Cement tube mill operation work summary

.jpg)

The Cement Plant Operations Handbook International Cement

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide Providing a Grinding systems with tube mills have been operated throughout the world for many decades Many practical ways to operate these mills in an easy way have been developed and many Operation of Tube Mills ArchiveIn any Tube mill, the grinding action is determined by the charge volume The power input for moving the mill charge at a given speed is directly proportional to the charge weight (Grinding media charge plus weight of material) and the Notes on Tube mills INFINITY FOR CEMENT To summarize, the tube mill machine's working process involves the preparation of raw materials, grinding, tube formation, welding, sizing, cutting, and additional processing The tube mill Tube Mill Machine Working Process Citic Ic Luoyang Heavy

Cement manufacturing: components of a cement plant

Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc This presentation includes the motor selection, a mill drive analysis, a failure analysis, the lubrication, the vibration measurement and the finite element analysis, covering strain and fatigue design and a brief writeup on materials Tube mill drive systems – a review Cement Lime HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants The paper describes the approach for the PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Abstract Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling The process simulation OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

Mill drives INFINITY FOR CEMENT EQUIPMENT

The motor was manufactured by Brown, Boveri and Comp, Baden, Switzerland The 5 m diameter mill was supplied by the WEDAG Co, now KHD Humboldt Wedag AG Koln, W Germany The tube mill has a diameter of 5000 mm; a Cement Plant Operation Handbook Free ebook download as PDF File (pdf), Text File (txt) or read book online for freeCement Plant Operation Handbook PDF Mill (Grinding) ScribdSection summary; 1 Cement production process overview: 2 Cement The use of a ball mill is common in the cement production process, as it is efficient, costeffective, and able to produce a consistent product size 23 Pyroprocessing in a kiln for clinker production The Cement Production Demystified: StepbyStep Process and Cement Milling Process Ball Mill Operation Using Simulator English VersionIn this session I will explain about How to Operate Ball Mill Cement Milling SysCement Milling Process Ball Mill Operation Using Simulator

Cement Plant Operation Handbook PDF Mill (Grinding) Scribd

Cement Plant Operation Handbook Free ebook download as PDF File (pdf), Text File (txt) or read book online for free Cement Plant Operation Handbook6 Cement milling process summary data – 8 Typical equipment downtime 110 1 Storage of clinker and other components – 2 Cement milling – 3 Separators (classifiers) – 4 Ball mill circuit control – 5 Cement storage – 6 Cement dispatch – 7 Distribution – 8 Quality assurance and customer service 7 Quality control 134 1 The Cement Plant Operations Handbook International Cement 2022年5月14日 Kiln and Coal Mill Operation In Cement Plant English VersionIn the previous video session, we explained how to start the Kiln operation, but the quality andKiln and Coal Mill Operation In Cement Plant English VersionFor a cement mill: intermediate or outlet diaphragm For the case of; cement mills with a drying chamber see raw mills Mill working conditions: ventilation air speed through the mill Bigger or smaller than 12 [m/s] Material abrasivity The [%] of slag or pouzzolana content on the fresh mill feed for cement grindingEverything you need to know about clinker/cement Grinding

.jpg)

The mill shell Optimum dimensions INFINITY FOR CEMENT EQUIPMENT

Mill bearings Generally, tube mills working in the cement industry are equipped with sliding bearings Contrary to this, the ore preparation industry employs tube mills equipped with roller bearings This contrast in mill bearing practice is not readily explainable However, roller bearings are substantially more expensive than sliding bearingsOPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinder s with ball mills Ball mills have been the traditional method of comminution in the mineral processingOPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLSABSTRACT The increasing demand for ‘‘finer cement’’ products, and the need for reduction in energy consumption and green house gas emissions, necessitate the optimization of grinding circuitsThe Improvement of Mill Throughput Using BarmacCement Separator Ball Mill Optimization – OperationMill ventilationClear diaphragm slot Common problems! Case mill test, CM6 STS (Aug,2008) Evaluate and correction – Tube Mill Feed rate, Return, Grinding aids, Cement Separator Ball Mill Optimization

.jpg)

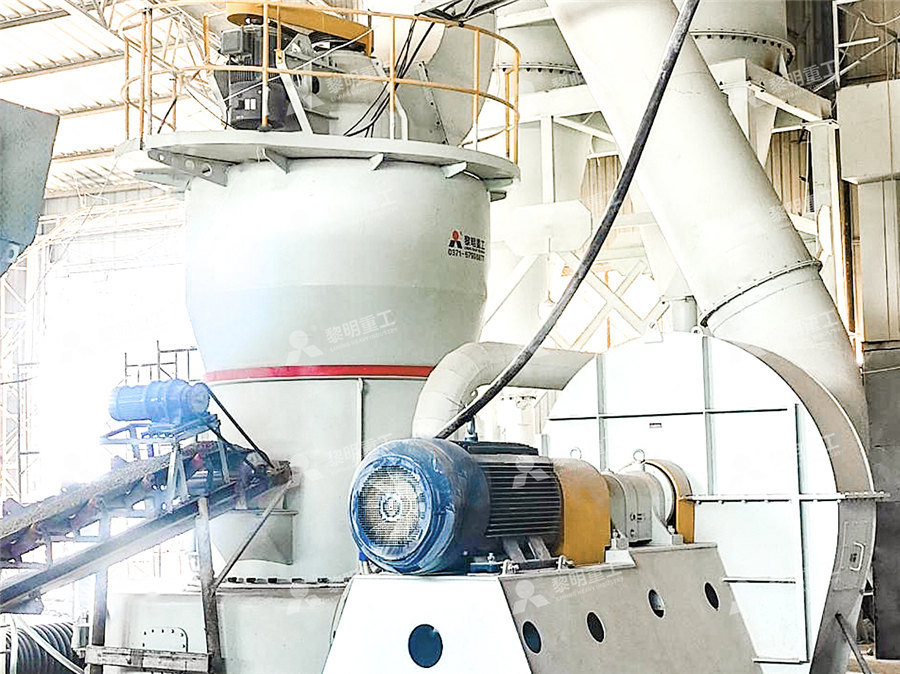

Ball Mill Cement Grinding System In Cement Plant

Ball Mill Cement Grinding System In Cement Plant English VersionIn this session I will explain about How To Operate The Ball Mill Cement Grinding SystemBal2022年11月20日 Raw Mix Design for Raw Mill and Kiln Cement Operation English VersionThe first goal in preparing raw materials is a thorough understanding of the raw materRaw Mix Design for Raw Mill and Kiln Cement OperationCCR Operator ((Crushers, Vertical Raw mill, Kiln, Cement mills, packing plant) Plant Profile: FLS design, 5000TPD, VRM Atox 425, Kiln 45mD*74mL, Coolax Grate Cooler, Dual fired (heavy oil and natural gas), 2 cement tube mills Responsibilities • In charge of Cement Production Manager Looking Globally Skills ProvisionBall mill in operation at a cement plant The mill shell was protected against wear by liner plates bolted Gas volume and power consumption of tube mills Schneider, U, “From ordering to operation of the first quadropol roller mill at the Bosenberg Cement Works,” ZKG International, No8,1999, pages 460466 Schultz, A, and Everything you need to know about cement Materials Preparation

Steps Operation of Tube Mills Ball Mills To avoid mistakes at Cement

Update this Video the new linkhttps://youtu/S6fqLywyfothis channel Designed to spread All you want to know about the cement industry, including mechanicsThe document discusses the OKMill, a vertical roller mill for grinding cement or slag Some key points: The OKMill uses proven technology licensed from Onoda and Kobe Steel and is suitable for grinding blended cement or slag It provides energy savings of 2040% compared to tube mills It has a simple and spacesaving layout with a vibrationproof grinding bed and highly wear OK Mill PDF Mill (Grinding) CementIF YOU WORK IN A CEMENT PLANT AND YOU NEED COURSES AND MANUALS LIKE THIS MANUAL AND BOOKS AND EXCEL SHEETS AND NOTES I SPENT 23 YEARS COLLECTING THEM YOU SHOULD CLICK • Processes Involve • Hazards Involve in Operation • Safety Counter Measures Summary Of Process The cement mill grinds the clinker to a fine Safety in Cement Plant INFINITY FOR CEMENT EQUIPMENT2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement

How Cement is Made: Inside a Cement Factory Did

2020年3月25日 Transcript Did you know the foundation of your house once looked like this? Well, this is a 300 million year old piece of limestone, and today, we're gonna Cement Ball Mill Sizing Calculators Exercises 12 Mill Ventilation Measurement Location of the measurement point(s) Pitot Tube Method of measurement Mill Ventilation Calculator Exercise 13 Material inside the mill and retention Summary sheet of the work to do 17 Grindability and Hardness Tests IntroductionTraining Courses based on the Grinding SoftwareKiller Resume Summary Write a Resume Objective What to Put on a Resume Will be required to work rotating shifts in a 24/7/365 operation Operate tube mill in safe and efficient manner Must be able to set up and operate tube mill Mill Operator Resume Samples Velvet Jobs2024年4月24日 In summary, ball mills play a vital role in the cement industry by grinding raw materials, clinker, and additives to produce cement with the desired properties The efficient and reliable operation of ball mills is essential for ensuring consistent product quality, optimizing production processes, and reducing energy consumption and operational costs in cement how ball mill work in cement industry Knowledge

Steel Ball Tube Mill Cement Machine Manufacturer CIC

Introduction of Ball Tube Mill The ball tube mill is a very important fine industrial grinding mill in modern industry, and the production capacity of a large tube mill is very high The difference between a single bin tube mill and a short cylinder ball mill is that a single bin tube’s length is 27 times larger than its diameter, the material experiences a long time in the tube mill Figure 332 Relationship between liquid phase and temperature as a function of A/F ratio A 100% LSF value expresses the theoretical limit to the amount of lime (CaO) that can be added to a mix until all of the calcium would be combined into clinker compounds, with no C2S remainingEverything you need to know about Kiln System Operations in Cement 2004年12月1日 During the last decade, semifinishgrinding plants have been used more and more for the energy efficient grinding of highquality cement In 1999, it was found that by decreasing the ball charge Optimization of continuous ball mills used for finishgrinding of 2001年8月16日 Operators must work the tooling the way it was designed This means setting up to the parameters of a setup chart 3 Lack of formal training Formal training helps operators perform the procedures for tube mill operation and maintenance and ensures that all operators are on the same track 4Solving problems on the tube mill The Fabricator

.jpg)

Grinding in Cement Manufacturing: Key Process, Types of Mills,

Mill Operation Settings Proper settings like mill speed, temperature, and load influence grinding performance Overloading or running mills at inefficient speeds can reduce the quality of the grind Material Feed Uniformity Inconsistent feed material can lead to CMHE >> Environmental Equipment >> Principal Machines For Cement >> Tubemill Environmental Equipment Principal Machines For Cement; Filter Our company is one of the most powerful national manufacturers to produce tube mill After exploration and summary in the design, China Mechanical and foreign cooperation Company Φ42×13m tube TubemillTubemillCMHE Cement Equipment2017年3月8日 4 Characteristics Of Cement • Color should be grey with greenish shade • It feels smooth when touched • It feel cool and warm when hand inserted in bag of Cement • It should free from hard lumps • When immersed Powerpoint presentation on CEMENT {PPT} SlideShareAdvantages of CHAENG cement ball mill: 1 With high stability, won a number of new patents: Doubleslidingbelt tube mill of CHAENG is the first one in China to solve the problem that grinding mills cannot continuously work due to the high temperature of slidingbelt shaft bush at the discharge end, and won national patent for utility models Cement ball mill Xinxiang Great Wall Machinery Co, Ltd PDF

A scaleup and design basis of continuous tube mills in cement

2020年3月1日 Batch grinding kinetics with assumptions is applied to continuous tube milling to describe the grinding performance, relating the degree of size reduction to the milling conditions including the scaleup variables As to the scaleup effect on the degree of size reduction, the trend predicted is confirmed with that observed in industrial cement mills in reasonable Ball MillOperation, Inspection Optimization Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document discusses parameters for quality finish milling including cement strength, Blaine surface area, and residue percentages It also covers inspection of ball mills including measuring filling degrees, conducting longitudinal testing of material Ball Mill Operation, Inspection Optimization2024年1月23日 The efficient operation of a cement mill is vital for the overall productivity and quality of the cement production process How Does a Raymond Roller Mill Work March 22, 2024 How Does a Vertical Coal Mill Work March 16, 2024 Application of Dry Ball Milling in Mineral Processing How To Optimize The Operation Of The Cement Mill2022年5月5日 How To Start Kiln Operation In Cement Plant With Simulator English VersionIn the previous video session, we explained how to do a Heating Up Kiln, the HeatHow To Start Kiln Operation In Cement Plant With Simulator

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

295% in both the chambers Both the chambers of the cement mill were charged with 80% of the designed charge, which works out to 86 t in Ist chamber and 172 t in the IInd chamber The mill is utilised for production of OPC 33 grade, OPC 53 grade and PPC The blaines for the cements of different grades are being maintained as given below:line for better mill operation and the procedure of practical mill assessment In a cement plant, the largest portion of electrical energy costs is related to cement grinding Any improvement in grinding efficiency results in considerable savingsOperation of Tube Mills Internet Archive2024年7月12日 Carefully selecting the right grinding media ensures efficient grinding and reduces wear on your ball mill equipment Summary of Ball Mill In conclusion, mills are versatile and efficient grinding machines They play a crucial role in various industries, from ore processing and ceramic production to paint manufacturingWhat Is a Ball Mill and How Does It Work? Certified MTP BlogGrinding aids also serve to reduce coating problems in cement storage and enhances cement strengths GRINDING MILLS Mills will be selected according to type most suitable for required capacity and duty and for overall power consumption Cement grinding operation may be performed in one of the following mill setups Ball and tube millsCement Grinding Cement Plant Optimization