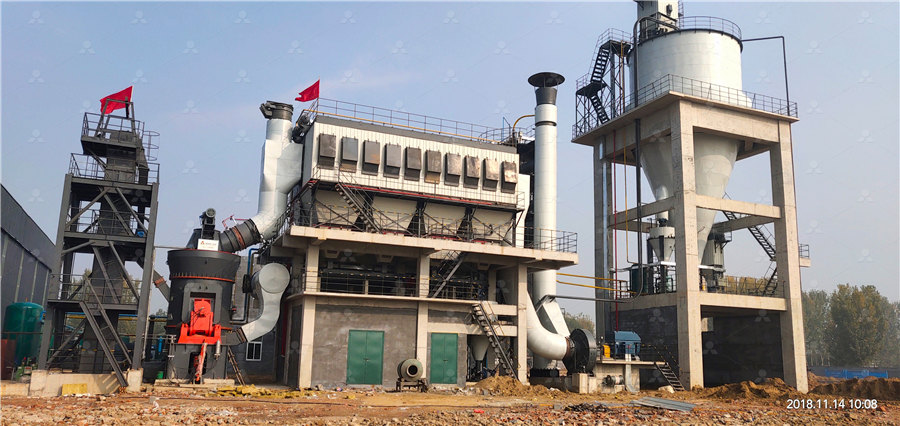

Highway ore powder plus calcium carbonate processing equipment parameters

ALPA Calcium Carbonate powder Processing Technology

Because different industrial applications have different requirements on the particle size, shape, whiteness and particle size distribution of ground calcium carbonate powder, the processing Hosokawa Alpine provides the perfect process technology for every demand and covers all areas of (fineness) ranges, capacity and logistical aspects in a customerspecific and costeffective CALCIUM CARBONATE (GCC) Hosokawa AlpineIn the production of ultrafine calcium carbonate additives, various aspects must be considered when selecting and deciding among available types of processing systems: Fineness range, Calcium Carbonate (GCC) Hosokawa AlpineThe common processing equipment of ground calcium carbonate produced by largescale dry process includes Raymond mill, Table Roller Mill, Ring roller mill and Ball mill Due to the CALCIUM CARBONATE POWDER

.jpg)

News Calcium powder processing machinery and equipment

Detailed explanation of calcium powder processing machinery and equipment: Ordinary heavy calcium carbonate with d97≥5μm is mainly produced by dry method The equipment includes The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production Calcium Carbonate Grinding Production Line TAYMACHINERY2015年12月1日 This study examined the surface properties, fluidity, flowability and floodability of untreated ground calcium carbonate (GCC) powder and treated GCC powder with stearic acid (PDF) Optimisation Of Process Parameters In High Energy Mixing 2021年6月22日 The calcium carbonate production line with an annual output of 300,000 tons uses a vertical grinding mill production line to crush, grind, and classify calcium carbonate 300,000 tons of calcium carbonate powder production line

How Calcium Carbonate is Produced?|Manufacturing|CORE

Calcium carbonate has three crystalline polymorphs: calcite, aragonite, and vaterite In the carbonation process, these crystals can be produced by changing various conditions such as 2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on Precipitated Calcium carbonate production, 2017年3月3日 PDF Beneficiation and Mineral Processing of Calcium Carbonate and Calcium Sulphate Find, read and cite all the research you need on ResearchGateBeneficiation and Mineral Processing of Calcium The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will How to Choose a Calcium Carbonate Grinding Mill

.jpg)

4 Steps to Build a Calcium Carbonate Processing Plant Zenith

In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh2012年11月26日 A precipitated calcium carbonate with Sauter mean diameter of 75 mu m was filtered under conditions of constant rate and constant pressure in a comparative laboratory investigationLaboratory Cake Filtration Testing Using Constant RateThe Calcium carbonate powder surface modifying, widely used in the fields of nonmetal stuffing or pigment like plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials and dope industries, is an outcome of the development of new and high technology nowadays It can not only improve the compatibility of both nonorganic mineral Calcium carbonate Powder Coating Machine2021年1月1日 Abstract The recycled high‐density polyethylene (rHDPE) feedstock containing calcium carbonate (CaCO3) mineral was obtained from post‐consumer single‐use grocery bags(PDF) Calcium carbonate enables sustainability in polymer fiber

.jpg)

(PDF) SYNTHESIS OF CALCIUM CARBONATE (CaCO3) FROM

2022年9月27日 The energy band gap of CaCO3 sample from chicken eggshell synthesis Figure 3 shows the absorption rate of CaCO 3 from the synthesis of chicken egg shells in the range of 2371 nm, 2515 nm, and 2022年4月26日 Effect of processing temperatures on decarbonisation of calcium carbonate in sodium hydroxide solutions at ambient conditions the Highsc orePlus software with the PDF − 4 2019 databaseEffect of processing temperatures on decarbonisation of calcium 2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Synthesis of precipitated calcium carbonate: a review2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the (PDF) Effects of Grinding Aids Used in Grinding

.jpg)

Guide to Calcium Carbonate Grinding: Mills, Tips, and

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the Calcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple cheap filler to highest quality functional additives GCC is used as dry powder or slurry in many industrial Calcium Carbonate (GCC) Hosokawa Alpine2 Polymorphism of calcium carbonate Calcium carbonate has six different polymorphs: one amorphous CaCO3, two hydrated crystalline ones (hexahydrate CaCO3 6H2O and monohydrate CaCO3 H2O), and three anhydrous crystalline polymorphs that are the hexagonal vaterite, the orthorhombic aragonite and the rhombohedra calcite [22–25]Effect of Operating Parameters and Foreign Ions on the Crystal Extemporaneous compounding formulation for Calcium Carbonate 80mg/mL in OraPlus™ and OraSweet™ [Paddock Perrigo] (Calcium Carbonate 400mg/5mL Suspension), including components, quantities, instructions, and referencesCompoundingToday Formulation: Calcium Carbonate 80mg/mL in Ora

Optimized Processing to Reduce Crystalline Silica in Ground Calcium

2020年4月7日 FIGURE 3 The most adapted mineral flotation technology for calcium carbonate is mechanical flotation Optimized Processing Through years of mineral processing knowhow, Imerys has been able to optimize the calcium carbonate processing at each step of the minetoplant process to enable the reduction of crystalline silica in the final productsOur heavy calcium grinding and grading technology, equipment and control technology all belong to the world's advanced level, especially suitable for the production of D97, 545 microns powder The ball mill can be customized and equipped with replaceable wearresistant linings to prolong the service life of the ball mill for saleCalcium Carbonate Ball Mill Plant DASWELL2018年2月23日 Request PDF Exploring the Influence of Reaction Parameters on the Preparation of Calcium Carbonate by Spontaneous Precipitation Different polymorph and morphology of CaCO3 powder are prepared Exploring the Influence of Reaction Parameters on the 2022年4月20日 The main component of limestone is calcium carbonate (CaCO 3) with a Mohs hardness of 3 After limestone is mined from limestone rock, it is crushed to form limestone particles, namely stone and sand Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other Limestone crushing and grinding production line SBM Ultrafine Powder

.jpg)

Calcium carbonate powder processing machine

400mesh Ultrafine Mineral Ore Powder Grinder Mill Processing Plant Limestone Gypsum Calcium Carbonate Ygm130 Grinding Mill Line $ 26,000 00 $ 30,000 00 Min Order: 1 setCalcium Carbonate Suppliers We are a highquality calcium carbonate manufacturer from Hechi, Guangxi, China, with more than 20 years of powder production experience and we are a collection of ore mining, technology research and development, calcium carbonate processing and sales, international trade in one of the enterprises, with 2 own highquality mines and calcium carbonate powder,Caco3,calcite powder,calcium carbonate 2020年11月4日 Due to the insufficiency of freshwater resources and to supply the drinking water populations, many desalination processes such as reverse osmosis, electrodialysis and distillation are widely used However, these Effect of Operating Parameters and Foreign Ions on 2021年2月25日 By replacing 10% polypropylene with calcium carbonate, the equivalent CO 2 emissions can be reduced by 85% Main benefits are the improved sustainability, opacity, haptic properties, and cost savings NOTE: Calcium carbonate enables sustainability in

The wet conversion of phosphogypsum by ammonium carbonate:

2023年3月1日 The PG conversion by ammonium carbonate ((NH 4) 2 CO 3) into calcium carbonate (CaCO 3 ) and ammonium sulfate ((NH 4 ) 2 SO 4 ) is classifying in the top of the PG conversion and it’s2015年1月1日 As fillers, mica, kaolin, calcium carbonate and talc are the most often used to reduce both the production cost and to improve the properties of the thermoplastics, such as rigidity, strength Mechanical, morphological and thermal properties of hdpe 2003年12月1日 Nanometer calcium carbonate reactants would deposit, nucleate and grow on surface of ground calcium carbonate with micron grain size by adjusting suitable technical parameters in Ca(OH)2–H2O Effect of processing parameters on the reparation of composite With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the worldCustomize Suitable Calcium Carbonate Plant DASWELL

The effect of nanosized calcium carbonate on thermodynamic parameters

2009年2月1日 Request PDF The effect of nanosized calcium carbonate on thermodynamic parameters of HDPE One of the main limitations in application of polymers, particularly thermoplastic polymers such as Calcium carbonate, or CaCO3, comprises more than 4% of the earth’s crust and is found throughout the world Its most common natural forms are chalk, limestone, and marble Calcium carbonate appears as white, odourless powder or colourless crystals Calcium carbonate (CaCO3) is the most widely used filler in polymer formulations As a filler, calcium carbonate []Calcium Carbonate SNG Microns Pvt Ltd2017年7月1日 In calcium looping (CaL), calcium oxide (CaO) is used as a sorbent for carbon dioxide (CO2) The CO2 reacts with CaO to produce calcium carbonate (CaCO3) in a carbonatorAspen Plus ® Process Simulation of Calcium Looping with 2015年1月1日 In this paper we present a mathematical model for the reaction between calcium carbonate (CaCO3) and a solution containing sulfuric acid (H2SO4)(PDF) A model for calcium carbonate neutralization

.jpg)

(PDF) Processing and Characterization of Surface

2021年3月1日 Processing and Characterization of Surface Treated Chicken Eggshell and Calcium Carbonate Particles Filled HighDensity Polyethylene Composites March 2021 Materials Research 24(3)2023年11月8日 Highend calcium oxide ultrafine powder milling equipmentHGM series 125 model production line, Processing materials: calcium oxide: Finished product particle size: 200600 mesh: The loader transports the Highend calcium oxide ultrafine powder making 2021年5月17日 In this study, the influence of acid solutions on the production of precipitated calcium carbonate (PCC) using seashells was investigated In terms of the Ca dissolution efficiency and atmosphere Elemental Impurities in Pediatric Calcium Carbonate Preparations 2017年11月1日 Tests were also performed at calcium chloride (CaCl2) concentrations of 01 and 03 M, resulting in specimens with average calcium carbonate (CaCO3) content ranging from 15 to 25% for the 50/70 (PDF) Methods for Calcium Carbonate Content Measurement

.jpg)

Polypropylene/calcium carbonate nanocomposites—Effects of processing

2010年9月4日 The mechanical properties and crystalline characteristics of polypropylene (PP) and nano precipitated calcium carbonate (NPCC) nanocomposites prepared via melt mixing in an internal mixer and melt PDF On Jul 24, 2017, Baljit Singh and others published Fundamentals of Extrusion processing Find, read and cite all the research you need on ResearchGate(PDF) Fundamentals of Extrusion processing ResearchGate2024年1月1日 Semantic Scholar extracted view of "Calcium carbonate and reactive silica recovery from waste cement: The influence of processing parameters on upcycled material properties and carbon intensity" by Jonah M Williams et alCalcium carbonate and reactive silica recovery from waste 2022年11月10日 In general, the processing equipment of calcium carbonate includes crushers, pulverizers, bucket elevators, conveyors, feeders, dust removal equipment, etc The main equipment is the pulverizer 1What are the calcium carbonate processing equipment? LinkedIn

.jpg)

Calcium carbonate and reactive silica recovery from waste

2024年2月15日 The morphology of calcium carbonates obtained depends on various parameters such as time, temperature, flow rate and partial pressure of CO 2, and pH [23] , [48] , [49] Conventionally, highly reactive amorphous silica (“silica fume”) can be incorporated into cement and concrete to greatly improve its strength and reactivity; [57] however, fumed silica