BF type large coal mill gives you a new experience

BLAST FURNACE TECHNOLOGY Paul Wurth

our products and services cover the full range of blast furnace projects ranging from complete new ironmaking plants, furnace modernisations and relines, new or upgraded equipment and 2023年2月14日 Modelling results show that, under optimum operating conditions, a hydrogen injection rate of 275 kg/tHM can effectively reduce CO 2 emission by 214% from the BF with Decarbonisation and hydrogen integration of steel industries: 2021年4月21日 BFBOF operation relies almost entirely on coal products, emitting ∼70% of CO 2 in the integrated plant (BF iron making) Hot iron is then charged to a basic oxygen furnace Lowcarbon production of iron and steel: Technology options, 2020年7月15日 The BF is large countercurrent metallurgical furnace where iron oxides and coke fed into the furnace from the top are moving downward, while reducing gases are moving Blast Furnace Ironmaking an overview ScienceDirect Topics

.jpg)

Optimization of Ironmaking Blast Furnace Operations Using an

Optimization of ironmaking blast furnaces (BFs) must consider bottom and top operations This is done by a recently developed integrated BF model covering the BF below the burden surface 2022年5月19日 Following the international climate change policy and the major use of coalbased blast furnace–basic oxygen furnace (BF–BOF) in the steel sector, with an average Climate Change and Emission Reduction Pathways for a Large 2023年8月2日 In today’s modern BF, pulverized coal injection (PCI) is dominant and routinely makes up roughly 25–40% of the carbon required This is the carbon that could most easily be Challenges and Opportunities of Agricultural Biomass as a Given that BFs constitute 90% of the capacity of ironmaking, this capacity, overlaid with carbon ideas for lowering carbon intensity of the process—can deliver faster reduction in emissions as The Blast Furnace: A Vital Tool in Climate Neutral Ore Springer

(PDF) Coal dust injection in blast furnace : experience at Durgapur

2012年1月1日 Coal dust injection gives rise to increased generation of fines due to coke degradation and due to increased accumulation of coal particles Thus problems like a dirty 2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns Therefore, an algorithm has been developed that Detection of Malfunctions and Abnormal Working 2015年11月1日 The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the educational simulator The coal mass flow and the outlet temperature are modeled by The Inferential predictive control method of coal mill2021年3月24日 existing coal mill and cofired with coal in the existing coal combustion system Biomass can be milled in a new dedicated mill to increase the cofir ing ratio; up to 50% on an energy basis can be (PDF) TECHNOLOGY DEVELOPMENTS IN THE

Dynamic steam inerting system for a ball tube mill pulverizing

tive was set by the authors' companies and UPGenCo to prevent coal mill explosions under all modes of operation when explosions could occur Early operating experience showed that mill 'puffs' or explosions could occur dur ing mill startup, stripping period during shutdown, and immediately after2021年8月10日 Metal production, and especially iron orebased steel production, is characterized by high fossil CO2 emissions due of the use of coal and coke in the blast furnaceExperiences of BioCoal Applications in the Blast Furnace Process 2024年11月19日 For example if you’ve ever had a job “wearing many hats” unless you’re applying for another “many hats” position, this strategy gives you a chance to focus your work experience on the hats that are most relevant for the new role Restarting this process every time you apply for a new job may seem excessiveHow to Write your Work Experience on a Resume [+ Examples]2010年9月23日 Based on the noise signal, BBD ball mill material detection method and mill pulverizing system optimization control are presented and this method can solve the control problems of ball mill, such as nonlinear, close coupled variables In this paper, based on the noise signal, BBD ball mill material detection method and mill pulverizing system optimization control Material level detection and optimum control of BBD coal mill

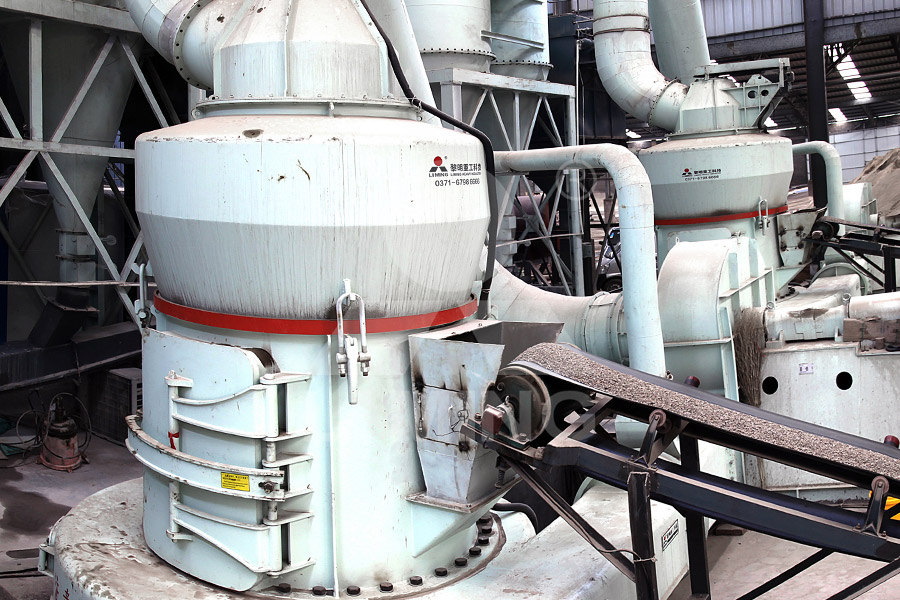

ATOX® Coal Mill FLSmidth Cement

Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture levelI've been using my BF 30 Super Mill form Bernardo for a while now, getting it ready to be converted to CNC As there isn't a lot of information about it out BF 30 SUPER Mill Review YouTube2018年10月21日 Fig 1 Pulverized coal combustion and gas composition in raceway The extent of combustion (combustion efficiency), and hence the amount of unburnt material transported out of the raceway, depends on several parameters which include (i) properties of the coal, such as the VM content, particle size and density, and (ii) operating conditions, for example, blast gas Understanding Pulverized Coal Injection in Blast Furnace2021年8月1日 HP type medium speed coal pulverizer produced by Shanghai heavy machinery works has been widely used in recent years, with common faults in operation, short maintenance cycle and heavy taskFault analysis and optimization technology of HP bowl type

.jpg)

Detection of Malfunctions and Abnormal Working Conditions of a Coal Mill

PDF On May 2, 2018, Teresa Kurek and others published Detection of Malfunctions and Abnormal Working Conditions of a Coal Mill Find, read and cite all the research you need on ResearchGate2023年1月31日 In this sequence, a new record was created in Blast Furnaces by increasing the quantity of daily Coal Dust Injection (CDI) By 30th January 2023, a new record of highest monthly coal dust injection of 137 kg/Tonne SAILBhilai Steel Plant Blast Furnace, SMS3 and Plate DOI: 101016/jjprocont202106008 Corpus ID: ; Coal mill model considering heat transfer effect on mass equations with estimation of moisture @article{Li2021CoalMM, title={Coal mill model considering heat transfer effect on mass equations with estimation of moisture}, author={Xinwen Li and Yingchun Wu and Huafeng Chen and Xijiong Chen and Yonggang Coal mill model considering heat transfer effect on mass 2009年9月1日 The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the educational simulator The coal mass flow and the outlet temperature are modeled by reinvestigating the mass balance and heat balance models physically The archived data from a plant database are utilized to identify the model Modeling and Parameter Identification of Coal Mill

Simplified flowsheet of an Integrated Steel Mill operating with

Download scientific diagram Simplified flowsheet of an Integrated Steel Mill operating with a TGRBF, showing carbonbearing material input (green, highlighted boxes), CO 2 emissions, expressed 520 P Niemczyk et al / Control Engineering Practice 20 (2012) 519–530 Nomenclature Dpmill mc mpc mcair mass of unground coal on the table (kg) mass of pulverized coal on the table (kg) mass of pulverized coal carried by primary air (kg) wc wpc wout wret mass mass mass mass flow flow flow flow of of of of the dry raw coal to the mill (kg/s) pulverized coal (kg/s) pulverized coal Derivation and validation of a coal mill model for control2024年11月20日 We've been independently researching and testing products for over 120 years If you buy through our links, we may earn a commission Learn more about our review process Sometimes, the best gift 31 Best Experience Gift Ideas Ever Good Housekeeping2017年12月15日 Two dominant methods account for the vast majority of underground coal mining: “room and pillar” and “longwall” mining In room and pillar mining, seams of coal are partially mined, leaving large pillars of coal intact to support the overlying layers of rockWhen finished, miners practice “retreat” mining, extracting as much coal as possible from the How Coal Works Union of Concerned Scientists

.jpg)

Coal mill pulverizer in thermal power plants PPT SlideShare

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and Coal Mill Free download as PDF File (pdf), Text File (txt) or view presentation slides online This dissertation examines technologies to enhance the maintenance performance of coal pulverizers through new technologies It Coal Mill PDF Mill (Grinding) Industries2017年11月9日 The Loesche coal grinding plant is put into operation by carrying out certain individual stepsHere's a 3D animation of how a coal grinding system works WilStart Up Sequence of a Loesche Coal Mill YouTube2019年1月25日 Pulverized coal (PC) injection with high injection rates for minimisation of coke consumption is state of the art in BF operation Increasing need for flexible production rate with changing operational conditions and limited availability of matching coal types cause constraints for high injection rates and result in higher total carbon consumptionImproved coal combustion under variable BF conditions (IMPCO)

.jpg)

COAL PREPARATION AND FIRING INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 COAL PREPARATION AND FIRING11 INTRODUCTION12 2COAL RESERVES13 CHARACTERISATION OF COALS BY CHEMICAL131 31 Major components132 32 Minor Components14 4CHARACTERISATION BY PHYSICAL AND MECHANICAL PROPERTIES141 41 Coal Storage142 42 Variation of Physical and 2020年7月15日 The volatile matter (VM) content in the coke is low A broad range of coals with respect to VM content has been successfully injected to the BF High volatile coals are gasified easily in the BF raceway but have a lower coke replacement ratio The high oxygen content of the coal decreases its heating value and coke replacement ratio [24]Blast Furnace Ironmaking an overview ScienceDirect Topics2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Modeling and Parameter Identification of Coal MillDOI: 101002/srin Corpus ID: ; Research on Utilization Factor of Injected Pulverized Coal into BF at Large PCI Rate @article{Wu2008ResearchOU, title={Research on Utilization Factor of Injected Pulverized Coal into BF at Large PCI Rate}, author={Keng Wu and Wenbo Pan and Wanren Xu and Xiaoying Yin and Jianmin Zhang and Weilu Wu}, Research on Utilization Factor of Injected Pulverized Coal into BF

A Modeling and Optimizing Method for Electricity Current

If the current intensity of a coal mill can be predicted with a given set of operation parameters, it is of significant help for optimizing operations of the coal mill running state The current intensity of the coal mill may be reduced or minimized subject to coal type parameters and the load of the boiler via optimizing the coal mill operationsYou are free to opt out any time or opt in for other cookies to get a better experience If you refuse cookies we will remove all set cookies in our domain We provide you with a list of stored cookies on your computer in our domain so you can check what we stored Due to security reasons we are not able to show or modify cookies from other Bed Type Milling Machines BF MTE520 P Niemczyk et al / Control Engineering Practice 20 (2012) 519–530 Nomenclature Dpmill mc mpc mcair mass of unground coal on the table (kg) mass of pulverized coal on the table (kg) mass of pulverized coal carried by primary air (kg) wc wpc wout wret mass mass mass mass flow flow flow flow of of of of the dry raw coal to the mill (kg/s) pulverized coal (kg/s) pulverized coal Derivation and validation of a coal mill model for control2014年1月1日 The emission factors of kiln end, kiln head, coal mill, crushing and cement mill was 0156 clinker g/t, 3914 clinker g/t, 1538 coal g/t, 0016 stone g/t and 0056 cement g/t respectively, the (PDF) MPS mills for coal grinding ResearchGate

.jpg)

Coal Mill an overview ScienceDirect Topics

A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is 3 Precise Control and Automation: Bellian Machinery's coal mills feature advanced control systems that enable precise control over various operational parameters Operators can adjust grinding variables, such as coal flow and mill rotation speed, in realtime to achieve the desired coal fineness and optimize mill performanceCoal Mill in Thermal Power Plant: Enhancing Efficiency and either high moisture coals, or largesized coals Coal Characteristics Coal characteristics are integral to pulverizer system selection, sizing and performance The production capaci ty for each mill depends upon the following feed properties: In general,the coal entering a mill system should be crushed to a size no larger thanA Comparison of Three Types of Coal Pulverizers Babcock Power2022年10月3日 With this being said, it’s still better to mine coal ores directly since they can give you up to 2 experience points And coal often spawns in a large vein, so it’s a winwin! Copper Ore; Copper ore is not so common compared to coal, but it can still spawn a large chunk, especially in the dripstone caves biomeWhat Ore Gives the Most XP in Minecraft? Gamer Empire

Crude steel production via the BF/BOF route ResearchGate

Download scientific diagram Crude steel production via the BF/BOF route from publication: RecoDust—An Efficient Way of Processing Steel Mill Dusts RecoDust is believed to be an efficient way 2002年4月1日 Grindability of coal is a central characteristic of coal which is closely related to pulverizer performance and mill capacity (ACARP, 1998) and is defined as ease of grinding of coal which is, in An assessment of grindability index of coal ResearchGate2009年1月30日 When Mill's The Subjection of Women was published in 1869 it was ahead of its time in boldly championing feminism It failed to inaugurate a respectable intellectual debate Feminist writers have tended to refer to it with respect but without any serious attempt to come to grips with Mill's actual argumentsMill and the Subjection of Women Philosophy Cambridge Core2019年10月1日 Request PDF Wet and dry grinding of coal in a laboratoryscale ball mill: Particlesize distributions In this study, experimental data for wet and dryground coal samples under wet and dry Wet and dry grinding of coal in a laboratoryscale ball mill: Particle

.jpg)

An investigation of performance characteristics and energetic

2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coal