How much does a set of calcium carbonate crushing and grinding system equipment cost

How to Choose a Calcium Carbonate Grinding Mill

Before choosing a grinding mill, you need to understand how calcium carbonate is produced At present, there are two main methods, dry grinding method and wet grinding method The dry grinding method is mainly used in primary grinding, On average, a small to mediumsized calcium carbonate powder grinding mill plant could cost anywhere from several hundred thousand to a few million dollars However, for a largescale, calcium carbonate powder grinding mill plant costDaswell supplies the complete set of equipment for the calcium carbonate plant, from crushing machine, transporting system to grinding mill, classifier, packing machine as well as optional Customize Suitable Calcium Carbonate Plant DASWELL2018年9月25日 Generally, the small crusher (like jaw crusher, hammer crusher), grinding mill (Raymond mill,high pressure grinding mill, ultrafine grinding mill), hoist (elevator), feeder, etc How Much Does It Cost to Invest a Small Calcium Carbonate

.jpg)

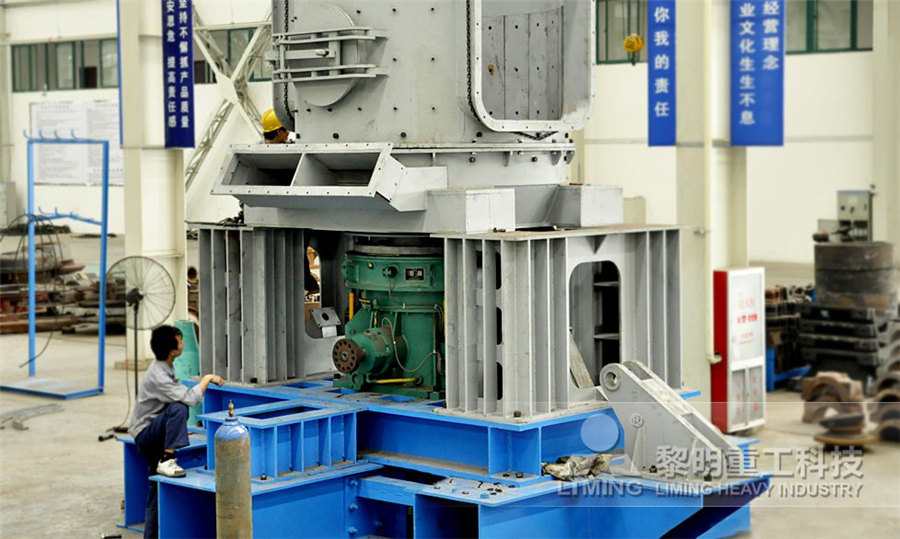

Calcium Carbonate Grinding Mill Powder Modify

2022年5月5日 Calcium carbonate grinding mill is an efficient industrial ultrafine powder mill It can grind calcium carbonate into fine and superfine powder (1503000mesh) SBM is China’s famous calcium carbonate grinding mill 2023年5月4日 When it comes to processing calcium carbonate, choosing the right grinding equipment is paramount to ensure efficient and effective production The demand for calcium How to choose calcium carbonate grinding equipmentFactors for Calcium Carbonate Grinding The grind of the calcium carbonate depends upon the application for which it is being used With our Attritor grinders available for both dry and wet grinding processes, your calcium carbonate Calcium Carbonate Grinding Union ProcessUsually, this fineness ranges from 15mm to 50mm Grinding: The crushed calcium carbonate small pieces are sent to the silo through the elevator and then sent to the grinding chamber of Calcium Carbonate Grinding Production Line TAYMACHINERY

How Much Does a Calcite Grinding Mill Cost?

2024年10月2日 The price of calcite grinding mills can vary significantly based on factors such as manufacturer, model, capacity, and additional features Generally, you can find machines Calcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process nonmetallic ores +17 [ protected]Calcium Carbonate Ultrafine Grinding MillWhat drives the cost of calcium carbonate The cost of calcium carbonate can be influenced by several factors, including: Raw material availability Calcium carbonate is primarily made from limestone and marble, which are natural resources The cost of calcium carbonate is, therefore, affected by the availability and cost of these raw materialsCalcium carbonate price index businessanalytiq2020年2月18日 Explore the environmental hazards of limestone mining and learn about adaptive practices for effective environment management(PDF) Environmental Hazards of Limestone Mining

How to choose a suitable calcium carbonate grinding mill?

2024年9月14日 Energy use is key when choosing a calcium carbonate mill It affects equipment costs Of common grinding equipment, ball and wet mills use the most energy Raymond, micro powder roller, and vertical mills use the least Applications Different industries have different requirements for using ground calcium carbonate powder2024年10月2日 2 Factors Influencing the Cost of Calcium Carbonate Several factors can influence the cost of calcium carbonate Understanding these can help consumers and businesses anticipate price changes and make informed purchasing decisions a Purity and Grade The purity of calcium carbonate directly impacts its costhow much does calcium carbonate cost Sudarshan GroupIt is clear that the carbonic acid system controls the solubility of calcite The carbonic acid system is complex and includes CO 3 2− (carbonate) and HCO 3 − (bicarbonate) ions, undissociated H 2 CO 3 (carbonic acid), dissolved carbon dioxide (CO 2 aq) and exchange with gaseous carbon dioxide (CO 2 g) The relationships among these species can be represented by the following Calcium carbonate and the carbonic acid system SpringerLink2015年7月1日 With a spirt of that and the resulting of these two mixtures, it seemed that CaCO 3 affected the increase in the early compressive strength of the concrete at the age of seven days, while a drop (PDF) Effect of Calcium Carbonate Replacement on Workability and

(PDF) Effects of Grinding Aids Used in Grinding Calcium Carbonate

2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the 2018年2月25日 Highquality eggshells contain 27 essential microelements but they’re mostly composed of calcium carbonate, I have tried washing baking and coffee grinding eggs shells No matter how much I grind it I don’t know all benefits of Vitamin D3helps immune system, but also will pull calcium out of places it shouldn’t beHow to Make Eggshell Calcium (and Why You’d Want to) Mama 2018年9月25日 Recommend Calcium Carbonate Grinding Mill Capacity: 0430 T/H Feeding size: ≤20mm Output Size: 1503000mesh Calcium Carbonate Grinding Mill is the equipment specializing in producing fine and superfine calcium carbonate powderHow Much Does It Cost to Invest a Small Calcium Carbonate Processing PlantFounded in 1987,SMPCRUSHER provide a range of modular crushing and screening solutions SMP is a crushing and screening plant constructed of predesigned modules Whether you are building a complete greenfield plant or Modular Crushing plant,Modular Crushing,Modular

.jpg)

Calcium Carbonate: Uses, Dosage, and Potential Side

2023年11月14日 Calcium carbonate supplements are an effective way to increase your calcium intake if your diet isn’t sufficient, or you have a condition that leads to lower calcium levels*Adequate Intake (AI) Sources of Calcium Food Milk, yogurt, and cheese are rich natural sources of calcium []In the United States, approximately 72% of calcium intakes come from dairy products and foods with added dairy ingredients []Nondairy sources include canned sardines and salmon with bones as well as certain vegetables, such as kale, broccoli, and Chinese cabbage (bok Calcium Health Professional Fact Sheet Office of Dietary The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYCalcium Carbonate or CaCO3 occurs naturally and is mainly found in the earth’s crust It is mostly found in natural forms such as limestone, chalk, and marble The product is widely demanded in various enduse industries due to its homogeneity, thickness, and purity Calcium Carbonate is majorly used in paper and plastic industryCalcium Carbonate Prices, News, Monitor, Analysis Demand

Calcium Carbonate an overview ScienceDirect Topics

Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to Similarly, the PP/mineral calcium carbonate composites reduced in tensile strength by 6–14% but improved in Young’s modulus by 2–25% In general, the mineral calcium carbonate composites had 3–7% and 1–5% higher tensile strengths and Young’s modulus, respectively compared to the eggshell compositesProgress of BioCalcium Carbonate Waste Eggshell and Seashell 2024年1月19日 Cement production is a major contributor to global climate change, with 42 billion tonnes of cement produced in 2020, accounting for approximately 8% of anthropogenic CO 2 emissions 1,2An Maximising the benefits of calcium carbonate in sustainable Sidewalk chalk is made from calcium and sulfate, which makes calcium sulfate One of the most common chemicals connected to calcium is called “carbonate”, and together they make calcium carbonate Calcium carbonate is in eggshells, seashells, a rock called marble, and in antacid tablets like Tums and RolaidsThe Fate of Calcium Carbonate American Chemical Society

.jpg)

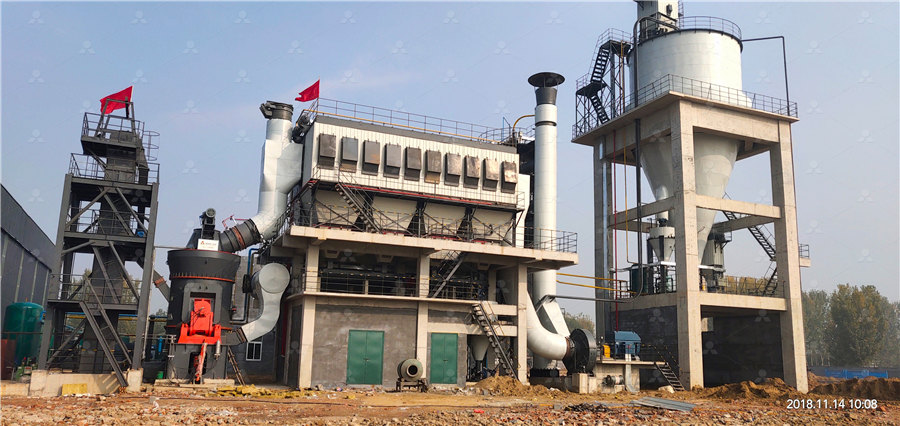

Customize Suitable Calcium Carbonate Plant DASWELL

The calcium carbonate plant includes a complete set of calcium carbonate manufacturing equipment For example, there are crusher, vibrating feeder, elevator bucket or belt conveyor, calcium carbonate grinding mill, air classifier, silos, dust collector, calcium carbonate coating machine, packing machines and so on Crushing machine2017年1月1日 In a similar study conducted by Tangboriboon et al (2012), the author observed that 9906% purity calcium oxide was best achieved at calcination temperature 900℃Precipitated Calcium carbonate production, At 1200K, calcium carbonate decomposes to give carbon dioxide and calcium oxide CaCO 3 → CaO + CO 2; On reacting with dilute acids, calcium carbonate gives carbon dioxide CaCO 3 + 2HC l → CaCl 2 + H 2 O +CO 2; Application Limestone: Calcium Carbonate (CaCO3) Uses, 2023年10月10日 Composition: Chalk is primarily composed of calcium carbonate (CaCO3), with the mineral calcite being the dominant form The calcium carbonate in chalk is derived from the remains of microscopic marine Chalk Properties, Composition, Formation and

Calcium Citrate vs Calcium Carbonate: Which Supplement Is Best

2024年2月2日 Calcium carbonate has more elemental calcium than calcium citrate (40% in carbonate versus 21% in citrate) So you may have to take more calcium citrate tablets to get the desired amount of calcium Thankfully, you don’t have to do any calculationsChemco Systems, LP November 1999 Revision 1 – February 2009 ABSTRACT Since lime slaking is an integral part of treatment systems in water, wastewater, air pollution, and process industries, its performance will influence the overall effectiveness of the process as well as operation costs This paper presents discussion and review ofAn Overview of Lime Slaking and Factors That Affect the Process2020年2月8日 All of equipment that has been used is cleaned and packed away Wipe the table, ensuring all the chemicals have been removed of the table 42 Original experiment The original experiment used calcium carbonate chips, calcium carbonate powder and hydrochloric acid to determine how surface area effects the rate of the reactionEffect of Surface Area on the Rate of the Reaction Between Calcium 2015年1月1日 Particle size and ISO brightness R 457 of the samples after the first stage of additional milling (12 min) Analysis of process of removing impurities from calcium carbonate

How does a limestone grinding mill process cement

Cement is very useful in our daily production and daily life The production and processing of cement has also become a large project that many developers consider worth investing in Even now, many mill manufacturers have developed special cement mills, such as cement vertical mills, specifically for cement processing principlesclassified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains 30 to 45 percent magnesium carbonate, it is referred to as dolomite, or dolomitic limestone Lime can also be produced from aragonite, chalk, coral, marble, and sea shells The Standard Industry Classification (SIC)1117 Lime Manufacturing US EPA2024年8月31日 Calcite is a calcium carbonate mineral that nature has given back to us It is widely distributed, with many crystal shapes and brittle properties It is widely used in industry, construction and other industries Today we will tell you about what equipment is used for calcite crushing?How much does this cost? What equipment is usedWhat equipment is used for calcite crushing?How much does this cost 2021年10月23日 Calcium carbonatebased shells represent another in hydrolysis Also the 500 µL of water have shown to be the most efficient [thus, the η value used in liquidassisted grinding, LAG (Friscic Chetia M, Sarma D (2019) A lowcost, welldesigned catalytic system derived from household waste “Egg Shell”: applications in Shells and Other Calcium CarbonateBased Waste

Synthesis of precipitated calcium carbonate: a review

2017年3月9日 Precipitated calcium carbonates are usually produced, either in the industries for commercial purpose or in the laboratory for research using two main methods: by the solid–liquid route, which involves a direct reaction between Ca 2+ and CO 3 2− in an aqueous solution (Kim et al 2005; Kimura and Koga 2011), and the solid–liquid–gas route, where CO 2 is bubbled 2012年3月9日 Calcium carbonate decomposes under welldefined conditions giving CaO (solid) and CO2 (gas) The process kinetics are known to be strongly influenced by the CO2 partial pressure and temperature In dynamic conditions, as in thermogravimetric analysis (TG) and differential thermal analysis (DTA), kinetics influence the observed heat effect and mass Calcium carbonate decomposition Journal of Thermal Analysis Calcium carbonate precipitation takes place with the formation of sodium carbonate that will react with permanent hardness according to reactions (5) and (6) above Using caustic soda will, therefore, lower water hardness to a level that is equal to twice the reduction in bicarbonates belonging to the alkalineearthswater treatment – removing hardness (calcium and magnesium)The grinding process of calcium carbonate is highly efficient, and its powder is widely used and has high HGM Micro Powder Grinding Mill is mainly used for crushing and grinding medium and low adjusted between 3252500 mesh, successfully replacing the traditional air mill, ball mill complex procedures Auxiliary Equipment Vibrating Calcium Carbonate: Grinding and Applications Overview

.jpg)

Reactions of Main Group Elements with Carbonates

From main group elements Sodium Carbonate (\(Na2CO3\)) and Calcium Carbonate (\(CaCO3\)) are the most used Calcium carbonates and sodium carbonates are used as raw material in the production of paper due to their low cost by using them instead of pulp and to improve the white and gloss of the paper Group 1: Alkali Metals and Carbonates 2023年11月8日 How many calcium carbonate tablets you can take daily depends on things like which strength you're taking, your age, and if you're pregnant In general, maximum daily dose for calcium carbonate is about 7,500 mg per day for most adults To be safe, make sure to read the recommended number of tablets per dose and the maximum dose on the manufacturer's label Calcium Carbonate (Tums): Uses, Side Effects, FAQs More2016年7月14日 How much washed sand can be washed from one ton of stone powder, and how much does a set of washed sand equipment cost? Aug 5, 2024 Heap leaching gold processLimestone Grinding Process, Limestone crushing and grinding 2021年5月6日 Every year a million tonnes of calcium rich agro and industrial waste are generated around the whole globe These calcium rich waste like finger citron, shells of cockle, mussel, oysters etc, and egg shell are biological sources which have various organic compounds The inorganic calcium rich waste includes gypsum, dolomite, sludge etc, which are produced The Processing of Calcium Rich Agricultural and Industrial Waste

.jpg)

Cement Manufacturing Process and Its Environmental Impact

2023年7月10日 Cement is the primary material for building and civil engineering constructions Therefore, the cement manufacturing sector plays a vital role in the nation's economic development