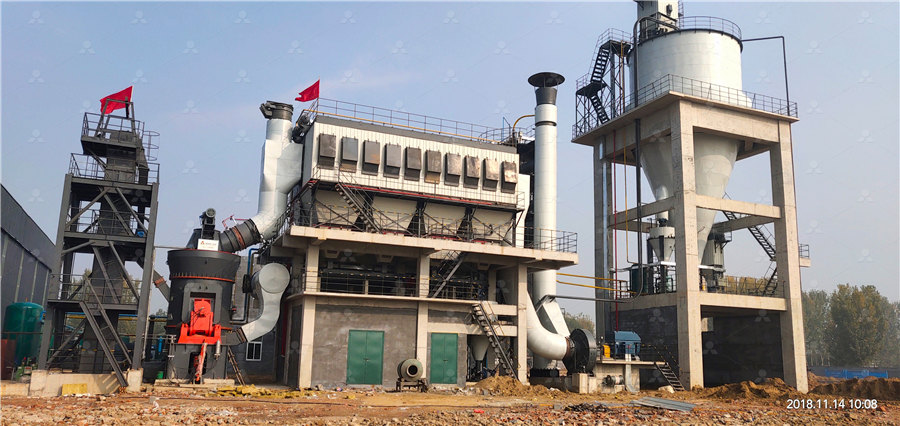

Lime transportation and crushing system

Lime Handling System for Operations Solutions VG

Efficient lime handling systems are essential for optimized industrial operations By utilizing a range of equipment, such as conveyors, crushers, silos with discharge systems, and dust collection technologies, our lime handling The Lime is transferred from the silo to a receiver mounted above a loss in weight feeder using a negative pressure (vacuum) pneumatic conveying system The loss in weight feeder calls for a Lime and Soda Handling System STB Engineeringlime injection systems are designed to minimize lime loss during delivery to the furnace, offer better control of slag, eliminate dusting, and reduce maintenance needsDESIGN, PROTECT MAINTAIN YOUR LIME STORAGE, HANDLING Unloading lime from container liners depending on the lime type requires experience and advanced bulk unloading systems as well as the liners with right technology BulkFlow has designed 2 unloading systems for hardtoflow Lime: Uses, Handling and Transport BULKFLOW BLOG

.jpg)

Conveying, Storing, Reclaiming in the Lime and Gypsum Industries

Equipped with powered manoeuvring systems and inline and parallel travel, the Link Conveyors may be rapidly moved and repositioned clear of the face for blasting The AUMUND Apron 2021年1月1日 其工艺流程为回转窑和双膛窑的成品块石灰以及除尘粉通过块石灰运输 系统到破碎中间仓 合格的物料进入粉仓,不合格的物料返回到破碎机继续加工,物料走向如 图1所示 Optimization and Improvement of Control Principle of Lime Our lime injection systems are designed to minimize lime loss during delivery to the furnace, offer better control of slag, eliminate dusting, and reduce maintenance needsYOUR LIME HANDLING EXPERTS CarmeuseIndustrial lime conveying systems are purposebuilt setups designed to manage the processing, storage, and distribution of lime in large quantities These systems are crucial for maintaining a continuous supply of lime while adhering Lime conveying System : Enhancing Efficiency and Safety

.jpg)

Modern Technological Applications for Limestone Mining

2021年7月15日 Savings in Transportation Costs (a) The maintenance of dumpers and other trucks deployed for the transportation of limestone using a centralized greasing system saves considerable cost Savings of Rs 16 million per annum coupled with reduction of manpower, breakdowns, etc, can be made (b)2023年12月5日 InPit Crushing and Conveying Systems in Open Pit Mines: A Technical Evaluation for Selecting the Most Effective Transportation System by System Dynamics Modeling December 2023 Logistics 7(4)TruckShovel vs InPit Crushing and Conveying The choice of active lime production process is determined by many factors: investment cost, lime activity requirements, fuel selection, raw material size, system capacity requirements, and environmental protection requirements Active Lime Production Line(3) the construction scope: including raw material storage system, feeding system, calcining rotary kiln system, waste gas treatment system (reserved denitration system), finished product storage, crushing screening dispersed system, finished the blues pneumatic conveying system, coal pulverizing system of desulfurizer, environmental dust removal system, water supply and 5000tpd Active Lime Production Process Machine Knowledge

.jpg)

ANALYSIS OF AGRICULTURAL LIME DEMAND AND SUPPLY

agricultural lime with respect to alternative factors such as prices of farm products, agricultural lime, and other inputs The supply equation is used to estimate the effect of agricultural lime price, prices of key inputs such as transportation and fuel, and prices of non agricultural lime products on agricultural lime suppliesNeutron Holdings, Inc, doing business under the name Lime, formerly LimeBike, is an American transportation company based in San Francisco, CaliforniaIt runs electric scooters, electric bikes and electric mopeds in more than 200 cities in nearly 30 countries around the world [1] The system offers dockless vehicles that users find and unlock via a smartphone app that knows Lime (transportation company) WikipediaThe two scraper chain systems are linked together at a knee joint The secondary scraper chain lifts the material to the crest of the pile, feeding the primary scraper chain system The primary scraper chain system conveys the material to the outgoing belt conveyor The system only requires an operator when shunting from one pile to anotherEverything you need to know about Stacker and reclaimer systems2022年9月1日 One of the transportation options in surface mining to reduce operating costs, especially in the deep open pit mines, is InPit Crushing and Conveying (IPCC)InPit Crushing and Conveying Systems in Longterm Open Pit

Stacker And Reclaimer Cement Plant Parts

The stacker and reclaimer is the prehomogenization system in the cement plantAs a necessary part of the cement production line, it can concurrently or respectively complete the stacking and reclaiming The stacker and reclaimer play a vital role in the limestone prehomogenization, stabilize the condition of cement kiln, ensure the clinker quality2019年7月4日 Abstract Inpit crushing and conveying (IPCC) systems have attracted more interest among miners as an alternative to the conventional truckshovel transportation system The semimobile IPCC (SMIPCC) system is a wellsuited type of IPCC system in openpit mining projects because of its relocation nature However, it is very important to design its optimum Optimum location and relocation plan of semimobile inpit crushing 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine Torsa brings to you Portable Lime Stone Crusher plant to give you experiences of highly professional C4 and C7 models are a pinnacle of compact, economical crushing and screening solutions By integrating all critical crushing and Lime Stone Crusher Plant Portable Stone Crusher Torsa

.jpg)

Dry Bulk Material Handling Systems Engineering and Construction

Leveraging over three decades of unrivaled expertise, IAC stands out as an OEM and EPC Contractor specializing in bulk material handling solutions, storage and transportation systems, process equipment, and site construction Our team has comprehensive experience in an array of bulk processing industries including aggregates, frac sand, ethanol, grain and feed, food and transportation systems has become a promising direction for improving productivity and reducing operating costs Conventionally, the truckandshovel system is used in openpitA Framework for OpenPit Mine Production SchedulingTransportation costs are a consideration in the design, as it may be more economical to place the hydrating plant closer to the market the system Lime crushing/screening and storage The product is typically the same size as the limestone, which can be crushed and screened per market Figure 2In the Limelight Penta Engineering CorporationGiven the existing potentials in aglime processing at the factories established mainly for lime crushing and the cement factories that could easily adjust and produce lime for agriculture, we (the authors) argue that producing a large quantity of aglime should not be an issue in EthiopiaAgricultural lime value chain efficiency for reducing soil acidity in

Lime Production: Industry Profile

24 Vertical kiln system for lime production 27 25 Parallel flow kiln with left shaft calcining and right shaft preheating 210 26 Fluidized The production of lime begins with the quarrying and crushing of limestone Limestone is a general term that covers numerous varieties of sedimentary rock2021年9月1日 Keywords Openpit mining, mining transportation systems, inpit crushing and conveying, truck and shovel, transition point Flow chart of investigation for the implementation of IPCC Determination of the optimal transition point between a truck and The thyssenkrupp Skip Way System is highly adaptable to the terrain of a mine and can also be used in rough weather conditions when truck haulage would typically be suspended The system also complements thyssenkrupp’s “Integrated Skip Conveying and Crushing System,” which has handling rates of up to 5000 mtph for uncrushed ore or overburdenNew steepangle material transportation concept for quarries 2019年5月20日 Inpit crushing and conveying (IPCC) systems have attracted more interest among miners as an alternative to the conventional truckshovel transportation systemOptimum location and relocation plan of semimobile inpit crushing

Crushing and Sieving of Lime Limebase

We know the processes, systems and procedures that work to crush and sieve the material to meet any specification To find out more about our crushed and sieved stone or if you are looking for something specific that you can’t find on 2019年11月6日 Optimally planned InPit Crushing and Conveying (IPCC) systems could resolve the transportation challenges of openpit mining operations There is a direct correlation between IPCC planning, Open Concurrent openpit mine production and inpit crushingNeutron Holdings, Inc, doing business under the name Lime, formerly LimeBike, is an American transportation company based in San Francisco, California It runs electric scooters, electric bikes and electric mopeds in more than 200 cities in nearly 30 Lime (transportation company) WikiMili, The Best Wikipedia 2020年2月18日 Explore the environmental hazards of limestone mining and learn about adaptive practices for effective environment management(PDF) Environmental Hazards of Limestone Mining and

Final Cement and Lime Manufacturing International Finance

• •Storage of screened sizes of burnt lime in bunkers or silos and storage of fine grades of hydrated lime in sealed silos; gases, followed by fabric filters; • •Implementation of routine plant maintenance and good housekeeping to keep small air leaks and spills to a minimum; • Conduct material handling (eg crushing operation s, raw2024年1月11日 limestone is the raw material for manufacturing cement, aggregates, lime, and calcium carbide in modern industry Skip to content Eastman Rock Crusher Eastman Rock Crusher +86 [ protected] Menu Home; the medium crushing system uses the impact crusher, and the fine crushing system uses the sandmaking machine 1Limestone Crushing And SandMaking Plant Eastman Rock The lime production line is a set of material processing production lines mainly used in industries such as mining, metallurgy, and chemical engineering During the production of lime, vertical lime kiln plays a very important role Lime production line consists of feeding equipment, crushing and grinding systems, powder grinding systems, finished product conveying systems, and dust Characteristics and Functions of Lime Production Line2021年7月15日 Ripping and dozing is an alternate method of excavation that has to be integrated with conventional loading, crushing, and transportation arrangements This method has limitations because it is not suited to achieve higher levels of production (ie, >1000 TPD) for many operationsLimestone Mining, Industry, and Society SpringerLink

.jpg)

Advances in cement filling plants and transportation in China

The system is flexible, stable and efficient, and successfully solves issues with jams, high throws and is adaptable to multiple vehicle types As it is completely unmanned, the exposure of workers to dust is avoided and hence reducing occupational health hazards, it improves the working environment and also solves the issue of pollution on the production lineA typical plant would involve complete design, manufacture and installation of crushing and screening equipment It can incorporate primary crushing, feeding, and supply to stockpile, storage bins and recycling systems to suit the customer’s specific requirements, considering all product types or sizeCrushing and Screening Systems PM Engineering Ltd2023年8月18日 The lime manufacturing process is the first thing to learn, all lime manufacturing plant design is based on this, it can be divided into raw material preparation, lime calcination system, conveyor system, dust collector How To Start A Lime Manufacturing Plant?2024年1月17日 Lime mud (LM), a solid waste generated in the papermaking industry, was proposed to manufacture lightweight artificial aggregates (LAAs) via the crushing technique(PDF) Upcycling of lime mud into lightweight artificial

Stacker And Reclaimer Cement Plant Equipment

As one of the stacker reclaimer manufacturers, AGICO offers quality stacker and reclaimer The circular stacker reclaimer plays a vital role in the cement material prehomogenization process, which is the most frequently used cement plant equipmentThe limestone jaw crusher is usually used as the first rock crusher, and it is suited for mediumsize crushing of ore and bulk materials with a compressive strength of not more than 320Mpa Jaw crusher is divided into coarse crushing and fine crushing The feeding size is 125mm~750mmLimestone Crushing Plant Layout and Price JXSC Machine2023年2月27日 regional states to increase aglime production and supply to enhance crop productivity in areas affected with severe soil acidity The study also focused on three stateowned (public) lime crushing factories: Guder, Dejen, and Kella lime factories in Oromia, Amhara, and SNNP regional states, respectivelyAgricultural lime value chain efficiency for reducing soil acidity in 2015年4月7日 The invention provides a preparation method and application of lime nitrogen The preparation method comprises the following steps: after crushing calcium carbide in a crushing machine, grinding calcium carbide into fine powder, and crushing finepowdery calcium carbide, fluorite and circulated lime nitrogen into powder smaller than 100mm, and lifting the Preparation method and application of lime nitrogen SciSpace

Process flow of hydrated lime production line Gaifeng

2022年3月16日 The hydrated lime production line is to crush the qualified hydrated lime blocks to a particle size of about 40mm by the jaw crusher, and send them to the hydrated lime storage tank silo through the bucket elevator The digester performs preliminary digestion When the hydrated lime completes the primary digestion, it enters into the Ⅱlevel digestion or the Ⅲ %PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources