Electrolytic aluminum waste slag mill micro powder mill

The recycling of carbonrich solid wastes from aluminum

2024年5月23日 16 Million metric tons of spent carbon electrodes modify carbonrich solid wastes from aluminum electrolysis are produced annually, threatening ecosystems by cyanide Aluminum electrolyte waste powder production can alleviate the stacking volume in the anode assembly workshop slag yard, while extracting renewable resources, thereby reducing raw Aluminum electrolyte waste powder production process2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic Research Progress of Electrolytic Aluminum Overhaul Slag Disposal2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe Efficient lithium recovery from electrolytic aluminum slag via an

.jpg)

Recovery of carbon and cryolite from spent carbon

2022年10月9日 When the carbon anode slag is discarded directly, it will pollute the environment; when it is burned as fuel, it will waste the high extra value electrolyte The comprehensive recovery and utilization of electrolytic 2022年10月10日 In this work, electrolytic aluminum carbon anode slag was separated by flotation Using the selectivity index ( SI ) as an indicator, the influencing factors of the carbon slag flotationRecovery of carbon and cryolite from spent carbon 2024年2月21日 Grind the aluminum electrolysis waste residue through a Cryolite Raymond Roller Mill to below 75250 microns After removing the carbon and iron in the waste residue, add concentrated sulfuric acid and react for 30 Aluminum slag recycled cryolite powder production line2020年8月1日 Here, we discuss the influence of different processing parameters on electrolytic refining of aluminum alloy and investigate the mechanism of extracting Al from coarse AlSi Recovery of aluminum from waste aluminum alloy by low

.jpg)

The Study of Carbon Recovery from Electrolysis

2021年1月12日 How to recycle carbon dust more effectively is a challenge in the aluminum electrolysis field In this study, Xray diffraction, scanning electron microscope, and other methods were used to analyze the phase composition Research on the Coprocessing of Mixed Electrolytic Aluminum Waste in Circulating Fluidized Bed Boiler Lei Shi1, With the structure of ash and slag, as well as the product after adding limestone, grinding the materials with an electric mill, 50 grams of electrolytic aluminum waste samples were sieved to 0075 mmResearch on the Coprocessing of Mixed Electrolytic Aluminum Waste SBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ protected] construction waste, industrial solid waste, and other Micro Powder Grinding Mill2024年2月21日 The raw material of the regenerated cryolite powder production line using electrolytic aluminum carbon slag treatment comes from the waste residue generated during the aluminum electrolysis process The production Aluminum slag recycled cryolite powder production line

.jpg)

Synthesis of Electrolytic Manganese Slag Solid WasteBased

Materials 2024, 17, 1431 3 of 16 the preparation of geopolymers Sodium hydroxide (NaOH) particles were purchased from Sinopharm Reagent (Shanghai, China), and sodium silicate (Na2SiO3) powder with a modulus of 314 was purchased from 2023年3月12日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and it must be disposed of in a harmless manner On the other hand, it contains a few valuable resources, as well In order for the aluminum electrolysis industry to Recovery of Carbon and Cryolite from Spent Carbon Anode Slag2024年9月23日 This critical review systematically explores the innovative utilization of ground granulated blastfurnace slag (GGBS), steel slag (SS), and other steel waste in concrete, addressing a crucial research gap in predicting concrete properties with these materials By analyzing 97 publications, this review offers a comprehensive understanding of how these Enhancing concrete properties with steel waste: a comprehensive 2022年10月10日 The comprehensive recovery and utilization of electrolytic aluminum spent carbon anode slag (Hereinafter simplified as “carbon anode slag”) are therefore necessary Flotation is a physical separation method used to separate particles by using the difference in surface property of particles ( Chen et al, 2022 ; Ni et al, 2022 )Recovery of carbon and cryolite from spent carbon anode slag of

Fluorineretaining agent for overhaul slag of aluminum electrolytic

2020年1月2日 The invention discloses a fluorineretaining agent for overhaul slag of an aluminum electrolytic cell The fluorineretaining agent comprises the following components of, by mass, 80100 parts of calcium sulfate, 6080 parts of calcium oxide, 5070 parts of calcium hydroxide and 3060 parts of calcium chloride The invention further discloses a method for 2024年2月2日 Calcium carbide slag is a difficult industrial waste to treat Millions of tons of calcium carbide slag are piled up in China yearly, occupying a large amount of land and easily causing secondary pollution []The main component of calcium carbide slag is Ca(OH) 2, with 71–95% content []Therefore, the current recycling methods of calcium carbide slag mainly Research on Using Carbide Slag to Mineralize the Carbon Dioxide 2023年3月12日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and (PDF) Recovery of Carbon and Cryolite from Spent Carbon Anode Slag Then, the powder is ground using a grinder to obtain powder with a particle size below 100 mesh, providing better conditions for subsequent processes For the grinding fineness and common production capacity requirements of electrolytic aluminum waste slag, both European and vertical grinding machines can meet their processing needsHow to extract lithium from electrolytic aluminum waste residue?

.jpg)

Sustainable Recovery of Fluorine from Waste Aluminum

2023年8月2日 The highvalue, green and harmless purification of aluminum electrolysis comprehensive solid waste can not only reduce its harm to the environment and soil but also separate and recover the highvalue rare elements This study aims to develop a process for recovering and treating waste aluminum electrolytes by sulfuric acid roasting The results of 2012年12月31日 During the treatment of spent cathode carbon from electrolytic aluminum, a large amount of fluoride containing wastewater is generated By adding different sodium source and aluminum source Study on Harmless and Resources Recovery 2022年9月1日 To better solve the waste pollution problem generated by the electrolytic manganese industry, electrolytic manganese slag as the main raw material, chromium iron slag, and pure chemical reagents (PDF) A study of the solidification and stability mechanisms of Materials 2024, 17, 1431 3 of 16 the preparation of geopolymers Sodium hydroxide (NaOH) particles were purchased from Sinopharm Reagent (Shanghai, China), and sodium silicate (Na2SiO3) powder Synthesis of Electrolytic Manganese Slag Solid WasteBased

.jpg)

Recovery of RareEarth Elements from Molten Salt Electrolytic Slag

2022年2月19日 Recycling waste containing rare earth has always been a research hotspot The molten salt electrolysis process of rareearth metals and alloys generates a large amount of waste slag, which contains high rareearth content and, thus, has very considerable recovery value However, the high content of fluorine in rareearth molten salt slag brings challenges to the 2022年6月17日 With the development of the solid waste slag industry, the special dry vertical mill for the equipment of the slag micro powder industry is a new type of powder mill to increase production and Should We Choose Raymond Mill or Vertical Roller Mill For Aluminum Powder Processing? Tel: +86(021) +95 Fax: +86(021 Slag Powder Vertical Roller Grinding Mill2021年10月1日 Aluminum electrolysis of China, solid waste, such as waste aluminum electrolyte, has been largely idled and caused serious environmental pollution In this paper, a novel approach is developed for achieving the separation/recovery of lithium from spent lithiumcontaining aluminum electrolyte by a sodium carbonate roasting–acid leaching processA novel approach for lithium recovery from waste lithium Steel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can provide an effective way for the recycling of steel slag HCMilling(Guilin Hongcheng) provides customers with professional micropowder Introduction To The Way Of Steel Slag Recycling The Micropowder

Micro Powder Grinding Mill

It is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Barite, gypsum, graphite, fluorite, phosphate rock, potassium ore, etc Micro powder grinding mill is double in capacity compare with Energy 2019年3月27日 According to the design structure, Jet Mill can be roughly divided into: fluidized bed Jet Mill (including vertical and horizontal types); Disc Jet Mill ALPA could produce jet mill with big capacity of 10T/H, could also produce mini milling machine/small vertical mill for laboratory Equipped with fully automatic PLC controlJet Mill ALPA Powder Technology2024年3月21日 manganese slag–solid wastebased geopolymer (SWGP) was evaluated by analyzing the mineral phase, morphology , and leaching concentration of the geopolymer 2Synthesis of Electrolytic Manganese Slag–Solid WasteBased 2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber How does HGM micro powder grinding mill process

Production of sponge iron powder by reduction of rolling mill scale

2012年4月1日 Primary and secondary mill scales (MSs) are waste products produced by the surface oxidation of steel during the hot (800 to 1200 °C) rolling process in downstream steelmakingBrief Introduction of superfine powder grinding mill (for slag) : Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is Superfine Slag Powder Production Line FTM Machinery2024年3月21日 The massive stockpiling of electrolytic manganese residue (EMR) has caused serious environmental pollution In this study, EMR, coal gangue (CG), and fly ash (FA) were used as raw materials to obtain the optimal mix ratio based on DesignExpert mixture design The effects of activator modulus, liquid–solid (L/S) ratio, and curing temperature on the mechanical Synthesis of Electrolytic Manganese Slag–Solid WasteBased2021年12月1日 Abtract Aluminum slag waste generated from the smelting process of bauxite was used to prepare roof tiles samples Clay was substituted by slag waste in percentages reaching 40% in the basic mix The use of aluminum slag waste in the preparation of roof tiles

.jpg)

How Can Manganese Powder Be Refined Into Electrolytic

Manganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is treated with sulfuric acid and other chemical materials is called "electrolytic manganese" Then, how can manganese powder be refined into 2023年1月1日 Suppression of CO2 discharged from iron and steel making companies is an example of the biggest issues for the protection of global environment and sustainable growth of steelmaking industry(PDF) Production of Reduced Iron from Mill Scale Waste Using Granule morphology of granulated blast furnace slag powders prepared with vertical mill (GBFSV) and close circuit ball mill (GBFSB) respectively were observed with SEMThe Vertical Mill Slag MicroPowders' Particle Size Distribution Micro Powder Mill Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; Micro Powder Mill is mainly used for Micro Powder Mill Kefid

.jpg)

Stepwise extraction of lithium and potassium and recovery of

2024年6月29日 Aluminum electrolyte is a necessity for aluminum reduction cells; however, its stock is rising every year due to several factors, resulting in the accumulation of solid waste Currently, it has become a favorable material for the resources of lithium, potassium, and fluoride In this study, the calcification roasting–twostage leaching process was introduced to extract After using vertical grinding to grind nickel slag into micro powder, it is beneficial to recover nickel iron and obtain considerable economic benefits; At the same time, the screened finished micro powder is added to cement to form composite cement, which can greatly increase economic benefits and waste resource utilization, reduce the occupation of land and environmental Nickel slag powder processing solutionLIMING HEAVY 2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe environmental pollution and wasting of Li resources This paper proposes a method for recovering Li from the slag using AlCl 3 as the leaching agent The effects of the leaching temperature, AlCl 3 Efficient lithium recovery from electrolytic aluminum slag via an 2024年4月17日 Recycling plays an important role in today's world due to its considerable contributions to mitigating energy concerns and environmental challenges One of them is dross recycling from aluminum (Al) cast houses Unlike other recyclable materials, dross has an abundance of components, including rare earth elements, heavy metals, ferrous, and recycled Aluminum dross: aluminum metal recovery and emerging

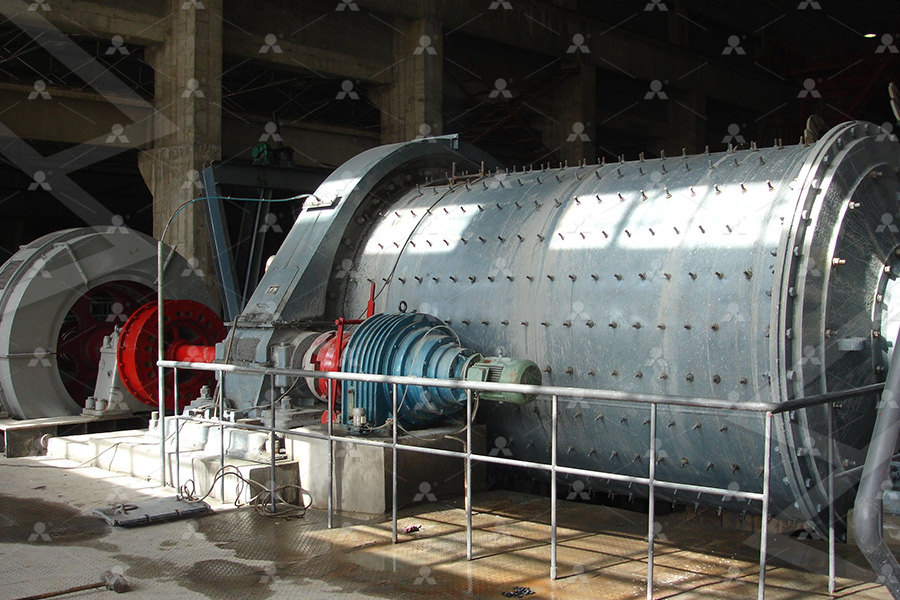

Aluminum slag grinding mill/powder mill/grinder mill

Aluminum slag grinding mill/powder mill/grinder mill Date: 02:14:50 Aluminum slag grinding mill/powder mill/grinder mill: —— five models: HGM80, HGM90, HGM100, HGM100A, and HGM125 ——finished production fineness: 300meshes~3000meshes, 547 micron ——the capacity (ton/hour) ranges from 04T/H to 12T/H Features of aluminum 2024年3月1日 One of the main electrolytic aluminum production costs is the consumption of carbon anodes, and carbon anode slag is a common hazardous waste in the aluminum industryEnhanced flotation separation of aluminum electrolysis anode slag 2023年4月13日 This paper proposes a technical viewpoint for the recovery of waste heat in aluminum electrolysis The idea of combining heatgenerating electrolysis process and the heatconsuming alumina tube A comprehensive review of aluminium electrolysis and the waste 2013年6月1日 Electrolytic manganese residue (EMR) is added into ground granulated blastfurnace slag (GGBS) as an activator to prepare EMR–GGBS cement The effects of chemical activation, mechanical Preparation of electrolytic manganese residue–ground

Recycling and utilization of the aluminum ash and slag Mineral

2020年11月23日 Doing size classification can seprate the sheet metal aluminum Then process the powder to get fine size metal aluminum powder The recycling plant of aluminum ash ans slag The aluminum ash and slag recycling plant include hopper, feeder, ball mill, vibrating screen,separator,dust collector and belt conveyor the plant will be supplied based