What crushing station specifications are used for 300350400

Combining legacy and expertise Mining Crushing Stations

Metso Outotec FIT™ Stations use the speed and flexibility of the modular design to provide a quick installation We offer 3 stations fitting the FIT™ Stations name: Primary gyratory, jaw stations and recrushing stations Most components for the stations can be supplied in Metso FIT™ Stations use the speed and flexibility of the modular design to provide a quick installation We offer 3 stations fitting the FIT™ Stations name: Primary gyratory, jaw stations Combining legacy and expertise Mining Crushing Stations MetsoThe document discusses the Nordberg HP300 cone crusher, describing its optimized performance, cost efficiency, safety features, and specifications It can be used for aggregates Nordberg® HP300™ Cone Crushers' Technical SpecificationsThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 Metallurgist

Mining crushing stations Metso

Metso is introducing two unique, cost efficient and modular mining crushing stations: FIT™ stations and Foresight™ stations FIT™ stations are focused on speed and flexibility for quick your specifications The benefits of our systems are numerous: high throughput coupled with low costs, minimum maintenance, ease of operation and maximum reliability thyssenkrupp impact Industrial Solutions Impact crushers ThyssenKruppyour specifications The benefits of our systems are numerous: high throughput coupled with low costs, minimum maintenance, ease of operation and maximum reliability thyssenkrupp impact crushers are suitable for both coarse and fine crushing From top: Stationary singleshaft impact crusher fed by two apron feedersIndustrial Solutions Impact crushers ThyssenKrupp2024年6月28日 Wide application: Suitable for both dry and wet crushing, for materials with up to 15% moisture Onetime forming: Eliminates the need for primary and secondary crushing, reducing costs by approximately 40% Large feed opening: Handles feed sizes up to 1000 mm, making it ideal for coarse crushing Nonclogging: Designed to ensure smooth flow of high What Crusher Should You Choose for Primary Crushing?

.jpg)

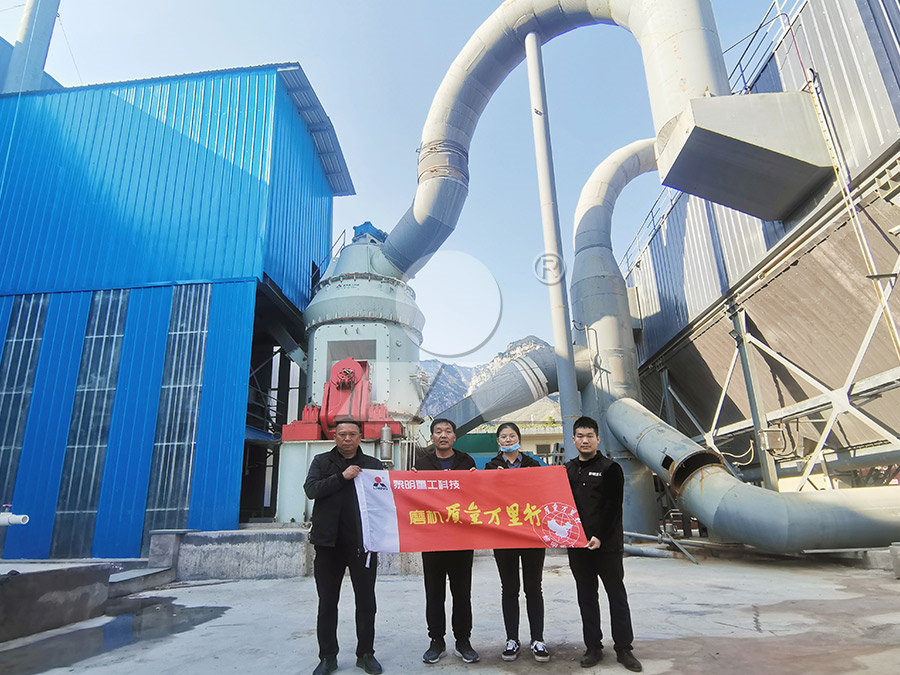

MOBILE CRUSHING AND SCREENING STATION

The mobile crushing station is suitable for the recycling of mine or urban construction waste resources, and can be configured according to the special requirements of customers for finished materials Note: Specifications and models are subject to change without noticeMining Crushing Stations Combining legacy and expertise Metso has experience in delivering tailormade mining crushing and screening plants With over 100 installations to a wide range of applications, our endtoend process has helped develop our Metso Mining Crushing Stations Metso Mining Crushing Stations are unique, costefficient and Combining legacy and expertise Mining Crushing Stations Metso2021年10月5日 Specifications for architecture, engineering, landscape, and the built environment give construction teams a detailed overview of the project work, required performance, and product selections This article answers some commonly asked questions about specification and NBSConstruction specifications: Everything you need to know NBSStages of Rock Crushing: Crushing Stations It is common to use multiple crusher types within a project and set them up as stations in a circuit format to perform the necessary material reduction work In many cases, primary, secondary, and tertiary, and quaternary stations are installed to reduce the rock to the desired size, shape, and Types of Rock Crushers Quarry Crushing Equipment Kemper

.jpg)

Crushing Products Size and Shape What to Expect

2016年2月26日 Although the group of curves we have been considering are intended for calulations involving primary crushing operations, they may also be used for secondary crusher products in those cases where no screening is performed between primary and secondary stages Such an arrangement is seldom encountered in modern plant design, M1 = Mass of used PET bottle fed into the machine M2 = Mass of crush PET bottle plastic waste T = Machine crushing time The mass of PET Bottles fed into crushing machine M1 (kg) was used for testing the crushing efficiency of the machine for each interval, and this was carried out for eighteen times during which the input (M1) and the output (M2) were recorded accordingly(PDF) Design of Used PET Bottles Crushing Machine for Small 2023年2月28日 In the recycling industry, primary crushers are used to break down larger materials, such as concrete and asphalt, while secondary crushers are used to further refine these materials for reuse Overall, both primary and secondary crushers play an important role in the crushing process and are essential components in the mining and construction industryPrimary Crusher vs Secondary Crusher: Understanding Their The roller crushers are used for moist and sticky materials Generally the machines have to be rigid enough to crush also hard inclusions As the reduction ratio is only about 5:1 a 2stage crushing is required in most applicationsEverything you need to know about Crushers in Cement industry

A Guide to Mobile Crushing Plants: Types,

2023年2月24日 They can also be used for secondary and tertiary crushing to produce the desired particle size Quarrying: Mobile crushing plants are used in quarrying to crush and screen stone and rock for use in construction and other 2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the SIZE REDUCTION BY CRUSHING METHODSThe mobile crushing station products designed and produced by Phoenix have a wide range of applications, including mining and crushing stone processing, construction waste recycling, finished aggregates, machinemade sand, refractory materials, building materials cement, roads and bridges, highways, mining and crushing stone processing, finished aggregate machine Mobile crushing stationCrushing and screening equipme菲尼 Crushing Stations Metso Outotec Mining Crushing Stations are unique, costefficient and productive solutions All are modular crushing and screening plants designed to significantly increase time and resource savings for mining operations Time savings Flexibility Ease of maintenance Design information available reducing feasibility, engineeringCombining legacy and expertise Mining Crushing Stations

.jpg)

Construction, Working and Maintenance of Crushers for Crushing

compression Shear crushing is normally used under following conditions When material is somewhat friable and has relatively low silica content For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing Systemfeed materials in the primary crushing stage They deliver the crushing performance you need, and have proven their reliability and productivity in well over 10,000 quarrying, mining, recycling and industrial minerals applications since 1975 C Series jaw crushers have a strong pinned and bolted, nonwelded frameProven reliability and performance Nordberg® C Series™ jaw crushaggregate (recovered from material previously used in construction) (BGS, 2013) This paper will focus on natural (primary) aggregate GEOLOGY OF AGGREGATE RESOURCES Any naturally occurring geological material can be used as construction aggregate as long as it satisfies the requirements of the enduse specificationConstruction aggregates: evaluation and specification2024年10月14日 This type of cone crusher can be combined with the jaw crusher, vibrating screen, and other equipment to form a mobile crushing station The crushing station has two types: crawler type and tire type Learn more about the Mobile Crushing Station The mobile cone crusher is not restricted by the site It can be easily and flexibly moved to the 4 Types of Cone Crushers: What Are They and How to Select

.jpg)

(PDF) Optimization Capabilities for Crushing Plants ResearchGate

2022年4月26日 There are two types of process simulations used fo r crushing plan ts in operation: steadystate simulation and dynamic simulation [9, 10] Steadystate simulation represents an%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resourcesThis solution is a stationary crushing plant for crushing limestone with a capacity of 300350t/h The stationary crushing station is characterized with long service life and stable performance and is suitable for medium and largescale mining 300350TPH Stationary Crushing Plant For Crushing 2024年5月25日 Conveyor Belt for Stone Crusher: Scaling Up with 1:14 Scale Conveyor Design and Specifications Scale Model Design The design of the stone crusher conveyor belt, particularly the 1:14 scale model, is meticulously Selecting Conveyor Belt for Stone Crusher Systems

What is Mobile Crushing Station in Mining? miningpedia

2021年8月31日 Mobile crushing station is an important form of openpit mine crushing station It is to place the mobile crushing unit on the working level of the open pit, and as the stripping face advances and the mining extends down to a certain distance, the mobile crushing unit is moved as a whole by crawler trucks and other traction equipmentSpecification: B500*28M: B650*33M: Ores: Mobile jaw crushing stations can be used to process various ores, including gold, silver, copper, and iron Industrial minerals: Mobile jaw crushing stations can also be used to process industrial minerals, including phosphate, potash, and Custom Mobile jaw crushing station Manufacturers, Factory, 2019年11月11日 Basalt: An igneous rock often used for road pavement or concrete aggregatesIt's also used for masonry projects Granite: A durable, easily polished igneous rock Because of its color, grain, and ability to be polished, it's often used inside homes for countertops or on the outside of monumental or civic buildingsThe Complete Guide to Crushed Stone and GravelThe first step in the mining and processing of nearly any mineral ore is comminution Since the oil embargo of 1979, the mining companies have been striving to reduce energy consumption and costs The first serious step was the introduction of inpit crushing in the early 1980s With inpit crushing accepted as a standard design mode, the energy saving emphasis turned to Primary Crusher Optimisation for Improved Comminution

.jpg)

Crushing Station With Horizontal Shaft Impact Crusher in

2024年6月27日 Crushing Station With Horizontal Shaft Impact Crusher in Recycled Asphalt Application,China,heavy duty, feeders frame conveyors, trussed frames, service platforms, support bents, transfer towers,control buildings specifications, contract documents and 2023年3月11日 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; 200t/h River Gravel Mobile Crushing Plant; In summary, impact crushers are a powerful and vesatile type of crushing equipment used in the mining and construction industriesHow Impact Crushers Work: A Comprehensive GuidePE Jaw Crusher: A singletoggle design that utilizes a lever mechanism for the crushing action PE models are typically used for primary size reduction PEW Jaw Crusher : Similar to PE jaw crusher, but may incorporate unique design elements Jaw Crusher Technical Specification For Mining2015年11月17日 He offers a primary sizer station in Colombia that handles 2,200 mtph as an example At this mine, the MMD 625 series primary sizer sits below a hopper that integrates an MMD D4 apron feeder “For that Colombian coal operation, we not only engineered the primary, but the entire system from the secondary sizers to the surge pile where they load the trains Crushing and Sizing Systems for Surface Applications

Rock Crushers Pulverizers Williams Crusher

Crushing may take place in one process with a single crusher However, secondary and tertiary crushing can be used to further break your material down to the desired size Many processing plants or rock crushing plants utilize 2023年2月28日 Learn everything you need to know about primary jaw crushers in this comprehensive guide Discover how they work, their applications, and where to buy them from reputable sources Whether you're in the mining or Primary Jaw Crusher – Everything You Need to KnowLicensed copy: MLA Cornwall Public CAT, Cornwall Enquiry and Information Service, Version correct as of 20/09/2011 15:09, (c) BSI BRITISH STANDARD Testing aggregates — Part 110: Methods for determination of aggregate (PDF) Testing aggregates Part 110: Methods for 2023年2月3日 The specifications of a crusher for crushing concrete will depend on the type of crusher being used and the desired output Some of the key specifications to consider include the following: Feed What are the specifications of the crusher for crushing concrete?

.jpg)

CONSTRUCTION SPECIFICATIONS FOR PREFABRICATED LIFT STATIONS

feeding the pump station When the pump station is eliminated, the space between stop planks and manhole wall will be filled with a concrete plug 502 Sanitary Pump Station Plan Submittal Procedures Sanitary Sewer Pump Station Submittals shall comply with the provisions as outlined in Section 100 and Section 300 of this manual2024年11月19日 In secondary crushing, reduction ratios become an important consideration Knowing just how fine you would like your final output to be, along side the feed requirements of your tertiary or final reduction crushing station, will assist you determine what proportion reduction must happen within this stage7 Types of Stone Crusher and How to Choose the Best?Discover the crucial role of crushing and screening equipment in construction projects Learn more from Wagner Used Equipment today! Phone: (303) 9005875 Contact Us Equipment Attachments Selecting the right crushing and screening equipment will vary depending on the needs and specifications of a construction project and its crewCrushing and Screening Equipment – Why It Matters2022年1月23日 This too helps keep the capital cost of the crushing station down Another major step in the crushing circuit, for bauxite ore applications and nearly all crushing applications, is the screening stage The screening stage separates particles in the material flow by their particle sizePhysical Bauxite Processing: Crushing and Grinding of Bauxite

Operation and Maintenance of Coal Conveying System Screening

usually set a screening crushing machine room; broken coal and screening equipment are used together, complete coal of broken and screening Through such processing, meet the requirements of the particle size is sent to coal pulverizer into the following process The screening and broken coal machinery as the key2020年10月22日 In this article, optimization of the layout of the fixed crushing station in the inpit crusher and conveyor system of openpit mining is studied First, Layout optimization of crushing station in openpit mine based