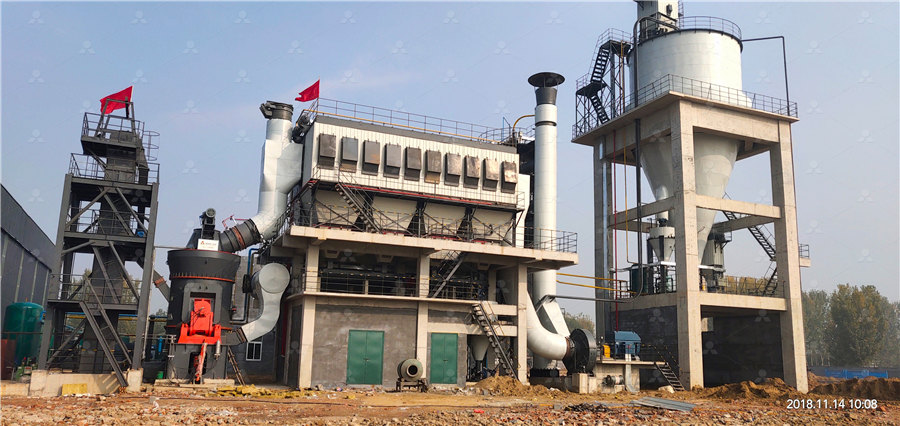

Kaolinite production plant

.jpg)

Kaolinite an overview ScienceDirect Topics

Kaolinite is a 1:1 hydrous aluminosilicate formed by the process of weathering feldspar and other aluminosilicates under acidic condition (Rumi et al, 2020)2021年8月27日 Kaolin is the deposit of naturally occurring minerals containing hydrated aluminum silicates Widely known as white clay or china clay, these minerals have desirable properties crucial for industrial and commercial All Steps in Kaolin Production Mining and Processing 2024年1月13日 In this study, biochar (BC) and hydrochar (HC) composites were synthesized with natural kaolinite clay and their properties, stability, carbon (C) sequestration potential, Impacts of kaolinite enrichment on biochar and hydrochar 2001年11月9日 In excess of an estimated 5 million tonnes of kaolin is produced in the Region from India in the west through to China, Korea and Japan in the Far East China is obviously Kaolin Production and Consumption in Asia AZoM

.jpg)

Kaolin: processing, properties and applications ScienceDirect

1991年9月1日 Kaolins are white raw materials, their essential constituent being fine grained white clay, which are amenable for beneficiation that make them ideal for an assortment of 2023年1月5日 Kaolinite is a suitable candidate for the immobilization of Ag nanoparticles to construct nanoAg/kaolinite composite with well dispersed nanoparticles and improved disinfection performanceThe Application of Mineral Kaolinite for Environment2021年5月19日 Here we propose a kaolinite shuttle which efficiently adsorbs phosphorus in continental weathering settings and releases it under marine conditionsThe kaolinite shuttle links the Great Oxidation and Lomagundi The extensive consumption of aluminum, combined with the shortage of the existing raw materials, and particularly bauxite, necessitates the exploitation of alternative raw materials for the production of alumina The present paper Exploitation of Kaolin as an Alternative Source in

.jpg)

Calcined clay limestone cements (LC3) ScienceDirect

2018年12月1日 Clays, however, are abundant materials worldwide Clays having a significant proportion of kaolinite have proven to be highly pozzolanic if calcined between about 700 and 850 °C [8]For decades, a very reactive mineral addition known as “metakaolin” has been produced based on calcining high purity kaolinitic clays [9]However, metakaolin is a product also used to increase kaolinite recovery in alkaline medium by using a macromolecule as a flocculant Without polyacrylamide, the kaolinite recovery decreased from 70 to 15%, with increasing the pH from 2 to 10 However, with polyacrylamide as a flocculant, kaolinite recovery increased under both acidic and alkaline conditions [11]Flotation of kaolinite from tailings of kaolinwashing plants by 1991年9月1日 The main constituent, kaolinite, is a hy drous aluminum silicate of the approximate composition 2H20A12032SiO2 Structurally, kaolinite consists of alumina octahedral sheets and silica tetra hedral sheets stacked alternately and has the theoretical formula The onsite production of PCC at paper plants Kaolin: processing, properties and applications ScienceDirectKaolin is a rock from which the clay mineral kaolinite is derived This one has been used for millennia as the principal ingredient in porcelain tableware Today Imerys kaolins bring critical properties to a host of end applications ranging from paper to paints, fiberglass to cosmetics and pharmaceuticalsKaolin Imerys

.jpg)

Wickepin Kaolin Project WA Kaolin Limited

WA Kaolin has an established Ore Reserve Estimate (JORC 2012) of more than 64 million tonnes1 of extremely highgrade, easy access kaolinite at a site near the town of Wickepin, 220km southeast of Perth, Western Australia This represents one of the largest known remaining premium primary resources of kaolin in2024年1月13日 Kaolinite enrichedBCs showed the highest cation exchange capacity than pristine BC Moreover, kaolinitecomposited BC and HC can be used for plant production, Impacts of kaolinite enrichment on biochar and hydrochar Production Plant for Water Purification using Kaolinite Clay from Kankara Kaolin,” International Research Journal of Advanced Engineering and Science, Volume 8, Issue 2, pp 200204, 2023 Design and Economic Analysis of Alum Production Plant for Water Purification using Kaolinite Clay from Kankara KaolinDesign and Economic Analysis of Alum Production Plant for2021年3月15日 Clay minerals such as kaolinite, smectite, chlorite, micas are main components of raw materials of clay and formed in presence of water A large number of clays used to form the different structure which completely depends on their mining source They are known as hydrous phyllosilicate having silica, alumina and water with variable amount of inorganic ions like Basics of Clay Minerals and Their Characteristic Properties

"Design and Economic Analysis of Alum Production Plant for

2023年6月1日 Production Plant for Water Purification using Kaolinite Clay fr om Kankara Kaolin,” I nternational Research Journal of Advanced Engineering and Science , Volume 8, Issue 2, pp 200204, 2023 4One of the MK production methods is heat treatment controlled by kaolinite at temperatures in the range of 600–900 ∘C Different residues have been used (coal mining, paper sludge and waste from a drinking water treatment plant) ADGEO Cements based on kaolinite wasteKaolinite, with the chemical formula Al2Si2O5(OH)4, is a layered silicate mineral that forms through the weathering of aluminumrich rocks Illite, on the other hand, has a more complex structure, often described by the formula (K,H3O)(Al,Mg,Fe)2(Si,Al)4O10[(OH)2,(H2O)], and is part of the mica group, known for its flaky crystalsKaolinite vs Illite: What’s the Difference?2022年3月1日 Introduction Humic substances (HS) are remains of decomposed plant and animal materials such as lignin, tannins, cellulose, and cutins (Tan et al, 2000; Billingham, 2012; Hayes and Swift, 2020)High quantities of HS are Frontiers Understanding the Role of Humic Acids on

Beneficiation Process of Kaolinite Clay: Kaolin Processing

2016年5月24日 Production advantages are that the process uses conventional equipment and ordinary flotation reagents Minerals such as calcite, fluorspar, silica, barite, sulphur, etc, are possible carriers The Flowsheet The first step in processing kaolin clay is to slurry it in a blunger with water and a dispersing agentproduction due to its high aluminum content The elevated aluminum content of kaolin (20–40%) renders it appealing as a substitute for bauxite in alumina production [3], [29] [25] anticipates that, in the near future, a commercial process utilizing lowgrade aluminum ore will be essential for aluminum productionEXTRACTION OF PURE ALUMINA FROM KAOLIN: A REVIEWIn this work, four naturally occurring (two kaoliniterich and two smectiterich) clay samples were collected from different areas around the Ashaka cement production plant, located in Gombe State Kaolinite content in clays Download Scientific Diagram2023年7月1日 Kaoliniteclay (C) was collected from a natural quarry in Morocco's “Shoul” block The kaolinite clay (Al 2 Si 2 O 5 (OH) 4) was used before for adsorption and food packaging studies [20, 21] Chitosan with 85 % deacetylation degree and a molecular weight of 161 × 10 5 g/mol was purchased from Across organics Ammonium vanadate (NH 4 VO 3) and Chitosan/kaolinite clay biocomposite as a sustainable and

Kaolinitebased zeolites synthesis and their application in CO

2022年7月15日 CO 2 capture from large releasing sources like fossilfueled power plants is currently a key target to reduce the anthropogenic emissions of CO 2Unfortunately CO 2 emissions into the atmosphere have been increasing yearly, due to the high energy demand related to industrial development and the increase in the world's population [1], becoming a 2019年12月1日 Trans Nonferrous Met Soc China 29(2019) 2627−2637 Dissolution kinetics and removal mechanism of kaolinite in diasporic bauxite in alkali solution at atmospheric pressure Yan WU, Xiaolin PAN, Yuejiao HAN, Haiyan YU School of Metallurgy, Northeastern University, Shenyang , China Received 29 March 2019; accepted 19 August 2019 Abstract: A Dissolution kinetics and removal mechanism of kaolinite in 2018年8月10日 In this present article, the influence of additives, reinforcements, and aggregates on kaolinite clay properties, its applications, and a case study had been established(PDF) Cements based on kaolinite waste ResearchGate2023年7月27日 We are about to unearth the captivating properties and astonishing applications of kaolin that will forever change the way you perceive the ordinary around you Imagine a substance that possesses the power to Exploring the Properties and Applications of Kaolin

Use of calcined water treatment plant sludge for sustainable

2021年12月10日 Water treatment plant sludge (WTPS) is a noninert waste composed of solid particles, heavy metals, and pathogensThis work investigated the potential of using calcined WTPS in Portland cement replacement for sustainable cementitious composite production Specifically, pastes with 0–45 wt% replacement of cement with calcined WTPS were produced2023年2月9日 BauxiteBauxite is the main ore for metallic aluminumAluminum production, To remove kaolinite, the beneficiation plant has two cycloning stages in two different circuits, fine particles classification circuit (FC) and superfine particles classification circuit (SFC)Process Simulation with Tertiary Cyclone for Kaolinite Removal kaolinite and is used mainly for bonding in ceramic ware, primarily dinnerware, floor and wall tile, pottery, and sanitary ware Fire clays are composed primarily of kaolinite, but also may contain several other materials including diaspore, burley, burleyflint, 1125 Clay Processing US EPA2016年1月1日 In this research recovery of kaolinite from tailings of the Zonoupz kaolin washing plant, and incurred a high alumina production costFlotation of kaolinite from tailings of kaolinwashing plants by

.jpg)

Plant Nutrients and Their Roles Under Saline Soil Conditions

2018年6月2日 Effect of soil alkalinity (pH: 89) and salinity of irrigation water (2500 ppm) on Asparagus officinalis plant in Wadi El Natrun, Beheira Governorate, where photo (a) represents salinity features 2022年1月23日 Chemical Processing of Bauxite: Alumina and Silica Minerals—Chemistry, Kinetics and Reactor Design(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals 2019年1月1日 Kaolinite, with the chemical formula of Al 2 [Si 2 O 5](OH) 4, is a naturally occurring inorganic silicate clay mineral with a layer structure consisting of siloxane and gibbsitelike layersThe siloxane layer is composed of SiO 4 tetrahedra linked in a hexagonal array The bases of the tetrahedra are approximately coplanar and the apical oxygen atoms are linked to Kaolinite Nanomaterials: Preparation, Properties and Functional Kaolin (china clay, kaolinite) processing and beneficiation can obtain highpurity products, increase the quality and utilization of minerals, and meet some high valueadded market applications Maximize kaolin grade and recovery rate; Achieve the necessary high brightness standard for kaolin applications; Optimize costperformance of plant operationsKaolin Processing plant JXSC Machinery

Alumina Extraction from Kaolinite via Calcification Springer

2020年7月6日 Kaolinite is dense or loose in bulk form and usually white The reserves of kaolinite in China total approximately 29 billion tons If kaolinite can be used as a raw material for alumina production, the resources may be able to maintain the alumina industry in China for more than 5 years (according to the current scale)2014年11月17日 Raw materials available locally in a Brazilian ceramics production plant were used The mixtures were defined through the use of a 2 3 factorial design of experiments The starting point was a composition reported in the literature as follows: 35% kaolinite, 25% quartz and 40% albite The mixtures were prepared by wet grinding, followed by Effect of kaolinite, illite and talc on the processing properties and by Altech (pilot plant stage 127Mt resource) and Andromeda Metals (Scoping Study stage 260Mt resource) which trade on US$227m and US$260m respectively IGM’s kaolin potential could easily open the doors to a whole raft of opportunities stemming from developing proprietary production with valueadding processes and offtake agreementsKaolin to HPA processing technologies InterGroup Mining2024年1月9日 Kaolinite, as a clay mineral, finds numerous applications in various industries Below are some of the products related to kaolinite: Pigments: Because of its white color and its ability to disperse easily in water, kaolinite is Kaolin: Properties and uses of a strategic mineral

.jpg)

250TPH Kaolinite Crushing Plant Sand Plant Eastman Rock

2020年3月31日 Material: Kaolinite Capacity: 250TPH Output size: 03mm, 37mm, 715mm, 1525mm Max Feeding Size: 450mm Locatione: Oman Equipment Configuration: Vibratory Feeder, Jaw Crusher For Primary Crush, Belt Conveyor, Impact Crusher, Vibrating Screen, Sand About Kaolin Clay Kaolin, also known as kaolinite or ceramic clay, is a mineral primarily extracted from kaolinite oreIt is named after the hill in China (Kaoling) from which it was mined for centuries Kaolin contains primarily aluminum silicate and is often represented by the chemical formula Al 2 Si 2 O 5 (OH) 4It is usually white or light gray and has a fine granular textureKaolin (Kaolinite) Processing JXSC Mineral2022年10月24日 production plant is situated close to huge clay d eposits [11–13] The pozzolanic mineral of interest in clay is the kaolinite content, but it also contains other passive phase crystals such as (PDF) Performance of Selected South African Kaolinitic Clays for The kaolinite content of processed kaolin varies, but is generally in the range of 75 to 94% Kaolins from different deposits in the UK and from different parts of the world have markedly different properties and the range of minerals associated with kaolin influence its suitability for different applications KAOLIN PRODUCTIONWhat is Kaolin The Kaolin and Ball Clay Association

Performance of Selected South African Kaolinitic Clays for

2022年10月24日 While kaolinite content improves the pozzolanic activity, consistency, and compressive strength of the mortar, the void refinement at the microscale depends on the degree of limestone filling/hydration implying cleaner production and sustainability if a production plant is situated close to huge clay deposits [11,12,13]2021年7月2日 Wash good quality lumps to remove fine kaolinite and goethite sticking on the surface of lumps, and feed only below 30 or 20 mm into the drum scrubber, to reduce the load and increase the overall recovery In the older plants, install hydrocyclones to recover fine bauxite from live tailings, as demonstrated aboveBauxite Beneficiation: An Approach to Value Addition in Mining2016年11月1日 The dissolution mechanism of kaolinite was regarded as a threestage process: kaolinite firstly dissolved in alkaline solution in form of soluble silicate and aluminate Dissolved silicate and aluminate in alkaline solution then reacted with each other and aluminosilicate transient phase with Si/Al ≈ 1 precipitated when silicon ion concentration exceeded its The dissolution behavior and mechanism of kaolinite in alkaliacid