Where are there machines for processing coal

.jpg)

Coal explained Mining and transportation of coal US Energy

2022年7月14日 Coal miners use large machines to remove coal from the earth Many US coal deposits, called coal beds or seams, are near the earth's surface, but others are deep underground Modern mining methods allow US coal miners to easily reach most of the There are two main methods used in coal extraction: surface mining (above the ground) and subsurface mining (below the ground) Location is the biggest factor in determining what COAL EXTRACTION AND PROCESSING WordPressThis appendix presents additional details on the individual processes that are involved in extraction of coal from surface and underground mines, and the subsequent beneficiation of the coal in coal processing plants to produce a Coal Mining and Processing Methods The National Devices related to the transportation of coal from the mine to processing facilities to rail loading and finally to the consumer: conveyors, underground and overland bargeModern Mining Equipment Coal Education

Coal mining Definition, History, Types, Facts

2024年10月11日 Since the mid20th century, coal has yielded its place to petroleum and natural gas as the principal energy supplier of the world The mining of coal from surface and underground deposits today is a highly Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce highquality coal for energy in both local and Coal Processing Multoteccountry and water for coal processing (and other purposes) is becoming scarcer and where it is available it is becoming more expensive The environmental problems associated with wet coal processing plants, specifically the disposal of slurry, is furthermore becoming more difficult and expensive to manage New plants built in the country, and evenDry Processing Versus Dense Medium Processing For Preparing Thermal CoalA coal mine mantrip at Lackawanna Coal Mine in Scranton, Pennsylvania Coal miners exiting a winder cage at a mine near Richlands, Virginia in 1974 Surface coal mining in Wyoming, US A coal mine in Frameries, Belgium Coal mining Coal mining Wikipedia

Dry processing for coal preparation: a review

Dry coal processing may well be established in the near future through new plant instalments and upgrades, in the arid and arctic regions; but may also be preferred for small and remote operations and shows promise for processing of fine and 2023年9月1日 The coal is transported to the processing plant where impurities are removed Coal that is deeper than a few hundred metres under the surface must be extracted using two underground mining methods Some coal is mined by the Bord and Pillar method This is where a machine continually cuts into the coalCoal Geoscience AustraliaCoal stockpile Coal stacker Coal reclaimer Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP Stockpiles provide surge capacity to various parts of the CPP ROM coal is delivered with large variations in Coal preparation plant WikipediaMaterial processing is where minerals go to be smelted, crushed, grinded, just as there are specific mining machines for surface mining techniques and specific tools for underground mining techniques Highwall miners are mining machines that extract coal from exposed seamsUltimate Guide to Mining Tools Equipment Flyability

.jpg)

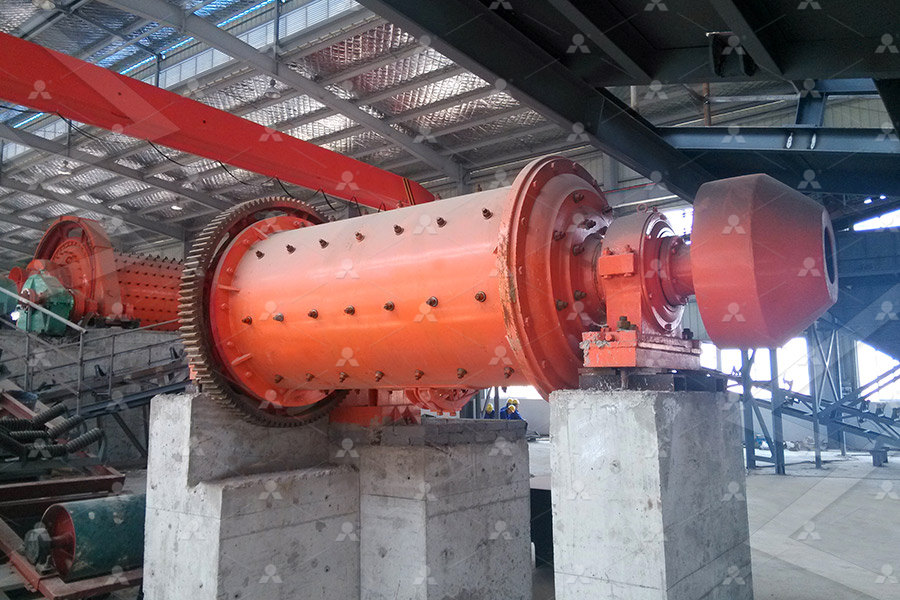

Research on vertical crusher equipment for coal mining and processing

A coal crusher is a type of crusher used to crush coal into the required size There are many different types of coal crushers such as hammer crushers, cone crushers and vertical coal crushers The hammer crusher consists of a rotor, on which there are hammer blades for continuous impact The hammer2024年1月11日 With a vertical roller mill (VRM) VRMs consist of a rotating table or bowl and rollers 1 To grind the coal, feed raw or initially crushed coal into the mill which is then ground between the rotating components; 2 Finally, hot air removes moisture, carries the pulverized coal out, and a classifier segregates the particles; Here is all you need to know about the VRM:How to Process Coal into Pulverized Coal in 5 Steps?2014年1月1日 The use of coal is negatively perceived, since the use of fossil fuels in power generation and other industry sectors contributes significantly to the CO 2 emissions worldwide Of the main fossil fuels, coal has the lowest H:C ratio, and consequently coal has the highest CO 2 footprint per unit of combustion energy produced Coal also contains percentage levels of Coal Processing and Use for Power Generation ScienceDirect2023年8月15日 Coal has a variety of physical properties, including: Color: Coal can range in color from black to brown to grayish; Hardness: Coal can range in hardness from very soft and crumbly, like graphite, to very hard, like Coal Properties, Formation, Occurrence and Uses

Coal mining in the UK: Where mines are still being

2020年3月12日 Once the coal has been extracted it is transferred by road and rail to the Celtic Energy’s own processing and distribution centre at Onllwyn Coelbren, South Wales Anne Harris, of the Coal Action Network said: “The Dry coal processing benefits downstream utilizations through possible cost and energy savings along with a reduction in water pollution As a result, dry processing has inspired interest in the coal preparation industry and research into many methods has commenced Addendum A: Performance report on the applicable dry coal processingDry processing for coal preparation: a review2023年6月12日 Our mission is to provide highquality coal and diesel to our customers while prioritizing safety, sustainability, and reliability Our vision is to be the leading supplier of coal and diesel, recognized for our commitment to safety, sustainability, and innovation National Coal Suppliers is a reliable South African coal supplierSouth African Coal Mining Techniques2023年7月4日 According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, lime briquette machine, and gypsum briquette machine They are popular for their unique properties, applications, and reasonable price 5 types of briquette machines 15 Types of Briquette Machines (With Budget Analysis)

(PDF) Application of signal processing technology for automatic

2003年5月6日 The paper reports on an industrial application of modern signal processing technology in the development of a new automatic conveyor and bolting machine for underground coal mininggoals Providing Republic of Tajikistan enterprises (including their own plants) with coal processing products, with the subsequent possibility of exporting the developed products to the foreign market Country's economy industrialization objectives Products production of deep processing of coal Increase the volume of coal produced and processed inCoal production and deep processing 日本タジキスタン投資 2024年11月15日 Coal is a black or brownishblack sedimentary rock that can be burned for fuel and used to generate electricityIt is composed mostly of carbon and hydrocarbons, which contain energy that can be released through combustion (burning) Coal is the largest source of energy for generating electricity in the world, and the most abundant fossil fuel in the United StatesCoal Education2021年6月24日 We know coalmining is one of Australia’s most important industries, supporting more than 50,000 direct jobs and $695 billion worth of exports in 2019 [1] But how is coal mined on a daytoday basis? There is a lot of talk about how we do coalmining but not all of it How Is Coal Mined? Bravus Mining Resources

Coal mining Underground, Surface, Drilling Britannica

2024年10月11日 Coal mining Underground, Surface, Drilling: The various methods of mining a coal seam can be classified under two headings, surface mining and underground mining Surface and underground coal mining are broad activities that incorporate numerous variations in equipment and methods, and the choice of which method to use in extracting a coal seam 2023年1月1日 The world’s coal resources are not abundant hence there is a need to use the available coal resources effectively Therefore, there is a requirement of new coal washeries, with improved washing technologies This section provides the description of typical noncoking coking coal washeriesCoal beneficiation: theory and practice ScienceDirectAbout US WOOD machinery is a subsidiary of Shuliy Group, which was established in 2011 Its major includes designs manufacturing and selling woodworking equipment and charcoal processing equipment, including wood Coal Briquette Processing Plant Coal Making MachineCoal Processing Machine By TwiistsGaming Mods; 8,297; Download Install About Project About Project Created Aug 25, 2018 Updated Nov 6, 2018 Project ID License Any modpack which uses Coal Processing takes full Coal Processing Machine Minecraft Mods

.jpg)

What Is Coal Mining and How Does It Work? BKV Energy

Coal mining is the process of extracting coal from the earth Coal miners use large machines to remove coal from underground or near the surface Some coal deposits, known as coal beds or seams, are located close to the earth’s surface, making them easily accessible There are also coal deposits that are deep underground Surface mining2015年7月1日 The United States currently operates 268 coal preparation plants in 14 states according to the latest annual census of coal processing plants conducted by Coal Age [3] The facilities, which are primarily located in West Virginia (80), Kentucky (56), and Pennsylvania (44), represent a total installed feed capacity of over 200,000 tons per hourA review of stateoftheart processing operations in coal preparation 2024年10月1日 However, coal mining wastes and coal processing byproducts such as coal gangue with low HGI could induce serious wear and tear on the crushing machine As such, wearresistant steel or new materials need be developed to Eliminating environmental impact of coal mining wastes and coal 2020年4月27日 PDF A theoretical data on CocaCola Company's Processing Packaging and how the Assure the Quality of its Product Find, read and cite all the research you need on ResearchGate(PDF) Coca Cola(Processing, Packaging Quality Assurance)

.jpg)

Environmental Impact of The Mechanical Coal Processing Plant

Environmental Impact of The Mechanical Coal Processing Plant Witold BIALY1*, Wes GREBSKI2, Greg GALECKI3 and Wojciech KANIAK4 technology was carried out The technology analysis showed that these technologies, and consequently machine systems for hard coal processing, are adapted to the characteristics of enriched coal, mainly type and 2020年2月13日 More coal processing is done in foreign coalproducing countries because of their requirements The Food Machinery and Chemical Corporation and the United States Steel Corporation have there is renewed interest in destroying these coking properties because a noncokingsized coal is required for either dryash or Coal Processing Methods 911MetallurgistCoal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine feeding by quantitative feeder uniform, sometimes need to improve the coal briquette strength, coal processing plants machines2024年4月18日 The coal industry provides a wide range of career opportunities in mining, transporting and processing coal for its various purposes Understanding what coal industry jobs there are can help you decide on your next career choice In this article, we discuss 24 jobs in the coal industry, including their national average salaries and primary duties24 Jobs in the Coal Industry (With Salaries and Primary Duties)

Operation and Maintenance of Coal Conveying System Screening

mentation of anthracite coal, common coal, inferior coal and lignitous coal etc Has not blocked, can eliminate impurity, has the advantages of simple structure, small in size, light weight, convenient maintenance etc In each big, mediumsized power plant has been widely applied 753 Screening and Crushing Coal Machinery 7531 Crushing Coal 2019年8月23日 Coal processing description from its geology mineral property to how to extract coal, Vibrating Blanket Machine; Suspended Vibration Cone Concentrator; Dewatering Machine Rotary Dryer; In general, there are four Coal Processing Equipment, Process Flow, Cases1983年10月1日 Thus, the success of the oil ag TABLE I 177 Chronological development of oil agglomeration Process/ Year Features/studies Objectives inventor Trent 1920 Selected recovery of coal fines by using oil Recovery of coal (30% wt of dry coal), separation by screening Convertol 1952 Reduced oil consumption over Trent Process Recovery of coal (315% wt%)Review of oil agglomeration techniques for processing of fine coals The job of a plough system in underground mining can be described in a nutshell as “eating through coal at a depth of 1300 m” In 2015, a new Cat GH 800 B will be put into operation for RAG Anthrazit Ibbenbüren GmbH, a subsidiary of RAG AG, in Germany’s northernmost coal mine, in Ibbenbüren, and there to cut and extract the around 1mthick coal seamPlough system for low thickness coal seams Mineral Processing

.jpg)

Where We Operate CCBSA

CocaCola Beverages South Africa (CCBSA) is a proudly South African company which began operating as a legal entity in July 2016, after the merger of six nonalcoholic ready to drink bottling operations We are a level 1 BBBEE empowered company We employ over 7000 people at 13 manufacturing facilities across the country2017年12月15日 Two dominant methods account for the vast majority of underground coal mining: “room and pillar” and “longwall” mining In room and pillar mining, seams of coal are partially mined, leaving large pillars of coal intact to support the overlying layers of rockWhen finished, miners practice “retreat” mining, extracting as much coal as possible from the How Coal Works Union of Concerned Scientists2023年10月19日 Coal obtained in different places is not the same and varies widely depending on the nature of the soil and geographic conditions There are two major types of coal mining: underground mining and surface mining Coal mining satiates roughly 1/4 of our global energy demands, and it is coal that has powered America’s power needs for decadesCoal Mining: How Is Coal Mined? Science ABC1982年8月9日 Coal processing refers to the practice of converting coal into various products such as coal tar, coke, The maintenance management system consists of a framework of 3M: man, machine and methods There has been continuous improvement in the procedures of maintenance approaches They can be grouped into reactive, preventive, Coal Processing an overview ScienceDirect Topics