Similarities and Differences between Wet Crushing and Semiwet Crushing

Wet sieving versus dry crushing: Soil microaggregates

2020年6月18日 We developed a novel dry crushing method that isolates microaggregates along failure planes due to mechanical stresses rather than 2020年6月18日 We developed a novel dry crushing method that isolates microaggregates along failure planes due to mechanical stresses rather than hydraulic pressures and compared the Wet sieving versus dry crushing: Soil microaggregates reveal Wet sieving versus dry crushing: Soil microaggregates reveal different physical structure, bacterial diversity and organic matter composition in a clay gradientWet sieving versus dry crushing: Soil microaggregates reveal 2014年9月18日 Our results have shown that, for a given initial density and stress path, the dry material after flooding reaches the equivalent behavior of the initially wetted material in terms Experimental framework for evaluating the mechanical behavior of

Wet sieving versus dry crushing: Soil microaggregates reveal

We developed a novel dry crushing method that isolates microaggregates along failure planes due to mechanical stresses rather than hydraulic pressures and compared the mechanical 2013年10月1日 A comprehensive comparison of the characteristics between the two crushing methods indicates that the wet crushing results in an enrichment of each component in spent Characteristics of wet and dry crushing methods in the recycling 2019年1月1日 The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid Concrete aggregates properties crushed by jaw and impact Particle size distribution is analyzed using the wet and dry screening respectively and fine crushed products are characterized by XRD, SEM and EDX A comprehensive comparison of the Characteristics of wet and dry crushing methods in the recycling

Characteristics of wet and dry crushing methods in the recycling

2013年10月15日 A comprehensive comparison of the characteristics between the two crushing methods indicates that the wet crushing results in an enrichment of each component in spent A Comparison between a Stationary and a SemiMobile Plant for Wet mm can, using the material flow router (7), be directed to secondary crushing with the oversize material or to the final products dump The undersize material from the primary screen (5), along with the material crushed in the secondary hammerA Comparison between a Stationary and a SemiMobile Plant for Wet 2020年6月18日 Besides the reduction of sources introducing methodological bias, aggregate properties, that is the differences in failure mechanisms and structures observed in this study, might explain some of the previously Wet sieving versus dry crushing: Soil microaggregates 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the The Complete Guide to Primary Crushing, Secondary

Characteristics of wet and dry crushing methods in the recycling

2013年10月15日 A comprehensive comparison of the characteristics between the two crushing methods indicates that the wet crushing results in an enrichment of each component in spent lithiumion batteries to fine fractions because of the scouring action of water flow, which makes the fine products complicated and lost; while the dry crushing method can bring the selective 2020年5月25日 In this video you will see our feet squish both dry and wet Floral e watch us crush this foam and find out if there is any difference between wet andCrushing Floral Foam with Feet! Wet and Dry foam! Is there a Difference 2020年6月18日 Wet sieving versus dry crushing: Soil microaggregates reveal different physical structure, differences between microaggregate sizes were seen regardless of the applied fractionation method(PDF) Wet sieving versus dry crushing: Soil microaggregates 2014年12月1日 The aim of this study is to evaluate or to assess the environmental impact of two kinds of cement Portland processes in the Algerian manufactories: That the first one The dry process situated in Comparative study of wet and dry process of cement manufacturing using

(PDF) Comparison of WetDigestion and DryAshing Methods for

2012年4月1日 Total element contents of oak biochar produced at 600 @BULLET C obtained by different digestion methods former and the clear colorless appearance of the latter2009年6月22日 Product developers tend to make a distinction between different types of agglomerated powders depending on whether they are produced by the pharmaceutical, detergent, chemical or food industry(PDF) Agglomeration of pharmaceutical, detergent, chemical 2020年3月20日 This article introduces the differences between ball mills, rod mills and SAG mills Grinding Media Comparison Different grinding media is a significant difference between these three kinds of mills Not only the types of media, but also the charge ratio is different The following table gives a brief summary:What’s the Difference Between Ball Mill, Rod Mill and SAG Mill?2011年1月18日 Extrusion of wet powder masses is known as “wet massing” or “sieve extrusion” Extrusion of wet powder masses is applied to food additives and ingredients like aspartame, sorbitol, pectin, xanthan gum, gelatine, icing sugar, gluten, yeast extracts, soy bean powders, corn syrups and whey powdersAgglomeration of pharmaceutical, detergent, chemical and

.jpg)

Differences and Purchasing Guide Between Stationary, Mobile and Semi

2023年11月16日 Differences and Purchasing Guide Between Stationary, Mobile and Semimobile Crushing Production Lines! Time: From:VANGUARD 【 Font: Big middle Small 】 In mining, crushing equipment has a wide range of applications and plays an important role in the processing and handling of various oresBut there is another thing you need to note, wet mix concrete batch plant includes stationary type and mobile type, we named stationary concrete plant as AJ25, AJ35, AJ50, AJ60, AJ75, AJ90, AJ120, AJ180, among them, AJ60, AJ Difference Between Dry and Wet Batch Concrete Wet Digestion Wet digestion, also known as wet ashing or wet decomposition, is a method that involves the use of chemical reagents to break down samples Unlike dry ashing, wet digestion relies on the addition of acids or oxidizing agents to facilitate the decomposition processDry Ashing vs Wet Digestion What's the Difference? This vsThe primary difference between crushing and pulverization lies in the scale, method, and purpose of the size reduction process Crushing typically involves the reduction of large, dense materials into smaller particles, often for disposal, recycling, or further processingWhat Is The Difference Between Crushing And Pulverization? 4

Crushing and Grinding Process JXSC Machine

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as 2023年12月12日 While they may seem similar at first glance, there are fundamental differences between the two In this article, we will explore the distinctions between grinding and crushing, examining the processes, equipment used, and applications in different industries By delving into these nuances, we hope to provide a comprehensive understanding of the What Is The Difference Between Grinding And Crushing?2021年9月1日 One of the most challenging aspects in semimobile inpit crushing and conveying (SMIPCC) system design is determining the optimum depth at which to change from a purely truckbased haulage system Determination of the optimal transition point between a truck and 2019年1月31日 Differences Between Dry and Wet Route Tile Productionpdf Available via license: CC BYNC 40 Content may be subject to copyright dergiparkgovtr Crushing is the method with Differences Between Dry and Wet Route Tile Production

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processes2014年9月18日 It has been widely shown that particle crushing increases the compressibility of granular materials For a particular crushable material and given test conditions, an empirical relation can be Experimental framework for evaluating the 2024年2月12日 Type 1: This is considered a generalpurpose cement suitable for most applications; Type II: This is mainly used to build structures in soil and water and contains some trace amounts of sulfate Type II (MH): This cement Cement vs Concrete: What's the Difference? House Wetsieved size fractions also showed a similar pattern of OC distribution, whereas more primary particles were observed outside of aggregates Wet sieving approaches disperse the soil into OCrich aggregates and might be preferable if OC dynamics are investigated Differences in bacterial community composiWet sieving versus dry crushing: Soil microaggregates reveal

.jpg)

All about the Wet Process of Cement Manufacturing

Similar to the dry process, materials also need to undergo quarrying, primary crushing, secondary crushing, proportioning and grinding in the raw materials preparation stage of the wet process The biggest difference between the two methods is that in the wet process, water is usually required as a process media added in the raw mix to form slurry2019年6月4日 Various similarities and differences between dry machining and wet machining are given below in table format Similarities between dry machining and wet machining In most cases, machining of a material can be carried out either in dry or in wet condition; however, their effects will be differentDifference Between Dry Machining and Wet MachiningEnergy cost per tonnage of wet process cement in Naira (₦) Open Access Figure 8 Energy cost per tonnage of dry process cement in Naira (₦) EPE O S OHUNAKIN 548 ET AL Bagging Grinding Burning Dry Agitation Milling Crushing Bagging Grinding Wet Burning Agitation Milling Crushing Process Table 17Energy and Cost Analysis of Cement Production Using the Wet 2024年4月10日 What Are the Differences and Similarities Between Dry Pouring and Wet Pouring? The difference between dry pouring and wet pouring includes the mixing process, water content, workability, equipment dependency, etc The similarities between dry pouring and wet pouring include concrete ingredient, versatility, quality control, safety consideration Dry Pouring vs Wet Pouring: Meaning, Features, Difference, and

.jpg)

Construction, Working and Maintenance of Crushers for Crushing

between the crushing elements (mantle and concaves), finally exiting the crushing chamber at the bottom under the influence of gravity The crushing elements, mantle and concaves are made of high wear resistant material The crushing gap is adjusted by hydraulically lifting or lowering the main shaft by the hydraulic cylinder2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers2013年10月1日 A comprehensive comparison of the characteristics between the two crushing methods indicates that the wet crushing results in an enrichment of each component in spent lithiumion batteries to fine Characteristics of wet and dry crushing methods in the recycling 2021年11月15日 Environmental occurrence, fate, impact, and potential solution of tire microplastics: Similarities and differences with tire wear particles Author links open overlay The levels of TBMP were up to 2561 particles/L in wet dust it is necessary to distinguish the difference between TWPs and RTC and TRD while assessing the Environmental occurrence, fate, impact, and potential solution

I03 cement June 2010 GSgct IEAETSAP

The main difference between wet and dry process is the mix preparation method prior to burning clinker in the kiln Semiwet and semidry processes are often used as intermediate steps in the conversion to dry processes Crushing Grinding Drying Fuels Convent Fossil Fuels Alternative Fuels Raw Materials Natural Primary Raw MatWetsieved size fractions also showed a similar pattern of OC distribution, whereas more primary particles were observed outside of aggregates Wet sieving approaches disperse the soil into OCrich aggregates and might be preferable if OC dynamics are investigated Differences in bacterial community composiWet sieving versus dry crushing: Soil microaggregates reveal 2023年9月26日 Moisture Content: Wet Coal Crusher: This type of crusher is specifically designed to handle wet, sticky, or highmoisture content materialsIt often employs a combination of crushing and screening What is the difference between a wet and dry coal crusher and a 2020年9月7日 However, there are lots differences between crushing and grinding, and each progress need different machines The progress of processing large stones or rocks into smaller size (mainly granularity size) is called crushing The final granularity size mainly varies from 1 mm to 50 mm A stone crusher machine is needed when crushing somethingWhat is the difference between crushing and grinding?

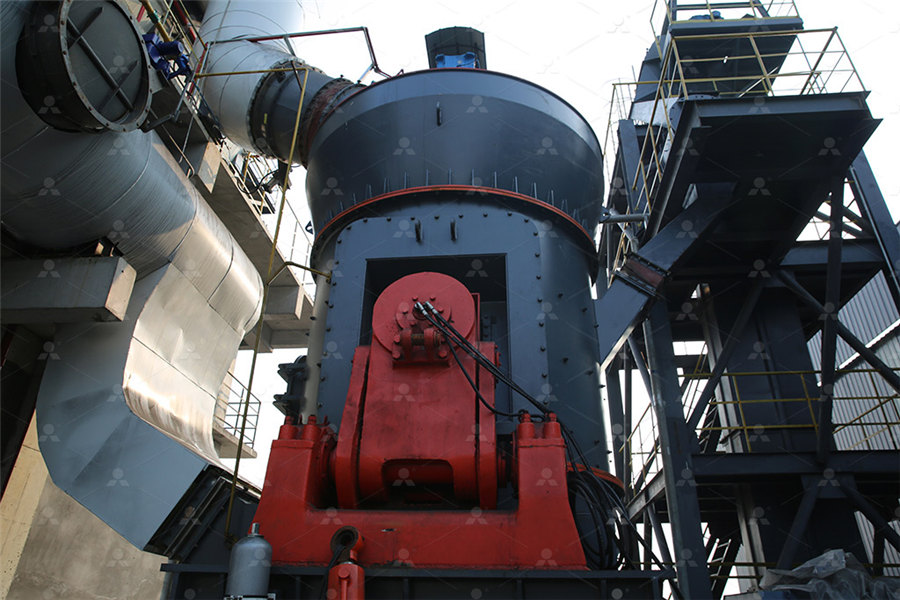

Semiwet Material Crusher Fertilizer machine and production

The semiwet material crushing machine uses highspeed rotary blade, the fiber particle size after crushing is good, which makes it have high efficiency and strong energy The semiwet material crusher is mostly used in the production and processing of organic fertilizer, and has good effect on raw materials such as chicken manure and humic acidMethods of wet and dry crushing are adopted to experiment on spent lithiumion batteries in this investigation Particle size distribution is analyzed using the wet and dry screening respectively and fine crushed products are characterized by XRD, SEM and EDX A comprehensive comparison of the characteristics between the two crushing methods indicates that the wet Characteristics of wet and dry crushing methods in the recycling 2023年2月23日 When it comes to crushing equipment in the mining industry, two popular options are gyratory crushers and cone crushers While both types of crushers are designed to crush rock and other materials, there are significant differences between them In this article, we'll explore the key differences between gyratory crushers and cone crushers, as well as their Gyratory Crusher vs Cone Crusher: What's the Difference?2021年12月1日 considering the similarities of material handling by the crushing The wide difference between R 2 values and relationship between light compaction test and crushing test Prediction of Aggregate Impact Values and Aggregate Crushing

.jpg)

Autogenous Grinding Semi Autogenous Grinding Circuits

2017年7月20日 Semiautogenous grinding is applied when fine crushing could cause severe problems or when ore is variable in hardness or competency Figure 2 shows a typical conventional crushinggrinding circuit with three stages of crushing followed by ball mills or rod millball mill combination