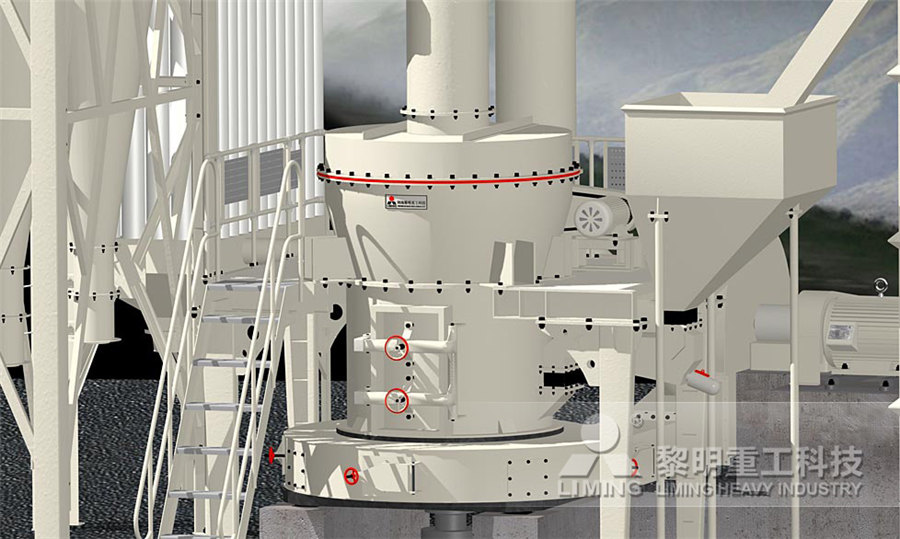

Ore mill threeinone complete set of equipment

.jpg)

Mining equipment and services FLS

As a premier provider in the mineral processing industry, we offer innovative solutions and unmatched expertise to enhance productivity From inpit crushing to comprehensive digital 2023年9月15日 Depending on the production process, metallurgical machinery can be classified into four types: smelting equipment, continuous casting equipment, rolling equipment, and Metallurgical Machinery SpringerLinkOur full selection of mining and surface equipment for rock drilling, crushing and screening, loading, tunneling, quarrying, breaking and demolitionUnderground Mining Equipment and Surface Mining EquipmentOur MaxRTM technology provides the most advanced method in the industry, combining precipitation reactors with solidliquid separation, which allows the seeding and particle growth Lithium processing technology Complete solutions that FLSmidth

35 No 9 Uranium Extraction Technology IAEA

This publication is one of a series of Technical Reports on uranium ore processing that have been prepared by the Division of Nuclear Fuel Cycle and Waste Management at the IAEA2022年7月25日 Color ore sorter, Xray ore transmission sorter, dualenergy Xray transmission ore sorter, Xray fluorescence ore sorter, and nearinfrared ore sorter have been successfully A review of intelligent ore sorting technology and equipment In the past, the mining industry has addressed dropping feed grades and higher costs by leveraging economies of scale The tendency has been to try and apply a “onesize fits all” Complete Optimisation from MinetoMill to Maximise Profitability2016年5月15日 Installing ore sorters in the pebble circuit of a SAG mill is a logical first step Ore sorters in a SAG circuit show payback terms of less than 24 months Sorting technology can Bridging the gap: Understanding the economic impact of ore

.jpg)

Friction and wear of liner and grinding ball in iron ore ball mill

2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are 100tph Complete Set Gravity Separator Tin Ore Processing Plant, which is generally treated by gravity separation method and equipment For placer tin ore with high monomer The underscreen particles will go to the ball mill for 100tph Complete Set Gravity Separator Tin Ore 2016年3月11日 In some copper concentrators, the mill feed is all passing 13MM(½”), using three stages of crushing and 14MM (9/16″) square openings on the closed circuit screens It was felt by some that crushing to this fine size is Crushing Plant Flowsheet DesignLayoutComplete set of equipment Hebei Machinery Import and Export Co, Ltd (HMIEC), established in 1974, has more than thirty years of experiences and a good reputation in International Trade HMIEC, one of the foremost members Complete set of equipment

.jpg)

The Processing of Copper Ore Beneficiation JXSC Machinery

2024年11月21日 In the development and utilization of copper resources, the grading operation of the copper ore beneficiation plant is also an important production link in the separation of copper ore As the difficulty of copper mining and sorting increases, the requirements for screening efficiency and classification efficiency are getting higher and higher Therefore, A SAG mill, also known as a semiautogenous grinding mill, is one of the essential equipment used in copper ore mining It plays a vital role in reducing large chunks of rock into smaller pieces to facilitate easier processingUnderstanding the SAG Mill in Copper Ore Mining Process2, HLM vertical mill: largescale equipment, high capacity, Phrase one: raw material crushing Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Equipment: 1 set of HLM21 Materials: iron ore Finished fineness: 200 mesh D90 Capacity: 15 Iron ore grinding mill Grinding plants for Iron Ore2016年6月6日 Once the process metallurgist has thoroughly tested the ore body and determined the optimum method of mineral recovery; and the plant designer has efficiently and economically laid out the circuit, instrumentation, equipment installation, and building design; and the mill manufacturer has completed his stress analysis and reliability engineering for mill design, the SAG Mill Liner Design 911Metallurgist

Wet Ore Pan MillWet Pan MillThe Nile Machinery Co, LtdThe

Structural Features of Wet Ore Pan Mill The base structure of a wet pan mill made in twoparts and supported by 4 concrete columns The bedding of whole equipment by damping elements on four concrete columns 1 It adopts the separated inner and outer grinding tracks 22024年11月21日 ♦ Jaw crusher is the main equipment for coarse crushing of nickel ore It not only has a large processing capacity in the crushing and processing of materials, but also the crushed nickel ore particles are uniform and complete, which can effectively improve the efficiency of the equipment in productionSelection Of Nickel Ore Beneficiation Process Equipment2024年11月21日 Drum magnetic separator The drum magnetic separator is used to separate ironcontaining impurities below 3 mm and can automatically remove magnetic contaminants that are difficult to separate from nonmagnetic materials The material is evenly fed to the magnetic field area on the upper part of the rotating drum through an electromagnetic vibrating feederWhat Are The Equipment Of Chrome Ore Washing Plant?Use of a ball mill is the best choice when long term, stationary milling is justified by an operation Sold individually or as part of our turnkey ore processing system For questions and/or an expert opinion on what size and accessories Ball Mills Mt Baker Mining and Metals

Unveiling the Efficiency and Significance of Ore Milling Machines

Ore milling machines are sophisticated pieces of equipment designed to crush, grind, and process raw ores into finer particles, ultimately extracting valuable minerals and metals These machines are instrumental in the journey from raw ore to refined products, playing a crucial role in industries such as mining, metallurgy, construction, and beyond2024年4月26日 Iron ore processing is a crucial step in the production of steel, one of the most essential materials in modern society Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed Iron Ore Processing: From Extraction to Manufacturing2018年10月1日 The impact of ore variability on process performance was observed at the OK Tedi mine in Papua New Guinea, where the variations in feed ore hardness (Bond work index 5–16 kWh/t) and in feed size distributions caused the SAG mill throughput to fluctuate between 700 and 3000 t/h (Sloan et al, 2001)Quantifying variability of ore breakage by impact ScienceDirectJXSC specializes in designing stateoftheart equipment and supplying the best mineral and ore processing solutions in the market Customize Your OneofaKind Plant JXSC designed a complete 200TPH alluvial diamond wash plant flow chart and a complete set of equipment for Angolan customers Leading Mineral Processing Equipment Manufacturer JXSC

.jpg)

(PDF) Sensor‐Based Ore Sorting Technology in Mining—Past,

2019年8月29日 expenditure is the investment for a complete plant—and not just the sensor ‐ based ore sorting machine—which is four ‐ to 10 ‐ fold of the main equipment value, and with capital costs China Complete Equipment wholesale Select 2024 high quality Complete Equipment products in best price from certified Chinese Mining Machine manufacturers, Mining Machinery suppliers, wholesalers and factory on MadeinChinaComplete Equipment MadeinChinaComplete set of equipment Hebei Machinery Import and Export Co, Ltd (HMIEC), established in 1974, has more than thirty years of experiences and a good reputation in International Trade HMIEC, one of the foremost members of China Chamber of International Commerce, Hebei Chamber of Commerce, has been awarded the ISO9002 Quality System plete set of equipment2016年6月20日 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Ore, Rock Aggregate Screening (Complete Guide)Ore, Rock Aggregate Screening (Complete Guide)

Friction and wear of liner and grinding ball in iron ore ball mill

2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to 3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for Population balance model approach to ball mill optimization in iron ore 2017年2月21日 Rockbreakers may be set to crush to any desired fineness, the coffeemill type still successfully holds its own against most of the newer while by no means an exaggerated example of this form of distortion, shows a 74/360, or 208per cent, sample taken on one side of the orestream and 88/360, or 244 per cent, on the Ore Sampling Methods: Good Proper 911MetallurgistFor the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers, screens and samplers give you the highest throughput with less manpowerReliable equipment for iron ore mines FLSmidth

.jpg)

Hard Rock Gold Mining Equipment: Essential Gear Guide

Grinding mills are essential equipment for this purpose as they efficiently grind down crushed ore using various mechanisms One type of grinding mill commonly used in hard rock gold mining is the ball mill This cylindrical device rotates around its axis and uses steel balls or other grinding media to pulverize the ore inside it2023年5月31日 In iron ore mineral beneficiation, the grinding process is one of the important process in iron ore processing As one of the commonly used grinding equipment, ball mill plays a key role in iron ore beneficiation This article will introduce 3 types of ball mills and their application in iron ore processing, aiming to help optimize the iron ore beneficiation process Different Types of Ball Mills in Iron Ore Mineral Beneficiation ProcessChina Threeroll Mill wholesale 1 set (MOQ) Guangzhou Jinfeng Light Industry Machinery Equipment Co, Ltd S65 Three Roller Grinding Equipment Laboratory Three Roll Mill Machine US$ 820880 / Piece 1 Piece (MOQ) Guangzhou Jinfeng Light Threeroll Mill MadeinChina2022年9月27日 In the past few years, the mining industry has seen a lot of operational changes Digitalization and automation of many processes have paved the way for an increase in its general productivity In keeping with this trend, this article presents a novel approach for optimizing underground mine scheduling for the short and mediumterm This problem is Short and mediumterm optimization of underground mine

.jpg)

Illite Ore Industrial Grinding Mill Machine SBM Ultrafine

2021年11月8日 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, So what are the equipment involved in the complete set of illite grinding processing? Illite Stone Crusher >> Jaw Crusher and the onetime screening rate can reach d97≤5μm2023年4月25日 The characteristics of these two types of nickel ore are quite different, so different nickel ore processing methods and equipment are rrequired 1 Process flow of coppernickel sulfide ore A complete coppernickel sulfide ore processing production line is crushing, grinding, flotation, and tailings treatment2 Types of Nickel Ore: Processing Methods and Equipment2023年9月4日 Iron ore flotation equipment; It is an 80100 tph iron ore processing plant The complete plant consists of the below machines: vibrating feeder, Output from the ball mill goes to the second set of dry magnetic separators for the separation of iron and waste sand again, Iron Ore Beneficiation Plant Equipment For Mining Process2016年4月14日 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of Crushing Screening Plant Design Factors

.jpg)

Future of Mining, Mineral Processing and Metal Extraction

2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices The demand for new metals and materials has also arisen concurrently This necessitates 2021年7月6日 then grinding with the different major equipment passes from one side of the mill and exists from the other three types of iron ores with 30425 mm were comminuted to −0425 mm Comminution a Heart of Mineral Processing ResearchGate45 TPH Gold Plant Description Turn Key system utilizes Jaw Crusher Module, Fine Ore Hopper Feeder Module, Set of Chrome Hammers; 1 Hammer Mill in Used Condition Featured Equipment Instagram Facebook Twitter Youtube Address: MBMM 45 TPH TurnKey Ore Processor Gold Recovery Plant Savona Equipment2024年1月19日 Sandmine machinery can provide a complete set of highquality iron ore processing equipment Welcome to contact us to recommend a suitable solution for you Next Page: How to choose a limestone grinding millHow to process iron ore SANDMINE

(PDF) Grinding in an air classifier mill Academia

2 Experiments 21 Experimental setup The flow investigations have been performed using a ZPS 100 air classifier mill (Hosokawa ALPINE GmbH) as shown in Fig 1 The mill itself consists of a rotating disk with 4 grinding pins at its periphery and an impeller wheel classifier integrated into the top section of the mill chamber2015年4月3日 Understanding Iron Ores and Mining of Iron Ore satyendra; April 3, 2015; 0 Comments ; blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining,; Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average Understanding Iron Ores and Mining of Iron Ore – IspatGuru2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpen2023年5月27日 Gold Flotation Equipment Flotation Cell Yes, I am interested! Gold ores finer than 10 μm are difficult to recover by gravity separation Froth flotation utilizes the hydrophobicity of gold to separate it from gangue, thereby recovering fine 8 Pieces of Gold Mining Equipment to Get Gold Concentrates