill Ball Mill Raw material mill Coal Mill Slag Mill Cement Mill Rod Mill Ball Mill 10005000kw: Fineness: 33003800 cm²/g: it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, 2015年12月3日 Rolling of steel in Hot Strip Mill satyendra; These reheating furnaces are nominally rated to produce heated slabs in the range of 250 tons per hour to 300 tons per hour with a capability of producing up to 25 % extra to their rated output with Up to 300 cubic meters of water are pumped each minute throughout the HSM Rolling of steel in Hot Strip Mill IspatGuruButler Mill Service @ Steel Dynamics 4506 North County Road 59 Butler, IN 46721 Materials and Usage Guide Commercial Steel Slag Aggregates **Please note: Duraberm cannot be used in confined spaces, under buildings or under paved roads For More Information, Please Contact: Contractor Sales: Kurt Crowel: 2194061194 : kcrowel@levycoMaterials and Usage Guide Commercial Steel Slag Aggregates2017年3月5日 Normalized CaO (MgO)SiO 2 (Na 2 O,K 2 O)Al 2 O 3 (Fe 2 O 3 ) phase diagram for various types of iron and steel slags Acronyms: blast furnace slag (BFS); basic oxygen furnace slag (BOFS (PDF) Iron and Steel Slags ResearchGate