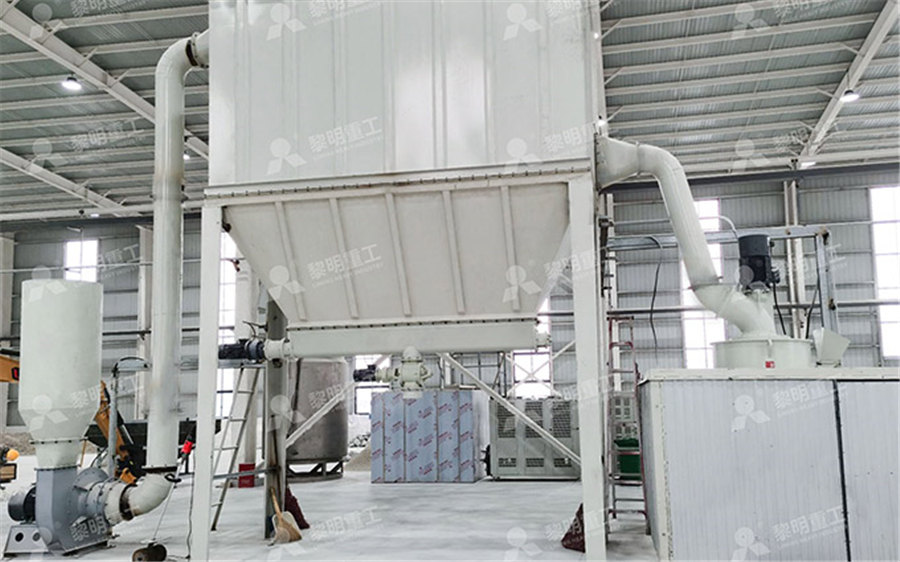

Microsilica powder powder making process

Microsilica an overview ScienceDirect Topics

Microsilica is initially produced as an ultrafine, grey powder and has the following typical properties: low carbon content An element of processing microsilica is the removal of coarse particles Such particles can be wood chips, pieces of coke and other components of the 2023年9月1日 In order to improve the output value of microsilica produced during the ferrosilicon production process as well as to reduce pollution, amorphous silica was prepared from Amorphous silica: Prepared by byproduct microsilica in the 2018年8月9日 It is shown that the microsilica presence in the powder component allows using a hydrous sodium silicate powder also as a part of this component to replace a liquid sodium Microsilica in Sodium Silicate Bonded Sands Springer2023年3月20日 Hu et al used three efficient procedures to make amorphous silica and activated carbon: toluene/ethanol, NaClO 2, and KOH Calcination was used to make nanoscopic silica Methods for the Preparation of Silica and Its Nanoparticles from

Microsilica Characterization of an unique additive

2006年11月15日 Microsilica is a finely dispersed powder, the direct processing (without preliminary preparation) of which into technical silicon is impossible in orethermal furnaces2022年10月4日 Lighttransmitting bulk silica was manufactured using an amorphous spherical nanosilica powder having uniform size without impurities Transmittance according to Fabrication of transparent amorphous silica by controlling forming Microsilica is a densified powder admixture with pozzolanic action, to be used in combination with plasticizers and superplasticizers for highquality mortars, grouts and concrete Microsilica complies with the provisions and specifications of Microsilica, technical sheet MapeiElkem MICROSILICA® powders, a coproduct of silicon or ferrosilicon manufacturing mainly consist of ultrafine, amorphous spheres of silicon dioxide (SiO 2) They feature highpurity properties, which can have a strong impact Microsilica for castable products in refractories

.jpg)

Surface modification of silica micropowder by titanate coupling

2021年11月8日 Surface modification of silica micropowder (SMP) was performed by using commercially available titanate coupling agent KTTO, and polyvinyl chloride (PVC) based The higher the fineness, the higher the cost Micro silica powder is naturally formed during the production process and the cost is relatively low 5From applications, microsilica powder is mainly used in the building materials industry which is mainly used to increase strength While silicon micro powder is another industry such as electronicsthe differences between silica fume and silicon micro powderSilica fume particles viewed in a transmission electron microscope Silica fume, also known as microsilica, (CAS number 6, EINECS number 2737611) is an amorphous (noncrystalline) polymorph of silicon dioxide, silicaIt is an ultrafine powder collected as a byproduct of the silicon and ferrosilicon alloy production and consists of spherical particles with an average Silica fume WikipediaSilica powder is widely used as a filling material and modifying agent Making high crackresistance, selfwaterproofing concrete, be used in the subway, tunnel, and basement of highrise structures Making highgrade concrete effectively Micro Silica Powder for Paint and Coatings

Micro Silica Powder Exporter Manufacturer from Gujarat India

The most reliable, costeffective and best quality Micro Silica, Amorphous Silica, Rice Husk Ash Powder, Silica Fume etc, to be found New Arraival Products We are a distinguished Exporter, Manufacturer and Supplier that is indulged in making the most of customers In order to process high quality products, we highly depend on 2021年11月8日 From Fig 10A, it can be seen that the tensile strength of SMP/PVC and mSMP/PVC composites is significantly lower than that of pure PVC, due to the fact that the stretching process of PVC is mainly dominated by the breakage of PVC molecular chain, while the silica micropowder filling leads to a decrease in the loadbearing capacity of the vertical Surface modification of silica micropowder by titanate Description of EMSilica (MicroSilica) Grade 85D (TDS) EMSILICA (MICROSILICA) GRADE85D is a fine powder which has great Pozzolanic properties is a byproduct material which consists of noncrystalline silicon dioxide with high specific surface area and high pozzolanic reactivity It is used in concrete mixes o replace part of the cement and enhance the resultant Micro Silica Manufacturers in IndiaWhy Choose Buildrock Microsilica? Increased Strength: The tiny particles of Microsilica bond with cement particles, creating a stronger and more durable concrete mix, perfect for highperformance projects Improved Durability: Buildrock Microsilica helps your concrete resist environmental damage such as corrosion, freezethaw cycles, and chemical attacks, making it ideal for harsh Buildrock Microsilica for UltraStrong, Durable Admixture

What is microsilica? HSA Microsilica

The microsilica is collected in a bag house, a system for filtering the hot air and gases vented from the furnace This gas vapor is condensed in bag house collectors as very fine powder of spherical particles that average 01 to 03 microns in diameter with a surface area of 17 to 30 m2/g Physical characteristics Color: gray or gray white powder1 Overview Micro silica (scientific name Microsilica or Silica Fume), in the department of smelting ferrosilicon and industrial silicon, through the flue exhaust steam oxidation, specially designed silica dust collector to collect the amorphous powder SiO2 The average particle size of the micro silicon powder is 015020μm, Specific surface area is 1500020000 m2/kg, which has []Microsilica properties HSA Microsilica2022年11月14日 Silica Fume 94% Densified Powder SiO₂:>94% Color:Dark Grey, Netural Grey PH Value:585 Bulk density: 380400kg/m³ Inventory: Adequate stock Packages:20kg soluble paper bags, 500kg plastic woven bags, 600kg plastic woven bagsmicrosilica powder,silica fume powder,silica fume applicationGet info of suppliers, manufacturers, exporters, traders of Silica Powder for buying in India IndiaMART Get Best Price Shopping Powdered Grade I Silica Dust Powder, For Making Solar Glass Panel, Packaging Size: 50 kg ₹ 2,600 Silica Powder at Best Price in India India Business

High Purity Porous Silicon Powder Synthesis by Magnesiothermic

2020年4月11日 Crystalline metallurgical silicon nanopowder was successfully produced from Tunisian silica sand by magnesiothermic reduction Silica sand was first transformed into silica powder via a specific chemical process The produced silica powder was reduced by magnesium granules at a temperature range of 500–800 °C Thermal analysis shows that a low 2021年11月8日 It is also an important measure of the adhesion of inorganic–organic substrates [7], [8], [9] Untreated silica micropowder has strong polarity, which can easily react with the carboxyl groups of water molecules in the air by hydrolysis, making it an obvious hydrophilic and oleophobic materialSurface modification of silica micropowder by titanate 2023年9月5日 Discover the process of powder metallurgy, its benefits, and applications Learn how this costeffective method can enhance your manufacturing process Close; various types of powdermaking equipment, and sintering equipment manufacturing Their products include bearings, gears, carbide tools, molds, friction products, and morePowder Metallurgy: A Comprehensive Guide for BeginnersAdded to that, Microsilica reduces the rate of carbonation and decreases permeability to chloride As a result, microsilica concrete is able to strongly protect reinforcement and embedments from aggressive agents Types of Microsilica Microsilica comes in three forms which are: Powdered microsilica ; Condensed microsilica; Slurry microsilicaMicrosilica in Concrete – Types, Properties, and Practical

.jpg)

How is fumed silica made Rawsource

2024年4月29日 Fumed silica, a pivotal material in countless industries, is crafted through a process known as flame hydrolysis This blog delves into “How is fumed silica made,” highlighting the intricate steps from silicon tetrachloride to the versatile, ultrafine powder used to improve products from cosmetics to coatings2023年12月7日 It includes a comparative analysis of the primary characteristics of microsilica from various sources and examines the extensive use of microsilica as a modifying additive in building This amorphous silica powder, This process yields microsilica with high purity and a dispersion ranging between 0062 and 0097 microns Analysis of Experience in the Use of Micro and Nanoadditives 2020年12月21日 Figure 1: Schematic diag ram showing produc tion process of microsilica Microsilica is grey colored powder, much similar to fly ash There are different forms of micr osilicaPotential use of microsilica in concrete: a critical reviewPrimary Information Services 21 Murugappan St, SwamyNagar Ext2, Ullagaram, Chennai , India Phone: 91 44 : primaryinfo@gmail Mobile numbers:, Fax : 91 44 Micro Silica General, Production process, Patent, Company

Microsilica Manufacturer Exporter Precision Drawell

One of the most heterogeneous items used in the construction sector is concrete The major ingredient required for making concrete is cement but its hackneyed usage marks to be a serious environmental concern This issue could be addressed by seeking the help of novel imperative cementing materials and microsilica proves to be one such alternativeSilica fume (also called microsilica), is made that during smelting silicon iron and industrial silicon, after the oxidation of silicon vapor discharged from the flue, the amorphous and powdered silicon dioxide (Sio2) is collected by specially What is silica fume? HSA MicrosilicaSilica fume: Basic chemistry and multiple advantages Silica fume is a coproduct of silicon or ferrosilicon production, consisting of ultrafine (submicron), amorphous, nonporous, perfectly spherical silicon dioxide (SiO 2) particles, What is silica fume? ElkemActivated Silicon Oxide SiO2 Powder Description: Activated Silicon Oxide (SiO2) Powder Features: Made by Coupling process – particle surface with a functional group, make micro silica work better crosslinking with the resin, greatly Activated Silicon Oxide SiO2 Powder low Price $40

.jpg)

Microsilica, technical sheet Mapei

Densified SilicaFume Admixture Microsilica is a densified powder admixture with pozzolanic action, to be used in combination with plasticizers and superplasticizers for highquality mortars, grouts and concrete Microsilica complies with the provisions and specifications of ASTM C1240 and AASHTO M3072024年9月23日 For example, during the concrete mixing process, the microsilica powder can be evenly dispersed in the cement paste, filling in the voids between the cement particles and making the overall structure of concrete more compact Promote the hydration reaction of cementWhat Is The Principle Of Microsilica Powder (Silica Fume) To 2021年6月21日 Powder detergent spray drying process explained Modern powder detergents comprise a lightweight, freeflowing, puffed mass Known as precipitate, it leaves visible deposits on fabrics, making it stiff and unappealing Hydrocarbons used in soap typically have a plant or animal origin, Powder Detergent: Ingredients Manufacturing Process Explained2020年10月26日 This research includes a review of powder metallurgy processes, advantages and disadvantages, applications, and production methods of metal powder Powder metallurgy process steps consist of Powder Metallurgy Processes and Making Metal Powder

Microsilica an overview ScienceDirect Topics

Microsilica as an Addition Robert Lewis, Per Fidjestøl, in Lea's Chemistry of Cement and Concrete (Fifth Edition), 2019 111 Introduction Microsilica is a very fine powder mostly composed of amorphous silicon dioxide The terms ‘condensed silica fume’ or ‘silica fume’ 1 are also used These can however be said to designate any powder coming out of the smelting 2021年3月1日 Silica sand was first transformed into silica powder via a specific chemical process The produced silica powder was reduced by magnesium granules at a temperature range of 500–800 °CHigh Purity Porous Silicon Powder Synthesis by Magnesiothermic 2019年8月13日 Concrete is a solid mass of fine aggregate, coarse aggregate, cement and water, which can be spread or poured into moulds and forms a stonelike mass on hardeningCONCRETE USING MICROSILICA IN MSAND CONCRETE MIXProduct Introduction: 95% Silica Fume Undensified Powder is a microsilica fume with 95% SiO ₂ content, and the Bulk density is 380400kg/m³ Undensified Silica Fume, which is made from a large amount of highly volatile silicon monoxide gas produced during the smelting process, is rapidly oxidized with air and condensed into silica dust Silica Fume 95% Undensified Powder Silica Fume, Microsilica,Silica Fume 95% Undensified Powder

.jpg)

Microsilica powder used in Several major fields

2024年1月25日 Anyang WeiYuan Alloy Co, Ltd was established in 2011 We specialize in producing various ferroalloys for steel making, including Ferro Silicon, Ferro Chromium, Silicon Carbide, Ferro Manganese, Metal silicon Cocoa Powder Manufacturing Process: From Bean to Powder The process of making cocoa nibs begins with harvesting ripe cocoa pods from cocoa trees The pods are then opened to reveal the cocoa beans inside, which are surrounded Cocoa Powder Manufacturing Process: From Bean to 2020年1月8日 In this study, an inorganic sand core that exhibited high tensile strength was fabricated by sodium silicate, silica sand, as well as silica fume The effects of the silica fume on the properties of the sand core were studied According to the optimal hardening process of sand core material, the mold was first heated to 175 °C and the compressed air purging Effect of Silica Fume on Humidity Resistance of Sodium Springer2022年11月5日 Fuji et al reported that the powder surface can be activated by a mild ball milling treatment at very low rotation speeds without sufficient pulverization and silane coupling agents [17]The cleavages of siloxane bonds (Si–O–Si) on the silica particle surface could be confirmed because of the friction between the balls and particles even under mild milling, resulting in the Surface modification of silica powder by mild ball milling

Silica Fume an overview ScienceDirect Topics

2011年3月4日 It is a byproduct of the smelting process in the silicon and ferrosilicon industry When highpurity quartz is reduced to silicon at temperatures of about 2000°C, silica vapors are produced, which oxidize and condense to tiny particles in the low temperature zone consisting of noncrystalline (amorphous) silica It is glassy powder of gray colorpurpose of making the test specimen At least six random subsamples shall be taken to prepare the test specimen 8 STORAGE AND INSPECTION 81 The silica fume shall be stored in such a manner so as to permit easy access for proper inspection and identification of each consignment 82 Adequate facilities shall be provided to the purchaserIS 15388 (2003): Specification for Silica Fume LawFigure 1 Schematic process flow diagram of the olivine process 21 Dissolution of olivine The dissolution of olivine can be subdivided in several processes During the dissolution hydrogen atoms are transported from the bulk of the solution to Nanosilica production by a sustainable process; application in 2022年10月4日 Quartz glass with excellent optical, chemical, and thermal properties was manufactured by a new method using sintering rather than the existing glass manufacturing method involving melting and synthesis With a spherical amorphous nanosilica powder, by controlling the forming and sintering conditions, the optimum conditions for producing a light Fabrication of transparent amorphous silica by controlling forming

.jpg)

The difference between the types of silica powder

2023年6月7日 Spherical microsilica powder has good fluidity and a high filling amount in the resin After being made into a plate, the internal stress is low, easy to process, can reduce the wear of the drill bit in the hole making process, reduce the dust pollution in