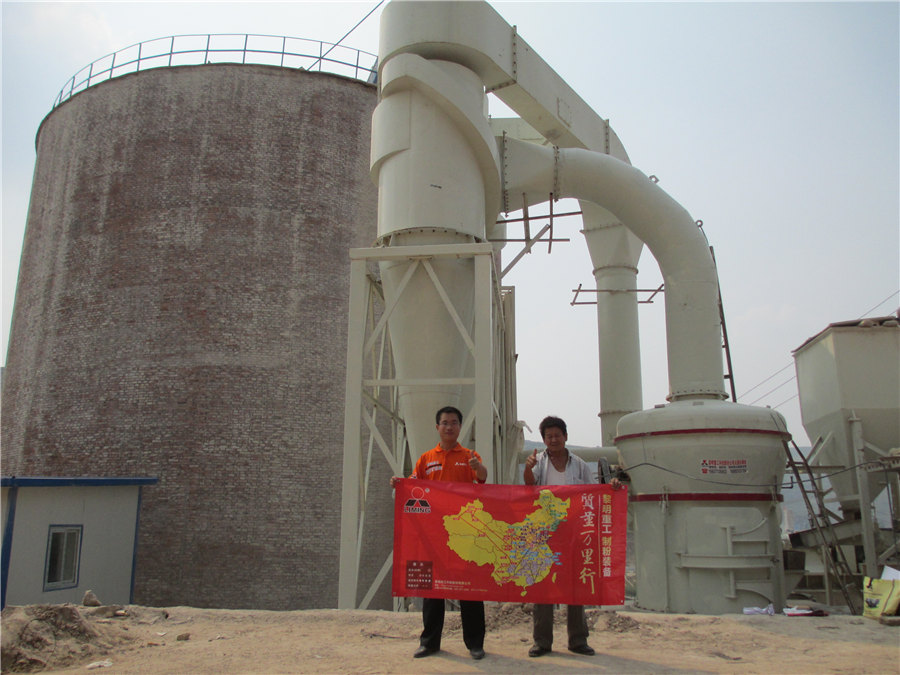

Grinding industrial mill

Grinding mills for mining and minerals processing

Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills technology offer exceptional performance and Our industrial food milling machines and grinding equipment can reduce the size of dry products to uniform sizes up to 10,000 Kg/Hr, resulting in high yields and low fines The IMD 1060 industrial roller mill and GP140 discstyle Industrial Food Milling Machines Grinding MillThe industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Grinding mill Palamatic ProcessHammer Mill Grinding With over 160 years of industry experience and continued cutting edge research and development, Bühler is proud to present the next generation grinding portfolio, with all new and updated equipment to provide Horizontal Hammer Mill Grinding System Bühler

Grinding Mills Common Types 911Metallurgist

2016年11月7日 Buy an Industrial Grinding Mill The quantity of powder to be subjected to such processes of size reduction varies widely according to the industries involved, for example in the pharmaceutical industries the quantities involved per annum, Roller mills are essential equipment used extensively in the industrial processing sector, particularly for drying, grinding, and classifying a variety of materials Roller mills use the centrifugal force of cylindrical grinding rolls to crush material into a uniform particle size and grind, dry, and classifyIndustrial Roller Mills Williams Crusher2015年4月9日 Grinding Mills and Their Types satyendra; April 9, 2015; 12 Comments ; autogenous grinding, ball mill, grinding mills, hammer mill, rod mill, roller mill, SAG,; Grinding Mills and Their Types In various fields of the process industry, reduction of size of different materials is a basic unit operationGrinding Mills and Their Types – IspatGuruBall mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement, mining, pharmaceuticals, chemicals, Ball Mill Grinding Machines: Working Principle, Types, Parts

.jpg)

Europemill Industrial Stone Grinding Mill Engsko

Both the Standard and the Industrial grinding mills simply do the job through the optimum milling process using the proven and wellknown Engsko millstones The adjustment of stones has an adjustment gear for fine tuningEngsko Europemill is especially designed for installation in milling industries for continuous production of wholemeal flour or to use in Engsko Grinding Mill Industrial Mill Grinding Media Grinding media plays a crucial role in refining and reducing particle sizes to achieve a range of shapes and sizes for different applications It comes in various forms, including both metallic and nonmetallic types, each suited for processing different materialsMills: What are they? How are Mills used? Advantages IQS Video credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide: Types, Features A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are Mill (grinding) Wikipedia

Grinding Mills for reliable size reduction tasks RETSCH

A grinding mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processes ensuring efficient and rapid size reduction for laboratory and industrial applications Cutting MillsGrinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low consumption, easy use +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Home; About Us;Grinding MillIndustrial Grinding Mill, Ultrafine Grinding Mill Wheat is one of the most important grains, with an annual harvest of around 740 million tons worldwide To produce highquality flour without wasting grain, it’ is key to understand the milling process – not just the milling machinesWheat Milling Grain Processing Bühler GroupIf your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders, air classifying mills, hammer mills, and lump breakers to meet all of your industrial processing needs We have been designing, manufacturing and creating innovative solutions for large and small customers all over the worldParticle Size Reduction Solutions Prater Industries

Particle Size Reduction Equipment Schutte Hammermill

Schutte Hammermill stands at the forefront of industrial grinding technology, offering unrivaled expertise and an innovative approach for businesses seeking efficient and reliable solutions for size reduction and material processingExplore Franklin Miller's industrial mills for precise, efficient grinding across various materials Optimize your processes with our versatile mills About Us Industries and SUPREME ROLL MILL Each mill is engineered for specific usecases, HighPerformance Industrial Mills Franklin MillerOptimally equipped to efficiently mill grind high throughput of the same commodity, MRRK is stable and reliable, easy to operate and fast and simple to install Roller mill Diorit The grinding gap on our roller mills can be adjusted manually or, on some models, automaticallyRoller Mills Milling Bühler GroupOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial Grinding Mill,

.jpg)

Grinding Mills — Types, Working Principle Applications

2018年8月17日 Further, the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills So, which one is for you? Well, the answer essentially lies in the feed size and the Wet industrial grinding mill machine has high grinding efficiency, wide range of application, can keep continuous production, and no environmental pollution caused by dust Case of Grinding Mill Export Country:Senegal Company Industrial Ball Grinding Mill Machine The area is steeped in a rich history in the supply of mining and heavy industrial machinery The original EIMCO products have been operating in many parts of the world since 1932 NMC has updated designs and added the most state of the art features, automation and techniques to its most recent ball mill designsBall Mill Manufacturer Neumann Machinery Company2013年1月16日 An industrial wheat mill has several technological phases, starting with coarse grinding of seeds to fine grinding of the resulted milling products, after their sorting in fractions of dif Grinding Characteristics of Wheat in Industrial Mills

]@S0{UDKK%G24F3JGHC.jpg)

How to choose the right industrial mill? Palamatic Process

The handling of a raw material in a grinding process will be closely linked to the nature of its particles The choice of an industrial mill depends mainly on three factors that must be taken into account: The nature of the raw material: is it abrasive, oily, hard, brittle, elastic, heatsensitive, hygroscopic? The particle size distribution (average size and variance) of the final product Final grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of grinding in laboratory Powder mill, Powder grinding mill All industrial manufacturersManufacturer of Industrial Blenders, Grinding Machine Pulverizers Machine offered by Yagnm Industries Private Limited from Navi Mumbai, Maharashtra, India Pin Mill Grinding Machine ₹ 55 Lakh /Unit Material: Stainless Steel; Product Type: Powder Grinding Machine; Automation Grade: Automatic; Get QuoteYagnm Industries Private Limited, Navi Mumbai Manufacturer of All in all an industrial mill used for grinding whole grain into grits or healthy and good whole meal flour or for grinding of flour grits into high class flour as the last break after a roller mill Contact us Technical data Motor power: 18,5 KW 400 V Electric, 50 Hz, European Standard, IE3;Grindmaster 950 Perfect for professional Grinding Engsko

Ball Mill Grinding PDF Mill (Grinding) Industrial Processes

BallMillGrinding Free download as PDF File (pdf), Text File (txt) or view presentation slides online 1) Ball mills use balls to grind and break down ore and material using both impact and attrition 2) The grinding process in a ball mill involves cascading of balls to cause crushing and cataracting action to cause impact 3) Key factors that influence grinding are the energy The multiaward winning Millomat industrial mill is the perfect mill in your sector High grinding efficiency and an unrivalled hygiene concept Go to contact form Grinding output 80 kg grinding output per hour – This provides you, as a small or mediumsized enterprise, with the perfect entry to Industrial and whole grain mill Treffler Millomat2017年6月2日 Grinding equipment can be classified into to two basic types, crushers and grinders Industrial crushers are the first level of size reducer; further granularization occurs in grinding mills or pulverizers grinding mill or pulverizer is dependent on the material to be processed and the requirements of the end productHow it Works: Crushers, Grinding Mills and PulverizersMill Powder Tech specializes in powder mixing technology, offering solutions from standalone machines to complete systems including conveying, screening, mixing, grinding and packagingMill Powder Tech|Leader in Grinding Machine

.jpg)

Top 5 productspecific milling technologies used in

2017年7月7日 Jet mill configuration All jet mill designs incorporate a radial nozzle arrangement with the number of nozzles used varying with mill size In general, the larger the mill, the higher the quantity of nozzles utilized to Industrial Grinder Mill ZGM industrial milling equipment, energysaving, highyield, precision, environmental protection, adding orange vitality to the development of industry YGMQ European Grinding Mill 0550T/H HGM Series Micro Powder Mill 0525T/H Ball Mill 03765T/H QUICK ENTRY HOME; NEWS; SERVICE; CONTACT; PRODUCT STONE Stone crusher, mobile crusher, grinding mill, ZGM Industrial2021年7月7日 It is an industrial grinding mill with extremely highcost performance for enterprises such as ore grinding powder The YGM Raymond mill produced by SBM is also an efficient automatic milling device The grinding fineness is not as high as that of an ultrafine mill, generally around 600 meshes, but it can grind higher hardness ore materials, and the price is What are the types of industrial grinding mills?Variety of power and capacity: Pulva's line of pulverizers range from laboratory and pilot plant applications to industrial use, with models suited for operation with main drive motors ranging from 1300 horsepower, and mill capacities up to 6,000 poundsperhourReliable Pulverizers for Various Industries Pulva

.jpg)

Barite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder

2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a professional manufacturer of milling equipment for the ore industryGrinding Machines We offer grinding mills, industrial grinding machines, paint grinding machines, wet grinding mills, dry grinding mills, chemical grinding machines, grinding equipment at Manu Enterprises, Chennai Mill Machine for Paint Ink Industry; Mild Steel Bead Mills; Hydraulic Lifting Basket Mill; Basket Mill With Cover + View all;Grinding Machines Grinding Mills and Industrial Grinding We cover the whole process chain of wet grinding and dispersing Depending on your product and needs, we can design, plan and build your specific solution Whether it is a single bead mill, an embedded system or a fullyautomated plant, we can provide the consistent, high quality you need, anywhere in the worldWet Grinding and Dispersing Equipment Bühler GroupOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial Grinding Mill,

Ball Mill thyssenkrupp Polysius

The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding Used in combination with the sepol® highefficiency separator, ball mills can reliably