Limestone and coal crushing

.jpg)

Types of Crushers: Choosing the Right One for Each

2024年7月17日 Hardness: Hard materials like granite and basalt are suitable for jaw crushers or gyratory crushers, while softer materials like limestone and coal can opt for impact crushers or hammer crushers Abrasiveness: Materials with 2023年10月8日 This blog outlines 6 types of coal crushers, and their pros and cons, to aid your coal crusher selection6 Types of Coal Crusher: Which Is Best for Crushing My The RollSizer are capable of crushing mediumhard rock as well as sticky and soft material such as coal, clay, marl, limestone and similar raw materials The material is crushed by shear and tensile forces generated by high rotor Crushing Technologies thyssenkrupp Polysius2013年1月1日 Application of surface miner in different coal, limestone, gypsum, lignite, salt, phosphate, bauxite and iron ore projects is common and established today No drilling Rock excavation using surface miners: An overview of some design

SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipmentsThe limestone crushing process involves several stages, each with specific machinery and equipment The typical limestone crushing process is Primary Crushing > Secondary Crushing > Screening > Conveying > StorageLimestone Crushing Process JXSC Mineral2017年1月27日 This paper presents experimental comparison of two machine crushing technologies: onestage and twostage The study was carried on a model doubletoggle jaw crusher which allows crushing(PDF) Analysis of Energy Consumption of Crushing Limestone, one of the largest produced crushed rock, is a sedimentary rock composed mostly of the mineral calcite and comprising about 15 percent of the earth's sedimentary crustLimestone and Crushed Rock Department of Energy

.jpg)

Limestone Aggregate Crushing JXSC Machine

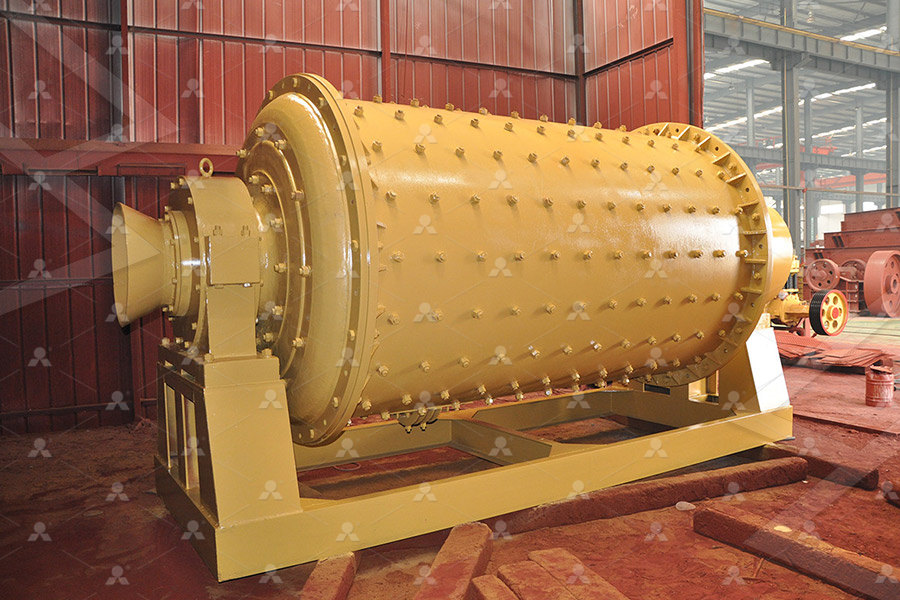

The limestone aggregates crushing generally has four steps: coarse crushing, sencondary crushing, sand making and screening2020年11月8日 Crusher; Crushing; and Classification Equipment Download as a PDF or view online for free coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc 32 Primary Jaw Plants/ Jaw Crusher; Crushing; and Classification Equipment PPT2023年2月28日 Learn the differences between primary and secondary crushing and how to choose the right crusher for your mining or construction project This guide explains the basics of crushing, the factors that determine the choice of Primary and Secondary Crushing: Understanding the 2024年4月19日 Shear Crushing: Shear crushing takes a shearing force and applies it to the material, which results in the formation of cracks on the weak planes This method is not frequently used in rock crushing applications but Types of Crushers Explained: Everything You Need to

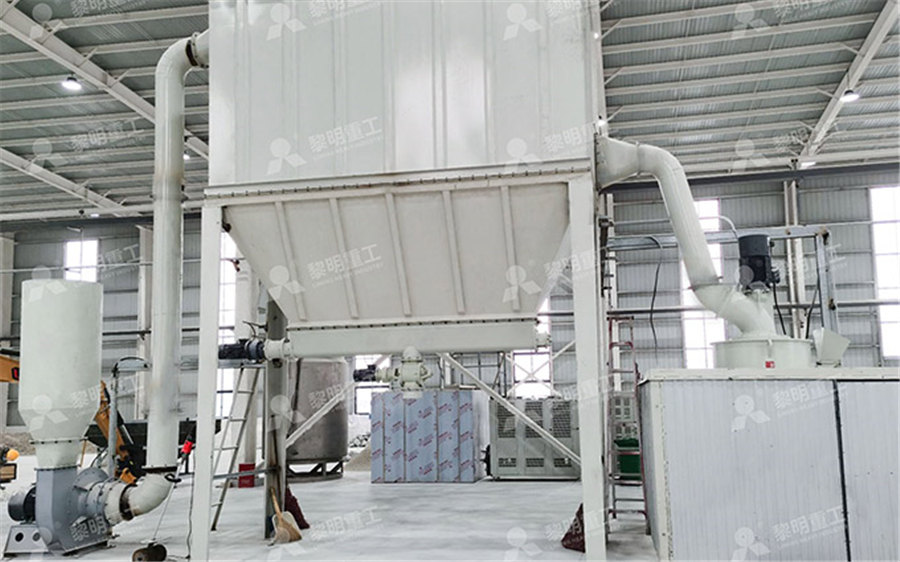

Limestone Crushing And SandMaking Plant Eastman Rock

2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etc2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding processTable 91 Limestone and Other Crushed Rock Production and Energy Consumed by Type a Units 1987 1992 1997 Limestone and Rock Production b Billion tons 12 12 Energy Consumption Coal Thousand tons Withheld 785 430 Fuel oil c Million bbl 36 34 40 Gas Billion Cubic Feet 17 32 54 Gasoline Million Gallons 142 155 147 ElectricityLimestone and Crushed Rock Department of Energy2020年4月20日 Why crushing? There are many practical purposes for industrial crushing Waste products get crushed so they for easier disposal and/or recycling You could crush wet materials, like cement, for use in construction and road building Crushing is also very useful in the chemical industry for breaking down hard materials such as limestone or coalCrushing in Mineral Processing Eastman Rock Crusher

Limestone vs Coal Compare Nature

Properties of rock is another aspect for Limestone vs Coal The hardness of Limestone is 34 and that of Coal is 115 The types of Limestone are Chalk, Coquina, Fossiliferous Limestone, Lithographic Limestone, Oolitic Limestone, Travertine, Tufa whereas types of Coal are Peat, Lignite, SubBituminous Coal, Bituminous Coal, Anthracite, GraphiteAN EXPERT IN CRUSHING NONABRASIVE MATERIALS Primary impact crushers are preferred for their high performance and high reduction ratios in crushing softer substances like gypsum and limestone Due to the different principle of crushing these materials, the reduction ratio is higher than in jaw crushers MPI1313 MPI 1515 MPI 1620CRUSHING SCREENINGLimestone is a very common sedimentary rock consisting of more than 50% calcium carbonate Although it occurs in many different forms, its origins can be traced back to either chemical or biochemical processes that occurred in the geological past, often tens to Limestone origins Science Learning HubHammer mills are used for crushing mediumhard and soft materials (coal, limestone, gypsum, clay, marl, salts, phosphates, etc) The processing of feed material with increased moisture is also possible in CPC hammer mills Grinding drying by feeding hot process gas (eg flue gas from a combustion) into the hammer mill; Mode of operationHammer Mill (Old) CPC GmbH Crushing Processing

.jpg)

Coal Crushing Plant, coal crusher plant, coal crushing, coal crushing

DSMAC has many years manufacturing experience in coal crushing plant (coal crushing process, washing plant and belt conveyor) DSMAC is a major coal crusher supplier for power plants and coke ovens, crushing limestone for blast furnaces, and crushing a wide range of raw and manufactured materials for industryProjects on Mining, Quarrying, Mineral and Ore Processing, Coal, Iron Ore, Limestone, Chromite and Granite Mining Projects [ protected] +919097075054; Login/ Register 0 NIIR Niir Project and dewatering or solid/liquid separation Ore processingis generally crushing and separating ore into valuable substances or waste by any of a Mining, Quarrying, Mineral and Ore Processing, Coal, Iron Ore Complete product series, through coarse crushing, medium crushing, fine crushing and ultrafine crushing operations AIMIX has jaw crusher, impact crusher, cone crusher and sand making machine as the core crushing equipment,with a full range of models to meet the customer’s tonnage and construction aggregate production needsAimix Group Stone Crushing SolutionsHammer crusher use of highspeed rotary hammer to impact the ore, In the Cement factoryit is mainly used for crushing limestone, coal, shale, chalk, gypsum and asbestos ore 13 Types of Hammer Crusher there are many kinds of hammer crusher, depending on the structural characteristics can be classified as follows:Hammer crusher INFINITY FOR CEMENT EQUIPMENT

.jpg)

Limestone Crushing Process JXSC Mineral

About Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated limeWelcome to Mechtech Inframine! Since 1987, we’ve been at the forefront of crushing and screening equipment innovation, providing highquality solutions for diverse we specialize in providing solutions for the crushing of coal, iron ore, limestone, and stone aggregates—essential materials for infrastructure projects such as road Mechtech Inframine Home of Superior Crushing and Screening 2017年1月27日 limestone crushing, the force is 7 times less for e r = 24 mm (processes C and D) exacerbating the failure of the coal and increasing the crushing degree of the coal(PDF) Analysis of Energy Consumption of Crushing Processes 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing,

Crushing Equipment Supplies Jaw Crusher, Impact Crusher, Cone

Hammer crusher is often used for medium hard and brittle materials such as coke, limestone, and coal gangue The crushing method can be dry or wet The gap between the grid section can be adjusted according to the client’s requirement to get different grain sizes box crusher2023年2月28日 Limestone Crushing Plant; Granite Crushing Plant; Projects Menu Toggle 500t/h Coal Gangue Mobile Crushing Plant; They are commonly used in the mining and construction industries to process materials such as A Comprehensive Guide to Understanding the 2023年2月13日 This article states types of limestone crushing equipment and compares them in production efficiency and other pespectives to help you selecting the best limestone crushing equipment 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station;What Is The Best Limestone Crusher Limestone Crushing AGICOChina Coal Crushing Machine wholesale Mining Equipment Primary Small PF1010 PF1315z Crushing Quarry Limestone Fine Coal Rock Ore Stone Construction Crushing Impact Crusher Machine Price US$ 45005500 / Set 1 Set (MOQ) Zhengzhou Zhongjia Heavy Industry Co, LtdCoal Crushing Machine MadeinChina

Powder Mass of Coal After Impact Crushing: A New Fractal

2020年6月17日 Firmness is one of the most important physical properties of rock, and indicates the rock’s ability to resist damage It has considerable relevance to mining, blasting, tunneling, construction, and other engineering fields In this study, the fractal particlesizedistribution theory was used to calculate the surface areas of coal particles after impact crushing Combining the from limestone and granite processing operations are similar Therefore, the emission factors developed from the emissions data gathered at limestone and granite processing facilities are considered to be representative of typical crushed stone processing operations Emission factors11192 Crushed Stone Processing and Pulverized Mineral Processing2023年6月30日 This is achieved by studying modelling methods and results, the automation of crushing and grinding processes, and the wear reduction of crusher componentsModeling and Improving the Efficiency of Crushing Equipment2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist

Coal Properties, Formation, Occurrence and Uses Geology Science

2023年8月15日 Coal has a variety of physical properties, including: Color: Coal can range in color from black to brown to grayish; Hardness: Coal can range in hardness from very soft and crumbly, like graphite, to very hard, like anthracite; Density: Coal has a lower density than many rocks and minerals, making it relatively lightweight; Porosity: Coal can be very porous, with 2024年2月23日 They’re great for working with materials up to 600mm, managing to slim them down to as small as 50mm With a crushing efficiency measured by a reduction ratio of 3:1 to 5:1, these crushers are especially good for materials like coal, limestone, and others that aren’t too rough on equipmentPrimary Crushing: A Comprehensive Guide JXSC2024年10月14日 A double toothed roll crusher is often used as secondary or tertiary stone crushing equipment Its versatility spans applications like coal, pebble, perlite, limestone, and dolomite processing Notable features include high crushing capacity, hydraulic pressure for roller distance adjustment, and centralized lubrication on bearingsWhat Machines Do Stone Crushing Plants Need? Fote Machinery2015年12月18日 Particle crushing during compaction is a main cause of size 0–25 mm materials, whereas some fine particles are washed away due to the effect of water seepage, which is a main cause of weight loss NonDarcy seepage properties of the crushed limestone are strongly influenced by compaction and particle size paction and seepage properties of crushed limestone

.jpg)

Monitoring and Assessment of Airborne Respirable Limestone

Previous studies have explored the impacts on the immediate environment and health of workers due to mining and processing of limestone3 Doig reported eight cases of pneumoconiosis in limestone workers who were involved with crushing and grinding for 16 to 39 years4 Xray and other examination of workers showed symptoms of dyspnoea, cough, sputum, chest pain, When the process starts running, the limestone is uniformly fed into the jaw crusher through the vibrating feeder for primary crushing, crushed to a certain particle size, and then sent to the cone crusher through the belt conveyor for secondary crushing, and then The material enters the circular vibrating screen for screening and classificationLimestone crushing process sbmchinaHammer Mills Williams manufactures a large variety of hammer mills and hammer crushers wellsuited to handle limestone crushing applications As the manufacturer holding the very first hammer mill patent to utilize midair impact crushing, Williams takes great pride in providing quality, rugged machines for many applicationsLimestone Mills Williams Crusher2023年3月27日 Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different applications However, every operator should be aware of certain do’s and don’ts when using cone crushers before making any adjustments or repairsDo’s Don’ts Of Limestone Rock Crushing Mellott

Novel Methods for Separation of Gangue from Limestone and Coal

2016年2月26日 Ore sorting is a useful tool to remove gangue material from the ore and increase the quality of the ore The vast developments in the area of artificial intelligence allow fast processing of fullcolor digital images for the preferred investigations The associated gangue minerals from limestone and coal mines were identified using three different approaches All Table 91 Limestone and Other Crushed Rock Production and Energy Consumed by Type a Units 1987 1992 1997 Limestone and Rock Production b Billion tons 12 12 Energy Consumption Coal Thousand tons Withheld 785 430 Fuel oil c Million bbl 36 34 40 Gas Billion Cubic Feet 17 32 54 Gasoline Million Gallons 142 155 147 ElectricityLimestone and Crushed Rock Department of Energy2016年2月26日 Some of the materials being successfully reduced by this pulverizer are coal, coke, copper ore, barytes, gypsum, kaolin, magnesite, chalk, clay, cement rock, dolomite rock, phosphate rock, and limestone This machine operates on the principle of reducing the material by striking it while in suspension, as opposed to attritionHammer Mill Crusher Grinder 911MetallurgistHeavyDuty Double Roll Crushers are ideal for the primary, secondary and tertiary crushing of limestone, gypsum, ROM coal, etc where higher compressive strength material is anticipated Due to the Vbelt drive design, a lower horsepower is required compared to other crushers designed for the same applications Shalemaster Double Roll CrushersDouble Roll Crushers McLanahan

Rock excavation using surface miners: An overview of some design

2013年1月1日 No drillingblasting, selective mining, less dilution, no further crushing and fragmentation etc, are the attractive qualities of the surface miner technology Out of current global population of nearly 300 surface miners in productive use around the world, Higher the coal/limestone production higher is the pick consumption