Gypsum ore raw ore processing equipment

.jpg)

Gypsum Processing Equipment, Process Flow, Cases

2019年8月23日 Gypsum processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design2023年11月13日 Crushers and grinding mills are fundamental components of the gypsum manufacturing process, with crushers responsible for reducing the size of raw gypsum ore, Gypsum Manufacturing Process Gypsum Processing EquipmentRaw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, gypsum wallboard and coagulant for food Tofu etcGypsum mining equipment, gypsum crushing and grinding Gypsum mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read moreGypsum Mining Processing Equipment Flow Chart

Gypsum processing plant for gypsum mining by SBM

SBM supplies all types of gypsum crushers, grinding machines and other essential equipments for gypsum processing plant Our full range of gypsum crushing products includes complete Gypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such Gypsum Powder Production Line Hongji Mining MachineryDSMAC will provide you with the right gypsum crusher and usual crusher’s spare parts and wear parts to meet your material reduction requirements Jaw crusher is used to crush gypsum ore Gypsum Ore Crushing Solutions DSMACRaw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or 1116 Gypsum Manufacturing US EPA

.jpg)

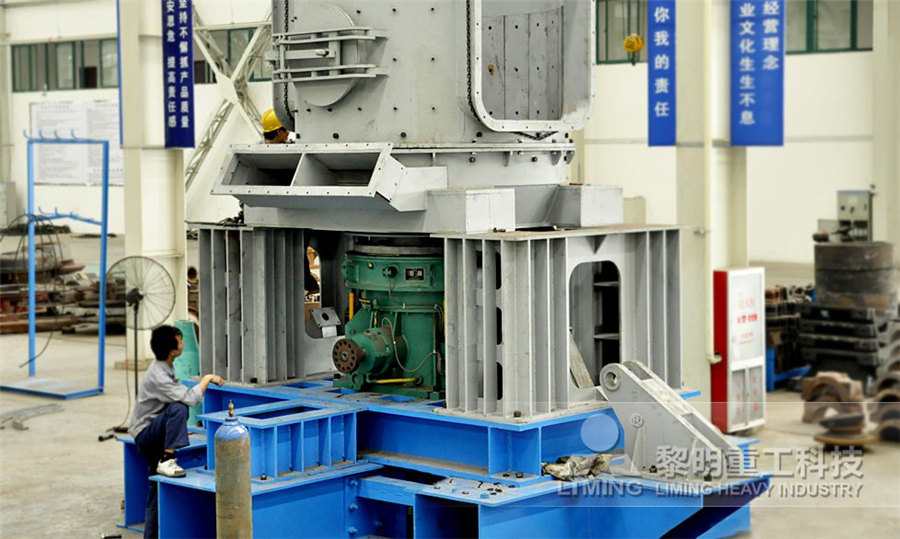

An overview of equipment used for producing 300,000 tons of

The annual production of 300,000 tons of gypsum powder requires a highly efficient and reliable equipment setup 1 Raw Material Preparation The first step in the gypsum powder production gypsum processing ABRASIVENESS Mined gypsum is a somewhat abrasive material As a result, robust equipment must be used when processing gypsum Rotary dryers are an ideal The FEECO Gypsum Processing Handbook FEECO International Inc2024年1月23日 Firstly, the jaw crusher or impact crusher crushes the gypsum raw ore to around 30 millimeters Then the crushed materials enter a powder mill for fine grinding The gypsum powder with the required fineness after grinding Gypsum Powder Grinding And Processing Plant 2023年2月15日 Gypsum (or common) ore is white, green, gray or light yellow It is massive and granular structure Its main minerals include dihydrate, a small amount of anhydrite (the sum of the two is over 85%), and a small amount of What Are the Types of Gypsum Ore and Their

.jpg)

Accurate mineralogical analysis for lithium ore processing Analyse

Accurate mineralogical analysis for lithium ore processing • Samples from several parts during mining and processing of lithium ores were analyzed • Lithium ore (raw material) Gypsum CaSO 4 ꞏ 2H 2O Kainite KMg(Cl,SO 4) ꞏ 275H 2O Lisulfate monohydrate Li 2SO 4 ꞏ H 2O2024年7月17日 1 Primary crushing equipment Primary crushing is the first stage of the stone crushing process At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers Jaw Types of Crushers: Choosing the Right One for Each Stagemineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or wallboard, gypsum must be partially dehydrated or calcined to produce calcium sulfate hemihydrate (CaSO4 ½H 2O), commonly called stucco1116 Gypsum Manufacturing US EPAWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stageThe six main steps of iron ore processing Multotec

.jpg)

ore processing equipment, ore processing machine, ore processing

Ore processing equipments include high efficiency concentrator, ball mill and other energy saving ore processing plant +86371 er Follow Us :2023年4月25日 In the nickel ore processing plant, different types of nickel ore need mineral processing procedures and mining equipment based on the characteristics and composition of the ore Therefore, it is necessary to conduct beneficiation tests, design a feasible nickel ore beneficiation process, and then equip corresponding mining machines2 Types of Nickel Ore: Processing Methods and EquipmentDSMAC has manufactured large amount of mining equipments to global countries, such as jaw crusher series, impact crusher series, cone crusher series and the grinding mill series, etc DSMAC mining equipments have been exported to more than 130 countries which are widely applied in mining industry including the bauxite crushingBauxite Ore Crushing Solutions DSMAC2023年2月15日 Among the gravity equipment, only the jigger can process coarse fluorite ore When the raw ore contains high mud content, accompanied by impurity minerals, or useful minerals inlaid with fine particle size, the flotation method is 4 Steps to Process Complex Lowgrade Fluorite Ore

Chrome ore washing process and equipment LZZG

Chrome ore washing process and equipment July16,2020 Gold, platinum, chromium ore, tungsten, tin, and other sand ores, as well as lead, copper, iron, manganese, and other ores with deep oxidation and weathering, washing ore Our Group Co, established in 1998 is a Mine Owner and Manufacturer of Gypsum range of products, such as Raw Gypsum, Gypsum Powder, Gypsum Special Plasters serving Fertilizer, Cement Building Construction IndustriesPlaster of paris Gypsum Powder Gypsum plasterEven wellknown minerals such as gypsum require testing on a case by case basis to ensure quality results The following list outlines key material characteristics that affect gypsum processing 1 Abrasive Mined gypsum is a Material Characteristics to Consider in Gypsum gypsum processing ABRASIVENESS Mined gypsum is a somewhat abrasive material As a result, robust equipment must be used when processing gypsum Rotary dryers are an ideal solution for many types of ore, as they are especially heavyduty Customizations can be made to other processing equipment as well, in order to protect againstThe FEECO Gypsum Processing Handbook FEECO International

Copper Ore Processing Plants, Flow And Equipment

5 天之前 The main beneficiation process of copper ore is flotation, contact us to customize copper ore processing plants and equipment get a quote now! Skip to content JXSC Machinery Us +86 Home; Equipment Gold Mining Equipment and the large raw ore is broken into small pieces of oreRaw gypsum ore is processed into a variety of products such as a portland cement industrial and building plasters, gypsum wallboard and coagulant for food Tofu etc Gypsum processing equipment Gypsum mining equipment is the mining equipment SBM provide for gypsum solution SBM gypsum mining equipment to process gypsum includes Jaw Gypsum mining equipment, gypsum crushing and grinding equipment2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments The primary objective of crushing is to reduce the ore size for subsequent processing and improve the liberation of valuable minerals from the gangue a Jaw Crushers: Jaw crushers are commonly used for primary Iron Ore Processing: From Extraction to ManufacturingThe raw material ball mill is key equipment for the grinding process of the raw material after the crushing process of it It is widely used in the cement silicate product industry, new type construction material industry, refractory matter industry and glass ceramic industry for grinding various minerals and materialsRaw Mill,Raw Material Ball Mill

Grinding Modeling and Energy Efficiency in Ore/Raw Material

2022年8月31日 Dear Colleagues, The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants It not only provides the appropriate particle size for subsequent separation operations but also enables the liberation of valuable minerals from the gangue2023年5月12日 Crush the raw ore to 100mm with a jaw crusher and a roll crusher 2 Washing: Set a trommel screen to remove the muddy impurities in the ore 3 Grinding: Use a ball mill to grind the raw ore to 95%0074mm 4 Magnetic separation: Use a magnetic separator to remove iron impurities in the pulp 5 Flotation:Magnesite Ore Processing: Separation and Calcination2 天之前 Who We Are Welcome to Vinayak Gypsum Our Group Co, established in 1998 is a Mine Owner and Manufacturer of Gypsum range of products, such as Raw Gypsum, Gypsum Powder, Gypsum Special Plasters Plaster of paris Gypsum Powder Gypsum plasterOur grinding equipment can grind 100+ kinds of nonmetallic grind hard stone into fine powder SBM ultrafine grinder is the ideal choice for ore processing Home; Materials; Processing Materials Our grinding equipment can grind Processing Materials SBM Ultrafine Powder Technology

Tungsten Processing 4 Successful Processing Plants

2023年3月24日 The raw ore is a finegrained tungstenmolybdenum ore with a grade of 013% Mo, 035% WO 3, and 004% molybdenum disulfide (MoS 2) In this ore, the main molybdenum mineral is molybdenite and the main tungsten 2016年10月28日 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slagforming elements and coke The purpose of sintering is to obtain a product with suitable Iron Ore Sintering: Raw Materials and Granulation ResearchGateOre Processing Plant, gold ore processing plant, copper ore processing plant, Iron processing plant +86371 er Follow Us :Ore Processing Plant2017年3月24日 Ore Processing Plant; Cement Production Equipment; Rotary Kiln ; Single Drum Cooling Machine; Cement Mill; Raw Mill; Rotary Dryer; Airswept Coal Mill; Lime Plant Gypsum Plant; Quick Lime Plant; Gypsum Plant; Hydrated Lime Plant; Tel: 0086371 :xingkuangjx@gmail More > > Solution; News; Case; Contact Us; InquiryQuick Lime Plant ore processing

Raw Gypsum Ore Washing System for HighEfficiency Remove Clay

Raw Gypsum Ore Washing System for HighEfficiency Remove Clay, Sand Processing Equipment, Sand Recycling Machine, Viberating Screen, High Frequency Linear Screen, Vibrating Feeder, Jaw Crusher, Raymond Mill, Tailings Dewatering Screen2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of Iron Ore Processing, General SpringerLink2024年2月23日 Mineral processing is a key activity in the mining world, focusing on boosting the worth of raw minerals pulled from the earth This crucial step turns the dugup ores into cleaner and more concentrated versions that are ready for more useMineral Processing: An InDepth Guide JXSCEDS) The equipment model is Leo 1450 with LaB 6 filament The samples were viewed at 200 X and 10 Electron Dispersive Spectroscopy Spectrum of raw gypsum ore (RWG) Fig 4DISSOLUTION KINETICS STUDIES OF NIGERIAN GYPSUM ORE IN

.jpg)

What is Gypsum How Gypsum is Processed MC

Raw Gypsum is calcium sulfate dihydrate ((Ca (SO 4) 2H 2 O), Crushing: The mined gypsum ore raw material enters the crusher through vibrating feeder, Grinding, processing equipments Reply jamal Sowid says: 07/07/2021 at Wet Grinding Mills is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and other minerals selected With less investment, fast results, small footprint saving power, sturdiness and Wet Grinding Mill ore processingHigh quality ore processing equipment, crushing plant and cement production equipment in our company with low price +86371 er Follow Us :ore processing equipment,crushing plant, cement Gypsum ore dressing process October09,2024 Gypsum ore dressing process is a complex and delicate process, which aims to increase the content of useful minerals in gypsum ore to meet different application requirements It can be roughly divided into crushingsortinggrindingcalcining The following is a detailed overview of the gypsum ore Gypsum ore dressing process LZZG

Upgrade Your Process: 3 Best Gypsum Powder Mills

2024年9月26日 2 Ultrafine mill Get the Latest Price As an advanced grinding mill combining crushing, grading, and static pressure, the ultrafine mill excels in both fineness and environmental performance It is mainly used to produce ultrafine gypsum powder or micronlevel particles, and is widely used in industries requiring highfineness powders, such as chemicals, coatings, and 2023年5月26日 Copper ore processing equipment is an excellent and efficient piece of equipment that can improve the value of copper ore The equipment includes a jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, and dryer It comprises leading equipment such as a feeder, hoist, and conveyor to form a complete beneficiation production lineCopper Ore Processing And Equipment JXSC MineralOre Processing Plant; Cement Production Equipment; Rotary Kiln ; Single Drum Cooling Machine; Cement Mill; Raw Mill; Rotary Dryer; Airswept Coal Mill; Lime Plant Gypsum Plant; Quick Lime Plant; Gypsum Plant; Hydrated Lime Plant; Tel: 0086371 :xingkuangjx@gmail More > > Solution; News; Case; Contact Us; InquiryLime Plant Gypsum Plant2015年8月3日 This study investigates the potential application of microwave imaging (MWI) in ore sorting systems for mineral processing Modern sensorbased ore sorting employs various sensing methods, such as (PDF) Overview of Mineral Processing Methods ResearchGate

Copper Mining and Processing: Processing Copper Ores

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively,