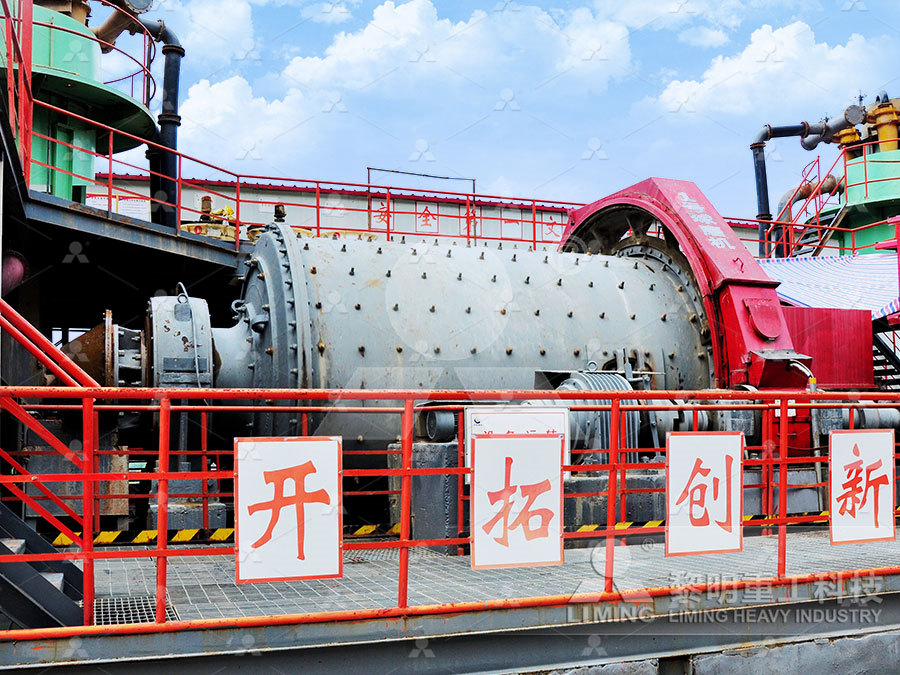

Direct impact ore mill

STEPPING FORWARD: USING VARIABLE SPEED DRIVES FOR

Indedrive VSDs are available for the whole low and medium voltage range and from hundreds of kW up to tens of MW milling applications These Variable Speed Drives (VSDs) can facilitate 2021年10月1日 It can be attributed to the faster disappearance rate of coarse particles when they are subjected to impact mechanism (ball milling) Since the action of the fine particles are Effects of impact and attrition mechanisms on size distribution and 2018年10月1日 Simulations using JKSimMet provided some insight on the impact of ore breakage variability on SAG mill performance The standard JK drop weight test breaks single Quantifying variability of ore breakage by impact ScienceDirect2021年7月1日 Among the collisions happened in the mill, collisions on ore directly affect the breakage and abrasion of ore, including the oreore, oremedia, and oreliner collision The DEM investigation of SAG mill with spherical grinding media and

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 Grinding media play a vital role in enhancing the efficiency of a ball mill through their direct effect on the breakage rate, mill load behaviour, power draw, and general energy 2019年6月12日 Results indicated that at 65% of the critical speed, the dominant charge motion in the mill with the steel liner was cascading At higher speeds, cataracting action became Investigations on the Charge Motion and Breakage Effect of2017年7月31日 Based on recent research for improving milling efficiency by selecting an appropriate combination of lifter design, mill speed and filling, little is known about a direct Impact Load Behavior between Different Charge and Lifter in a 2023年8月3日 In this study, grinding contribution and quantitative separation of impact and grinding mechanism in cylindrical mill were creatively researched, and the grinding technical Grinding Contribution and Quantitative Separation of Impact and

Direct Mechanocatalysis: Using Milling Balls as Catalysts

2020年4月21日 Direct mechanocatalysis describes catalytic reactions under the involvement of mechanical energy with the distinct feature of milling equipment itself being the catalyst This novel type of catalysis features no solubility 2021年10月21日 This study presents a novel derived theoretical model for MAassisted leaching in investigating the effects of ball mill parameters on the particle sizes (retained and recovered)Effect of Ball Mill Parameters’ Variation on the Particles of a 2018年1月19日 The Ban Houayxai Mine (BHX) is a relatively low grade, low cost, open pit goldsilver deposit in Laos operated by Phu Bia Mining, a subsidiary of PanAust Ore production rate is 45Mt pa with direct tipping to a SAB mill with a carbon in leach process plantPredicting Mill Ore Feed Variability Using Integrated Geotechnical 2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to Friction and wear of liner and grinding ball in iron ore ball mill

.jpg)

Consumption of steel grinding media in mills – A review

2013年8月1日 Apart from these cost factors, one of the major unsolved problems in the optimal design of ball mills concerns the equilibrium media size distribution in the mill, which is determined by the rate at which makeup media is added to the mill, as well as the rate at which these grinding media are consumed (Austin and Klimpel, 1985)Reliable prediction of grinding media 2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills MiningpediaGoldquest 1400 Impact Mill Using a 3/4 inch keyed shaft with a direct drive coupler, you don't have to worry about belts coming loose or double screen, or no screen, depending on how fine or coarse you need to process your ores Screen “floats” between grizzly bars giving faster output of crushed materials No tools needed to Goldquest 1400 Impact Mill Gold Prospecting Mining January 2007, two complete grinding circuit surveys were performed followed by a SAG mill crash stop and grindout After stopping the mill, a SAG mill feed sample was also collected from Conveyor parison of SAG mill feed size throughputs

Converting AG to SAG mills: The GolEGohar Iron Ore Company case

2012年2月1日 Considering the charge shape and impact points it is evident that mill fillings should be more than 20% to prevent direct impact of balls to liners Given the promising results obtained in the laboratory mill, the new liners with 30° lifter face angle and unchanged lifter height (ie, 225 cm) was constructed and installed in one of the three parallel dry AG mills2006年12月1日 Worldwide, the mining of uranium has generated 938 × 106 m3 of mill tailings The radioactivity of these tailings depends on the grade of ore mined and varies from less than 1 Bq/g to more than (PDF) Uranium Mill Tailings: Geochemistry, Mineralogy, and 2022年9月1日 Waste rocks occupy space from ore in the grinding mill, thus lowering the mill’s ore grinding capacity and mineral concentrator’s concentrate production Moreover, in most cases, waste rock is harder and, consequently, more difficult to grind than the ore which is often found in the weaker areas of the rockTowards waterless operations from mine to mill ScienceDirect2022年1月1日 The operation process of comminution has been studied in the past based on data gathered from various ores and semiempirical models [2]The pioneer of the study was Bond and the equation proposed by him is known as the Bond's grinding equation [3, 4]As the Bond equation did not consider breakage kinetics, all the effects in grinding were lumped into Impact energy of particles in ball mills based on DEM simulations

Simulating the Impact of Ore Competence Variability

2019年9月24日 There are numerous examples in the literature, some of which are quantifying the effect of Mine to Mill Grundstrom et al, 2001;Hart et al, 2001;Scott et al, 2002;Burger et al, 2006;Jankovic et al PanAust Ore production rate is 45Mt pa with direct tipping to a SAB mill with a carbon in leach process plant Approximately 100,000 oz of gold is produced per annum The operation is located in mountainous terrain with minimal ROM stockpiling are which results is limited capacity for blending from stockpile with thePredicting Mill Ore Feed Variability Using Integrated Geotechnical Find out all of the information about the POITTEMILL / FORPLEX product: impact mill FNG for ceramics, for ore Other characteristics laboratory, dry milling, compact, cryogenic, benchtop, ultrafine, variable speed, highperformance, FNG Impact mill by POITTEMILL / FORPLEX2013年2月1日 The experimental data for iron ore comminution in the impact hammer mill are plotted in Fig 7 The data show that such a relationship indeed holds good in this case as the correlation coefficients (R 2) are observed to be greater than 095 in all minution features in an impact hammer mill ScienceDirect

.jpg)

Understanding the impact of geotechnical ore properties and blast

2021年8月15日 Therefore, blast design and geotechnical ore properties have a significant impact on downstream processes such as crushing and grinding This work aims to understand this impact at an open pit case study by applying the simulations of the Mine to Mill methodology2024年4月26日 These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into smaller particles The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption bIron Ore Processing: From Extraction to Manufacturing2024年3月28日 What is a Vertical Shaft Impact Mill construction and recycling for crushing materials like ores, rocks and concrete aggregates Performance: Both types have their advantages; VSI mills are often more efficient in certain Vertical Shaft Impact Mill vs Horizontal Shaft Impact Mill JM The Ban Houayxai Mine (BHX) is a relatively low grade, low cost, open pit goldsilver deposit in Laos operated by Phu Bia Mining, a subsidiary of PanAust Ore production rate is 45Mt pa with direct tipping to a SAB mill with a carbon in leach process plant Approximately 100,000 oz of gold is produced per annum The operation is located in mountainous terrain with minimal ROM Predicting mill ore feed variability using integrated geotechnical

]@S0{UDKK%G24F3JGHC.jpg)

Predicting mill feed grind characteristics through acoustic

2021年9月1日 Results per the study present an indication that mill noise has the potential to inform the nature of ore material in the mill and slurry solids loading, Quantifying variability of ore breakage by impact – Implications for SAG mill performance Miner Eng, 127 (2018), pp 8189 View PDF View article View in Scopus Google Scholar2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to Friction and wear of liner and grinding ball in iron ore ball mill 2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill of tantalum ore through thermography images taken after breakage by direct impact 2 To develop a numerical model to predict the heat losses to the environment during the grinding of a ball mill with different conditions of operations: percentage of load, and mill speed The model is based on the method of control volumes and balance of energy 3Heat generation model in the ballmilling process of a tantalum ore

.jpg)

Impact Load Behavior between Different Charge

2017年7月31日 Besides, the impact force on the lifter was affected by mill speed, grinding media filling, lifter height and iron ore particle The maximum percent of the impact force between 600 and 1400 N is 2023年1月1日 The NG/DREAF process serves as a transitional technology in the transformation process of integrated steel mills toward low carbon steelmaking In the long term, NG/DR can be substituted by hydrogenbased direct reduction (H/DR) of iron ore If hydrogen is used, direct GHG emissions can be reduced by up to 97% [6]Lowcarbon primary steelmaking using direct reduction and The Stutenroth Impact Mill has garnered a loyal following of satisfied customers who have achieved remarkable results in their hard rock gold mining operations One customer, John from Nevada, shared his exhilarating experience of using the Stutenroth Impact Mill to Stutenroth Impact Mill – GameChanging Gold Mining Machinery2019年6月12日 More recently, a metal magnetic liner was installed in a ball mill at Cleveland Cliff’s Northshore Mining iron ore concentrator in Minnesota, USA [13, 26] and direct impacts with the mill shell were observed at a higher frequency compared to the steellined millInvestigations on the Charge Motion and Breakage Effect of

.jpg)

Understanding the impact of geotechnical ore properties and

2021年8月15日 Therefore, blast design and geotechnical ore properties have a significant impact on downstream processes such as crushing and grinding This work aims to understand this impact at an open pit case study by applying the simulations of the Mine to Mill methodology2021年6月30日 In the field of extraction metallurgy, the direct reductiongrinding separation process is an effective technology, especially for the treatment of vanadium titanium magnetite and lowgrade iron ores [1], [2], [3]Direct reduction is a process in which gaseous (H 2, CO) or solid reducing agents (coal, biomass) are used to reduce the metal oxides in the ore to Novel insights into the reoxidation of direct reduced iron (DRI) 2022年2月17日 minerals1200258An Evaluation on the Impact of Ore Fragmented by Blasting on Mining Performancepdf minerals1200258pdf Content uploaded by Ahmad HassanzadehAn Evaluation on the Impact of Ore Fragmented by2021年7月1日 As the SAG mill enters a stable operation state, the grinding system's charging behavior in the PHSP and SP grinding systems is different As shown in Fig 9, the shoulder and the head in the SAG mill containing polyhedral ore particles are slightly higher than that of the SAG mill containing only spherical particlesDEM investigation of SAG mill with spherical grinding media and

DEM investigation of SAG mill with spherical grinding media

2021年7月1日 In the study of Cleary [3], particles were modeled by the superellipsoids in 2D, and the influence of ball and rock shape on the charging behavior and power draw was initially exploredKiangi et al [26] combined experiments and simulation to conduct similar research in a 3D millFurthermore, Xu et al [35] used a 3D superellipsoid model in a SAG mill to 2023年3月23日 Hydrogenbased direct reduced iron (H2DRI) is an alternative pathway for lowcarbon steel production Yet, the lack of established process and business models defining “green steel” make it Green steel: design and cost analysis of hydrogen 2023年11月1日 Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is also an important factor to determine the Energy conservation and consumption reduction in grinding 2015年4月15日 Impact Crushing – Bond Work Index; Rod Mill Grindability – Bond Work Index; Ball Mill Grindability – Bond Work Index; This allows a direct comparison of pilot plant test results and grindability test results ore lumps are available an impact crushing Work Index test If 30 mm x 20 mm What Ore Testing is Required For Mill Selection

Development of ore sorting and its impact on mineral processing

2014年10月15日 The energy costs required to refine metal values contained in ore to concentrates constitute the majority of the cost to produce metals On average across the mining industry, 44% of the total electricity consumption is dedicated to crushing and milling activities (Fig 1)Size reduction operations, nearly 150 × 10 9 kW h, are the largest single consumer of 2022年5月23日 Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to (PDF) Modeling and application of stirred mill for the coarse 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Processing 2011年2月1日 The mill rotates around its axis at 41 rpm which is 64% of the critical speed needed to centrifuge the media inside The lifters lock into the charge, lift it up and drop it This generates direct impacts and shear between balls which all contribute to grinding of the feed material that fills the space between the ballsUnderstanding fine ore breakage in a laboratory scale ball mill using

Ultrafine mill, Ultrafine grinding mill All industrial manufacturers

glass for ore for clinker vibratory disc mill RS 200 20 µm The Autofill system avoids direct contact with Compare this product Remove from comparison • Fluidized Bed Jet Mill CGS 10 • HighDensity Bed Jet Mill ConJet®® 10 • Classifier Mill CSM 50 • Fine Impact Mill Compare this product Remove from comparison tool2024年4月1日 The impact of stirrer design in wet stirred milling was investigated by Stehr [34] and Kwade Optimization of wet grinding parameters of calcite ore in stirred ball mill Çukurova Üniversitesi MühendislikMimarlık Fakültesi Dergisi, 33 The impact of different stirrer designs and mill orientations on the