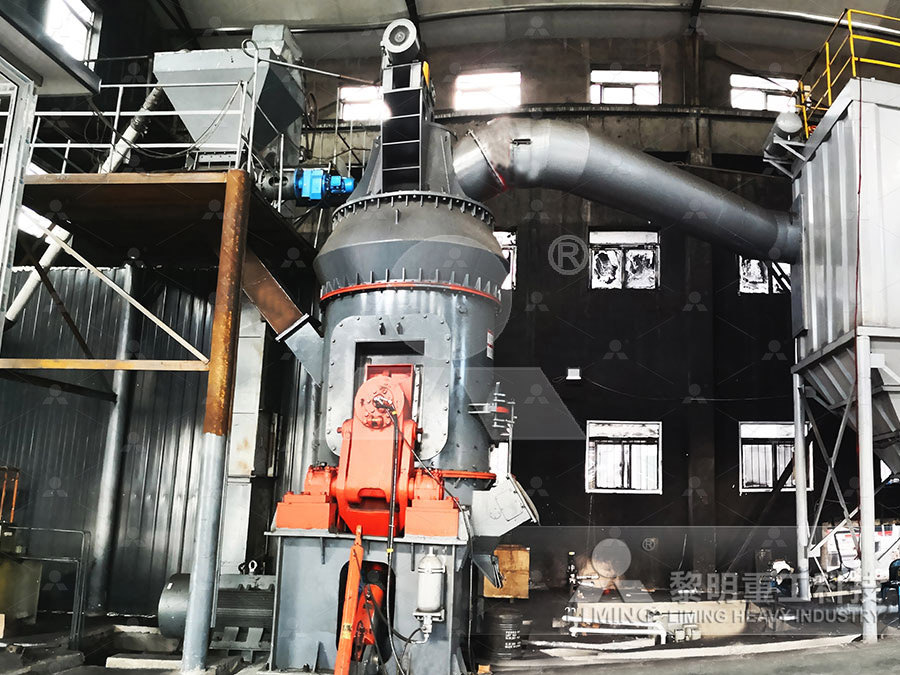

Carbide mud lithium carbonate Complete equipment

.jpg)

Lithium processing technology Complete solutions that FLSmidth

We ofer everything you might need for your lithium brine conversion operation – from cuttingedge equipment, to islands, to total process flow solutions In developing our lithium spodumene concentration solutions, we draw upon decades of experience in concentrator technologyBepex has been supplying processing technology for lithium carbonate or lithium hydroxide production since the early 1990s Now, with lithium producers straining to fulfill ever increasing demand, Bepex is pioneering systems to streamline Lithium Processing Systems and Equipment Bepex2023年10月12日 We demonstrated that the presence of molybdenum or chromium carbides promotes the performance of C/Si electrodes, improving the cycling stability compared to pristine graphite/silicon electrodes Lithiumion Metal Carbide Additives in Graphite‐Silicon 2019年8月23日 Subsurface brines trapped in the Earth’s crust are major source material for lithium carbonate These sources are less expensive to mine than from rock such as Lithium Processing Equipment, Process Flow, Cases JXSC Machine

Battery minerals: Find here complete process solutions

Complete process solutions for dewatering, purifying, and drying of cathode and anode active materials as well as solutions for battery recycling and black mass recovery Because of the boom in the battery industry, demand for lithium, Lithium carbide, Li2C2, often known as dilithium acetylide, is a chemical compound of lithium and carbon, an acetylide It is an intermediate compound produced during radiocarbon dating Lithium carbide WikipediaSaltworks is DLE agnostic and works downstream of DLE, where we use concentrating, refining, and converting (CRC) technology to produce batterygrade lithium carbonate or lithium Lithium Extraction and Refining Saltworks Technologies2011年1月21日 Three carbon materials were prepared for the synthesis of Li–C compounds, such as Li intercalated graphite The materials were asreceived high purity polycrystalline Synthesis and characterization of lithium–carbon compounds for

.jpg)

The preparation of graphite/silicon@carbon composites for

2020年5月9日 Here, lowcost raw materials are used for the preparation of a graphite/silicon@carbon composite negative electrode material, which synergizes ball milling, 2018年8月21日 With demand rising for electric cars, manufacturers are under pressure to provide high quality grade lithium carbonate – something that will be extremely profitable for Lithium Carbonate Milling; Just One of Many Exciting Applications PengFei Group has the great comprehensive ability to provide best services on turnkey basis with technology design, complete plant, erection and debugging, commissioning for the new type dry process rotary kiln lithium carbonate Lithium Carbonate Production Line Pengfei Rotary Production of lithium carbide using of carbonate sampleBenzene line: benzeneline Equipment for radiocarbon dating benzeneline02 Production of lithium carbide using of carbonate

RECENT DEVELOPMENTS IN THE PROCEDURES AT THE SSCER

212 V V Skripkin and N N Kovaliukh Simultaneous Pyrolysis and Chemisorption Our answer to minimizing the loss of genuine sample carbon during pyrolysis has been via the devel opment of a stainless steel reactor that allows thermal degradation of the raw sample to be carried out with simultaneous exposure of the volatile organics to a lithium meltDownload scientific diagram Overview of main processing options for production of lithium carbonate from rock minerals from publication: Minerometallurgical processes for lithium recovery from Overview of main processing options for production of lithium carbonate After the lithium brine solution is concentrated to the specifications you desire, it is transferred to the mixing tank Soda ash is added to lithium brine in order to precipitate lithium carbonate (Li₂CO₃)The solution is processed by the Filter Press where the lithium carbonate is captured between the plates, and the remaining liquid is dischargedLithiumion Battery Recycling Process Equipment MetChemBuy Battery Grade (995%) Lithium Carbonate (Li2CO3) for Battery Research with the best value at MSE Supplies, trusted by 20,000+ scientists and engineers worldwide Highpurity lithium carbonate is primarily used for preparing highend lithiumion battery cathode materials and batterygrade lithium fluorideBattery Grade (995%) Lithium Carbonate (Li MSE Supplies LLC

.jpg)

Lithiumion capacitors using carbidederived carbon as the

2016年11月1日 After complete removal of titanium from the carbide, the CDC was transferred to another quartz tube reactor and posttreated with hydrogen (AGA, On the use of soft carbon and propylene carbonatebased electrolytes in lithiumion capacitors J Electrochem Soc, 159 (2012), pp A1240A1245, 101149/2jes2019年1月2日 XRD Pattern of Expired Lithium Carbonate Powders The crystalline structure of expired lithium carbonate powders was examined by Xray diffraction technology, as shown in Fig 3Totally, 18 diffraction peaks were detected, well matching with the standard pattern of Li 2 CO 3 (PDF card No 801307) These diffraction peaks were sharp and narrow, indicating high Recovery of Expired Lithium Carbonate Tablets for LiFePOLithium carbide, Li 2 C 2, often known as dilithium acetylide, is a chemical compound of lithium and carbonIt is an intermediate compound produced during radiocarbon dating procedures Li 2 C 2 is one of an extensive range of lithium− carbon compounds which include the lithium rich; Li 4 C, Li 6 C 2, Li 8 C 3, Li 6 C 3, Li 4 C 3, Li 4 C 5, and the graphite intercalation compounds LiC Lithium carbide chemeurope2020年1月9日 In recent years, the methods of lithium preparation by metallothermic reduction of its oxide in negative pressure have been developed Since Li 2 CO 3 was considered as an important raw material for the preparation of Li 2 O, it is important to clarify the decomposition and melting mechanisms of Li 2 CO 3The behaviors of decomposition of lithium carbonate under Process of Thermal Decomposition of Lithium Carbonate

Lithium Carbonate Li2CO3 CID 11125 PubChem

Most prepn currently used in the US are tablets or capsules of lithium carbonate Slowrelease prepn of lithium carbonate also are available, as is a liq prepn of lithium citrate (with 8 mEq of Li+, equivalent to 300 mg of carbonate salt, per 5 Since the industrial revolution, cumulative CO 2 emissions from fossil fuels have reached 173 trillion tons By 2023, the global atmospheric concentration of CO 2 reached 4193 ppm, representing a 51 % increase from preindustrial levels of approximately 278 ppm [1], [2]Currently, compared to preindustrial times, the global average surface temperature has Integration of CO2 sequestration with the resource recovery of red mud This process is lengthy and can take over 15months to complete before the material is transitioned to lithium chloride Carnallite is transitioned into lithium carbonate which is used to manufacture products such as batteries, and Lithium Mining Pumps EDDY Pump2024年10月30日 In the present study, we report a methodology for the selective recovery of lithium (Li), cobalt (Co), and graphite contents from the endoflife (EoL) lithium cobalt oxide (LCO)based Liion batteries (LIBs) The thermal treatment of LIBs black mass at 800 °C for 60 min dissociates the cathode compound and reduces Li content into its carbonates, which Recovery of Lithium, Cobalt, and Graphite Contents from Black

What is the chemical formula of lithium carbide? Answers

2024年6月19日 Li4C is the chemical formula for lithium carbide, a compound composed of lithium and carbon atoms It is an ionic compound that is typically synthesized through the reaction of lithium metal with 2023年9月25日 The Lithium Carbonate and Hydroxide Production Business is a growing industry in Nigeria and Africa, driven by the increasing demand for lithiumbased products such as lithiumion batteriesHow To Start A Lucrative Lithium Carbonate and Hydroxide2022年12月12日 Calcium carbide slag is a waste slag produced after the hydrolysis of calcium carbide to obtain acetylene gas, with very fine particles, offwhite color due to the presence of trace carbon and sulfur impurities, slightly odorous, with Ca(OH) 2 as the main component, and a slag liquid pH value of 12 or more, thus often causing serious pollution to the environment [18]Comprehensive performance study of aluminum ash and calcium carbide 2015年12月31日 In the paper the results of experiment are presented which main goal was to examine the influence of lithium carbonate addition on the phase composition development of calcium aluminate cement(PDF) The Influence of Lithium Carbonate on Phase Composition

.jpg)

Lithium carbide composition, cathode, battery and process

The gist of the instant invention is the use of lithium carbide in the cathode of a rechargeable lithium ion battery 352, pp252257, (1967)) or by reacting lithium carbonate with carbon at 800950 degrees Celsius (Kroger, et al, Zeitschrift fur Anorganische und charging equipment, and integrated circuit USA (en 2023年4月25日 The SEM images of the samples were shown in Fig 1a, b According to SEM (Fig 1a), the morphology of unground powder particles was irregular, and the TaC particle size was about 200–300 nm After ball milling, the size of carbide particles changed, it could be seen that the diameter of the sample was reduced and the size were more uniform, about 100–200 Fabrication of tantalum carbide cathode by ball milling processes Lithium carbide, Li 2 C 2, often known as dilithium acetylide, is a chemical compound of lithium and carbonIt is an intermediate compound produced during radiocarbon dating procedures Li 2 C 2 is one of an extensive range of lithium− carbon compounds which include the lithium rich; Li 4 C, Li 6 C 2, Li 8 C 3, Li 6 C 3, Li 4 C 3, Li 4 C 5, and the graphite intercalation compounds LiC Lithium carbide chemeurope2024年5月17日 Red mud (RM) is an alkaline industrial solid waste generated by alumina enterprises during the extraction of aluminum and subsequent drying [3]Statistics show that between 10 and 18 tons of RM can be discharged per ton of alumina [4], [5]And, the global production of RM stands at approximately 15 billion tons annually, with a total stockpile that Improved macromicroscopic characteristic of gypsumslag based

.jpg)

Lithium carbide wikidoc

Template:Chembox new Lithium carbide, Li 2 C 2, often known as dilithium acetylide, is a chemical compound of lithium and carbonIt is an intermediate compound produced during radiocarbon dating procedures Li 2 C 2 is one of an extensive range of lithium− carbon compounds which include the lithium rich; Li 4 C, Li 6 C 2, Li 8 C 3, Li 6 C 3, Li 4 C 3, Li 4 C 5, Download scientific diagram Typical XRD patterns of Li 2 CO 3 crystals from publication: Lithium carbonate precipitation by homogeneous and heterogeneous reactive crystallization Lithium Typical XRD patterns of Li 2 CO 3 crystals ResearchGateMajor Midwest US manufacturer of capital equipment We ordered our zirconium tubing from Stanford Advanced Materials because we were promised delivery in half the time of the other competitive bids When we received the parts, not only Global Supplier of Fabricated Products Machining Parts2022年8月30日 (a) Schematic representation of the employed experimental setup for lithium precipitation with sodium carbonate: (1) sixposition magnetic stirrer, (2) doublewalled beaker, (3) heating water from (PDF) Recovery of Lithium Carbonate from Dilute LiRich Brine via

.jpg)

Electrochemical manufacturing of nanocarbons from carbon

2015年12月9日 One simple and fast way to manufacture a useful product from CO2 is to capture the gas by, and then carry out electrolysis in molten alkali metal carbonates Carbon electrodeposition in molten Li2CO3Na2CO3K2CO3 (molar ratio: 435:315:250) has been widely reported in literature However, studies in each of the individual alkali metal carbonates either 2019年2月1日 Recovery of lithium from lithiumrich electrolytes has attracted worldwide attention because of issues related to the electrolytic production of aluminum and its environmental impactsHydrometallurgical preparation of lithium carbonate from lithium 2004年5月1日 The company concluded that lithium increased the melting rate and lowered melting temperature and fuel usage 1 However, little or no additional productionscale research was reported on lithium's effect in a glass batch until the early 1980s, when Glass Containers Corp decided to run two tests, one in Jackson, Miss, and the other in Hayward, Calif, with GLASS FORMING PROCESSING: Saving Energy with LithiumHint:The compounds that consist of carbon and less electronegative elements and that are distinguished by their chemical bonding (ionic or covalent) are known as carbidesThey are generally prepared at high temperatures Complete step by step answer: Carbides are compounds that consist of carbon and less electronegative elementsThe carbide of Lithium has the formula:A$LiC$ B$L{i2}C$C

Comprehensive Utilization of Carbide Slag SpringerLink

2019年5月23日 714 Basic Performance of Dry Acetylene Carbide Slag Dry acetylene technique is compared to the traditional “wet” acetylene preparation technique It uses water a little more than the theoretical amount, which is sprayed on calcium carbide powder in a foggy state to hydrolyze it2014年10月5日 Lithium in the form of a carbonate salt is given as oral tablets (04–20 g/day) This is dependent on renal function and concomitant use of other drugs Lithium serum levels rise following the introduction of diuretics, dehydration and salt depletionLithium: A review of pharmacology, clinical uses, and toxicity2019年8月23日 Mining for Lithium: Lithium is often recovered from brine, or water with a high concentration of lithium carbonate Subsurface brines trapped in the Earth’s crust are major source material for lithium carbonate These sources are less expensive to mine than from rock such as spodumene, petalite, and other lithiumbearing mineralsLithium Processing Equipment, Process Flow, Cases JXSC 2024年9月1日 Lithium carbonate (Li 2 CO 3) stands as a pivotal raw material within the lithiumion battery industryHereby, we propose a solidliquid reaction crystallization method, employing powdered sodium carbonate instead of its solution, which minimizes the water introduction and markedly elevates onestep lithium recovery rateCrystallization of batterygrade lithium carbonate with high

.jpg)

Sustainable Lithium Extraction: How is Lithium Mined and

2023年10月6日 How is lithium carbonate produced from extracted lithium? Lithium carbonate is produced from extracted lithium by subjecting the concentrated lithium solution or hydroxide to further chemical reactions and purification steps These steps involve the conversion of lithium hydroxide to lithium carbonate, followed by precipitation, filtration, and 2024年4月29日 such cathode materials, large amounts of lithium carbonate (Li 2 CO 3) are required, followed by lithium hydroxide (LiOH H 2 O) with a very high chemical purity, and batterygrade compounds (over 995%)6 Lithium carbonate and hydroxide impurities classify the finalproduct as battery or technical grade, for instance, technical grade lithium Analysis of Trace Impurities in Lithium Carbonate ACS 2023年8月30日 This article analyzes lithium carbonate (Li ₂ CO ₃) extracted from salars using XRay diffraction (XRD)Salars, which are salt flats or salt pans, are sources of lithium, where Li ₂ CO ₃ or LiOH is derived from brines or saltwater through a series of evaporation steps Lithium carbonate finds wide application in batteries, ceramics, glass, and other industries, Lithium Carbonate Quality Control via XRay Diffraction (XRD) 2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environment(PDF) Lithium extraction from hard rock lithium ores: technology

John Parker Ceramic Artist and Designer Auckland New Zealand

john parker ceramics contents introduction early work 1966―1973 hand building 1969―1973 agate 1973 decals 1973―76 bronze 1974 vortex ware 年6月25日 Silicon is receiving discernable attention as an active material for next generation lithiumion battery anodes because of its unparalleled gravimetric capacity However, the large volume change Silicon carbidefree graphene growth on silicon for lithiumion