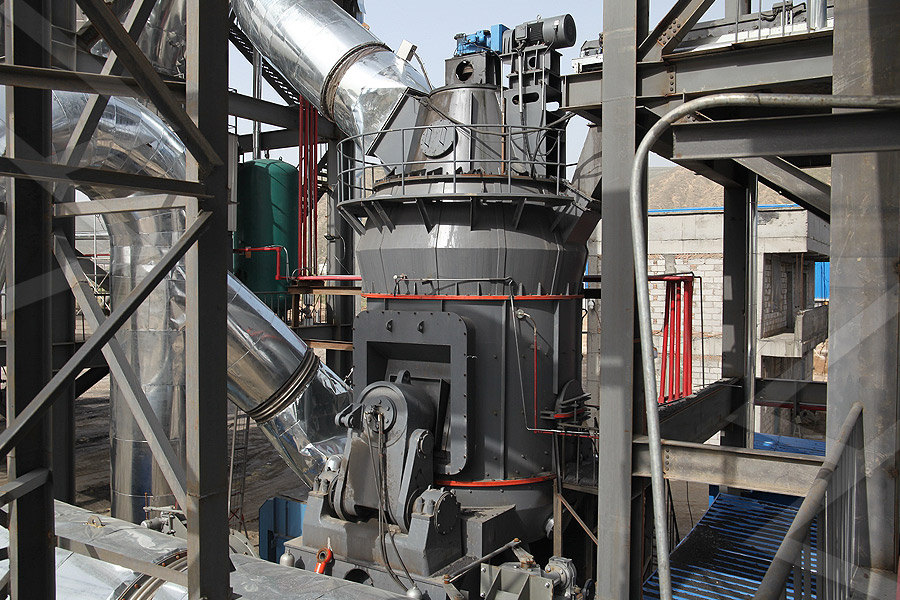

Carbon felt processing equipment

.jpg)

Carbon Fibre Felt Dilo

Carbon fibres are brittle and difficult to process in a carding machine where wired rollers work in a counterrotating mode DILO succeeded in realising a stable web forming process and in ONEJOON offers an excellent energy reduction strategy for the complete Carbon Fiber production line This strategy includes reduced energy consumption in every single process step as well CARBON FIBER FELTS ONEJOONCarbon fiber felt production process Carbon fiber felt is darker in color, has good electrical conductivity, and can withstand temperatures up to 1300°C It is often used in longterm high Carbon fiber felt production process Karssen MetalWhen you’ve reached production scale, Harper’s 3M and 4M Carbon Fiber lines are the ideal choice, focused on process effectiveness, product quality, and operational optimizationCarbon Fiber Production Equipment Harper International

.jpg)

Carbon Felt AvCarb Material Solutions

AvCarb’s Felt products are crafted by converting 100 % Oxidized PAN staple fiber into a nonwoven felt via a needle punching process that permits a wide range of thicknesses and areal weights to be constructed for various industries2017年2月28日 The presented technoeconomic assessment reveals significant ecologic advantages in the manufacturing process of carbon felt or carbon fiber from cellulose, which is Carbon felt and carbon fiber A technoeconomic assessment of 2021年7月14日 The current study was intended to synthesize and characterize the physical, chemical, and mechanical properties of carbon/carbon (C/C) composites using the chemical Preparation and characterization of carbon felt/carbon composites Soft felts are flexible insulation materials for high temperature applications in inert or vacuum atmosphere and consist purely of carbon fibers Stability of the felt is already defined in the first production step, the needling process and prevails Soft felts for hightemperature furnaces SGL Carbon

.jpg)

Home Carbon Felt Inc

Here at Carbon Felt Inc (CFI) we are dedicated to providing the highest quality products to fit our customers every need CFI began in 2008 as a research and development plant to manufacture and produce high quality carbon felt and 2024年6月5日 Industrial Equipment Insulation Carbon felt serves as an ideal insulation material for industrial equipment operating in hightemperature environments For instance, in metallurgy and chemical processing, carbon felt protects equipment from heat damage while maintaining stable internal temperatures, Why Carbon Felt Fire Blanket is Suitable for Insulation1 What is Carbon Felt Made Of? Carbon felt is made from carbon fibers These fibers come from other materials that are turned into carbon by heating them up really high The fibers are then put together in a messy, tangled way that gives What is Carbon Felt? 5 Key Points Explained for Non Hightemperature graphitization furnace is a professional equipment for graphitization treatment of carbon materials It is a key equipment for the production of highquality graphite products It has high temperature, high efficiency and uniform heating It is suitable for various hightemperature treatments and graphitization treatmentsConductive Carbon Cloth / Carbon Paper / Carbon Felt

.jpg)

CARBON FIBER FELT Cxinduction

Soft Carbon and Graphite Felts are used as insulation in vacuum,high temperature furnace and protective atmosphere (nonoxidizing) furnaces and process equipment used in the heat treating, semiconductor, ceramic, aerospace, defense, biomedical appliance, and sintered metals industries Carbon felt Property Measured Valuecarbon felt made of natural or manmade fiber by special techniques such as high temperature and catalysis Highly efficient adsorption material beyond granular activated carbon, containing highly developed microporous structure and rich organic functional groups, has good redox properties, and has excellent adsorption to organic and inorganic impurities in the gas phase Carbon Felt Needle Felt Texture Supplies2017年10月1日 Carbon Felt (CF) is commonly used as electrodes due to their good electronic conduction They have high surface area and porosity able to provide abundant redox reaction sites, excellent electrolytic efficiency and mechanical stability at relatively low cost [1], [2], [3], [4]Other carbonbased materials like vitreous carbon, carbon sponge, carbon fiber or carbon Carbon felt basedelectrodes for energy and ScienceDirectCarbon and graphite felt industry size was USD 500 million in 2022 and is projected to USD 950 million by 2032 owing to increasing adoption in térmica insulation in furnaces, kilns, and hightemperature processing equipmentCarbon " Graphite Felt Market Informe de tamaño, 2023 – 2032

How carbon fiber is made material, making, used, processing,

Hello! My name is Alexander i am a student and UPB(University Politehnica Bucharest) and my specialisation is Material ScienceAnd i am writing a project about recycling fiber carbon and the equipment it implies,and i was wondering if you could give me some more details about the equipment,something more like an inside look of how it works the process that the fiber carbon 2017年2月28日 Carbon felt has been the most widely used electrode type in VRFB although a variety of electrode types has been considered, Note that production costs are total costs consisting of materials and processing costs of carbon felts Download: Download highres image (141KB) Download: Download fullsize image;Carbon felt and carbon fiber A technoeconomic assessment of felt 2022年5月16日 CDI is based on the capacitive principle and is characterized by low energy consumption (from 013 to 059 kW h m −3) since it operates at low voltages (06–20 V) 108,135,136 The electrodes used in CDI are mainly Review—Carbon Cloth as a Versatile Electrodeactivated carbon felt made of natural or manmade fiber by special techniques such as high temperature and catalysis Highly efficient adsorption material beyond granular activated carbon, containing highly developed microporous activated carbon felt needle felt texture supplies

COIDAN

graphite carbon felt unusual fire/explosion hazards thermal decomposition or combustion may produce dense smoke, oxides of carbon and lower molecular weight organic compounds whose compositions have not been characterized finely divided carbon dusts form potentially explosive mixtures in air at concentrations greater than 18BOST Carbon Materials Co, Ltd is a manufacturer with over 10 years' experience engaged in RD, production and sales of carbon fiber felt, established in 2012, located in Changsha, China The factory covers an area of 20, 000 square meters and 200 professional staffs, and produce 1, 300 tons of carbon fiber felt per yearCarbon Fiber Felt Manufacturer, Graphite Felt, Rigid Graphite Felt 2023年11月1日 The objective of this study was to develop a carbon felt impregnated with iron (III) sulfate (CFFe) for its use both as a cathode and reusable heterogeneous catalyst source in the Fenton reaction for the elimination of sulfamethazine (SMT) The CFFe cathode was characterized with Scanning electron microscopyenergy dispersive spectrometric (SEM–EDS) Heterogeneous ElectroFenton Process Using a Cathode of Carbon Felt 2024年6月14日 This article will delve into its processing, covering grinding, granulation, drying, and the necessary equipment What is carbon black? Carbon black is typically produced from coal tar, petroleum, or natural gas, heated at temperatures ranging from 1,420 to 1,980℃, causing the carbon to evaporate and then cool into particlesCarbon Black Processing: Turning Soot into Industrial Gold

Top Graphite manufacturer and supplier from China

2017年12月27日 Graphite Felt Production Flow; Carbon composite Production Flow; Process Animation Click to learn more about our flow Equipment Gallery Visit our professional production and development facilities GO Inquir Now Any questions or needs? Send us a message GO Contact Us2024年9月26日 Step 1: Processing Graphite Raw Materials In graphite manufacturing, the choice of raw materials is the foundation of your process If you are producing natural graphite, you will source it directly from mining operations, where the graphite is extracted in its natural form Flake graphite is one of the most common types, known for its high purity and conductivityGraphite Manufacturing Process – A StepbyStep Guide East CarbonSingleWalled Carbon Nanotubes (SWCNTs): These are made from a single graphene sheet rolled into a tube MultiWalled Carbon Nanotubes (MWCNTs): These consist of multiple concentric graphene cylinders nested within each other FewWalled Carbon Nanotubes (FWCNTs): Similar to MWCNTs, but with only a few layers of graphene cylindersFaqs Conductive Carbon Cloth / Carbon Paper / Carbon Felt2023年2月15日 The representative thermal insulation materials at present are porous fibers/ceramics, aerogels, carboncarbon (C/C) composites, and carbongraphite [4,5,6] Wang et al prepared a novel hightemperature vacuum insulation material consisting of a graphite felt core and a sealing layer via chemical infiltration (CVI), named pyrolytic carbon and impregnated Mechanical properties and thermal conductivity of lightweight and

[Retracted] Electroadsorption Desalination with Carbon

2014年5月12日 Engineering Research Center for Polymer Processing Equipment, Ministry of Education, College of Mechanical and Electrical Engineering, Beijing University of Chemical since the nanotubes with curved winding structure are dispersed in the carbon felt, the resistivity of electrodes reduces while conductivity improves, with electrode Browse through 5 Manufacturer producer in the carbon felt industry on Europages, a B2B platform Since 1992, we are specialized in the manufacturing and processing of nonferrous metal materials Besides China, we export our countries ships, aerospace or national defense industry Our advanced equipment allows us to operate on more than Manufacturer producer carbon felt europagesEngineering Research Center for Polymer Processing Equipment, Ministry of Education, College of mechanical and electrical engineering, Beijing University of Chemical Technology, Beijing , This study adopted PPy/PANbased carbon fiber felt composite as a new electrode for desalination experimentStudy on the Treatment of Circulating Water: PPy/PANbased Hydrogen Equipment; Power Devices; Solar Power; Hydro Power; Wind Power; Bioenergy Power; Lab Accessories; Clearance; PAN carbon felt product is manufactured from polyacrylonitrile precursor and it is prefired at 2192 $2500 Add to Cart PAN Carbon Felt Carbon and Graphite Felts Fuel Cell Store

.jpg)

Pan based graphite felt and its applications–CFCCARBON LTD

Graphite felt is divided into three types, say PANbased, Rayonbased and Pitch coke based graphite felt the main application is as insulation, heat insulation materials for monocrystalline silicon smelting furnace In the chemical industry, it can be used as highpurity corrosive chemical reagents’ filter material Definition of graphite felt After high temperature process of above Processing temperature(℃) 1200 Operating condition in the air(℃) ≤400 PANbased carbon felt are used as insulation in vacuum and protective atmosphere (nonoxidizing) furnaces and process equipment used in the heat treating, semiconductor, ceramic, aerospace, defense, China PANbased Carbon Felt factory and manufacturersIn situ growth of B 4C nanowires on activated carbon felt to improve microwave absorption performance Cite as: Appl Phys Lett 116, (2020); doi: 101063/5In situ growth of B4C nanowires on activated carbon felt to Carbon Surfacing Veil – Wet Processing Dymriton T04:56:27+00:00 Carbon Surfacing Veil Carbon fiber surface felt is widely used in industry: These include pultruded handrails kayaks, skis, bicycles and boats are just some sports equipment using our products Our materials improve aesthetics, impact resistance and wear Carbon Surfacing Veil – Wet Processing Dymriton Composites

Carbon Felt Nanorh

Carbon Felt (Upto 1800 °C) It is employed in furnaces, kilns, and other industrial equipment to insulate and protect components from heat Aerospace Thermal Protection Systems: Chemical Processing: Catalyst Supports: Carbon felt is used as a support for catalysts in chemical reactorsand characterization results of activated carbon fiber felt (ACFF) produced from textile PAN fiber, using a set of homemade equipment by Multivácuo Aerospacial Ltda and FAPESP PIPEMICROPOROUS ACTIVATED CARBON FIBER FELT PRODUCED Carbon Black Processing Equipment Supplies 21 equipment items found Recovered Carbon Black Refining Manufactured by Enrestec Inc based in TAIWAN The recovered carbon black produced by the pyrolysis reaction must be processed through a series of processes to make it into recovered carbon black The environmental Carbon Black Processing Equipment Supplies Environmental We demand a lot from our equipment as we are using our equipment all day every day, so we can test the equipment very thorough We are glad we can offer the equipment we like best for sale! We are very happy to offer the Felt Pro Here you can find vaulting equipment

.jpg)

Carbon Fiber CF Felt Needle Felt Texture Supplies

Carbon Fiber CF Felt, High strength, low consumption, good filling, winding performance and equipment adaptability Skip to content WhatsApp / Mobile: 0086 133 7311 0862 jeffsong@360felt Home; PostProcessing Felt Also known as viscose graphite felt, it is made of viscose based fibers (rayon) that are cured, shaped, and purified through secondary hightemperature processing, and precalcined at 4532 °F (2500 °C) to complete the graphitization of the material, making it suitable for working in environments above 2200 °CSoft Graphite Felt – Excellent Refractory Insulating MaterialPitch Based Carbon Fiber Insulation Figid Felt Introduction Pitch Based Carbon Fiber Unit Cylinder Density g/cm³ 022 Carbon Content wt % >99 Ash Content ppm we have CNC and turning machine for C/C composite material processing equipment Normally we will process carbonization and purification treatment more than 2,000 ℃ What Pitch Based Carbon Fiber Insulation Rigid Cylinder Feltcarbon felt at dierent magnications It should be noted that SMP200 binocular microscope was used to produce these images Also, for the manufacture of carbon ber felt/ carbon (CF/C) composites through the CVI process, the present researchers used methane gas (purity 99%, DAYAN ˃ GAS International Trading Co, Iran) as the source of carPreparation and characterization of carbon felt/carbon

.jpg)

Pan Graphite Felt Manufacturer in China East Carbon

Ultrathin Carbon Fiber PANbased Graphite Felt for Flexible Electrode Material Send Inquiry Now 8 Products Found metallurgy, aerospace and chemical processing high temperature kilns and other heat treatment equipmentAutomated Manual Equipment for Surface Finishing Applications Technic supplies a full range of equipment capabilities for electroplating and related applications, from fully automated systems for new facilities to replacement parts and upgrades to improve operational efficiency Our custom wet processing equipment may be highly engineered for special applications or laid out for Surface Finishing Equipment Technic Inc2020年7月20日 With the development of technology, in civil carbon fiber products, professional sports equipment is a more extensive and mature field of carbon fiber application At present, there are many molding methods of carbon fiber materials for sports equipment, mainly including winding molding, molding, RTM molding, pultrusion molding and so onThe Main Process Used In The Carbon Fiber Sports Equipment2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill independently developed and produced by our SBM micropowder technology Both mills can produce fine carbon black powder up to 3000 meshTire pyrolysis carbon black deep processing grinding equipment