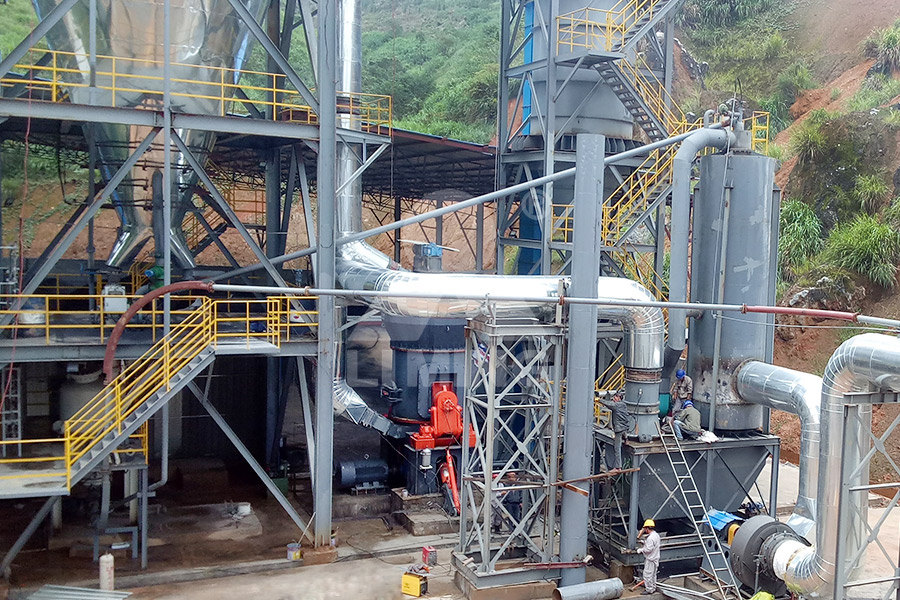

Configure as the fourth stage of ultrafine crushing after threestage crushing

CrushingScreening Flowsheet of Concentrator SpringerLink

2023年7月21日 The threestage crushingscreening flowsheet of concentrator is suitable for processing ores with high mud content in underground mining and openpit mining It simplifies 2023年12月1日 The objective of this work is to understand the wear mechanisms experienced by the concave and mantle coatings of a crusher installed in the fourth stage of crushing in an Tribological study of fourthstage crusher coatings applied in an 2014年10月22日 » Super Fine crushing in combination with advanced conventional fine crushing could add a whole new dimension to comminution practice » This combination also has the potential toNew Crushing Concepts and Super Fine Crushing2020年12月1日 Crushing behaviour in a VSI involves multiple mechanisms of impact breakage Particle scale modelling of comminution processes can provide significant insight into the flow Advanced comminution modelling: Part 1 – Crushers

.jpg)

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushing In the majority of cases, 2023年9月13日 For materials that require very fine particle size and are easy to agglomerate, a multistage ultrafine crushing process in series can be used to improve operating efficiency 7 basic process flows of ultrafine grinding ALPA Powder2015年7月25日 Lets begin with an over view of these two crushing stages Then describe various flow sheets, and discuss the variables that influenced their design After the whys have Secondary Tertiary Crushing Circuits 911Metallurgist2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, Evaluation of size reduction process for rock aggregates in cone

Crushing Screening Plant 911Metallurgist

2016年7月12日 Coarse crushing or breaking is the primary mechanical step in ore reduction It is frequently done underground in large plants such as the McIntyre and Hollinger mines Where 2021年6月10日 Understanding the crushing stages and the type of crusher best suited for each stage can simplify equipment selection Each type of crusher is different and is used to achieve a specific end result Similarly, it is expected Understanding the Crushing Stages of a Crusher2017年3月4日 There are three stages in crushing as stage 1, 2 and 3 In each stage the reduction in siz e ranges as the final particle size with the cubic shape ,no crack ,fine shapeSIZE REDUCTION BY CRUSHING METHODS2018年3月1日 The drug concentration recovered at each stage of crushing, Ultra Fine Cut N Crush 9465 082 369 064 Medication is lost after crushing due to powder being left behind in the (PDF) Drug loss while crushing tablets: Comparison

.jpg)

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

This means that the number of crushing stages can be reduced depending on the feed size accepted by primary grinding stage Image of a “Classical” 3stage ore crushing prior to rod mill [image: (13551)] Diagram of Typical 12 stage ore crushing prior to AGSAG mill [image: (13552)] Calculation of Reduction Ratio in CrushingARK 2416 jaw crusher in action Gyratory crushers Run of mine material is transferred into a gyratory crusher’s upperlevel hopper The walls of the gyratory crusher’s hopper are lined with “Vshaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a coneTypes of Crushers: What You Need to Know Machinery Partner2022年1月1日 The geology is Brockman bedded iron deposit Two stage crushing is used, jaw crusher for the primary and cone crushers for the secondary crushing There are three stages of screening, before primary crushing, scalping screens, before secondary crushing, primary screens, and product screens for lumps and fines minution and classification technologies of iron ore2023年7月22日 Ore fine crushing is a process of crushing ore blocks with a feeding particle size of 50–150 mm to 5–25 mm, and the maximum crushing ratio of fine crushing is about five The main equipment suitable for fine crushing operations includes a fine crushing jaw crusher, short head cone crusher, highpressure roller mill, etc Ore superfine crushingOre Crushing SpringerLink

(PDF) ThreeStage Spray Drying: New Process Involving Instant

2008年4月2日 The goal of this article is to define a new industrial operation called threestage spray drying that can increase the specific surface area of powder while reducing the amount of fine dustIn this study, the effects of three different choke feed level (1/1, 1/2, and 1/4) and four different effective reduction ratios (25, 5, 10, and 20) depend on the capacity of the crusher of the The flowchart of crushing process with onestage and threestage 2019年8月14日 Mill feed size distribution before and after secondary crushing stage The precrushing stage has reduced the proportion of 100mm to + 40mm intermediate size fraction from 30% to 20%Optimisation of secondary crushing stage before Single Stage 2018年11月1日 It is concluded that the proposed testing methodology is simple and highly repeatable and could be utilized as a predesign tool in the design stage of the crushing process for rock quarries(PDF) New testing methodology for the quantification

Design of a crushing system that improves the crushing efficiency

The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design 24 CrushersThere are three stages in crushing as stage 1, 2 and 3 In each stage the reduction in size ranges as referred to as R1,R2 and R3SIZE REDUCTION BY CRUSHING METHODS By ResearchGate2016年2月29日 Usually, when we arrive at the third stage in a crushing plant, we are dealing with reduction or finereduction crushers where the feed size, as established by the openside setting of the preceding stage, must be checked against the maximum oneway dimension of rock that the reduction crusher will nipSingle VS MultiStage Crushing 911Metallurgist2023年7月21日 Its basic forms include the threestage crushingscreening flowsheet of concentrator with open circuit and threestage crushingscreening flowsheet of concentrator with single closed circuit (Fig 2)Preliminary screening is generally provided in front of each crushing operation to improve the production capacity of the crusherCrushingScreening Flowsheet of Concentrator SpringerLink

.jpg)

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 Fine crushing is, of course, a relative term Obtaining a final crusher product of minus ¾” is commonplace today and can occasionally be obtained in an open circuit final crushing stage As the need for finer crushing increases, consideration must be given to the achievement of maximum crushing and screening efficiency2020年1月13日 by i nstalling a finel y screening stage after crushing or eve n modif y the current screening stage in crushing plant (eg, smaller aperture s ize at higher capacity range) it would be pos sible ENERGY EFFICIENCY IN COMMINUTION GETTING MORE FROM THE CRUSHING STAGE2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist2024年4月19日 The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is crushing the material by using larger crushers that can reduce the material into smaller sizes that will be used in the next stageTypes of Crushers Explained: Everything You Need to Know JXSC

.jpg)

Stages In Crushing Circuit Recycling Equipment Reviews

Quaternary crushing is the final stage in the crushing process, where ultrafine products are desired This stage involves reducing the material size to its smallest possible size What types of crushers are used in quaternary crushing? Crushers designed specifically for quaternary crushing, such as cone crushers with fine crushing chambers 2024年1月1日 Ore fine crushing is a process of crushing ore blocks with a feeding particle size of 50–150 mm to 5–25 mm, and the maximum crushing ratio of fine crushing is about five The main equipment suitable for fine crushing operations includes a fine crushing jaw crusher, short head cone crusher, highpressure roller mill, etc Ore superfine crushingOre Crushing SpringerLink2023年1月2日 Secondary Crushing The secondary rock crushing step is the most important of all rock crushing stages, as it directly affects the product quality and size range This stage consists of two rolls that typically operate at The Stages of Rock Crushing Mellott2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment Crushing and Grinding Process JXSC Machine

What Are the Differences Between The 7 Types of Crushers?

2024年7月15日 VSI crusher is generally used for the third or fourth stage crushing after the first and second crushers, which is the final link of aggregate production It is the best machine to produce manufactured sand even better than a roll crusher The final product of the VSI crusher is cubic in wonderful shape even can replace natural sandUltra Fine Grinding UFG mills overcome these limitations by the use of rotating stirrers inside a stationary mill shell Ultra fine grinding mills have been in use for many years in a large number of every day applications such as pharmaceuticals, dyes, clays, paint and pigments before being used in the mineral processing industryUltra Fine Grinding A Practical Alternative to Oxidative 2023年2月28日 Secondary Crushing Secondary crushing is the second stage of crushing that takes place after the primary crushing The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1Primary and Secondary Crushing: Understanding the Basics A 2016年7月12日 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the Crushing Screening Plant 911Metallurgist

.jpg)

Types of Basalt Crushing Machine and Price for Sale

2024年7月15日 Stage 1: Coarse crushing Large basalt stones are uniformly fed by a vibrating feeder through the silo, and then transported to the jaw crusher for coarse crushing After the coarsely crushed materials are screened by the vibrating screen, they are transported to the impact crusher or cone by a belt conveyor for medium and fine crushingThe first stage: coarse crushing Large pieces of limestone are uniformly fed by the vibrating feeder to the jaw crusher for coarse crushing After the coarse crushed materials are screened by the vibrating screen, they are transported to the impact crusher by a belt conveyor The second stage: medium and fineLimestone Crushing Solution Eastman Rock Crusher2010年7月1日 Two stage crushing is very common with some three stage crushing where a fine product is required Liner wear is still an issue as it relates directly to costs and bowl and mantle changeout times The Evolution of Crushing and Grinding: Changes in the Industry 2018年1月17日 For both basalt samples, rock crushing in a cone crusher system resulted in a higher content of noncubical and flaky grains (especially for classes above 16 mm) in the product after crushing The influence of stone crushing processes on aggregate

.jpg)

Investigation on effects of different crushing stages on morphology

2018年3月15日 The present study evaluates the effects of three different stages of crushing mechanism, namely two stage (2S), three stage (3S) and four stage (4S) on various morphology parameters (ie angularity, texture, flatness elongation, sphericity and form2D) of aggregatescrushing, or at high hardness of ores in the fourth stage of crushing, which enables the ore to be softened before ball milling The oreprocessing flowsheet at the Metcalf mill (United States) includes two stages of crushing: coarse crushing in a gyratory crusher and medium crushing in a cone crusher manufactured by Metso (Finland) in a closed Current Status of CopperOre Processing: A ReviewIts basic forms include the threestage crushingscreening flowsheet of concentrator with open circuit and threestage crushingscreening flowsheet of concentrator with single closed circuit (Fig 2)Preliminary screening is generally provided in front of each crushing operation to improve the production capacity of the crusherCrushingScreening Flowsheet of Concentrator SpringerLink2023年7月3日 In recent years, the development of nanotechnology enhanced the delivery of agrochemicals and agricultural productivity From raw lime, ultrafinecrushing processes were carried out to prepare the nano calcite particles This study aimed to investigate the effectsA Comparative Study on the Use of Fine and UltraFine Springer

.jpg)

SIZE REDUCTION BY GRINDING METHODS ResearchGate

2017年3月4日 For instance rock crushing or grinding to produce uniform aggregate size for construction purposes, or separation of rock, soil or aggregate material for the purposes of s tructural fill or land 2022年4月26日 Figure 1 presents an overview of a generic threestage crushing p lant The purp ose of the crushing plant is to reduce the rock material size from up to 1000 mm to below 30 mm depending on the (PDF) Optimization Capabilities for Crushing Plants ResearchGate2010年1月1日 132 Cryocrushing When the material is not hard enough, it is cooled by immersion in liquid nitrogen to make it hard and brittle It is then ground in the agate mortar, as in the general case, still in the presence of liquid nitrogenMechanical Preparation Techniques SpringerLink2015年7月25日 Open Circuit Crushing In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating variables These variables are anything that affect the performance of the equipment Lets begin with an over view of these two crushing stagesSecondary Tertiary Crushing Circuits 911Metallurgist

Selecting the right type of crushing equipment Quarry

2016年4月7日 In general, material reduction is handled in stages Although there are some single crusher systems, the most common systems involve at least two or three crushing stages Crushing stages Primary crushing – The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt In most aggregate crushing