Ceramic waste processing

Sustainable ceramics derived from solid wastes: a review

2020年9月8日 The present review is aimed to provide an uptodate overview of the recent wastederived ceramics including refractories, glasses, whitewares, 2022年6月1日 Sanitaryware ceramic wastes arrive from faulty products rejected during quality control Main faults include glaze damage, nicks, and cracks Ceramic solid waste is Use of waste ceramics to produce sustainable concrete: A review2021年8月10日 In this paper, a review is conducted into the methods used to prepare solid wastebased glass ceramic foams Depending on the exact processing route, these methods A review of glass ceramic foams prepared from solid wastes: 2024年4月1日 The rapid growth of the global construction industry has resulted in the generation of large amounts of ceramic solid waste, such as ceramic tile waste (CTW) The efficient Recycling of ceramic tile waste into construction materials

Reduce, reuse, recycle: How the ceramics industry is

2024年11月22日 These articles describe efforts to minimize the amounts of virgin raw materials and natural gas in the manufacturing process Researchers are exploring the use of recycled and waste materials as input streams, along 2024年11月19日 Developments of glassceramics from waste using different processing methods are described comprehensively in this review, covering RD work carried out From waste to resource: energyefficient production of glass 2022年1月11日 This review presented various findings and discussions on possible potentials of ceramic tiles waste and marble waste as concrete ingredients to supplement the strength Recycling of ceramic tiles waste and marble waste in sustainable These proceedings capture advances in the state of knowledge in nuclear and waste materials science and technology In addition, the proceedings addresses the environmental issues Environmental Issues and Waste Management Technologies in the

Industrial Ceramics: From Waste to New Resources for

2023年6月15日 Reusing ceramic industrial waste as precursors for building blocks/binders, exploiting their aluminosilicate composition for an alkaline activation process, could solve the problem This chemical process facilitates 2021年2月25日 In this work, we propose a “designer waste form” prepared via spark plasma sintering to limit interaction between phases and grain growth during consolidation, leading to Preparation and characterization of multiphase ceramic designer 2022年2月2日 The Use of Ceramic Waste in the Construction Materials Industry Based on the Concept of Sustainable Development Conference paper; First Online: Globally, the generation of construction and demolition waste as well as waste from the processing of various construction materials is a major problem in environmental pollutionThe Use of Ceramic Waste in the Construction Materials2022年1月11日 Both strong solid wastes, ie, ceramic tiles waste and marble waste, should serve the purpose of recycling because of compact unit structures (Daniyal Ahmad 2015; Ulubeyli and Artir 2015)Such practices not only guarantee the reduction in resources required for efficient waste management but also reduce the demand and production of cement, which is Recycling of ceramic tiles waste and marble waste in sustainable

Designing Advanced Ceramic Waste Forms for Electrochemical Processing

2016年3月1日 This report describes the scientific basis underlying the approach being followed to design and develop “advanced” glassbonded sodalite ceramic waste form (ACWF) materials that can (1) accommodate higher salt waste loadings than the waste form developed in the 1990s for EBRII waste salt and (2) provide greater flexibility for immobilizing extreme waste salt 2024年3月12日 Abstract The applicability of bentonite claybased ceramics for immobilization of waste from pyrochemical reprocessing of spent nuclear fuel–spent electrolyte, which consists of alkali metal chlorides, was studied Main matrix characteristics such as the phase composition, mechanical durability, leaching rate and microstructure were studied The results obtained Assessment of Applicability of Bentonite ClayBased Ceramics for 2024年4月10日 Over two centuries, concrete has been crucial to building Thus, ecofriendly concrete is being developed Emulating these tangible traits has recently gained popularity Ceramic waste concrete’s mechanical properties were modeled in this study Ceramic waste percentages ranged from 5 to 20% Compressive and tensile concrete strengths were Prediction and modeling of mechanical properties of concrete Journal of Ceramic Processing Research Vol 24, No 2, pp 266~273 (2023) (Received 12 August 2022, Received in revised form 10 October 2022, Accepted 19 November 2022)Performance enhancement of concrete by using ceramic waste as

.jpg)

Recycling of industrial wastes in ceramic manufacturing: State

2016年9月1日 The recycling of waste in ceramic manufacturing is theoretically beneficial because it is possible to absorb great amount of waste, also hazardous, that would otherwise be disposed off in landfill Even if the waste incorporation is done in small amounts, high production rates will translate into significant consumption of wastesDesigning Advanced Ceramic Waste Forms for Electrochemical Processing Salt Wastes March 18, 2016 ix ACRONYMS AND ABBREVIATIONS ACWF Advanced Ceramic Waste Form AFCI Advanced Fuel Cycle Initiative ANL Argonne National Laboratory ASTM ASTMInternational CWF Ceramic Waste Form DIW Demineralized Water DOE US Department of EnergyDesigning Advanced for Electrochemical Processing Salt Waste2024年5月20日 Waste ceramic is produced from different sources and, if not reused, is often disposed of in landfills, contributing to the pressure on landfill capacity and potentially releasing toxins into the surrounding environment as ceramics break down over time The waste can easily be crushed to the required sizes, which has interested many researchers It has been used as The Use of Waste Ceramic in Concrete: A Review MDPI2014年11月1日 Melt processing of waste forms is considered advantageous over the conventional solidstate synthesis methods given that melters are currently in use for HLW vitrification in several countries, greatly facilitating the technology readiness of ceramic waste forms, and melter technology can reduce the potential for airborne contamination during Melt processed multiphase ceramic waste forms for nuclear waste

.jpg)

Recycling waste, reusing water, reducing consumption

2023年7月4日 Ratio between waste returned to the production cycle and waste generated Every drop counts The Italian ceramic industry does not waste a single drop of water Ceramic tile production plants purify and reuse 99% of 2024年7月1日 Changing from traditional materials like clay, sand, aggregates, and Portland cement to more sustainable options is a challenge for the construction material sector This study aims to find out the viability of using Reducing Environmental Footprint: Investigation of 2024年4月1日 Ceramic tiles are exquisite and have smooth surfaces and high brightness, making people sensuous in their daily lives (Li et al, 2019a, b)Therefore, ceramic tiles are undoubtedly among the most popular ceramic products used by the public in building decoration products (Li et al, 2023a, b)However, this inevitably leads to the generation of a large amount Recycling of ceramic tile waste into construction materials2021年5月1日 Waste recycling in ceramic tiles can be traced back to the pioneering study of Kats and Kvyatkovskaya (1972) and a few others issued in the 1980s and early 1990s (Higgins et al, 1979; Brown and Mackenzie, 1982; Abdrakhimov et al, 1990; Dondi et al, 1990, 1992)In the same period, the ceramic industry began to recycle its own processing residues and a Waste recycling in ceramic tiles: a technological outlook

.jpg)

Study on engineering strength properties of ceramic waste

Journal of Ceramic Processing Research Vol 23, No 6, pp 902~911 (2022) (Received 29 June 2022, Received in revised form 27 September 2022, Accepted 26 October 2022)2021年8月10日 The safe utilization of solid wastes containing heavy metals plays a crucial role in environmental preservation As an efficient technology to achieve this goal, the preparation of glass ceramic foams from solid wastes can produce an excellent solidification effect on heavy metals At present, there have been plenty of efforts made to achieve an excellent combination A review of glass ceramic foams prepared from solid wastes: Processing 2024年10月9日 Step 1: Assess the Condition of the Ceramic Item Before deciding to recycle a ceramic item, consider its condition: Functional ceramics: If the item is still in good condition (like a mug, vase, or tile), consider reusing or donating it instead of recycling; Broken ceramics: If the item is cracked or shattered, you’ll need to find a more specific recycling solutionHow to Recycle Ceramic: The Complete Guide for Sustainable Living2024年8月16日 In general, challenges with ceramic nuclear waste form processing include avoiding radiation exposure for the technicians and preventing further nuclear reactions More specifically, the heat required for certain processing methods to create ceramic nuclear waste forms can result in phase transitions within the ceramic matrix , which can weaken the Immobilizing nuclear waste: Status and future developments in

Ceramic bodies with rock processing residues (RPR) for constructing

The rock processing residue (RPR) waste is used for part of the ceramic products The present work deals with the unused waste useful for making ceramic materials and save the area and the dump space The residues are initially analyzed with the chemical and spectroscopic method The residues are mixed with clay of proportions 0–50 wt% in steps of 10% The prepared 2013年11月1日 needs no special processing when used as an aggregate The activity of glass and redclay ceramic waste as cement mortars components Constr Build Mater 2012;31:1971–7 [31] Using ceramic sanitary ware waste as concrete aggregateSimplifying Ceramic Waste Form Processing The glassbonded sodalite ceramic waste form (CWF) was developed in the 1990s to immobilize chloride saltbearing waste streams generated during treatment of spent sodiumbonded nuclear fuel This was necessary because chloride salts are essentially insoluble in borosilicate glasses(on the order of 1%)Simplifying Ceramic Waste Form Processing Argonne National 2023年6月15日 PDF Today, the need to dispose of a huge amount of ceramic industrial waste represents an important problem for production plants Contextually, it is (PDF) Industrial Ceramics: From Waste to New

Designing Advanced Ceramic Waste Forms for Electrochemical Processing

2016年3月1日 This report describes the scientific basis underlying the approach being followed to design and develop “advanced” glassbonded sodalite ceramic waste form (ACWF) materials that can (1) accommodate higher salt waste loadings than the waste form developed in the 1990s for EBRII waste salt and (2) provide greater flexibility for immobilizing extreme waste salt process In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all Ceramics can be glazed or unglazed, porous or vitrified Firing of ceramic bodies induces timetemperature transformation of the constituent minerals, usually into a mixture of new minerals and glassy phasesCeramic Manufacturing Industry Europa2018年5月21日 Incorporating solid waste materials in concrete has three advantages – the immediate environmental benefit of recycling a material from landfills, reducing the negative impact of cement production and preserving natural resources Ceramic waste powder (CWP), produced during the process of polishing ceramic tiles, is dumped in landfills and can cause Ceramic waste powder: from landfill to sustainable concretes2023年1月1日 Ceramic Processing Research Performance enhancement of concrete by using ceramic waste as a partial replacement for coarse aggregate January 2023 DOI: 1036410/jcpr2023242266Ceramic Processing Research Performance enhancement of

.jpg)

Studies on Ceramic Wastes based Composites for Capacitors

2022年3月29日 A huge quantity of waste ceramics are generated inside the industrial unit that are badly affecting the surroundings It was observed that one third of waste material is produced during ceramic processing Reusing these wastes is an economic, reduction in pollution and energy saving strategy for industries as well as academia2014年11月1日 There have been several comparative studies of crystalline ceramic waste forms produced by hot pressing and inductive melting [6], [7] These prior studies have indicated that the specimens fabricated by melt processing and solid state sintering exhibited similar mineral compositions, with the exception of a watersoluble molybdate phase observed in melt Melt processed multiphase ceramic waste forms for nuclear waste 2007年5月1日 Abstract The treatment of spent nuclear fuel for disposition using an electrometallurgical technique results in two highlevel waste forms: a ceramic waste form (CWF) and a metal waste form Reactive metal fuel constituents, including all of the transuranic metals and the majority of the fission products, remain in the salt as chlorides and are processed into The Ceramic Waste Form Process at Idaho National Laboratory2019年8月19日 Among the methods of obtaining ceramic wasteforms, special attention in recent years is paid to sintering methods which ensure the formation of ceramics that, first, are almost nonporous eg, have a relative density of up to 990–999% of theoretical, and, second, can be obtained within a small processing time eg, within a few minutes (ie, 2–3 min)Ceramic Mineral WasteForms for Nuclear Waste Immobilization

Waste recycling in ceramic tiles: a technological

2020年12月1日 The ceramic industry is going to be deeply involved in the transition to a circular economy However, the main obstacle to a widespread recourse to waste recycling is the lack of knowledge about 2015年11月12日 Number: DESC, “Radionuclide Waste Disposal: Development of Multiscale Experimental and Modeling Capabilities”, DOE Nuclear Energy University Programs CFA146357 “A New Paradigm for Multiphase Ceramic Composites as Hosts for 2024年11月6日 [Image above] Scientists melt radioactive waste into glass in a test platform at PNNL designed to mimic Direct Feed LowActivity Waste system being constructed at Hanford Credit: Pacific Northwest National Laboratory According to the World Nuclear Association, the US is the world’s largest producer of nuclear powerThere are 99 nuclear reactors that Vitrification process turns radioactive waste into durable glass for TEACHER INSTRUCTIONS Ceramic Processing: Slip Casting Objective: Students will learn the fundamentals of slip casting and be able to think critically about why slip casting is used Background Information: Historically, ceramic materials in the form of clay figurines and pots were the first manmade materials over 10,000 years ago, and maybe even as long as 25,000 yearsCeramic Processing: Slip Casting American Ceramic Society

Ceramic Waste Recycling HMA Group

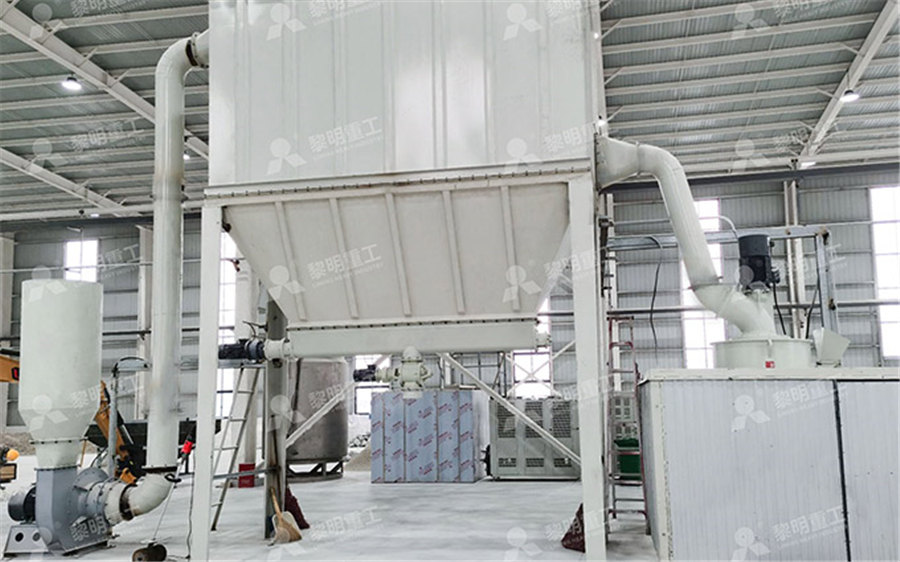

Ceramic waste has been classified in this group Due to the fact, that biodegradation period of ceramic is very long (up to 4 thousand years) and ceramic industry waste constitutes significant Skip to content We are experts for the final processing stage, refinement of high quality end products, From a broad machine portfolio, 2021年3月23日 Mullite (3Al2O32SiO2) is an aluminosilicate characterized by excellent physical properties, which makes it an important ceramic material In this way, ceramics based on mullite find applications MulliteBased Ceramics from Mining Waste: A Review2023年2月20日 The rapid development of the traditional ceramic industry contributes considerably to economic advancements; however, the ecological hazards caused by the large amount of sintered ceramic wastes generated during ceramic production and discarded at landfill sites are becoming increasingly severe To realize the largescale resource utilization of Preparation and Properties of Environmentally Friendly Resin head and stored for future use in the ceramic waste form Figures 4 show the zeolite2 processing equipment Figure 2 Prater CLM18 Mill/Classifier, Cyclone Separator, and Baghouse used for grinding zeolite Figure 3 Rotex model 12ASSSS Sieve Shaker Table used in processing ground zeolite Ceramic Waste ProcessingCERAMIC WASTE FORM PRODUCTION AND DEVELOPMENT AT

Valorization of ceramic sanitary waste into Resilient phosphoric

2024年3月15日 Medina et al [36] delved into the feasibility of incorporating ceramic sanitaryware waste as a coarse aggregate in the production of recycled concrete In a parallel effort, Reig et al [37] introduced novel binders by alkaliactivating ceramic sanitaryware waste in conjunction with Portland cement through the partial replacement of ceramic DOI: 101016/jhydromet2020 Corpus ID: ; Hydrometallurgical processing of waste multilayer ceramic capacitors (MLCCs) to recover silver and palladium @article{Panda2020HydrometallurgicalPO, title={Hydrometallurgical processing of waste multilayer ceramic capacitors (MLCCs) to recover silver and palladium}, author={Rekha Panda Hydrometallurgical processing of waste multilayer ceramic