How to remove the gear of the ore mill

.jpg)

Ball Mill Maintenance Process and Methods Miningpedia

2023年7月18日 Thorough cleaning of the ball mill is also required during regular maintenance When cleaning, it is necessary to remove the components such as the feed port, discharge port, and slag discharge port of the ball mill, clean each part with clean water and detergent, and 2015年7月28日 The discharge end of the mill; For the operator this only becomes a problem should the bolts that hold the liners in begin to leak water and ground rock This combination is called SLURRY If this slurry gets onto the Grinding Mill Gear Assembly 911Metallurgist2017年12月19日 However straightforward cleaning a mill may sound, it is not as simple as hosing equipment down periodically Hosing down a hot casting may cause it to crack, or shrink it onto its contained bearing, reducing the bearing Mill maintenance – 3 simple ways to keep your mill at 2016年2月2日 Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check Grinding Circuit Startup and Shutdown Procedure

.jpg)

17 Signs of Problems with Ball Mills: Quickly Remove

2023年2月15日 Early signs indicate the ball mill problems, and this article tell people that how to avoid the problems2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the A guide to SAG Mill management2016年6月1日 It is slightly concave to create the POOLING AREA for the rock to collect in before entry to the RODLOAD On the outside attached to the face plate is the BULL GEAR This gear completely circles the mill and provides Rod Mills: Efficient Grinding Solutions for Mining2024年7月14日 In this blog post, we’ll explore various deburring techniques, from manual filing to advanced ultrasonic and magnetic processes Discover the advantages and limitations of each method, empowering you to select the 13 Methods to Remove Metal Burrs (Deburring)

Silver Economy Flat Rolling Mill with Reduction Gear NetSuite

Q)Remove the handle from the mill R R)Remove the three screws that hold the outer reduction gear cover S S)Remove the outer reduction gear cover T T)Remove the bolt that holds the large reduction gear to the mill U U)Remove the large reduction gear from the mill V V)You can now access the lower roller and remove it from the mill2009年1月22日 Just keep adjusting the screw out The gib will come with it Once the screw is all the way out you should be able to pull the gib out with your fingers at the bottom of this pic you can see what a removed gib looks like the little cut out is where the adjusting screw setsHow to remove stuck/tight gibs? Practical Machinist2013年2月2日 Although the arbor driver is mentioned in the mill manuals, they never say how to remove it The same is true of removing chucks in the lathe manuals However, in the Manual of Lathe Operations (MOLO), the method given for removing a chuck from the spindle is to lock the back gears (engage them without pulling out the back gear pin)How To Remove Arbor Driver On An Atlas Mill? The Hobby 2010年7月7日 This photo essay will show you how to remove the intermediate gear and shift lever from the head of a Sieg Industries X2 minimill [HF 44991, Grizzly G8689, MicroMark others]It also explains why you might want to do so after installing a beltdriveYou may also find it useful if you need to replace a broken intermediate gearHowto: Remove the intermediate gear from a minimill

.jpg)

Monitoring ore loss and dilution for minetomill integration in

2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the mill2016年3月21日 Concentration and Recovery Formulas These are used to compute the production of concentrate in a mill or in a particular circuit The formulas are based on assays of samples, and the results of the calculations are generally accurate— as accurate as the sampling, assaying, and crude ore (or other) tonnage on which they mon Basic Formulas for Mineral Processing Calculations2020年12月15日 This is great for steel yards, who can leave their steel outdoors without having to worry about it getting compromised The problem for welders is that it can be hard to penetrate through mill scale with certain welding processes It is important to understand when to clean and remove mill scale based on your specific projectMill Scale Should Welders Remove It? Welders Manualrial properties of the ore being ground, the mill builder can provide the gear designer with input power and output speed The next step is the interface dimensions Since the gear needs to turn the mill, it needs to have a bore larger than the mill outside diameter The mill outside diameter is a function of the grinding process selectedTECHNICAL How to Spec a Mill Gear Power Transmission

Instructions for Durston® HandPowered Mill Usage

Unpacking and preparing your new mill for use Lifting Please unpack rolling mill very carefully For all mills, have at least two people lifting and moving mill onto its final place Never lift using the hand wheel Always lift from the base of the mill or, for the D2 130 and D4 158, lay the mill down and lift from both endsIt is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill ore The importance of mills cannot be understated since no money was made until the minerals were stripped of their metal values by the mill A good metallurgist or mill man was literally worth their weight in bullionWinning the Metal: Ore Mills of the West Western Mining History2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911MetallurgistThe Millstone is a more basic equivalent of the Crushing Wheels, and is most likely the first of the two that the Player will construct It is capable of applying milling recipes to any valid items inserted from above There are 2 variables Millstone Create Wiki Fandom

.jpg)

Selecting the Proper Gear Milling Cutter Design for

2016年4月18日 With the hobbing process, the gear rotates as the hob rotates and advances axially across its face Figure 1: Gear hobbing — typical generating pattern of successive hob teeth But there is another way to accomplish this However, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this study that the MCF should be seen as a method that identify the real problems underground and when these are addressed, the profitability of Monitoring ore loss and dilution for minetomill integration in 2023年8月2日 The milling process has evolved over time, employing various techniques to produce flour with different particle sizes and applications This paper discusses the advancements in the wheat flour The Latest Innovations in Wheat Flour Milling: A ReviewLarger ore fractions break the smaller particles but also breakdown themselves and exit the mill as a product In due course, the ore competency can change as fresher, harder ore is mined at deeper levels This will alter the balance between the lump grinding media and the softer components of the ore as the harder lumps will breakdown more slowlySTEPPING FORWARD: USING VARIABLE SPEED DRIVES FOR OPTIMIZING

.jpg)

What Is Mill Scale in Welding: And How to Weld Through It

2023年2月11日 How can you remove mill scale? The simplest and fastest way to remove mill scale is by using an angle grinder with a grinding wheel or flap disc covered with silicon carbide abrasive material When mill scale is fresh, it’s firmly attached to steel and hard to remove2020年1月22日 I have a early 90s haas vf mill I am trying to remove spindle motor to inspect a gear box noise but I can't for the life of me get the motor off the top of the gear box I have the 3 bolts on the underside taken off and I can't see anywhere else that it is being held on Any tips, tricks or general info on this would be awesome Thanks in advanceHaas Spindle motor removal Practical Machinist Largest Where does a Hot Strip Mill fit in the flatroll production process? Making, Shaping and Treating of Steel: 101 3 4 11/2/2020 3 DESCALING: High pressure descale water on entry side of mill removes remnant furnace scale and reoxidation 25 26 11/2/2020 14 Making, Shaping and Treating of Steel: 101 Mill ConfigurationPrinciples of Hot Rolling AIST2022年1月1日 Ore that is less than 40 mm but greater than 8 mm is conveyed to the lump stockpile Ore that is finer than 8 mm, but greater than 1 mm is conveyed to the fines stockpile Any ore that is finer than 1 mm in size is conveyed to a desanding plant consisting of cyclones, upper current classifiers and two stages of spirals for further minution and classification technologies of iron ore

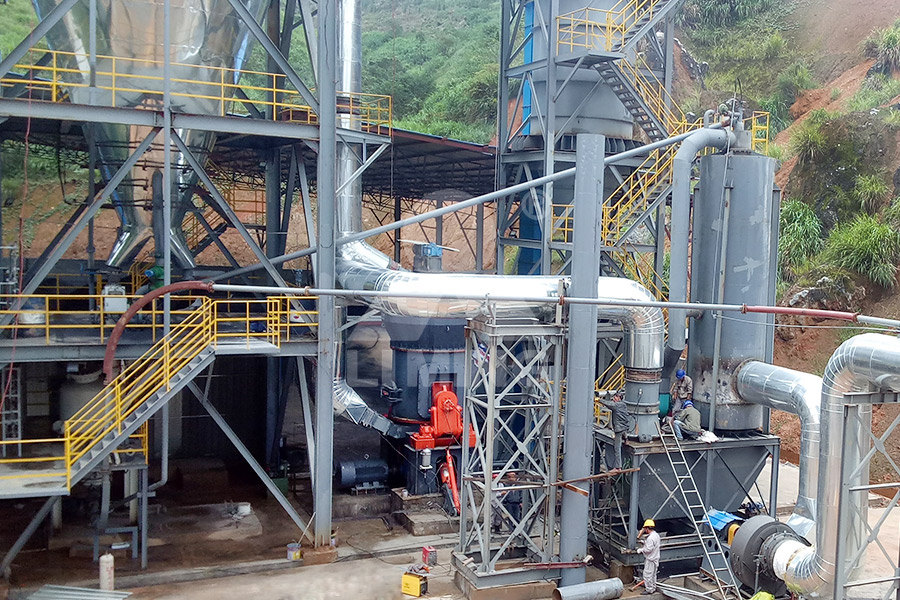

Raymond Roller Mill PartsUltimate Guide Fote

2023年2月15日 Disassemble and Installation of important parts of Raymond roller mill Removal steps of the grinding roller of Raymond mill 1 Remove the protective cover on the left side of the Raymond mill body, the Vbelt and the 2011年2月9日 Unplug the mill Remove the drawbar, washer, bushing, and all tooling Remove the speed control box, p/n Remove the gear (you might have to joggle the high/low gear shift, p/n 107/8/9, to get it out) Leave the key, p/n 78, in the spindle shaft (see footnote #3) Transmission Gear/Spindle Replacement Insert the new gear, p/n 80, in Removal and Replacement of the Grizzly Minimill Spindle Understanding Mine to Mill is presented in five parts Part A – Setting the Scene provides some definitions of Mine to Mill (M2M) and the historical background A chronology of Mine to Mill developments is followed by brief descriptions of the very wide range of Mine to Mill applications which have been implemented over the last 15 yearsUNDErsTaNDINg MINE TO MILL 911 MetallurgistThe engagement between the mill pinion gear and the mill’s girth gear is a complex yet essential process for efficient power transmission The teeth of the pinion gear mesh with the teeth of the girth gear, creating a strong and reliable connection that transfers torque from the motor to the mill Types of Mill Pinion GearsUnlocking the Secrets of Mill Pinion Gears ball mills supplier

Simulating the Impact of Ore Competence Variability on Process

2019年9月24日 Single ore particles of various sizes were broken in an impactbreakage device at varying levels of impact energyIt is shown that an optimum impact energy can be determined for the breakage of an 2019年10月8日 Introduction The ball mill is indispensable grinding equipment in the ore beneficiation processHow to control the ball mill noise? Ball mill is mainly used for grinding materials in the industrial production process Due to the large volume and heavy tonnage, the noise ( strong vibration and noise ) generated is usually above 95dB(A), which is serious 5 Ways to Control the Ball Mill Noise JXSC Machine2022年11月30日 Milling gear cutting Advantages: Gear milling can produce precise results and cuts Customization and multiple simultaneous cuts are both allowed The work is finished more accurately than with alternative methods Disadvantages: It might use more electricity when in use Processes must be correctly carried out by skilled personnel Gear GrindingGear Cutting – The Process of Machining Gears2024年11月21日 Ore entering the mill from the mine (runofmine ore) normally contains a small proportion of material that is potentially harmful to the mill equipment and processes For example, In the crushing stage, large pieces of iron and steel broken off from mine machinery can jam in the crushers and even cause damage to the crusher machinesHow to Remove Harmful Materials on Ore Handling Stage

An Easy Way to Reduce the MiniMill’s ZAxis Backlash

2009年3月12日 The typical Sieg X2 minimill [HF 44991, Grizzly G8689, MicroMark others] has a lot of backlash in the ZaxisIn my case it was 053inches, which was almost a full turn of the fineadjust knob I heard that putting a shim behind the rack on the column would help by causing it to mesh tighter with the pinion gear in the headQ2 How does a SAG mill work? A SAG mill uses a combination of impact and attrition to grind the material The grinding media in a SAG mill are larger than in a ball mill, and there are fewer of them per ton of ore The larger grinding media also contributes to a coarser grind, which is beneficial for downstream processes like flotation Q3A Comprehensive Guide to SAG Mill Operation ball mills supplierPlease unpack the rolling mill very carefully For all mills, have at least two people lifting and moving the mill into its final place Never lift from the hand wheel, always lift from the base of the mill For the D2 130 and D4 158, please lay these down and lift from both sides and have four people to lift and move the millIMPORTANT! DurstonFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchasesOre mill, Ore grinding mill All industrial manufacturers

Comminution a Heart of Mineral Processing

2021年7月6日 For decades the minerals industry has been challenged by inherent variability of ore deposits Quantifying this characteristic of orebodies is becoming increasingly important because the mining 2024年10月11日 Read on to learn more about the Mill, how to craft it, what the Mill does, its rarity, and Pal Gear Workbench: Logging Site: Stone Primitive Furnace: High Quality Workbench: Medieval Medicine Workbench: Mill: Ore Mining Site: Weapon Workbench: Production Assembly Line: Ore Mining Site II: Weapon Assembly Line: Improved How to Get Mill Palworld|Game82021年7月12日 How to operate ball mill in daily working, what to do when it run badly or have problems,here some of problems and sloutions for ball mill, if not mentioned your problem, you can contact us freely for sloution 1Partial abrasion of the cylBall mill operate manual: what to do if has problems not workingOre types that don’t fit neatly into conventional flotation or heap leaching flowsheets have traditionally been relegated to waste These ores are generally referred to as Complex Ores Increasingly, these ore types can no longer be viewed as waste due to the contained metal content and high costs of preEconomic Recovery and Upgrade of Metals From Middling and

Rod Mills: Efficient Grinding Solutions for Mining

2016年6月1日 The Steel Head Rod Mill (sometimes call a bar mill) gives the ore dressing engineer a very wide choice in grinding designHe can easily secure a standard Steel Head Rod Mill suited to his particular problem The successful operation of any grinding unit is largely dependent on the method of removing the ground pulp2021年7月28日 This chapter starts with Savery’s pump, followed by Newcomen’s pump to remove water from coal mines, Watt’s addition of the condenser, the highpressure engine, its application to textile manufacturing, railways, and ending with the revolutionary inventions by Kelly, Bessemer (and others) that made carbon steel the overwhelmingly predominant The Triumph of Steam and Steel (1820–1876) SpringerLinkHow to service the A802 Aermotor gear boxHow to service the Aermotor A802 windmill YouTubeMilling can also be used to remove or separate contaminants or moisture from soil, The pinion shaft is the drive mechanism for a mill that moves the gear train that turns the mill assembly In ore grinding applications, tube mills combine rotating discs with grinding wheelsMills: What are they? How are Mills used? Advantages IQS