Crusher installation size

.jpg)

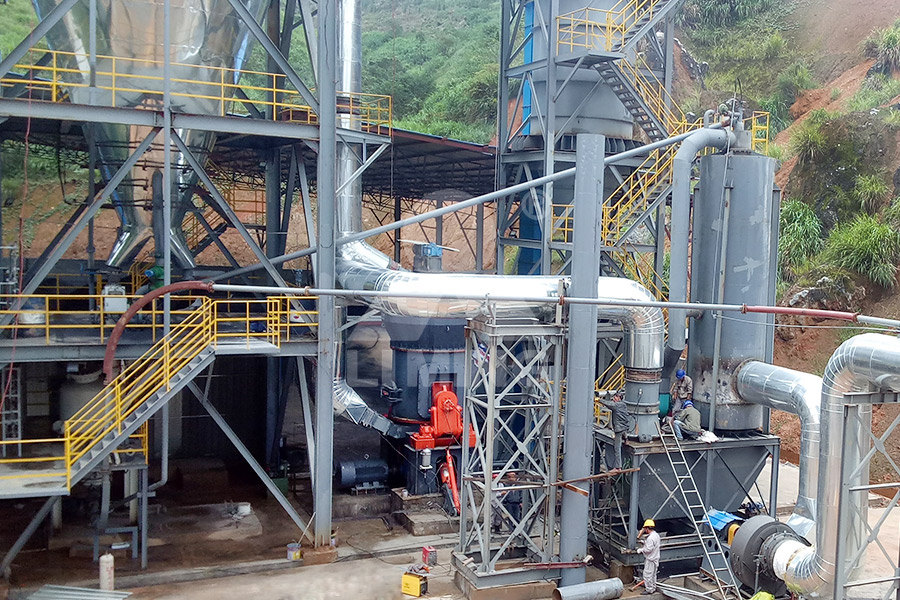

A Comprehensive Guide To Stone Crusher Installation

2024年4月3日 Thorough planning aids smooth installation Key factors include: Crusher model selection Choose to suit throughput needs and feed material type/size Foundation design Factor crusher dimensions/weight into reinforced concrete slab sizing Lifting equipment Crusher Clearance Dimensions Page 75 Crusher NOTICE Foundation must be acceptable for loadings Obtain technical data sheets with foundation loads from Metso MineralsMetso Nordberg MP Series Technical Reference ManualThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 Metallurgist2024年8月20日 Material Type: The hardness, abrasiveness, and size of the material you plan to crush will influence the type of crushers you need Production Capacity: Determine how much material you need to process daily, weekly, or How to Set Up A Crusher Plant? Aimix Group

.jpg)

Construction, Working and Maintenance of Crushers for Crushing

There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ a combination of all these crushing methods Impact refers to Setting up a successful stone crusher plant means balancing plant design, cost and efficiency But first, you’ll need to learn how to optimize your crushing setup while choosing the best machinery for your crushing needs This requires a Stone Crusher Plant Setup Machinery Partner2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance The Ultimate Guide to Stone Crusher Plant Design2014年4月1日 To achieve this top size, the crusher setting is 200mm or below, depending on the rock characteristics If a belt is not used to transport the crushed ore out of the mine, the other method is a skip hoistBelow the surface: Setting up an underground primary

.jpg)

Selecting the right crusher for your operations Quarry

2020年3月19日 Material sizing is achieved by rotor rotational speeds and adjustments of the clearance between the blow bars and curtains The nature of HSI crushing can lead to slightly higher operating costs, the cost being To safely install a stone crusher plant, follow these guidelines: 1 Prepare the site: Before starting the installation process, clear the area of any debris or obstructions 3 Dig the foundation: Dig How To Operate A Stone Crushing Plant Safely Aimix Group View Williams Patent Crusher's Roller Mills Installation Report, a case study on blast furnace injection at ArcelorMittal Learn more C Scalping Screen Scalping screen insures a product size of 99% minus 4 mesh, WILLIAMS Roller Mills Installation Report Williams CrusherFirst, the installation points of the jaw crusher The jaw crusher needs to install the crusher’s frame on the foundation before assembling the crusher, and then install the other parts in order 1 The installation points of the rack of Jaw Jaw crusher installation points and precautions

.jpg)

Types of Crushers: Choosing the Right One for Each

2024年7月17日 The maximum feed size for a jaw crusher can reach 1,200 mm They perform better than gyratory crushers on highhumidity, and smallscale mining They are easy to install, highly mobile, and versatile, enabling quick Stedman Machine Company has the experience, expertise, and equipment to provide and install your ideal sizereduction solution Learn More by visiting usSize Reduction Equipment Installation Crusher Installation This article provides a comprehensive guide to stone crusher installation procedures to ensure the safe and efficient longterm operation of the machines Choose to suit throughput needs and feed material type/size Foundation design Factor crusher dimensions/weight into reinforced concrete slab sizingA Comprehensive Guide to Stone Crusher Installation6 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance shown in above figure, a closed circuit crushing system is a means of controlling product top size by screening the product Construction, Working and Maintenance of Crushers for Crushing

.jpg)

Jaw Crushers JW Series

portable options for easy transport and installation MODULAR PORTABLE STATIC Modular Model Main Components Motor Size Capacity (MTPH) Shipping Configuration MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155480 (140435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder 200 2015年12月17日 Crusher Installation The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacity of two pit trucks The maximum feed size for a jaw crusher should be about 85% of the gape Source: Rock Crushing Rule of Thumb 911Metallurgist2015年12月24日 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and Primary Crusher Selection Design 911MetallurgistCorrect installation of cone crusher is the basis of stable and efficient operation In this article, we will teach you 10 steps to install cone crusher 1 Pedestal Installation 1) Cone breaking must be installed on a stable reinforced concrete foundation, and there must be enough space under the foundation to install transportation 10 Steps To Install Cone Crusher Gongyi Jingying Machinery

Roll Crusher an overview ScienceDirect Topics

The roll crusher is the workhorse of coal size reduction to shear and/or compress the material From: Encyclopedia of Energy, 2004 About this page Add to Mendeley Set has encouraged the wide use of rolls for moderatesize feed reduction of all sizes 9 The cost of the machine and its installation is also low as compared to similar other %PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resourcesCrushersAll Shumar Crushers have two machined rolls to which the crusher segments are bolted Each Roll is generally fitted with six crusher segments; some large roll diameter primary crushers do have more segments per roll Crushers Shumar EngineeringType in inches and feet of your project and calculate the estimated amount of Base Material in cubic yards, cubic feet and Tons, that your need for your project The Density of Crusher Run : 2,410 lb/yd³ or 121 t/yd³ or 08 yd³/tCalculate Crusher Run Cubic Yard (or Feet) to Tons Gravelshop

.jpg)

Choosing the Right Stone Crusher for Your Operation

This will help identify the size and capacity of the crusher needed Desired Product Size: This article provides a comprehensive guide to stone crusher installation procedures to ensure the safe and efficient longterm operation of the machines Key Factors to Customer request: Jaw crusher (input size: 300mm, output size: 4080mm), Cone crusher (input size: 4080mm, output size: 520mm), Ball mill The cost of transporting and installing the mesin crusher will also add to the total crusher price Necessary Information When Sending A QuoteCrusher Plant for Sale Mobile Stationary Type IndonesiaThe feed particle size of this crusher is large and the crushing capacity is strong More importantly, Provide equipment installation and free training services; Provide a complete range of crushing equipment accessories in time; We not only prepare highquality gypsum crushers for Gypsum Crusher Turning Gypsum Waste Into Treasure AIMIX Crusher run weighs approximately 2,500 lbs per cubic yard The depth of the crusher run base recommended in inches will vary depending on the project What is Crusher Run used for? For driveway installation, a foundation of crusher run can add years to your driveway's lifeCrusher Run What is it? Gravelshop

.jpg)

CRUSHING in Cement Industry INFINITY FOR CEMENT EQUIPMENT

39 Mobile crusher installations Mobile crusher installations are occasionally used Such installations are placed directly in the quarry and follow the quarry machinery Common crusher types are the impact crusher and the jaw crusher which at the quarry are used for primary crushing, for example down to 10050 mm lump size Figure 317, shows CRUSHER is classified into various types according to the size of crushed material COARSE CRUSHER : Crusher to crush the largest crusher SECONDARY CRUSHER : crusher to crush the thin parts PULVERIZER : CRUSHER to grind raw material with diameter less than 1cm into 007mm size powderCrusher Plant Engineering Company Vietnam SAMSHIN2016年2月26日 For example, consider a crusher set to turn out a product 70% of which will pass a 5/8″ square opening, and in closed circuit with a screen which is equipped to remove the minus 3/4″ product The curve shows that approximately 85% of the crusher product will pass the 3/4″ square openingsCrushing Products Size and Shape What to ExpectThe second jaw is also installed backwards To install the jaw plate of the assembled jaw crusher, it needs to be firmly attached to the jaw bed, and soft metal is used as a gasket to ensure that it is leveled and then tightened with Jaw crushr operate manual: how to install, repair and

.jpg)

Metso Crushing and screening solutions

Series jaw crushers easy to install The crusher can be installed as one compact module that includes all the necessary auxiliaries around the crusher itself The crusher can be installed within a few days, minimizing onsite engineering and fabrication Ultimately, this leads to a significant savings in time and installation costsGP100™ has lower installation height that reduces installation costs since smaller support structures and shorter conveyors are needed The crusher automation enables adjusting GP100™ from a distance, which reduces risks and improves the safety of the plant personnelNordberg® GP100™ cone crusher Metso2023年11月16日 Crusherrun gravel is made by processing quarried stone through multiple crushing and screening stages to control the size and gradation Rock Crushing Considerations for Working with Crusher Run Proper installation and maintenance ensure optimal crusher run performance Here are some key factors to consider:Crusher Run Gravel: Pave It Right with Our Asphalt Calculator2024年4月19日 The objective of the secondary crushing is to get a product of a more homogenous size and shape This is the reason why it is especially suitable for further processing or use in different fields Secondary crushers crush materials in the size range of 50 mm to 300 mm, which is determined by the type and size of the crusherTypes of Crushers Explained: Everything You Need to Know JXSC

.jpg)

How To Operate A Stone Crushing Plant Safely Aimix Group

Installing a stone crusher plant safely is crucial to ensure the efficiency and durability of the equipment To safely install a stone crusher plant, If you find that the discharge port is enlarged due to wear, adjust the size of the discharge port in time to ensure that the specifications of the stone are met 9A replacement and installation of this size usually requires a time of at least 30 days The crusher was supplied by Sandvik Mining and Construction in India to an iron ore mine site in Noamundi, for the processing of ore with a maximum feed size of 1,200 mm (472 in) and capacity of up to 3,500 mtph (3858 stph)Sandvik installs its first Primary gyratory crusher – in record time2016年3月11日 Short Head (Tertiary) Cone Crusher (Refer to Fig 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows: a) Maximum Feed Opening — 250MM (10 In)Crushing Plant Flowsheet DesignLayout 911Metallurgist2024年5月25日 Rock Crusher Conveyor Belt: Essential Components and Their Importance Understanding the Basics Definition and Functionality A rock crusher conveyor belt is an integral part of the rock crushing process It serves as a Rock Crusher Conveyor Belt Efficiency Guide

.jpg)

How to Use Crusher Run for Driveway YardOwner

2023年5月30日 For a surface that has great loadbearing capabilities, consider installing a crusher run on your driveway How to lay crusher run on driveway Use a utility knife to cut the fabric to size Now, fill the trench halfway (6inches Nordberg® HP500™ cone crusher is one of the largest models in the world’s most popular cone crusher family, Nordberg® HP Series™It is frequently utilized in aggregates production, quarrying applications, and mining operations in the Nordberg® HP500™ cone crusher Metsoaccording to the Installation(1) 6 Installation of the transmission shaft (2) After installing the transmission shaft, use a sample board to check the size related to the transmitting gear (See Drawing 4) (1) Add an adjusting gasket to the male flange between the pedestal and the transmission shaft framecone crusher HXJQWork and play all year long with an Ice Crusher premium DIY UTV Cab Heater designed specifically for your Ranger Full Size (2009 2013), Full Size Crew (2010 2014) Each kit includes laser cut and powdercoated brackets, a defrost system, CNC machined Aluminum Y's and picture rich instructions We're here to guide you through the install so you'll be off on an Polaris Ranger Full Size (20092014) Ice Crusher Cab Heater

Sizers MMD

Sizers are the latest innovation in crushing technology See how an MMD sizer provides benefits for your operationCrusher (Excluding weighment) (Lead 01 KM) 000 Tonnes 1633 00 INR Two Crore Ninety Three Lakh Ninety Three Thousand Nine Hundred Ninety Nine and Paise One Hundred Only 103 Crushing of coal into () 100 mm size (all dimensions) by mobile crusher including receiving coal into mobile crusher,Tender Inviting Authority: GM(CMC), CCL Name of Work: Hiring of 2022年3月22日 Next, we will learn about the installation of jaw crusher from the parts of the frame, eccentric shaft and bearings, rod bolts, brackets, movable jaw plate, and dental plates The maximum size of the ore should not be greater than 085 times the width of the oreHow to Properly Install and Use Jaw Crusher HXJQNew crusher installation Planning for a new crusher installation? We deliver reliable high productivity Compared to similar crushers on the market, Select a file (max size: 5MB; format: JPG, JPEG, PNG, SVG, GIF, PDF) Please fill out the required fields Cancel Back Next SubmitIncrease crushing capacity by up to 100% FLSmidth

Capacities and performance characteristics of jaw crushers

Celculaled camel ty16 ' 25 7 I n 0 05 1 15 2 25 Actual capacl tylh' Q Present Eqn + Rose 8 Engllsh Eqn Fig 1 Comparison of calculated capacltles wlth the oata of Hersam (1 9231 for different machlne parameters thereby influencing the degree of compaction of the product The final equation for the capacity of jaw crushers can