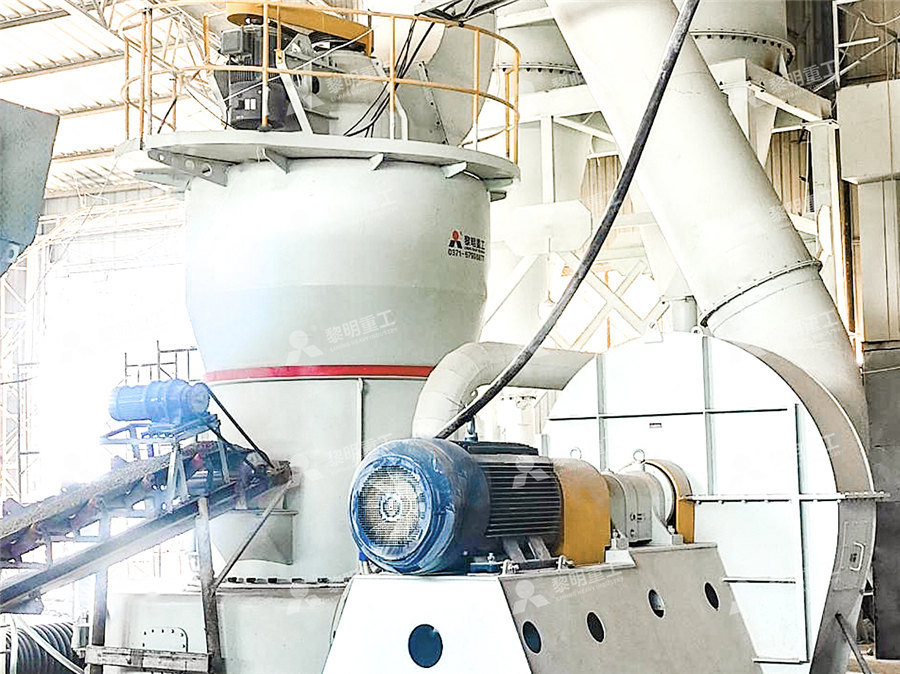

Small powder processing Ball mill

.jpg)

Ball mill Wikipedia

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the 展开2010年4月1日 Ball milling is the simplest, costeffective, fast, and ecofriendly method that is used to convert largesized particles to fine size particles through grinding This method can Powder Milling an overview ScienceDirect TopicsBall milling is a grinding method that grinds nanotubes into extremely fine powders During the ball milling process, the collision between the tiny rigid balls in a concealed container will generate Ball Milling an overview ScienceDirect TopicsSearch for used ball mills (powder processing) Find Sigma, Baichy, Ascend, Beifan, Gandong, Nanbei, Mingyuan, Alpine, Baxit, 05 ton to 5 ton per hour small ceramic batch ball mill grinding machine Ceramic batch ball mill is used for fine grinding of feldspar,quartz,clay,ore and so onUsed ball mills (powder processing) Machinio

Used Ball Mills (mineral processing) for sale in USA Machinio

Used ball mills (mineral processing) for sale in USA AllisChalmers Find used ball mills for grinding iron ore and other mineral materials on Ball mills are critical pieces of equipment used in mineral processing to grind materials into fine powder They work by rotating a cylinder filled with steel balls, which crush and grind the Ball Mills Steel Ball Mill Lined Ball Mill Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction The basic construction of a ball mill is a Ball Mills Orbis MachineryA section cutthrough of ball mills A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shellBall mill WikipediaThe small ball mill is a smallcapacity grinding equipment, which is defined relative to large ball millIt is generally suitable for smallscale production in the trial production stage Due to its small size and easy movement, small ball mill is sometimes referred to as mobile ball mill The mobile ball mill can be easily moved to the location of the material for onsite grinding and Small Ball Mill Mini Ball Mill for Small Scale Mineral Grinding

.jpg)

Ball Mills in the Mineral Processing Industry MechProTech

2024年5月27日 Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger Investing in cuttingedge equipment improves operational efficiency and contributes to a more sustainable and productive future for the mineral processing industryPaul O Abbe Find all types of industrial ball mills for chemical, mining, pharmaceutical and food processing on Machinio Processing » Ball Mills » USA By Manufacturer Paul O Abbe (18) Ball mills are industrial devices used to grind materials into fine powder They are commonly used in mining, Used Ball Mills for sale in USA MachinioApplications of Small Scale Ball Mills Small scale ball mills are versatile pieces of equipment that can be used for a wide range of material processing applications Some of the most common applications of small scale ball mills include: Grinding and milling: Small scale ball mills can be used for grinding and milling materials to a fine powderCostEffective Solution for Small Scale Ball Mill Material ProcessingOil, Gas Mining » Ball Mills (mineral processing) By Manufacturer AllisChalmers (19) Hardinge (11) Ball mills are critical pieces of equipment used in mineral processing to grind materials into fine powder They work by rotating a cylinder filled with steel balls, which crush and grind the material insideUsed Ball Mills (mineral processing) for sale Machinio

Small Ball Mill Capacity Sizing Table 911Metallurgist

2016年2月14日 Do you need a quick estimation of a ball mill's capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Small Ball Mill Capacity 2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed Grinding in Ball Mills: Modeling and Process ControlZhengyuan is China powder grinding mill manufacturer, offer jet mill, impact mill, ball mill, roller mill, plastic pulverizers We also provide accessories for powder grinding equipment, like air classifier, dust collector and rotary feeder We offer fine grinders for different uses, such as for grinding large quantities of material, superfine grinder mills for grinding sample material and Ball Mill Jet Mill Powder Grinding Mill Impact Mill 2024年1月1日 Ball mill is a type of grinding equipment that uses the rotary cylinder chemical fertilizer, ferrous and nonferrous metals mineral processing, powder metallurgy, glass ceramics, and other production Dry grinding or and transmission part (speed reducer, small drive gear, motor, and electric control) The cylinder is Ball Mill SpringerLink

HighEnergy Ball Mill Machine Primet Lab

The planetary ball mill is compactdesigned with high efficiency and low noise It is a powder processing equipment widely used in scientific research institutions, universities, and enterprise laboratories to obtain fine powder samples Four samples can HAMMER MILL Highimpact lab hammer mill for achieving finer particle sizes Benefits Adaptable to specific material characteristics including hard and fibrous products Handle samples as small as 5g without loss of yield or screen residue Fully scalable to the Fitzpatrick milling range Features at a glance FitzMill TM L1A hammer millLab Scale Milling and Processing MachineMechanical alloying uses ball mills to fuse powder particles an alternative to hightemperature alloy production methods small quantities Learn more Retsch GmbH Mechanical alloying is a powder processing technique that achieves homogeneity in the material by repeatedly cold welding, fracturing, and rewelding the powder Mechanical Alloying with Ball Mills Retsch2016年11月7日 For the preparation of small quantities of powder many types of mill are available but, even so, the ball mill is frequently used For the grinding of the largest quantities of material however, the ball, tube or rod mill is used almost exclusively, since these are the only types of mill which possess throughput capacity of the required magnitudeGrinding Mills Common Types 911Metallurgist

.jpg)

(PDF) Producing Metal Powder from Machining Chips Using Ball

2023年6月27日 Nevertheless, parameter factors, such as the type of ball milling, balltopowder ratio (BPR), rotation speed, grinding period, size and shape of the milling media, and process control agent (PCA 2023年11月22日 The laboratory attritor ball mill is a unique grinder that uses highenergy impact and friction to produce a fine powder This ball mill has a rotating shaft with arms or discs that ensure efficient grinding by continuously stirring the media under controlled conditions The main advantage is its versatility in processing different materials Various Types Of Laboratory Ball Mills Supplied JxscLabBenefits of Powder Processing with Ball Mill Media Powder processing with ball mill media offers numerous benefits: Fine Powder Production: Powder processing produces 10 microns or fewer particle sizes, creating ultrafine powders Enclosed Milling for Toxic Materials: This method provides a safe solution for milling toxic materials due to its High Energy Ball Mill For Sale Vertical Ball Milling MachineBall mill is widely used in mineral processing plants for wet or dry grinding materials and equipped with spiral classifier, Batch small ball mill: It often forms a closedcircuit ring grinding device with a spiral classifier to produce Ball Mill Mining Grinding Mill JXSC Machinery

.jpg)

Ball Mill SpringerLink

2023年4月30日 Ball mill is a type of grinding equipment that uses the rotary cylinder chemical fertilizer, ferrous and nonferrous metals mineral processing, powder metallurgy, glass ceramics, and other production Dry grinding or and transmission part (speed reducer, small drive gear, motor, and electric control) The cylinder is The mini ball mill is a type of smallscale ball mill, quartz, iron ore, aluminum powder, slag, fly ash, gypsum, limestone, cement, etc GET FREE ceramics industry, chemical industry, etc It is a necessary device for processing quartz stone, cement clinker, nano materials, and hightech materials Free Services We Offer Material TestingMini Ball Mill – Mineral Grinding Small Ball Mill For Sale AGICOIn its simplest form, the ball mill consists of a rotating hollow cylinder, partially filled with balls, with its axis either horizontal or at a small angle to the horizontal The material to be ground may be fed in through a hollow trunnion at one end and the product leaves through a Ball Mill an overview ScienceDirect TopicsFind out more about Pilamec's batch powder processing plant capabilities, including ball mills, screening equipment, and bagging facilities From the beginning of any project, small or large, through to final processing and supply, Pilamec Toll Processing

.jpg)

Ball milling: a green technology for the preparation and

Amongst all the methods that can be employed for the mechanochemical processing of cellulose, ball milling is an emerging technique, which allows avoiding organic solvents Being easy to use, Influence of reaction parameters on the depolymerization of H 2 SO 4impregnated cellulose in planetary ball mills, Powder Technol, Industrial Ball Mill Grinder Machines are essential tools in various Scientific and industrial applications, HDPE jars Quiet no chains or belts These unique lab mills will operate continuously for long periods of time for powder processing ColeParmer CG200 Freezer/Mill® Small Cryogenic Grinder, 01 to 5 g; 115 VACIndustrial Ball Mill Grinder Machines Thomas Scientific2019年8月14日 The powder is discharged through the unloading grates to complete the grinding operation When the number of steel balls in the ball mill is too small, In the production of the processing plant, the more common steel ball ratio of ball The Ultimate Guide to Ball Mills Miningpedia2013年2月7日 Processing in planetary ball mills Fine grinding, balltopowder ratios and small ball sizes which intense the frictional action are helpful to support amorphization andProcess Engineering with Planetary Ball Mills ResearchGate

Particle Size Reduction Mills and Sizing Equipment

Over 120 years of experience designing and manufacturing particle size reduction mills and equipment, powder milling technology, grinding and delumping Skip to content Products Conical milling equipment has become one of the most The planetary ball mill is compactdesigned with high efficiency and low noise It is a powder processing equipment widely used in scientific research institutions, universities, and enterprise laboratories to obtain fine powder samples Four HighEnergy Ball Mill Machine Landt InstrumentsBall Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are Ball Mill (Ball Mills Explained) saVRee saVReeIt works on the principle of impact and friction between rotating balls and the powder materials The ball mill consists of a rotating drum and a hollow cylinder filled with grinding media, typically small metal Applications of Ball Mills 1 Mineral Processing: Ball mills are widely used in mineral processing industries for the grinding Understanding the mechanism: How does a ball mill work?

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD centers Discover our comprehensive range of powder processing equipment, including laboratory crushing,ball milling, screening, mixing, and morePlanetary Ball Mill Series Manufacturer from China Changsha 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Processing Ball Mills Through the continuous development of our ball mill line up, these have been optimized on a number of points over the years They all have a rigid steel frame and generously dimensioned wear parts and energy efficient drivesBall Mills

Planetary Ball Mills Glen Mills, Inc

The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 grinding stations You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for2023年11月24日 Autogenous and semiautogenous mills are used in primary grinding whilst rod and ball mills are used in secondary grinding, with the ball mills being the most commonly used The ball mills are either used in a drymilling or wetmilling setup depending on the needs of the industry in which they are utilisedGrinding Media in Ball Mills for Mineral Processing