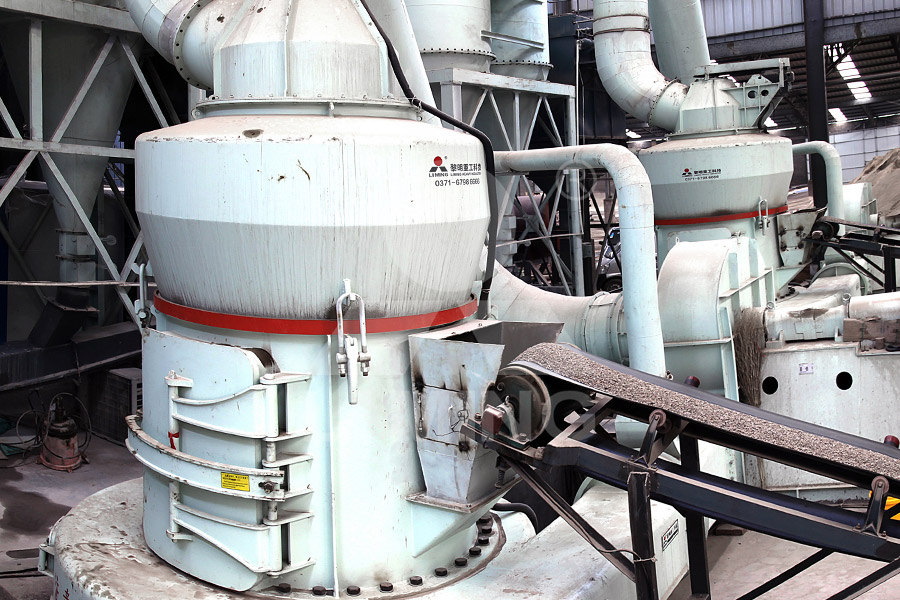

Medium speed coal mill talks about fine ring

.jpg)

Modeling of a medium speed coal mill ScienceDirect

2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of Various factors affecting the output capacity of MPS255 medium speed coal mill for boiler no3 in Yuanbaoshan Power Generation Co Ltd have been analysed It is believed that the main RETROFIT OF NOZZLE RING FOR MPS255 MEDIUM SPEED COAL Taking hp1103 medium speed roller disc coal mill as the carrier, this paper mainly describes the common faults in the normal operation of this type of coal mill, and analyzes and judgesSHPHGLXP VSHHGFRDOPLOO ResearchGateMills are mechanical devices used to break different types of solid materials in small pieces by grinding, crushing or cutting In pulverised coalfired power plants, a pulveriser coal mill grinds Coal Mill an overview ScienceDirect Topics

Mediumspeed coal mill air ring dynamic and static clearance

The sealing device disclosed by the invention can prevent the increase in air leakage from the dynamic and static clearance of the coal mill in case that the air ring dynamic and static 2014年3月1日 Comparing to the E ball mill of Tarong power plant in Australia, the mediumspeed mills have several significant advantages, which are widely used recently The purpose Breakage and separation mechanism of ZGM coal mill based on coal mill is an important component of a steam power plant which grinds precrushed raw coal particles of size 1020 mm to fine particles of size less than 150 μm using heated primary air Mathematical validation and comparison of ball tube and bowl 2021年8月1日 In order to facilitate the staff to complete the maintenance task more quickly and with higher quality, this paper introduces the common faults in HP type bowl type medium Fault analysis and optimization technology of HP bowl type

Comparison and selection for the materials Semantic Scholar

Carbon sealing rings prepared by adding infiltrators,considered as the essential and damageable parts,are widely applied in medium speed coal mills in thermal power plantsIn view of the The versatile MPS vertical mill – with a fine tradition of quality grinding Pull rods outside mill housing: 7: Nozzle ring centering in case of grindingcalcining: 8: MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2020年7月31日 From the above graph this very clear for coal type having VM 30% then recommended fine coal residue (+90 µ) for kiln will be 15% and for PC use, it must be maximum 10% And overall residue of 40% (kiln use) * 15% Coal drying Grinding Coal Mill by ASen MediumMedium speed coal mill is suitable for grinding bituminous coal, vertical grinding roller seal ring etc, we have a large number of mature and reliable antiwear solutions, and successfully applied in cement, thermal power, steel, Mediumspeed coal mill wearresistant ceramic liner

.jpg)

Modeling of a medium speed coal mill Semantic Scholar

2017年8月1日 Semantic Scholar extracted view of "Modeling of a medium speed coal mill" by Yaokui Gao et al Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,591,235 papers from all fields of 2011年8月1日 Raw coal top size: −3% throughput for 5 mm increase in top size for lowspeed mill; no loss in throughput below 60 mm top size for mediumspeed mill Pulverized fuel size distribution: reduction of fraction going through lt;75 μm mesh screen by 035% for a 1% increase in throughput for lowspeed mill; reduction by 09% for a 1% increase in throughput Mill Speed an overview ScienceDirect Topics2017年8月1日 In this study, the lumped parameter modeling method is adopted with the following assumptions: 1) the parameters of the medium in the coal mill are uniform; 2) the media in the coal mill are incompressible; 3) the parameters of the medium in the coal mill change along the axial direction only; 4) the change in the flow power in the coal mill is ignored; 5) the coal Modeling of a medium speed coal mill ScienceDirect2017年8月1日 In this study, MPS180HPII medium speed coal mill is used as the research object Subsequently, the primary air that enters the coal mill through the air ring dries and brings the coal powders into the coarse coal separator at the upper part of Modeling of a medium speed coal mill ScienceDirect

.jpg)

Characteristics of Pulverizer Rejects and Numerical Simulation for

2011年8月1日 The densities, heating values and ash components of pulverizer rejects are tested in the laboratory for the ZGM95 medium speed mill, which indicates that the characteristics of pulverizer rejects pulverizers is ¾” to 1” Raw coal feed should never exceed 1¼”, raw coal this size can plug throats and cause vibration Raw coal that is too fine can plug the pulverizer or delivery components upstream of the pulverizer Regular yard crusher inspection and maintenance is required to maintain optimum raw coal sizing Mill FiresOptimum Operation and Maintenance of EL PulverizersHPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading device and other componentsHP Series Medium Speed Bowl Mill2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, Coal mill pulverizer in thermal power plants PPT

A Comparison of Three Types of Coal Pulverizers Babcock Power

The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in the mill and flat grinding surfaces, develops shearing action as well For both mills a constant centrifugal force is maintained The speedmedium speed coal mill Dou Jie Shandong Huayu Institute of technology, Dezhou, Shandong, China : Abstract: HP type medium speed coal pulverizer produced by Shanghai heavy machinery works has been widely used in recent years, with common faults in operation, short maintenance cycle and heavy taskSHPHGLXPVSHHGFRDOPLOO IOPscienceThe mediumspeed coal mill system is mainly composed of raw coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and cold air regulating valves The structure of MPS mediumspeed coal mill systemGenerally, the outlet temperature of the mediumspeed coal mill is controlled at 100 to 120 degrees Celsius The material processed by the mediumspeed mill barrel is particles of various sizes and hardnesses These materials move inside the mediumspeed mill, constantly causing friction, scouring and impact on various parts of the mediumspeed The cylinder of the mediumspeed coal mill is lined with wear

.jpg)

(PDF) Program Design and Calculation Example of Direct Fired

2018年12月13日 The large amount of calculation and iteration for manual thermal calculation are easily lead to errors In this paper, based on the direct fired systems with medium speed mill, a common computing 2020年6月29日 6 TYPES OF COAL PULVERIZER • Tube or ball mills: Lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube millclassifications and working of mills in a power plant PPTCoal and mill Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document discusses pulverized coal mills used in power plants It describes different types of mills including tube mills, ball mills, and bowl mills Tube mills are low speed while bowl mills are medium speed The document explains the construction, operation, and maintenance of bowl Coal and Mill PDF Mill (Grinding) Mechanical Engineering2017年5月1日 Gao et al [5] established a dynamic model for a medium speed coal mill based on mass and energy balance and predicted the dynamic performance of a coal mill Wang et al [6] Modeling of a medium speed coal mill ResearchGate

2FD{P}PC]854]XQ.jpg)

“Blueprint” Your Pulverizer for Improved Performance

be readily divided equally between coal pipes leaving the mill and will burn much like natural gas when the coal is ground very fine to a mean particle size of about 50 microns Keep in mind that the density difference between coal and air is about 1,000 to 1 Performing this balancing act efMedium speed coal pulverizer Introduction Medium speed coal pulverizer also known as medium speed coal vertical roller mill is an equipment widely used in the cement production plant and cement grinding stationThe mediumspeed coal mill refers to the coal mill with a working speed of 50300r/min, which belongs to the professional equipment for the preparation and processing Medium speed coal pulverizerVertical roller millHigh speed impact mill; The slow speed and medium speed mills are selected for coals ranging from subbituminous to anthracite The highspeed mills are used mainly for lignite Operation Of Bowl Mill Pulveriser In bowl mill pulveriser Pulveriser in Thermal Power Plant Bowl Mill Ball MillHGM series threering (fourring) mediumspeed mill is mainly suitable for processing nonflammable and nonexplosive brittle materials with Mohrenheit hardness less than 7, such as calcite, limestone, dolomite, kaolinite, bentonite, mica, illite, pyrophyllite, barite, sepiolite, fluorite, potassium ore and so onHGM Threering Grinding Mill vanguardtec

COAL PREPARATION AND FIRING INFINITY FOR CEMENT EQUIPMENT

Fine coal leaves the mill with the gas stream, the coal fineness is adjusted by altering the angle of the separator vanes, or the rotor speed Coal drying is ensured by controlling the coal mill inlet temperature, to give a target mill exit temperature, usually between 70 and 900C2009年1月1日 below shows the particle tracks colored by the particle velocity magnitude for particles with a diameter size of 58 μm Fine particles of such a size are easily entrained in the flow and follow a CFD Modeling of MPS Coal Mill for Improved Performance and SafetyIntroduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee2014年3月1日 JKMRC of Queensland University is the only reported research team who got the samples from the industrial mill and analyzed the actual operation condition of the coal mill [13], [14] Comparing to the E ball mill of Tarong power plant in Australia, the mediumspeed mills have several significant advantages, which are widely used recentlyBreakage and separation mechanism of ZGM coal mill based on

What are the advantages and characteristics of ring roller mill?

2017年11月23日 Ring roller mill has widely application in the field of slag, coal mine, cement, nonmetallic mineral and other industries, Fujian Fengli produced ring roller mill has many advantages andWorking principle of medium speed coal millWorking principle of medium speed coal mill YouTube2022年8月10日 Mediumspeed coal mill wearresistant ceramic plate such as Protective sleeve of vertical mill roller shaft, Air guide ring, concentrator (inverted) cone, support rod, Mediumspeed coal mill wearresistant ceramic plate2022年7月26日 Coal mills are important equipment of the coal pulverizing system The structure of the MPS mediumspeed coal mill is shown in Figure 1 []As can be seen from Figure 1, the raw coal entering the coal mill through the Fault Diagnosis of Coal Mill Based on Kernel Extreme

.jpg)

Schematic diagram of the working principle of MPS

Download scientific diagram Schematic diagram of the working principle of MPS medium speed coal mill [1] from publication: Fault Diagnosis of Coal Mill Based on Kernel Extreme Learning Machine swirl ring having multiple sloped nozzles surrounding the grinding table The air mixes with and dries coal in the grinding zone and carries pulverized coal particles upward into a classifier Fine pulverized coal exits the outlet section through multiple discharge coal pipes leading to Coal Pulverizer Design Upgrades to Meet the Demands of Low 2020年4月7日 The mediumspeed coal mill system is mainly composed of raw coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and cold air regulating valves The coal feeder transports the raw coal from bunker to mill for grinding The primary air is divided into two paths after being pressurized by primary fansModeling of Coal Mill System Used for Fault Simulation MDPIThe MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking systemMPS ZGM Coal MillGrinding Equipment YingYong Machinery

ATOX® Coal Mill FLSmidth Cement

The coal mill can also grind petroleum coke and anthracite down to a fineness below 5% +90 micromillimeters (mm) when coupled with a variable speed mill motor No sticky situations The ATOX® Coal Mill can grind and dry raw coal with up to 25 percent moisture level2024年10月20日 The Medium Speed Coal Mill market features key players such as FLSmidth, Tenova, Thyssenkrupp, Trends in the Global Rolling Ring Turnings Crusher Market: Forecast and Analysis (2024 2031)Medium Speed Coal Mill Market: Global Market Insights and Download scientific diagram Schematic of medium speed coal mill [5] from publication: Early Warning of Critical Blockage in Coal Mills Based on Stacked Denoising Autoencoders Schematic of medium speed coal mill [5] ResearchGate2020年1月1日 of a medium speed coal mill is provided in Fig 1 The common malfunctions in coal mill operation are due to coal blockage, coal interruption, and coal selfignitionEarly Warning of Critical Blockage in Coal Mills Based on